Overview

This article delves into the critical considerations for selecting the appropriate HPLC column with 150x2 specifications, underscoring the pivotal role of dimensions, materials, and application requirements in achieving optimal analytical outcomes. By examining how the length and diameter of the column affect separation efficiency and sensitivity, it elucidates the necessity of choosing suitable materials and types tailored to meet specific analytical demands across various applications. Ultimately, understanding these factors is essential for enhancing the effectiveness of laboratory analyses.

Introduction

In the realm of analytical chemistry, High-Performance Liquid Chromatography (HPLC) columns are indispensable instruments for the precise separation of complex mixtures. Their specifications—column length, inner diameter, particle size, and stationary phase chemistry—are pivotal in determining the efficacy of chromatographic processes.

As advancements in HPLC technology continue to emerge, understanding these specifications becomes increasingly critical for laboratory managers aiming to optimize their systems. This article delves into the intricacies of HPLC columns, exploring key metrics, material compositions, and application-specific requirements that inform the selection process.

With insights drawn from recent case studies and industry trends, it seeks to equip professionals with the knowledge necessary to enhance analytical capabilities and ensure reliable results across various applications.

Understanding HPLC Columns: Key Specifications and Their Importance

High-Performance Liquid Chromatography (HPLC) devices are indispensable in analytical chemistry, serving as the cornerstone for the separation of complex mixtures. The critical specifications that define high-performance liquid chromatography tubes encompass length, inner diameter, particle size, and the chemistry of the stationary phase. Each of these factors plays a pivotal role in determining the efficacy of the chromatography process.

Research demonstrates that longer structures typically yield enhanced resolution, facilitating the effective separation of closely related compounds. However, this improvement in resolution frequently comes at the expense of increased analysis time. In contrast, employing smaller particle sizes can significantly enhance separation efficiency, although this necessitates higher operational pressures, which may stress the system.

Recent advancements in , particularly in 2025, have led to the introduction of high-capacity ENrich size exclusion tubes. These innovations deliver reproducible, high-resolution separation of biomolecules even at elevated flow rates, underscoring the continuous evolution within this discipline. Furthermore, automated programs have been developed to assist in high-performance liquid chromatography method development, especially for complex mixtures such as hair dyes, thereby streamlining the process and improving accuracy.

The forthcoming AOCS Annual Meeting & Expo on April 27, 2025, in Portland, OR, USA, is poised to spotlight these advancements and their implications for the scientific community, underscoring the necessity of remaining informed about the latest technologies.

The impact of specifications transcends mere performance metrics; they are vital for achieving optimal results across diverse applications, including pharmaceuticals, environmental testing, and food safety. For instance, case studies, such as 'High-Performance Liquid Chromatography (HPLC) Characteristics,' illustrate that the careful selection of liquid chromatography specifications can lead to significant improvements in analysis speed and sensitivity, establishing them as essential tools in modern research environments.

In conclusion, understanding the interplay between tube length, diameter, and particle size is essential for managers aiming to optimize their HPLC systems. By prioritizing these specifications, research facilities can enhance their evaluation capabilities, ensuring precise and reliable outcomes in their scientific endeavors.

Exploring 150x2 HPLC Columns: Dimensions and Performance Factors

The designation '150x 2' signifies a length of 150 mm and an inner diameter of 2 mm, both crucial in determining the structure's capacity and efficiency. The 150 mm length provides between the analytes and the stationary phase, which is vital for effective separation. This length proves particularly advantageous in applications such as food safety and environmental analyses, where precise separation is critical.

Significantly, the Symmetry C18 support also possesses a length of 150 mm and includes endcapping, which further enhances its performance across various testing methods. The 2 mm diameter is specifically designed to improve sensitivity while minimizing solvent usage, making it an ideal option for facilities aiming to maximize efficiency without compromising performance. However, these dimensions also influence key performance factors, such as back pressure and flow rate.

For instance, while a narrower tube can enhance sensitivity, it may also lead to increased back pressure, necessitating adjustments to the chromatographic system to maintain optimal performance.

Recent case studies have demonstrated that the Raptor C18 tube, featuring similar dimensions and priced at $804.00, allows for faster analysis times and improved peak separation when utilized with existing chromatographic and UHPLC instrumentation. This capability not only enhances efficiency but also increases reproducibility in research environments, underscoring the importance of selecting appropriate dimensions for specific testing methods.

In 2025, the relevance of the '150x 2' specifications remains prominent in performance statistics, indicating that these dimensions are essential for achieving high sensitivity and efficiency in chromatography applications. Comprehending the relationship between dimension specifications and examination results is crucial for laboratory supervisors aiming to enhance their liquid chromatography techniques and ensure dependable outcomes. JM Science Inc.'s commitment to quality, customer assistance, and innovation in scientific tools further solidifies its status as a reliable supplier of chromatography equipment and associated products.

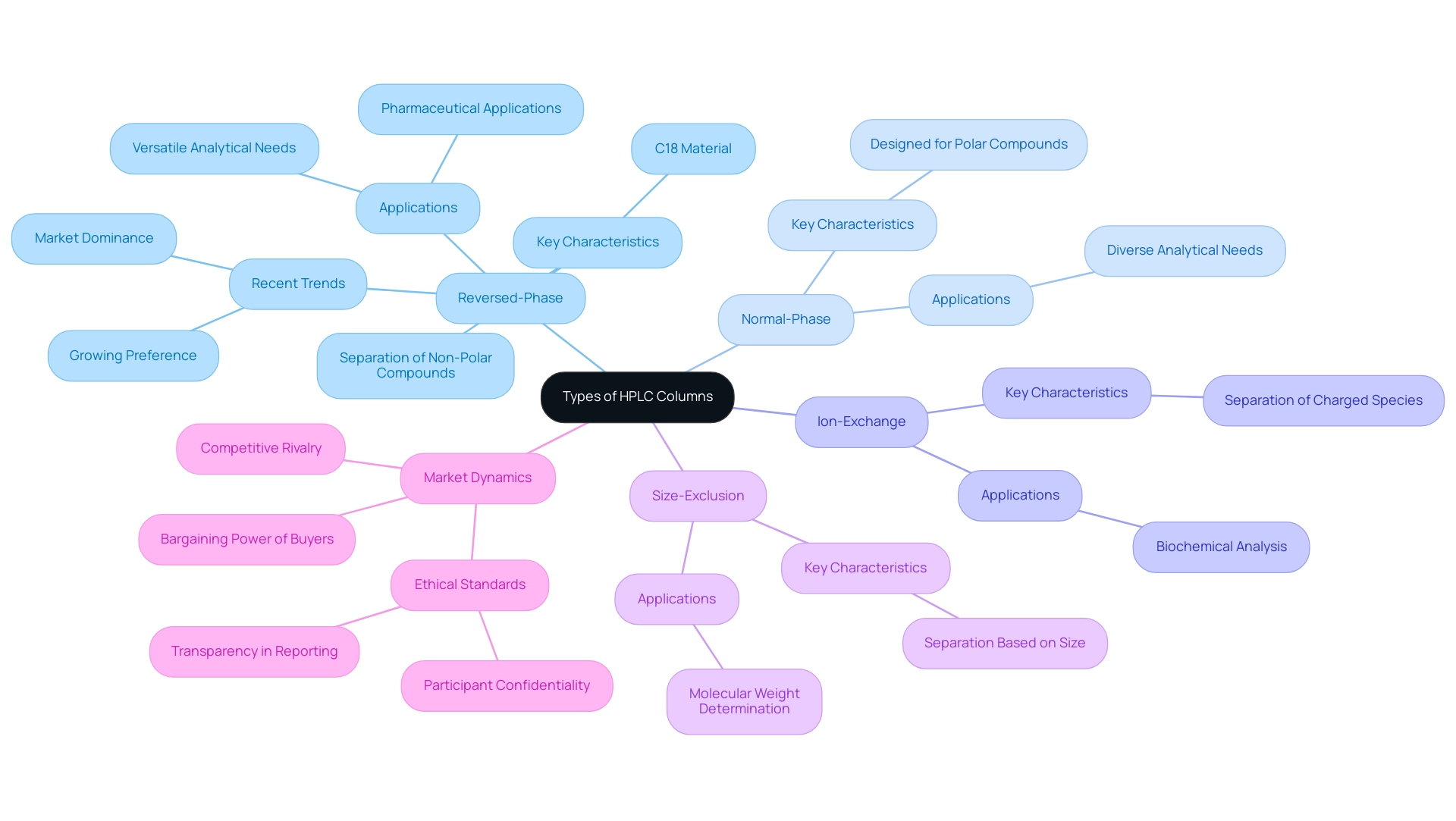

Types of HPLC Columns: Finding the Right Fit for Your Analytical Needs

HPLC devices are essential instruments in the field of chemistry, categorized into various types, including reversed-phase, normal-phase, ion-exchange, and size-exclusion types. Reversed-phase supports, typically packed with C18 material, dominate the market due to their effectiveness in separating non-polar and moderately polar compounds. In contrast, normal-phase materials are specifically designed for polar compounds, making them suitable for diverse analytical needs.

Ion-exchange systems excel in separating charged species, while size-exclusion setups focus on separating molecules based on their size. When selecting the appropriate type, it is vital to consider the characteristics of the analytes, the desired separation mechanism, and the specific requirements of the application. For instance, when analyzing a complex mixture containing both polar and non-polar compounds, utilizing a combination of types may be necessary to achieve optimal separation.

Recent trends reveal a growing preference for reversed-phase materials in pharmaceutical applications, driven by their versatility and reliability. Statistics indicate that reversed-phase materials comprise a substantial share of the high-performance liquid chromatography market, highlighting their extensive use in laboratories. Furthermore, the competitive landscape of the chromatography systems market is characterized by high rivalry, with buyers enjoying due to the availability of multiple suppliers.

This competitive environment underscores the importance of selecting the right option to meet specific analytical needs.

As Manoj Phagare, a Senior Research Analyst, observes, "The strategic significance of high-performance liquid chromatography components cannot be overstated, as they play a pivotal role in shaping evidence-based strategies that fuel the success of key business initiatives." This insight highlights the essential role that high-performance liquid chromatography systems play in the broader context of pharmaceutical research and development.

Case studies emphasize the importance of ethical standards in high-performance liquid chromatography research, ensuring participant confidentiality and transparency in reporting findings. This commitment to ethics not only enhances the credibility of studies but also fosters trust among stakeholders in the pharmaceutical industry. Additionally, the liquid chromatography market is segmented by product type, material, application, end-user, and region, providing a comprehensive understanding of the market landscape.

As the market evolves, staying informed about the latest advancements and expert guidance on chromatography selection will be crucial for laboratory managers seeking to enhance their analytical procedures.

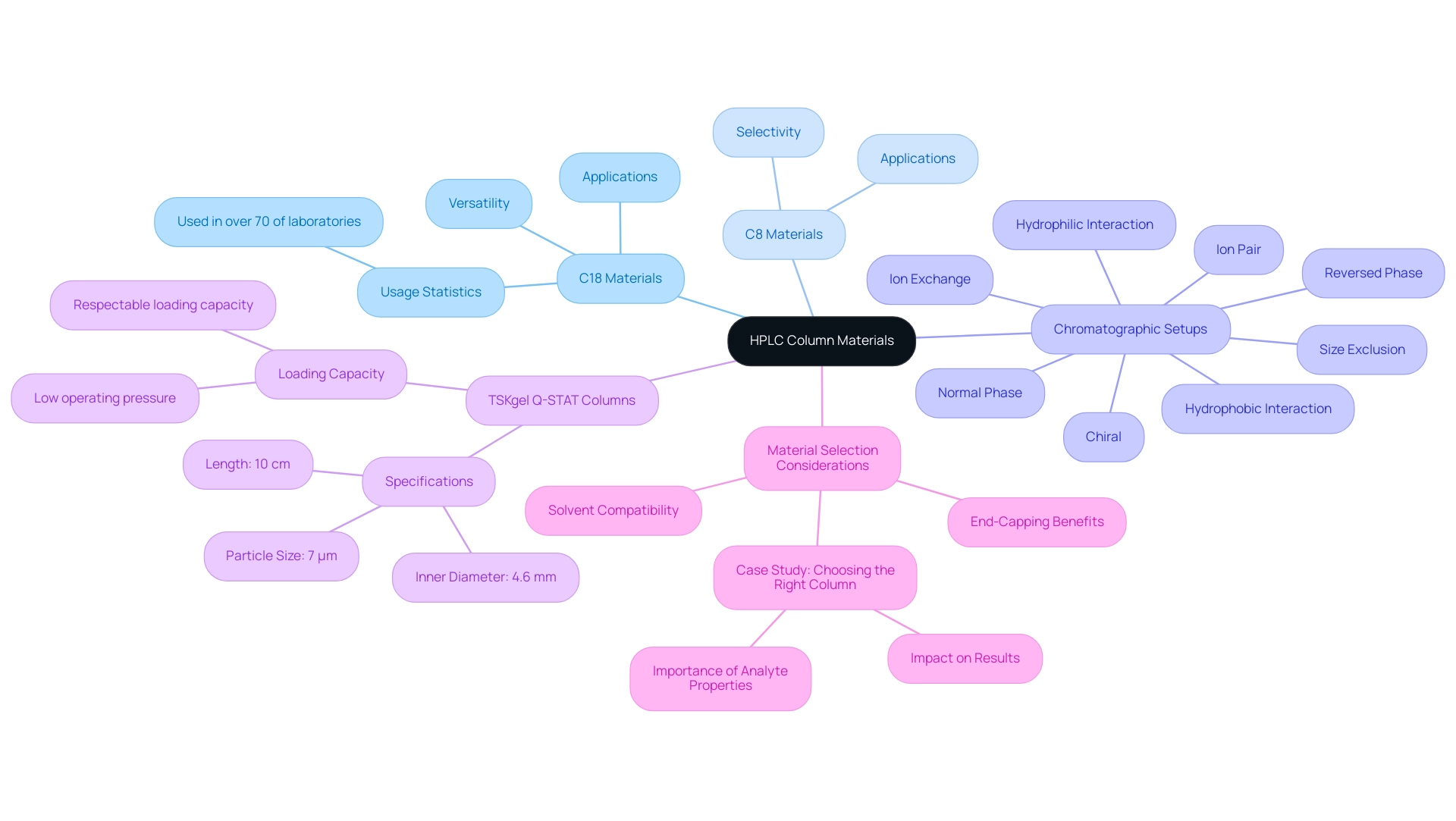

Material Matters: Choosing the Right Composition for Your HPLC Column

High-Performance Liquid Chromatography (HPLC) structures are primarily composed of silica-based materials, which are crucial for providing a high surface area that facilitates interactions with analytes. Among the most prevalent materials are C18, C8, and phenyl phases, each characterized by unique selectivity and retention properties. C18 materials, for example, are particularly valued for their versatility, effectively separating a diverse range of compounds across various applications.

Recent statistics reveal that C18 materials are employed in over 70% of laboratories, highlighting their critical role in chromatographic analyses. Beyond C18, other types of high-performance liquid chromatography setups include:

- Reversed Phase

- Normal Phase

- Hydrophilic Interaction

- Ion Exchange

- Ion Pair

- Chiral

- Hydrophobic Interaction

- Size Exclusion

Each of these setups is tailored for specific applications, with the TSKgel Q-STAT cartridges exemplifying a design that boasts respectable loading capacity and low operating pressure, making them compatible with all HPLC and FPLC systems.

When selecting materials for HPLC structures, solvent compatibility is a vital consideration, as certain substances may degrade under highly aqueous or acidic conditions. This factor is essential for maintaining structural integrity and ensuring reliable assessment results. Moreover, the end-capping of structures can significantly enhance stability and reduce bleed, which is crucial for improving overall analytical performance.

In practical applications, the choice of can profoundly affect the outcomes of chromatographic analyses. A case study titled "Choosing the Right Column" underscores that comprehending the physical and chemical properties of analytes, along with their interactions with the chromatographic phase, is essential for achieving accurate and dependable results. This meticulous selection process is not merely a technicality; it is a fundamental aspect of effective laboratory practice that can lead to significant advancements in research and diagnostics.

Notably, the TSKgel Q-STAT chromatography column features a phase of ammonium ion, with specifications that include a length of 10 cm, an inner diameter of 4.6 mm, and a particle size of 7 μm. This information aligns with the current needs of pharmaceutical lab managers, providing relevant product details that enhance decision-making in laboratory settings.

Application Requirements: Tailoring Your HPLC Column Choice to Specific Needs

Selecting the appropriate HPLC apparatus is crucial for achieving optimal results in analytical applications. Key factors to consider include the nature of the samples, the required resolution, and the analysis time. For instance, when working with complex biological samples, it is essential to choose a medium that provides high selectivity and resolution to effectively separate closely related compounds.

Conversely, for routine quality control analyses, a more robust support that can endure a broader range of conditions may be more appropriate.

Understanding the anticipated concentration levels of analytes significantly influences the choice of dimensions and particle size. Analytically narrowbore high-performance liquid chromatography devices, for example, can efficiently handle sample quantities ranging from 20 to 100 µg, making them ideal for applications that demand . Furthermore, large molecule structures are specifically designed for proteins and higher molecular weight compounds, offering various phases that provide different retention characteristics tailored to specific needs.

As Kromidas observes, 'The pore size can be produced with a narrow distribution of silica gel,' which is a critical consideration when selecting chromatography materials for biological samples. Expert guidance suggests that when choosing liquid chromatography phases, it is vital to consider the resolution needs and analysis duration. Recent studies indicate that achieving high resolution can significantly enhance the quality of results, particularly in applications such as the analysis of underivatized amino acids in wine, where high reproducibility and sensitivity are essential.

This case study exemplifies how customized chromatography selection can enhance testing capabilities, rendering it a valuable asset for quality control and research.

JM Science Inc. distinguishes itself through its dedication to quality, customer support, and innovation in scientific instrumentation. By thoughtfully selecting liquid chromatography supports based on application-specific needs, laboratories can not only elevate testing performance but also contribute to the overall effectiveness of their processes.

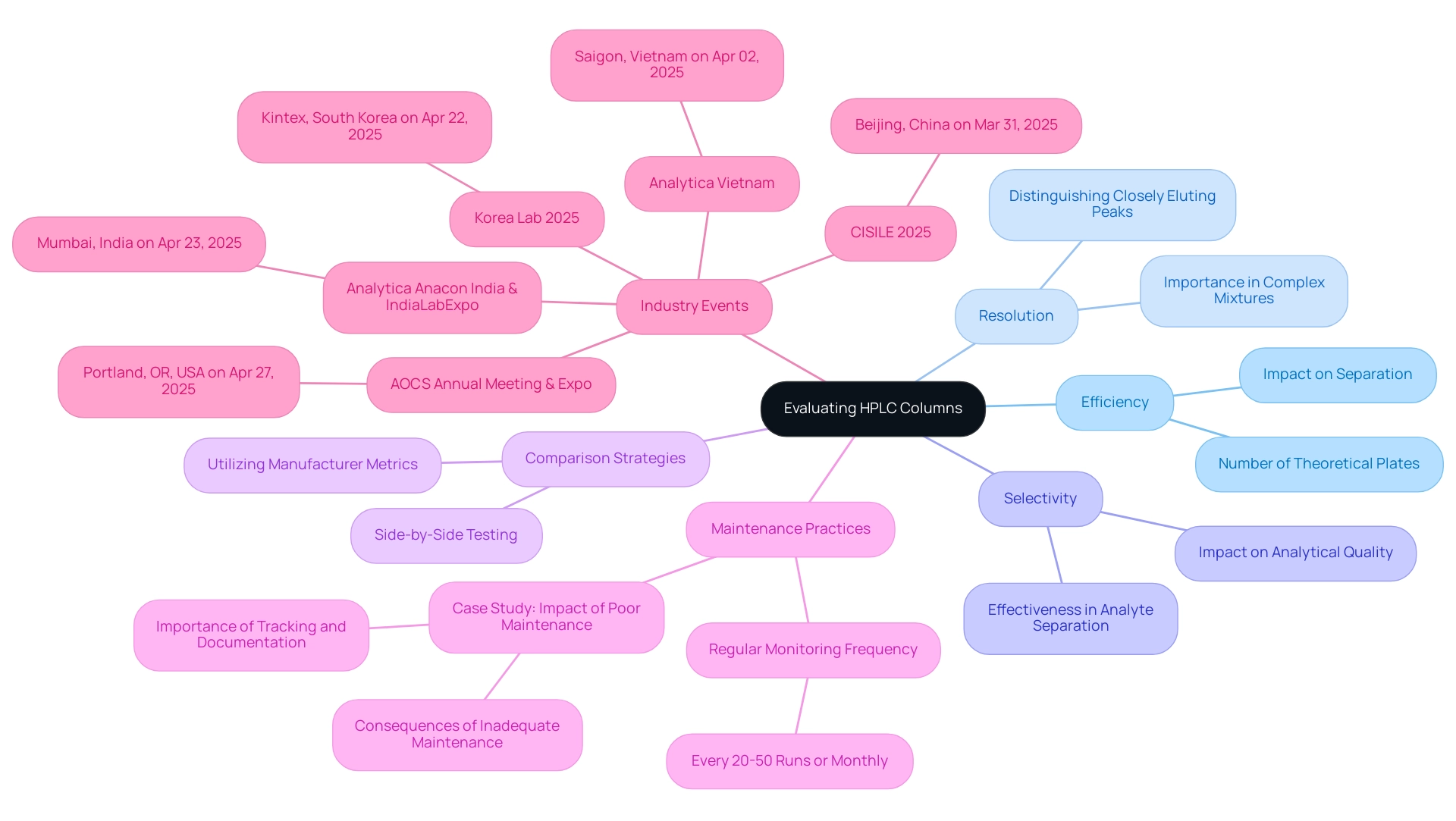

Evaluating HPLC Columns: Key Metrics and Comparison Strategies

When assessing HPLC setups, it is essential to consider several key metrics that significantly impact analytical performance. Efficiency, often quantified by the number of theoretical plates, serves as a primary indicator of a system's ability to separate compounds effectively. A higher plate number suggests better separation, which is critical for achieving precise results in complex mixtures.

Resolution is another crucial metric, as it determines the ability to distinguish between closely eluting peaks. This is particularly important in applications where analytes have . Selectivity, conversely, pertains to the effectiveness in separating various analytes according to their distinct chemical properties, which can significantly impact the quality of analytical results.

To compare HPLC devices effectively, utilize performance metrics provided by manufacturers, including chromatograms derived from standard mixtures. These visual representations can provide valuable insights into how well each section performs under specific conditions. Additionally, conducting side-by-side tests using identical sample conditions can yield practical data on the performance differences among various structures.

For example, a case study titled "Impact of Poor Maintenance on Chromatography Columns" highlights that inadequate upkeep led to increased operational costs and compromised analytical results, underscoring the necessity of rigorous maintenance practices to extend lifespan and enhance efficiency.

Regular monitoring of chromatography units should take place every 20-50 runs or monthly, depending on sample complexity, to ensure optimal performance. In 2025, the latest performance metrics for HPLC systems emphasize the importance of efficiency and resolution, with many manufacturers reporting advancements in selectivity metrics. By concentrating on these essential aspects, managers can make informed choices that enhance equipment longevity, reduce unforeseen downtime, and ensure consistently high-quality evaluation results.

As Joe Har aptly stated, "Ultimately, your goal is to optimize durability, minimize unexpected downtime, and maintain through strategic, data-driven maintenance interventions."

Additionally, staying informed about industry events such as CISILE 2025 in Beijing on March 31 and Analytica Vietnam in Saigon on April 2 can provide valuable insights and networking opportunities for managers in the field. Ultimately, the objective is to utilize strategic, data-informed maintenance actions to guarantee optimal performance from chromatography systems, thereby improving overall efficiency in the workspace.

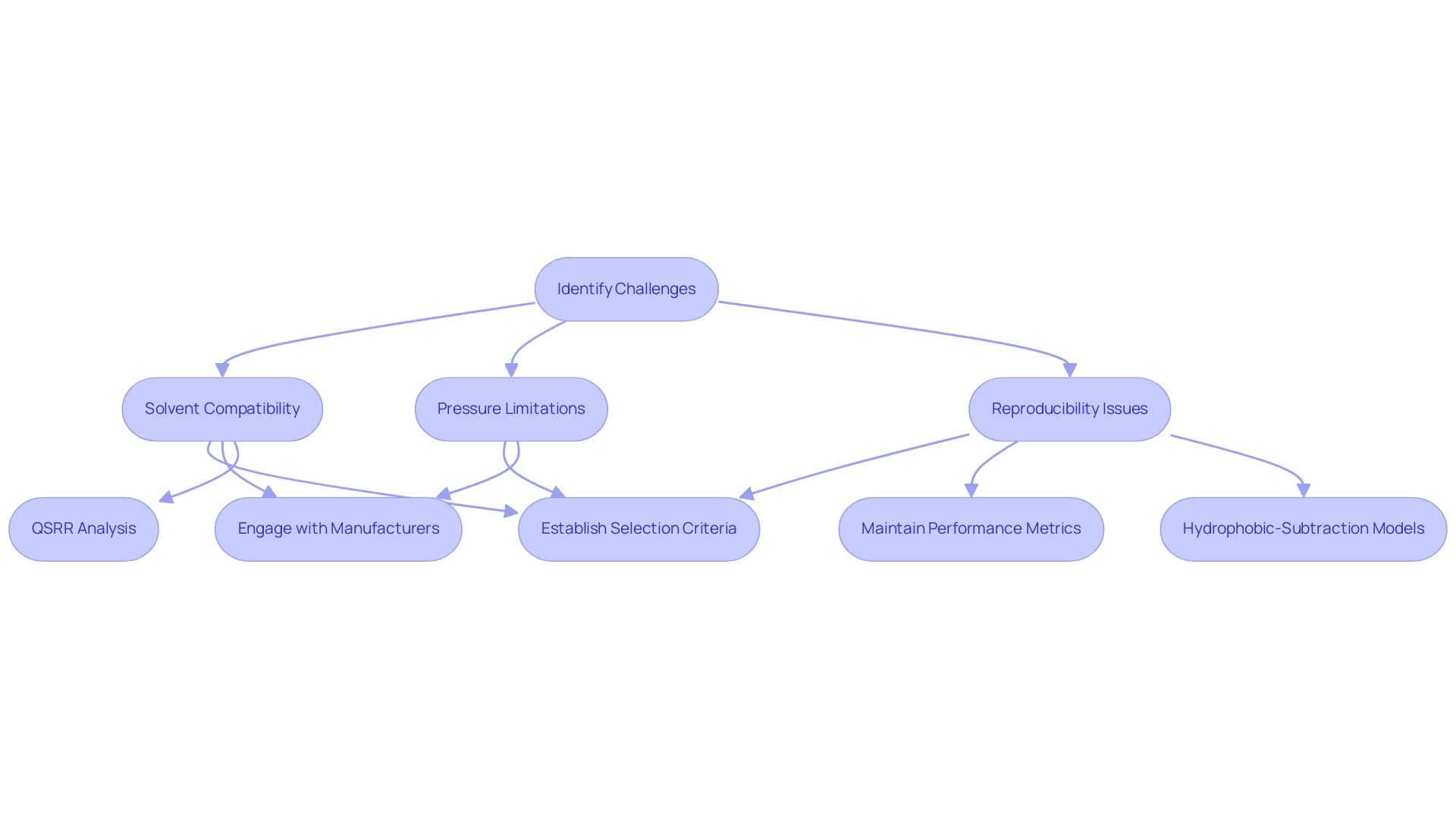

Overcoming Challenges in HPLC Column Selection: Solutions for Lab Managers

Selecting the right HPLC setup can pose significant challenges due to the extensive range of options and the specific requirements of various applications. Lab managers frequently face obstacles such as solvent compatibility, pressure limitations, and the imperative for reproducibility across different batches. Notably, statistics reveal that solvent compatibility issues rank among the top concerns in laboratories, with nearly 40% of lab managers acknowledging difficulties in aligning columns with the solvents utilized in their analyses.

To effectively address these challenges, it is essential for lab managers to establish clear selection criteria tailored to their analytical needs. Engaging with manufacturers for technical assistance can provide invaluable insights, particularly when considering the latest advancements in chromatography technology. For example, a recent study on quantitative structure–retention relationships (QSRR) underscored how specific retention properties of various reversed-phase chromatographic supports can be characterized, facilitating informed decisions based on the types and magnitudes of intermolecular interactions that influence analyte retention.

As Kateřina Novotná aptly stated, "All the approaches allow a quantitative, although multidimensional, characteristic of HPLC structures; however, is simpler and requires less labor."

Furthermore, maintaining a well-documented history of performance metrics emerges as a strategic approach that can bolster future selections. This practice not only aids in identifying trends and potential issues but also enables comparisons across various categories over time. Real-world examples illustrate that laboratories implementing systematic documentation and performance analysis can significantly diminish the frequency of compatibility issues.

Moreover, expert guidance emphasizes the importance of staying informed about the latest advancements in chromatography technology and solvent compatibility solutions. By leveraging application notes and case studies, such as those detailing the application of QSRR in chromatographic material characterization, managers can enhance their understanding of the nuances involved in selection. Additionally, incorporating insights from hydrophobic-subtraction model parameters can further refine the selection criteria.

This proactive approach not only alleviates common challenges but also positions laboratories to achieve optimal results in their analytical endeavors.

Key Takeaways: Making Informed Choices for HPLC Column Selection

Selecting the appropriate chromatography segment is a pivotal step that hinges on a thorough understanding of essential specifications, dimensions, types, materials, and application requirements. The optimal approach in high-performance liquid chromatography (HPLC) selection involves evaluating performance metrics such as resolution, efficiency, and capacity, while also addressing common challenges that may arise during the process.

Recent findings reveal that can vary significantly with pH fluctuations, particularly between pH 2.8 and pH 7.0. This underscores the critical importance of considering pH during method development. Moreover, leveraging in-silico models and databases like PQRI can greatly enhance the selection process, facilitating more informed decisions that align with specific analytical needs.

A notable case study on throughput enhancement in HPLC illustrates the significance of design structure. It demonstrates that while shorter structures can expedite analysis time, they may compromise resolution. This emphasizes the essential role of sample preparation; inadequately prepared samples can lead to increased maintenance and downtime, ultimately impacting throughput.

Consequently, achieving high-quality results requires aligning well-prepared samples with the appropriate HPLC equipment. This case study exemplifies how informed decision-making in selection directly influences efficiency and outcomes.

Expert insights stress that the selection of the mobile phase is inherently connected to the choice of stationary phase. As Tom Elich, Manager of MSAT Purification Process Engineering at MilliporeSigma, articulates, "The mobile-phase selection is dictated by stationary-phase selection," reinforcing the interdependent nature of these choices. By documenting the selection process and its outcomes, professionals can refine their strategies, leading to enhanced practices and improved evaluation methods.

In conclusion, informed decisions in HPLC column selection not only bolster efficiency in the laboratory but also enhance the accuracy of analytical results. By concentrating on these key factors, professionals can ensure their methodologies are both effective and reliable, paving the way for advancements in research and diagnostics. JM Science Inc.'s commitment to quality and customer support further highlights its dedication to providing dependable solutions for laboratory professionals, aligning with their needs.

Conclusion

Understanding the intricacies of High-Performance Liquid Chromatography (HPLC) columns is essential for laboratory managers aiming to optimize their analytical systems. Key specifications such as column length, inner diameter, particle size, and stationary phase chemistry directly influence the performance metrics of chromatography processes. The ongoing advancements in HPLC technology, including innovative column designs and automated method development tools, underscore the necessity of staying informed about the latest trends and solutions available.

The selection of the appropriate HPLC column type—whether reversed-phase, normal-phase, ion-exchange, or size-exclusion—should be dictated by the specific analytical requirements and the nature of the samples being analyzed. Each column type presents unique advantages that can significantly impact the quality of results, making it imperative to align the column with the application at hand. Additionally, the choice of materials, particularly silica-based compositions, is critical in ensuring compatibility with various solvents and maintaining column integrity over time.

Ultimately, the success of analytical endeavors hinges on a comprehensive understanding of HPLC column specifications and their implications for performance. By prioritizing informed decision-making and leveraging expert insights, laboratory professionals can enhance their analytical capabilities, ensuring precise and reliable results across diverse applications. This strategic approach not only boosts laboratory efficiency but also contributes to advancements in research and diagnostics, reinforcing the indispensable role of HPLC columns within the scientific community.