Overview

The article delineates seven pivotal benefits of employing a 0.2 micron filter syringe within laboratory environments, underscoring its significance in enhancing sample purity, safeguarding analytical instruments, and ensuring adherence to regulatory standards. Each benefit is substantiated by evidence showcasing improved operational efficiency, diminished contamination risks, and notable cost savings. This compelling data illustrates the syringe's essential role in facilitating reliable and high-quality scientific research. By integrating these advantages, laboratories can elevate their operational protocols and reinforce their commitment to excellence in scientific inquiry.

Introduction

In the realm of laboratory science, precision and reliability are paramount, particularly regarding sample filtration. The JM Science 0.2 micron filter syringe stands out as an essential tool, meticulously engineered to eliminate contaminants while preserving the integrity of samples. Its pore size effectively blocks bacteria and larger particles, making this filtration solution indispensable in pharmaceutical and medical diagnostics, where even the slightest impurity can skew results.

As laboratories strive to uphold stringent safety and efficacy standards, recognizing the significance of these filters is crucial—not only for achieving accurate analyses but also for ensuring compliance with regulatory guidelines. This article explores the multifaceted benefits of 0.2 micron filters, examining their applications, cost-effectiveness, and the vital role they play in enhancing the quality of scientific research.

JM Science 0.2 Micron Filter Syringe: Precision in Filtration

from JM Science is an essential instrument for high-precision separation, adeptly eliminating contaminants while preserving sample integrity. Engineered with a pore size specifically designed to block bacteria and larger particles, this syringe is indispensable in pharmaceutical applications and medical diagnostics. The accuracy these devices provide is crucial, ensuring that outcomes from subsequent analyses are both reliable and reproducible—a necessity in both research and clinical environments.

Recent studies highlight the critical importance of particle safety in therapeutic applications, revealing that even a minimal number of particles can obstruct larger blood vessels during IV infusions. Notably, it has been documented that as few as 10 to 20 particles can lead to significant blockages, underscoring the urgency for stringent purification standards in pharmaceutical preparations. Experts assert that adherence to cutting-edge Good Manufacturing Practices (GMP) is vital for effectively managing particulate contamination risks. Richard Hutchinson emphasizes, "To assess and manage VPs, in a parenteral DP, acceptable levels of VP need to first comply with state-of-the-art GMP principles and compendial requirements."

Moreover, advancements in 0.2 micron filter syringe technology have enhanced purification capabilities, ensuring that pharmaceutical products meet the highest safety and efficacy standards. Laboratory professionals have observed that employing these syringes not only elevates the quality of results but also streamlines workflows, making them the preferred choice in high-stakes environments. The ongoing monitoring and evaluation of particle-related hazards, as discussed in the case study 'Pharmacovigilance and Particle Safety,' further underscore the crucial role of these purification devices in safeguarding patient safety and product effectiveness.

In conclusion, the 0.2 micron filter syringe from JM Science emerges as a pivotal tool in the quest for precision in purification, significantly contributing to the safety and effectiveness of pharmaceutical products. Recognizing the contributions of experts like Dr. Mike Barnett in the study of particulate contamination adds depth to this discussion.

Enhance Sample Purity with 0.2 Micron Filters

Utilizing a 0.2 micron filter syringe significantly enhances sample purity by effectively eliminating microbial contaminants and particulate matter. This improvement is crucial in sensitive applications such as cell culture and analytical chemistry, where even minor impurities can skew results. By ensuring that samples are devoid of contaminants, laboratories can achieve more accurate and reliable outcomes in their experiments. The implementation of a 0.2 micron filter syringe and these membranes not only safeguards experimental integrity but also reinforces the credibility of laboratory results, ultimately driving the pursuit of excellence in scientific research.

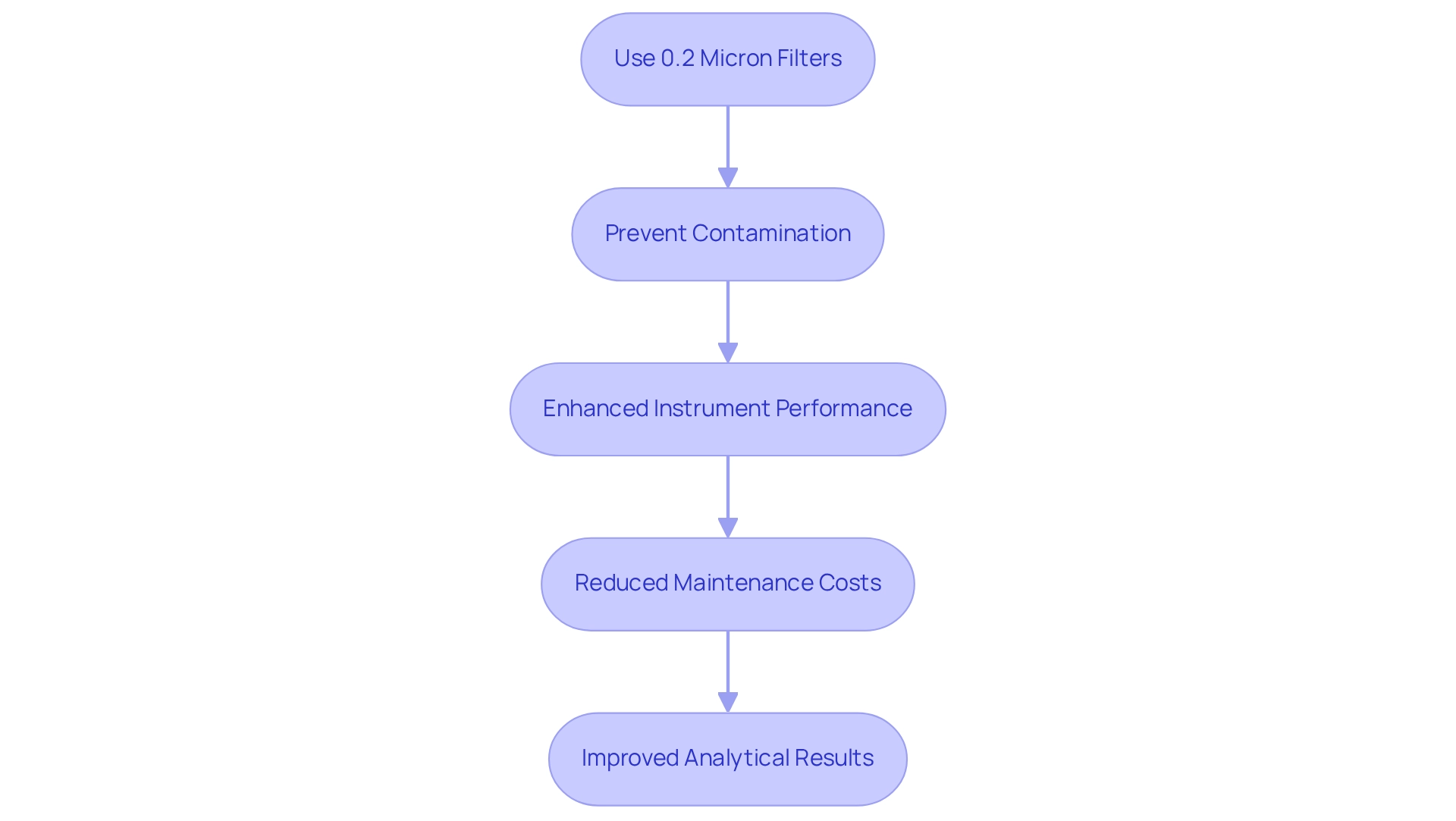

Protect Analytical Instruments from Contaminants

0.2 micron screens serve as a critical barrier against pollutants that jeopardize the integrity of delicate analytical instruments. By effectively eliminating particulates and microorganisms before samples reach systems like HPLC, these devices guarantee the accuracy and reliability of analytical results. This protective measure not only extends the lifespan of the equipment but also significantly reduces maintenance costs associated with repairs and replacements.

For instance, the application of 0.2 micron membranes has been shown to prevent contamination in HPLC systems, resulting in enhanced performance and reliability. Lab managers recognize that employing these devices is essential for maintaining the quality of their analyses, with one asserting, 'Preventing contamination is vital; it directly affects our results and operational efficiency.'

Moreover, studies indicate that contaminants can lead to substantial instrument damage, with repair costs escalating rapidly. By investing in a 0.2 micron filter syringe, research facilities can achieve significant cost reductions while ensuring their analytical devices remain in optimal condition. The advantages of utilizing these filters extend beyond mere protection; they are integral to upholding the high standards required in pharmaceutical and research environments.

In experimental settings, timely and accurate outcomes are paramount. For example, onsite qPCR assays can quantify HF183 marker genes within 3 hours of sampling, highlighting the necessity for effective filtration to ensure that results are not compromised by contaminants. Furthermore, the case study on the MinION sequencer by Oxford Nanopore Technologies underscores the importance of cost efficiency and accessibility in research, reflecting the benefits of employing a 0.2 micron filter syringe in research environments. As noted, 'Processing, storing, and interpreting large data sets remains a major challenge for ubiquitous genetics and democratizing sequencing applications,' which further underscores the need for maintaining data integrity through contamination prevention. Therefore, the incorporation of a 0.2 micron filter syringe is essential for facilities striving to uphold the highest standards in their analytical procedures.

Save Time with Quick Filtration Processes

The design of the 0.2 micron filter syringe facilitates swift filtering, significantly reducing the time required to prepare samples for analysis. proves especially beneficial in high-throughput environments, where time is of the essence. By optimizing sample preparation with JM Science Inc.'s premium scientific instruments, including HPLC solutions and cutting-edge medical devices, research facilities can boost their productivity. This allows them to focus on more critical tasks, ultimately leading to faster project completion. Investing in these advanced tools not only enhances efficiency but also empowers researchers to achieve their goals with greater speed and reliability.

Reduce Costs with Efficient Filtration Solutions

Utilizing a 0.2 micron filter syringe can lead to substantial cost reductions for research facilities. These filters effectively prevent contamination, significantly reducing the need for re-testing and minimizing waste. This efficiency conserves valuable resources and enables research facilities to process a greater number of samples in a shorter timeframe, thereby enhancing overall cost-effectiveness.

Financial analysts emphasize that the adoption of effective purification solutions can lead to a notable decrease in operational costs, underscoring the necessity of assessing suppliers to guarantee quality while controlling expenses. As highlighted in the case study ',' facilities utilizing a 0.2 micron filter syringe have experienced enhanced resource management, demonstrating the financial advantages of integrating such filtering technologies into their processes.

Furthermore, Patrick Hill, Director of Field Engineering, remarked, "That’s the kind of news that puts a smile on corporate’s face," illustrating the positive impact of efficient filtration on operational processes. By reducing waste and improving processes, facilities can achieve enhanced financial sustainability, ultimately supporting their long-term viability.

In the current environment, where a $500 early career scientist grant is awarded each month, the financial implications of cost-saving strategies become increasingly critical for facilities striving to maintain operational viability.

Utilize Versatile Applications of 0.2 Micron Filters

0.2 micron filter syringes are essential instruments in research facilities, recognized for their versatility across various applications, such as:

- Microbiological testing

- Sterile processing of culture media

- Sample preparation for chromatography

Their design facilitates the effective removal of bacteria and particulates, rendering them indispensable in:

- Pharmaceuticals

- Biotechnology

- Environmental testing

This versatility not only optimizes research processes but also enhances the reliability of outcomes, establishing these membranes as a trusted choice for numerous scientific endeavors. In drug and medicine testing, particularly with the Hiranuma Aquacounter AQV-300 Volumetric and AQ-300 , the use of a 0.2 micron filter syringe is crucial for ensuring the sterility and purity of samples. This is essential for accurate analysis and adherence to the Japanese Pharmacopoeia, which imposes rigorous standards for pharmaceutical testing.

The AQV-300 and AQ-300 titrators are engineered to provide precise moisture content analysis, making them ideal for pharmaceutical applications. Additionally, their role in sterile separation is vital for maintaining the integrity of culture media, thus supporting optimal experimental conditions.

Case studies have illustrated that the implementation of 0.2 micron filter syringes in pharmaceutical settings has led to significant improvements in product quality and safety, underscoring their importance in modern research practices. The extensive applicability of these devices empowers researchers to achieve high levels of accuracy and reliability in their work, particularly when integrated with advanced titration methods.

Ensure Regulatory Compliance in Filtration Processes

Employing a 0.2 micron filter syringe is essential for facilities striving to meet stringent regulatory benchmarks regarding sample purity and contamination management. Compliance with the guidelines set forth by the FDA and EPA is critical, particularly for organizations involved in pharmaceuticals and environmental testing. By integrating the 0.2 micron filter syringe into their workflows, facilities enhance their operational integrity while safeguarding their reputation in a competitive landscape.

Notably, statistics indicate that approximately 30% of primary interviews were conducted with demand-side participants, underscoring the market's perspective on compliance with filtration standards. Furthermore, the growth of the research facility purification market is fueled by increasing R&D investments in biopharmaceutical initiatives, highlighting the vital role of purification in maintaining high-quality standards.

are emerging, challenging conventional methods and presenting new opportunities for ensuring compliance. For instance, case studies reveal that research facilities employing advanced purification solutions, such as the IDEX system, have successfully adhered to FDA and EPA standards, demonstrating the impact of purification on regulatory compliance.

As the filtration market evolves, driven by technological advancements and innovations in filtration materials, the importance of reliable filtration methods remains fundamental to achieving compliance and ensuring the integrity of scientific analyses.

Achieve Consistent Results with Reliable Filtration

The dependability of 0.2 micron membranes is paramount for research facilities aiming for uniform outcomes across various experiments. These filters proficiently eliminate contaminants, thereby preserving sample integrity and facilitating reproducible results. Such consistency is essential for facilities that demand precise measurements and analyses, as it directly influences the reliability of research findings and the development of new products. Research indicates that maintaining cleanliness levels of ISO 17/16/13 (c), which pertains to the cleanliness of fluids utilized in laboratory processes, can extend the lifespan of laboratory equipment by four-fold. This underscores the critical role of efficient separation in sustaining operational effectiveness.

Moreover, case studies elucidate the impact of reliable purification on reproducibility. For instance, round-robin testing has shown that facilities employing a 0.2 micron filter syringe consistently produce comparable results, highlighting their efficacy in method validation. This strategy not only delivers valuable feedback regarding a laboratory's reproducibility but also pinpoints areas for methodological enhancement. As , PhD, Editorial Director of Lab Manager, articulates, 'Generating reproducible results is the key to good science,' reinforcing the imperative of high-quality purification in securing trustworthy experimental outcomes.

In practical applications, facilities that have embraced advanced purification systems report notable improvements in fluid cleanliness, resulting in enhanced sample integrity and more reliable data. The ENG-2 system, for example, has allowed a mining operation to uphold superior cleanliness standards and recoup its investment in just over five months, illustrating the tangible benefits of investing in dependable purification solutions. By ensuring consistent outcomes through efficient separation, particularly with the use of a 0.2 micron filter syringe, research facilities can bolster their investigative capabilities and contribute to advancements within their respective fields.

Experience User-Friendly Filtration Solutions

0.2 micron screens are specifically engineered for seamless integration into laboratory processes, allowing staff to adopt them effortlessly. Their intuitive design and straightforward operation significantly diminish the likelihood of errors during sample preparation, rendering them accessible even to less experienced personnel. This inherent simplicity not only boosts operational efficiency but also enables staff to focus on their primary tasks, free from the complications of intricate procedures. Facilities utilizing these screens report a notable reduction in training duration for new employees, facilitating quicker onboarding and heightened productivity.

Moreover, the robust outer enclosure of these devices provides crucial support to the media, enabling them to withstand high differential pressure, which further enhances their reliability. Case studies illustrate that the integration of into testing workflows leads to smoother operations, ultimately improving user satisfaction and overall outcomes in analytical tasks. For instance, in the surface finishing sector, comparable purification methods underscore the necessity of efficient filtering to maintain product quality, thereby accentuating the critical role of dependable purification in testing environments.

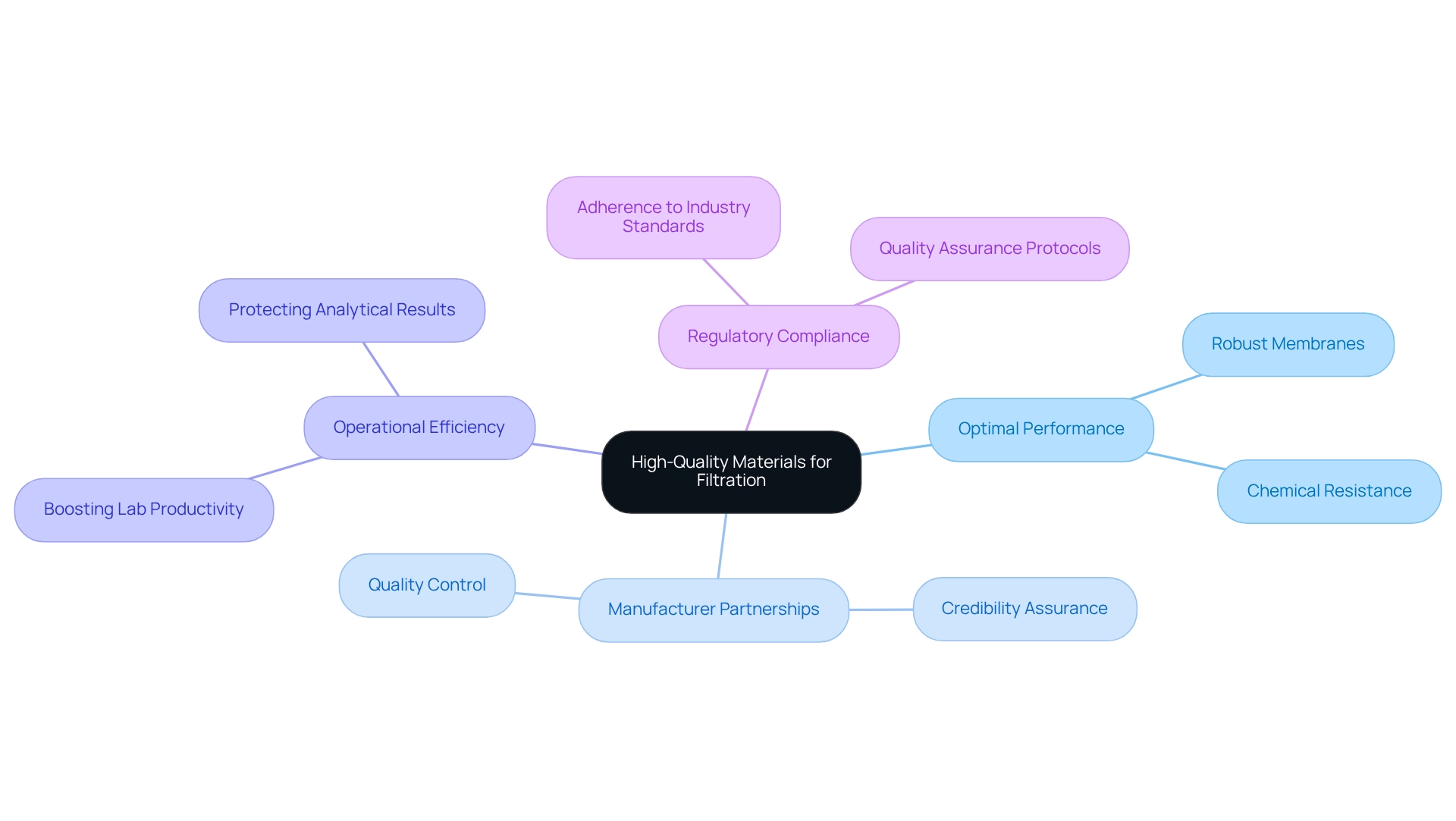

Ensure High-Quality Materials for Optimal Filtration

The creation of a 0.2 micron filter syringe using high-quality materials is crucial for achieving optimal separation performance. These filters feature robust membranes designed to withstand chemical degradation, thereby maintaining their integrity under various experimental conditions. JM Science's strong partnerships with leading manufacturers enhance the credibility of these products, assuring research facilities of their quality and reliability.

By prioritizing high-quality filtration solutions, laboratories can significantly boost their operational efficiency and protect their results from the risks associated with inferior materials. This unwavering commitment to quality not only enhances the reliability of analytical outcomes but also ensures compliance with stringent industry standards.

To achieve the best results, pharmaceutical lab managers must evaluate 0.2 micron filter syringes based on , ensuring they select products that align with their specific operational needs.

Conclusion

The JM Science 0.2 micron filter syringe is an essential instrument in laboratory filtration, delivering high precision by effectively eliminating contaminants while safeguarding sample integrity. Its capability to block bacteria and larger particles is vital in pharmaceutical and medical diagnostics, where even the slightest impurities can jeopardize results. These filters not only enhance the reliability of analyses but also ensure adherence to stringent regulatory standards, thereby protecting patient safety and product efficacy.

Versatile in application, 0.2 micron filters are crucial for microbiological testing, chromatography, and various other processes. Their user-friendly design optimizes workflows, reduces training time, and enhances productivity, allowing laboratory personnel to concentrate on critical tasks while consistently achieving reliable results.

Furthermore, the adoption of these filters results in substantial cost savings by averting contamination and minimizing the necessity for re-testing. This efficiency, coupled with improved analytical outcomes, underscores the significance of investing in high-quality filtration solutions. Laboratories that prioritize 0.2 micron filters not only improve operational efficiency but also contribute to advancements in scientific research and healthcare.

In summary, the integration of 0.2 micron filters signifies a commitment to excellence in laboratory practices. By selecting dependable filtration methods, laboratories can ensure research integrity and uphold regulatory compliance, paving the way for innovation. The JM Science 0.2 micron filter syringe emerges as a leader in this crucial domain of laboratory science, establishing itself as an invaluable asset for achieving precision in scientific analysis.