Overview

The article examines the indispensable applications of 0.45um filters in pharmaceutical laboratories, underscoring their vital function in maintaining sample purity and adhering to industry standards. These filters are proven to effectively eliminate particulates and microorganisms, which significantly enhances the accuracy of pharmaceutical analyses and quality control processes. Recent studies provide compelling evidence of substantial contamination reductions achieved through the use of these filtration devices, reinforcing their importance in laboratory settings. Consequently, the implementation of high-quality filtration systems is not merely a recommendation but a necessity for ensuring the integrity of pharmaceutical products.

Introduction

In the realm of scientific research and quality assurance, the role of 0.45um filters is paramount. These precision-engineered tools are indispensable across various industries, including:

- Pharmaceuticals

- Biotechnology

- Food and beverage safety

- Environmental testing

Their capability to effectively eliminate particulates and microorganisms ensures that samples remain uncontaminated, thereby safeguarding the integrity of critical analyses. As regulations tighten and the demand for high-quality products escalates, the significance of these filters becomes increasingly evident. From enhancing drug formulation processes to ensuring safe drinking water, the applications of 0.45um filters are extensive and vital. This article explores their multifaceted roles, emphasizing best practices and innovations that drive efficiency and compliance in laboratory operations.

JM Science 0.45um Syringe Filters: Precision for Pharmaceutical Applications

JM Science's 0.45-micron syringe devices are engineered for exceptional accuracy in pharmaceutical applications, effectively eliminating particulates and microorganisms to ensure sample purity. These devices are integral to drug formulation and quality control, where maintaining sample integrity is paramount. Recent studies indicate that utilizing a 0.45um filter significantly reduces contamination rates in pharmaceutical samples, with evidence suggesting that at least three independent experiments are required for dependable results. This highlights their critical role in laboratory processes.

Compatible with a broad spectrum of solvents, these devices excel in sterile purification applications, making them a trusted choice for laboratories dedicated to pharmaceutical research and development. Furthermore, advancements in syringe purification technology continually enhance their performance, ensuring that JM Science's offerings remain at the forefront of industry standards. Real-world applications, such as the dissolution studies of felodipine patches, illustrate that these devices not only safeguard the integrity of drug formulations but also bolster the overall reliability of pharmaceutical analyses.

Moreover, when used in conjunction with , these devices can further refine the precision of in pharmaceuticals, adhering to compliance standards set forth by the Japanese Pharmacopoeia. As Alessandro Manenti aptly notes, 'The function of syringe screens in drug formulation is essential for ensuring the precision and safety of pharmaceutical products.

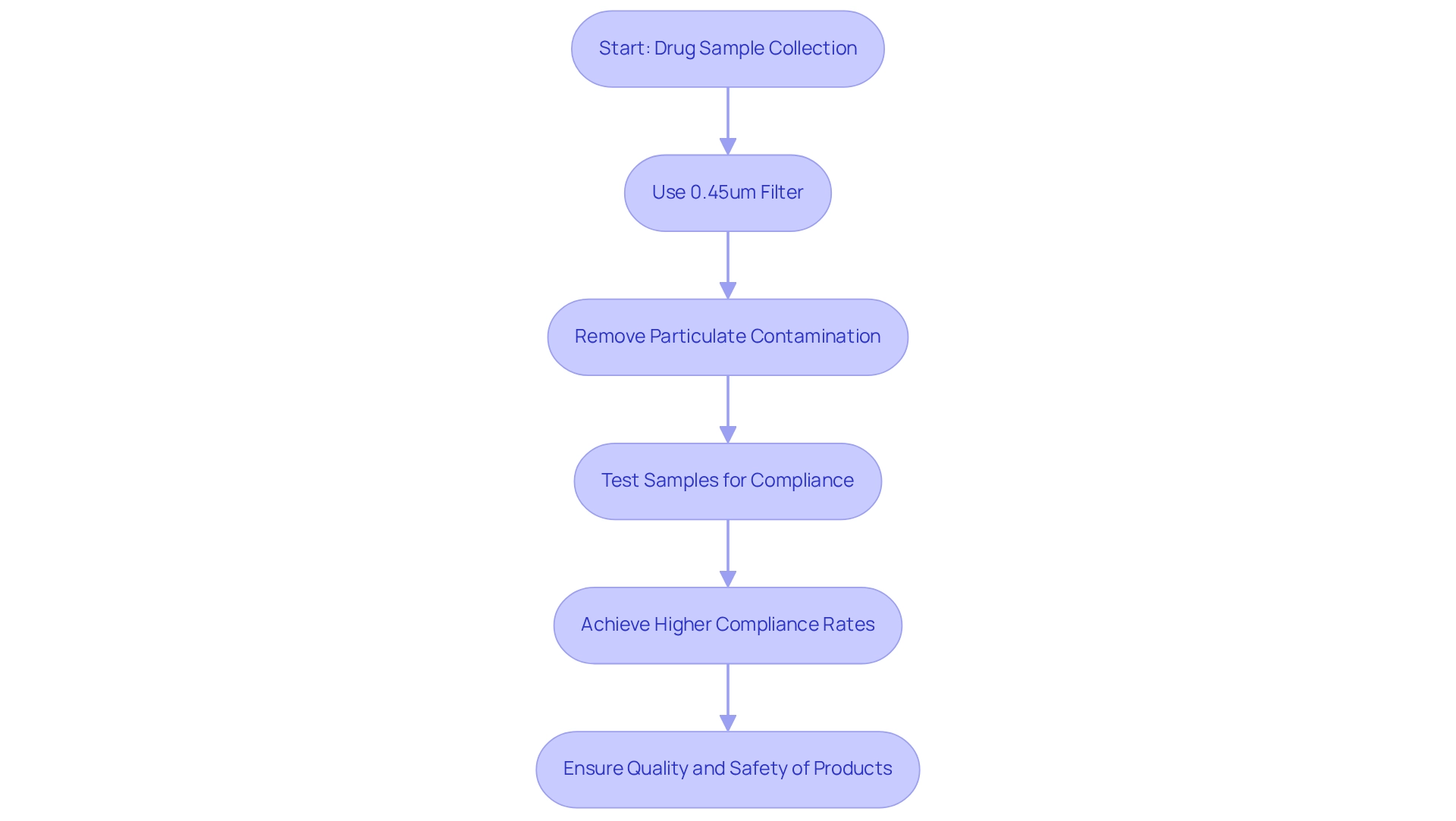

Quality Control: Utilizing 0.45um Filters for Compliance in Drug Testing

In pharmaceutical laboratories, 0.45um filters are essential in quality control processes. These devices play a crucial role in cleansing drug samples prior to testing, effectively removing particulate contamination that could compromise results. This purification step is not merely procedural; it is a critical requirement for compliance with the stringent regulatory standards established by the FDA. By employing , laboratories improve the reliability of their testing outcomes, ensuring that only safe and effective products reach the market.

For samples ranging from 10-200ml, a 33mm syringe strainer with a hold-up volume of less than 125μl is recommended, underscoring the importance of selecting the appropriate separation technique. Recent studies reveal that laboratories utilizing the 0.45um filter achieve higher compliance rates in drug testing, which highlights the significance of this filter in maintaining the integrity of pharmaceutical products.

Furthermore, regulatory specialists emphasize that adherence to purification standards is vital for mitigating risks associated with particulate contamination. As H.K. noted, "The integration of strong purification techniques is essential for ensuring the quality and safety of pharmaceutical products."

Additionally, a case study on an automated screening pipeline for drug repurposing illustrates how effective separation enhances quality assurance in drug testing, reinforcing the necessity of the 0.45um filter within the pharmaceutical industry.

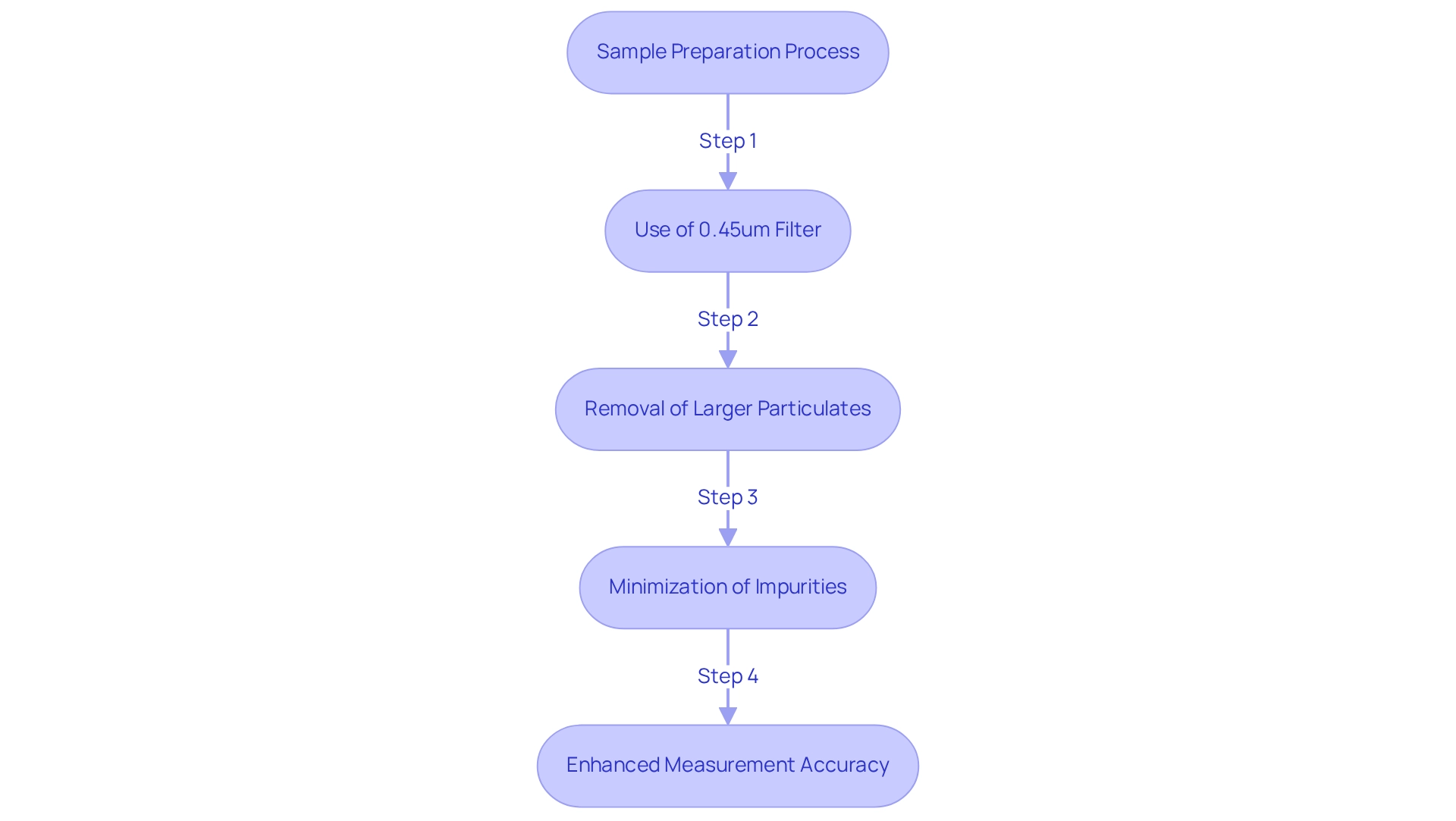

Sample Preparation: Enhancing Accuracy with 0.45um Filtration Techniques

The 0.45um filter membranes play a crucial role in the sample preparation process for analytical methods such as HPLC and LC-MS by effectively removing larger particulates, preventing clogging and ensuring that samples are primed for precise analysis. This purification step significantly enhances result accuracy by minimizing interference from impurities, which is essential for the precise measurement of active components in pharmaceutical formulations.

Research indicates that the application of the 0.45um filter can lead to significant improvements in the precision of HPLC and LC-MS assessments. Notably, the time required for 0.45 μm membranes is considerably longer than that for 0.8 μm membranes, which is vital for preserving sample integrity.

Furthermore, analytical chemists emphasize that appropriate sample preparation methods, including the use of the 0.45um filter, are essential in reducing preparation errors that could compromise the reliability of outcomes. As Dr. Paul Whitehead notes, the human factor in establishing purification systems and selecting compatible membrane elements can also introduce contamination.

Real-world applications, such as those illustrated in the case study on HPLC with for Environmental Analysis, demonstrate that the use of a 0.45um filter not only streamlines the analytical process but also enhances the overall quality of pharmaceutical analysis, establishing it as a fundamental practice in modern laboratories.

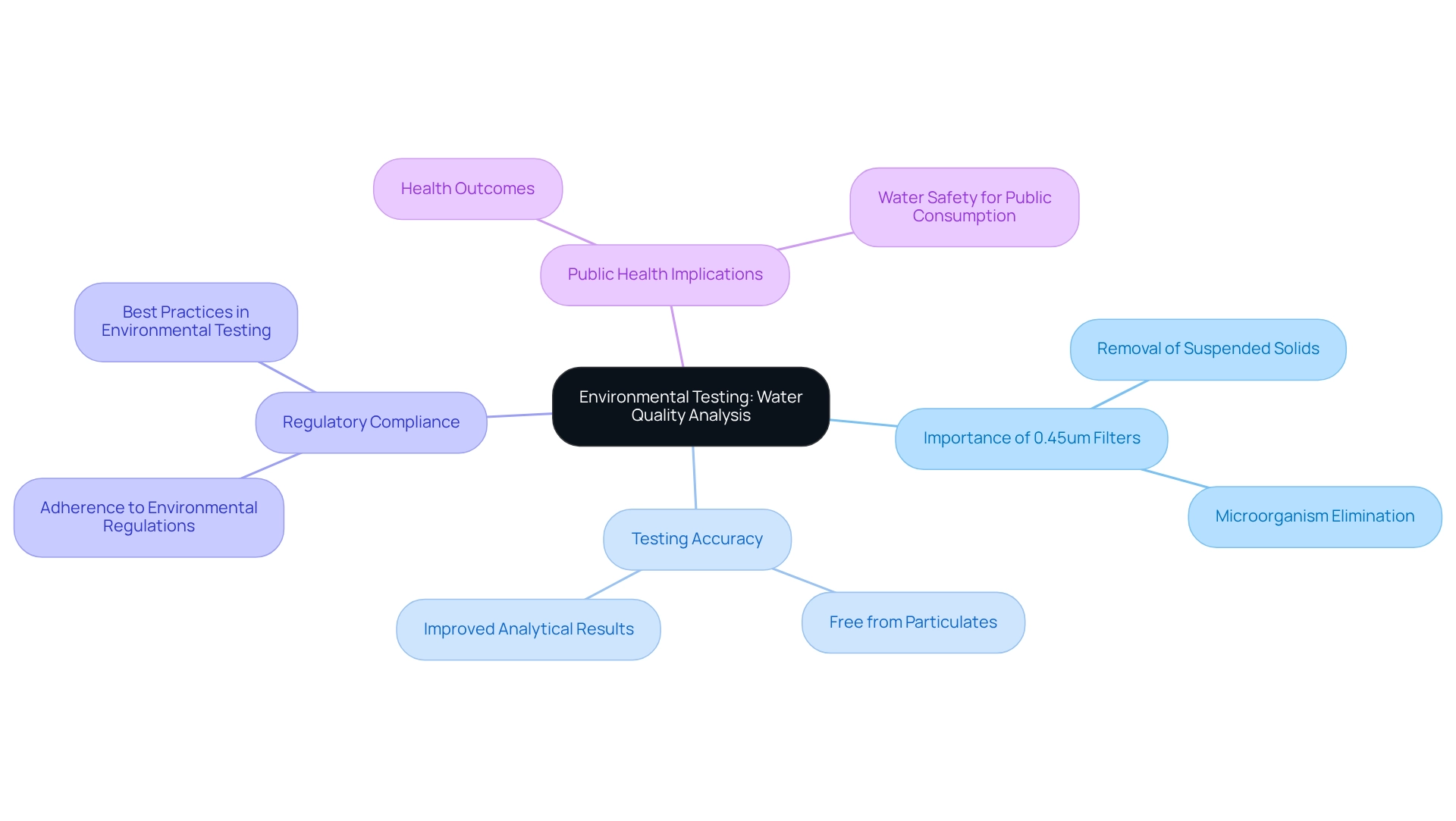

Environmental Testing: Leveraging 0.45um Filters for Water Quality Analysis

In environmental laboratories, a 0.45um filter is essential for assessing water quality. These purifiers effectively remove suspended solids and microorganisms from water samples, which is crucial for maintaining the accuracy of analytical results. By ensuring that samples are free from particulates, the use of 0.45um filters not only improves testing accuracy but also supports compliance with stringent environmental regulations. This adherence is vital for evaluating water safety, particularly for public consumption, as it has direct implications for health outcomes.

As Edward O. Wilson aptly noted, 'To summarize the future of resources and climate, the wall toward which humanity is evidently rushing is a shortage not of minerals and energy, but of food and water.' This underscores the critical need for effective purification in safeguarding water quality.

Furthermore, R. Buckminster Fuller’s perspective on pollution as an unexploited resource highlights the innovative potential of purification technologies in environmental contexts. The utilization of these devices is increasingly recognized as a best practice in environmental testing, emphasizing their importance in preserving water quality.

Recent regulations on water quality testing further underscore the necessity of employing reliable purification techniques, positioning specific membrane devices as indispensable tools for committed to compliance and excellence in water safety.

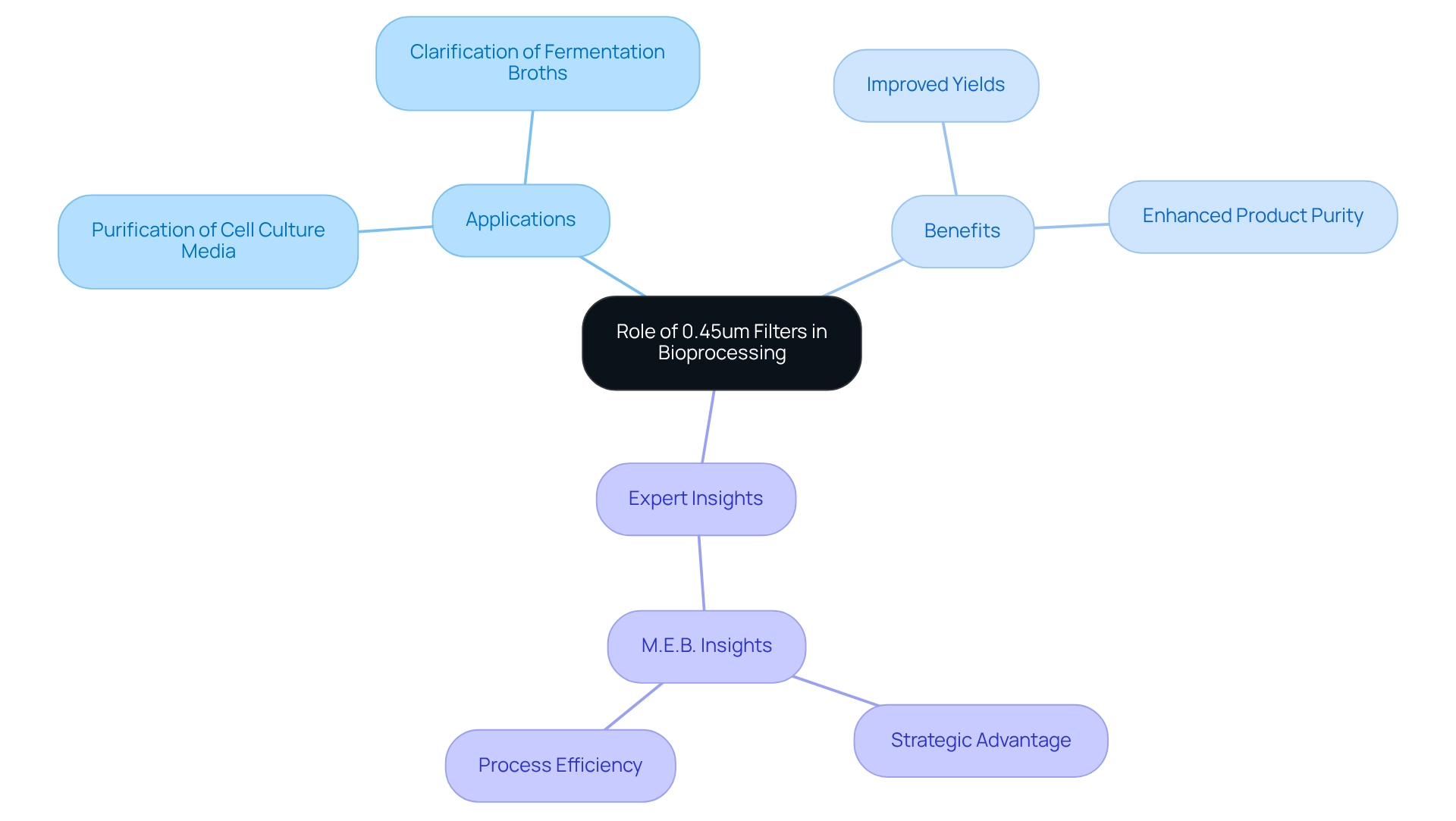

Biotechnology Applications: The Role of 0.45um Filters in Bioprocessing

The purification of and the clarification of fermentation broths in biotechnology heavily rely on the use of a 0.45um filter. By effectively removing cellular debris and particulates, these devices guarantee that final products are pure and ready for further processing. Their application is vital for preserving the integrity of bioprocessing workflows, which directly contributes to improved yields and enhanced quality of biopharmaceuticals.

Recent advancements in bioprocessing filtration techniques have underscored the importance of the 0.45um filter. Research indicates that the use of these devices can lead to significant yield improvements during biopharmaceutical production. Expert insights further validate the necessity of using a 0.45um filter in biotechnology. M.E.B., a founder and consultant in the field, emphasizes that these systems not only enhance product purity but also improve overall process efficiency.

The measurement of cytokines such as IL-2 and IFN-𝛾 from culture supernatants, facilitated by fine membranes, highlights their importance in delivering accurate and reliable outcomes in bioprocessing.

In conclusion, the integration of the 0.45um filter in bioprocessing is not merely a technical requirement but a strategic advantage that promotes innovation and quality in biopharmaceutical manufacturing.

Food and Beverage Safety: Implementing 0.45um Filters for Quality Assurance

In the food and beverage sector, the 0.45um filter plays a vital role in safeguarding product integrity and quality. These filters effectively eliminate impurities from liquids, ensuring that food items meet stringent health regulations. By integrating the 0.45um filter purification into their production processes, manufacturers not only comply with industry standards but also enhance their quality assurance protocols, thereby protecting consumers from potential health risks.

The economic ramifications of foodborne illnesses are considerable, encompassing medical expenses, productivity losses, and even fatalities. This underscores the necessity of robust filtration systems, as filtration failures can precipitate serious food quality incidents, jeopardizing both public health and brand reputation.

Recent trends reveal a growing emphasis on food safety, with over 70% of consumers preferring brands that prioritize transparency and safety in their products, as demonstrated by the practical applications of the 0.45um filter in preserving food quality. In beverage manufacturing, for instance, these sieves are essential for ensuring the removal of microbial contaminants, thus extending shelf life and enhancing product quality.

Expert insights affirm that the implementation of a 0.45um filter is not merely a regulatory requirement but a critical component of a comprehensive food safety strategy. Moreover, the case study titled 'Medical Provider's Role in Food Therapy' highlights the link between food quality and well-being, demonstrating how dietary modifications, supported by the use of a 0.45um filter for adequate purification, can prevent health issues.

As the food sector evolves, the adoption of advanced purification techniques will be essential in addressing emerging challenges and fulfilling consumer demands for .

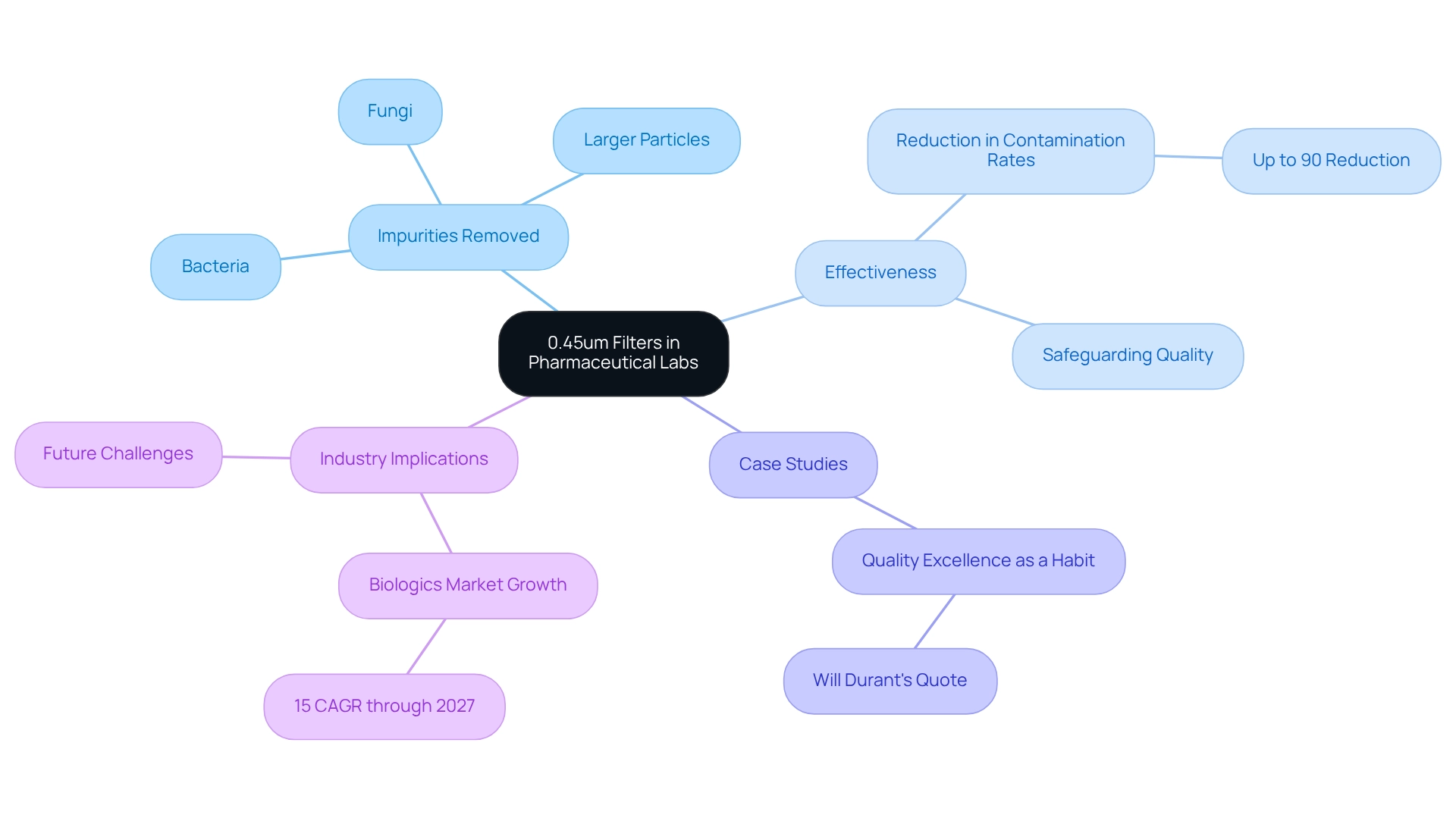

Substance Filtration: What Can 0.45um Filters Remove in Pharmaceutical Labs?

plays a critical role in pharmaceutical laboratories by effectively removing impurities such as bacteria, larger particles, and certain fungi. Their primary function is to ensure that drug formulations are free from microbial contamination and particulate matter, which is essential for maintaining product quality and adhering to stringent industry standards. Recent studies demonstrate that the use of these membranes significantly reduces microbial contamination rates in drug formulations, with some reports indicating a reduction of up to 90% in contamination levels post-treatment, as evidenced by a relevant study.

In practical applications, the effectiveness of the 0.45um filter has been proven in safeguarding the quality of pharmaceutical products. A notable case study illustrated the successful elimination of specific bacterial strains from a drug formulation, underscoring the reliability of these devices in maintaining sterility. This case study supports the idea that quality excellence is an ongoing process, as articulated by Will Durant's quote, "Excellence, then, is not an act but a habit." The consistent use of the 0.45um filter membranes fosters a culture of quality excellence in pharmaceutical laboratories, highlighting the importance of these separation technologies.

Moreover, the biologics market, projected to grow at a compound annual growth rate of 15% through 2027, underscores the increasing demand for effective purification solutions in drug development. As the industry evolves, the role of specialized membranes in ensuring microbial safety will remain vital, equipping pharmaceutical laboratories with the necessary tools to address both current and future challenges in drug formulation.

Best Practices: Maximizing Efficiency with 0.45um Filter Usage

To maximize efficiency with the 0.45um filter membranes, laboratories must recognize the critical significance of effective separation in enhancing overall operational performance. Implementing several best practices is not just advisable; it is essential.

- Pre-screening samples significantly reduces the strain on the primary sieve, thereby enhancing its effectiveness and longevity.

- Regular performance monitoring is crucial to ensure optimal operation, while proper storage and handling of these components effectively prevent contamination and degradation.

- Selecting the appropriate mesh size and type tailored for specific applications can greatly improve filtration efficiency, particularly when utilizing a 0.45um filter, which is especially effective for filtering fine particulates and removing bacterial contamination and larger particulate matter.

- Recent studies reveal that the T** value for the BX + PTFE primary strainer escalates from 4.3 to 4.66 as the pre-strainer grade advances from F7 to H11, underscoring the necessity of utilizing high-quality pre-strainers.

- Furthermore, a case study examining the impact of pre-filters demonstrated that efficient pre-screen performance not only prolongs the lifespan of primary screens but also sustains operational efficiency. However, excessive pre-filter replacements can lead to increased resistance and diminished efficiency, highlighting the need for a balanced approach.

As Henry Ford aptly stated, efficiency is paramount to success in any endeavor. Laboratory managers have noted that adherence to can yield more reliable analytical results, ultimately enhancing the overall efficiency of laboratory operations. To implement these best practices effectively, managers should consider conducting regular training sessions for staff on proper screening techniques and the importance of maintaining system integrity. By following these guidelines, laboratories can ensure that their purification processes are both effective and sustainable.

Performance Monitoring: Ensuring Consistent Results with 0.45um Filters

Effective performance monitoring of the 0.45um filter is essential for upholding the integrity of laboratory analyses. Regular evaluations must focus on identifying signs of blockage, reduced flow rates, and increased backpressure, as these factors can significantly affect efficiency. As one laboratory technician aptly noted, "Maintaining purification effectiveness is crucial; even minor clogging can lead to substantial inaccuracies in outcomes."

It is imperative for laboratories to establish structured protocols for replacing screens, informed by usage patterns and performance metrics. Data reveals that clogging rates can soar to 30% in high-throughput environments, directly impacting laboratory results and necessitating timely replacements to maintain accuracy.

By committing to , laboratories can ensure their filtration processes are reliable and reproducible, ultimately enhancing the quality of their scientific outputs. Recent studies have unveiled promising data for developing prognostic methodologies in management, further underscoring the necessity for diligent performance monitoring.

Safe Handling and Disposal: Best Practices for 0.45um Filters in Labs

The careful management of 0.45um filters is crucial in pharmaceutical laboratories, requiring the utilization of appropriate personal protective equipment (PPE) and strict adherence to . Filters that have been in contact with hazardous materials must be disposed of meticulously, in accordance with local regulations and laboratory guidelines. Inappropriate disposal can lead to significant incidents; statistics indicate that human factors are a primary contributor to laboratory mishaps, underscoring the necessity for stringent protective measures.

Implementing effective disposal practices not only protects laboratory personnel but also plays a vital role in environmental conservation by minimizing waste and preventing contamination. Case studies demonstrate that comprehensive risk assessments can enhance both security and financial outcomes, as they reduce maintenance and aftercare costs associated with incidents. Furthermore, expert opinions stress the importance of training staff on safe handling and disposal protocols. As Robert Bouchard, a rack protection expert, asserts, "Train your employees on rack precautions and they’ll recognize and report the damage. Empower them to report damage and you’ll avoid accidents." This statement highlights the critical need to empower staff to identify and mitigate risks effectively.

To comply with the latest guidelines on laboratory waste disposal, laboratories should routinely assess and update their protocols for the disposal of 0.45um filter membranes. This process involves understanding the specific regulations governing the disposal of laboratory waste, particularly for materials that may contain hazardous substances. By fostering a culture of safety and responsibility, laboratories can significantly reduce the likelihood of incidents related to improper filter disposal, thus enhancing overall operational efficiency and contributing to advancements in research and healthcare.

Conclusion

The significance of 0.45um filters in various industries is paramount. From pharmaceutical applications to environmental testing, these precision-engineered tools are essential for ensuring sample purity and compliance with stringent regulatory standards. Their capacity to eliminate particulates and microorganisms is vital in enhancing the accuracy of analytical processes, safeguarding product quality, and protecting public health.

In pharmaceutical laboratories, the implementation of 0.45um filters is critical for quality control and effective sample preparation. By removing contaminants, these filters ensure that drug formulations remain reliable and compliant, ultimately contributing to the safety and efficacy of pharmaceutical products. In biotechnology and food safety, these filters similarly help maintain the integrity of processes and protect consumers from potential health risks associated with contaminated products.

Best practices in the use of 0.45um filters—such as proper handling, performance monitoring, and safe disposal—further enhance their effectiveness and sustainability in laboratory operations. Continuous advancements in filtration technology promise to improve their performance, making them indispensable tools in the quest for higher standards of quality and safety across various sectors.

In conclusion, the multifaceted roles of 0.45um filters across pharmaceuticals, biotechnology, environmental testing, and food safety underscore their critical importance in maintaining quality assurance. As industries increasingly prioritize compliance and safety, the adoption of these filters will remain a key strategy in achieving operational excellence and safeguarding public health.