Overview

The article delineates ten significant benefits of PVDF filter membranes specifically designed for pharmaceutical laboratories. These membranes are characterized by their high filtration efficiency, robust chemical resistance, and minimal protein binding capabilities. Such attributes not only enhance operational efficiency but also ensure reliability within laboratory settings. By achieving high purity levels and demonstrating compatibility with various solvents, these filters effectively minimize sample loss. Consequently, they support precise and consistent research outcomes, underscoring their pivotal role in advancing scientific endeavors.

Introduction

In the pharmaceutical laboratory, the selection of filtration membranes is crucial to the success of experiments. Polyvinylidene fluoride (PVDF) membranes are highly favored for their outstanding performance and diverse applications. These membranes not only offer high flow rates and low protein binding capabilities but also maintain stability in harsh chemical environments, ensuring the accuracy and reliability of experimental results. As the pharmaceutical industry increasingly demands high purity and efficiency, the advantages of PVDF membranes become particularly prominent.

But what is the true value of these membranes? How do they assist laboratories in optimizing processes, reducing costs, and playing a key role in various scientific research fields? This article will delve into the top ten advantages of PVDF filtration membranes in pharmaceutical laboratories, revealing their significance in modern scientific research.

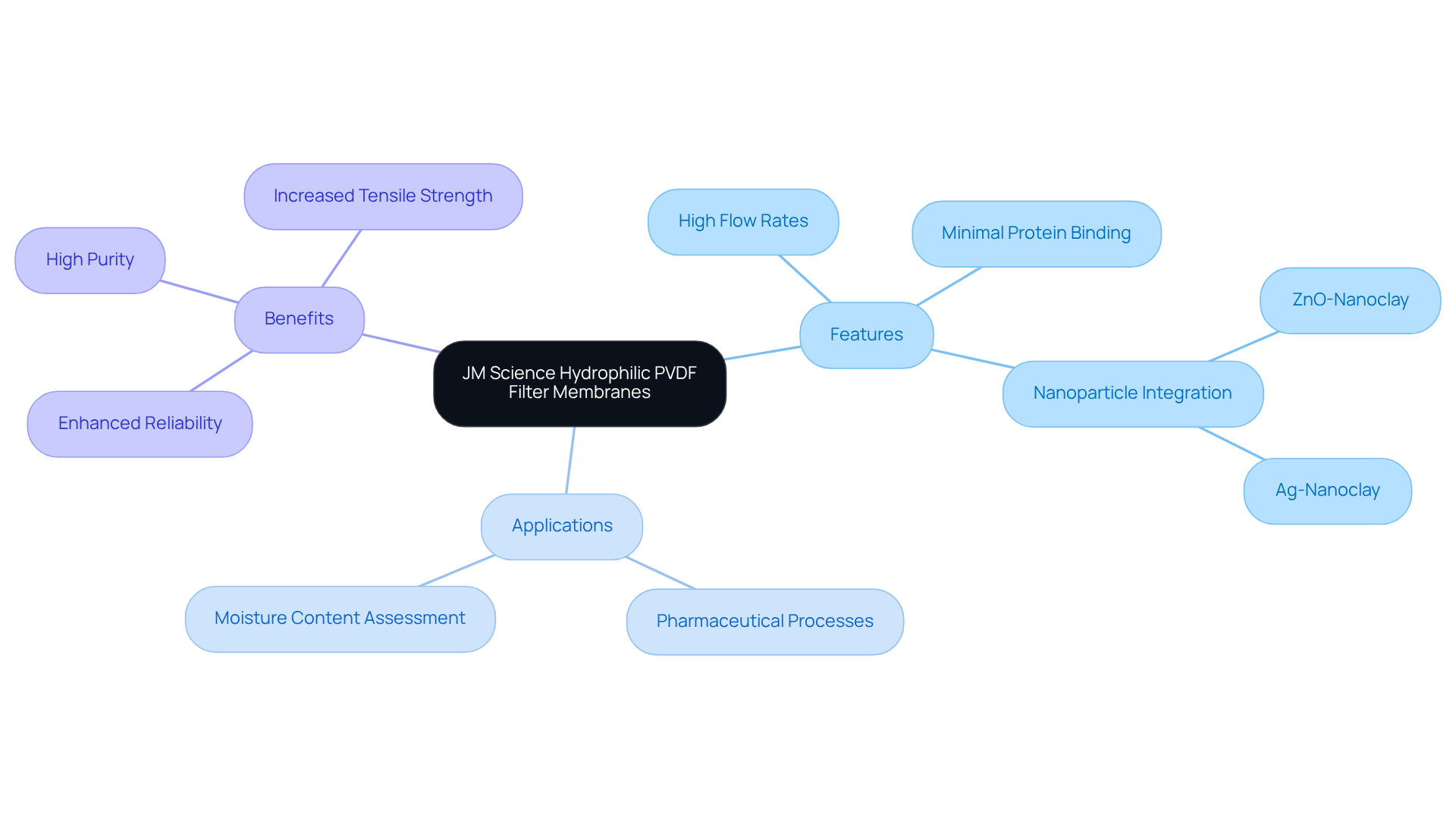

JM Science Hydrophilic PVDF Filter Membranes: High-Quality Laboratory Solutions

JM Science's hydrophilic pvdf filter membranes are meticulously engineered to meet the stringent standards of pharmaceutical facilities, providing a range of advantages that significantly enhance operational efficiency and reliability. These filters are recognized for their exceptional flow rates and minimal protein binding, making them particularly suitable for applications demanding high purity and precision. Their hydrophilic characteristics guarantee compatibility with a wide variety of solvents, thereby expanding their applicability across diverse laboratory environments.

In practical applications, fluoropolymer sheets have demonstrated remarkable performance, achieving oil purity levels exceeding 99.95 wt% in filtrates, a critical factor in maintaining the integrity of pharmaceutical processes. The integration of nanoparticles, such as ZnO-Nanoclay, has proven to enhance the mechanical properties of these materials, increasing tensile strength by as much as 500% and improving antifouling characteristics with inhibition rates reaching 99.92%.

When employed in conjunction with the AQ-300 Coulometric Karl Fischer Titrator, JM Science's polymeric films can significantly elevate the in pharmaceuticals. The compatibility of these films with the titration process ensures that research facilities can achieve precise measurements while adhering to high purity standards. By selecting JM Science's pvdf filter membranes, laboratories can access high-quality solutions that not only meet but exceed industry benchmarks, ensuring that their analytical and research endeavors are supported by dependable and efficient filtration technology. This unwavering commitment to quality establishes JM Science as a trusted ally in the pharmaceutical sector, where precision and reliability are of utmost importance.

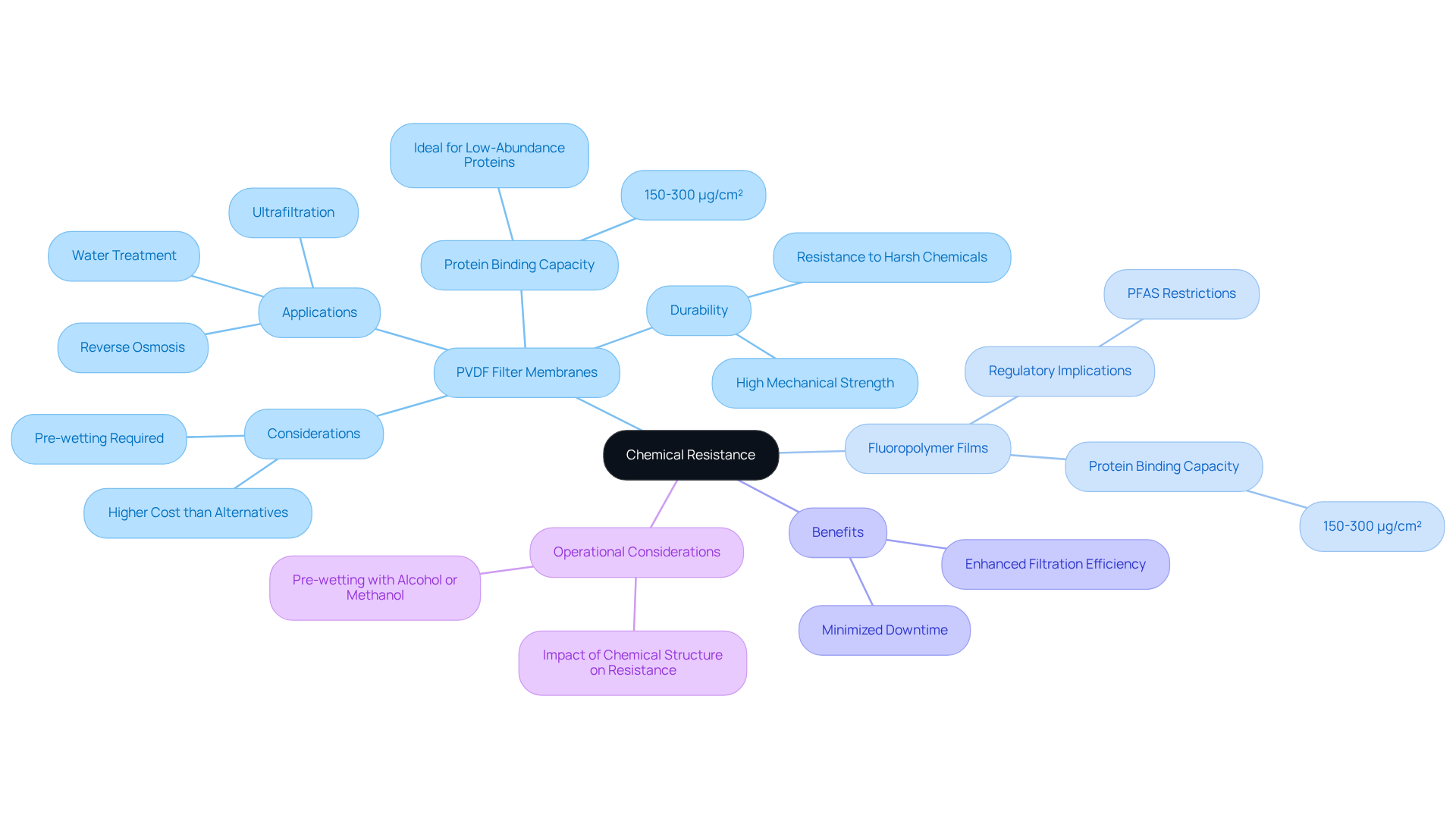

Chemical Resistance: Enhanced Durability for Harsh Laboratory Conditions

PVDF filter membranes are recognized for their exceptional chemical resistance, making them particularly suitable for environments where aggressive solvents and reagents are common. Their robust construction enables PVDF filter membranes to endure exposure to strong acids, bases, and organic solvents, ensuring they uphold integrity and performance over extended periods. This durability significantly reduces the frequency of replacements, thereby .

For instance, PVDF filter membranes are frequently employed in processes related to ultrafiltration and reverse osmosis, where their resilience against harsh chemicals is critical. Furthermore, fluoropolymer films exhibit a protein binding capacity of 150-300 µg/cm², making them ideal for identifying low-abundance proteins. However, it is essential to acknowledge that fluoropolymer films generally come at a higher cost compared to alternatives such as polyethersulfone (PES) or polysulfone (PSF).

Facilities can confidently utilize fluoropolymer sheets without sacrificing filtration efficiency, even in challenging conditions, ultimately enhancing the longevity of equipment and contributing to more efficient workflows. Additionally, it is crucial to pre-wet fluoropolymer films with alcohol or methanol prior to application, which is a vital operational consideration for research workflows. As the suggested PFAS limitations approach, facilities must also consider the regulatory implications of incorporating fluoropolymer sheets into their processes.

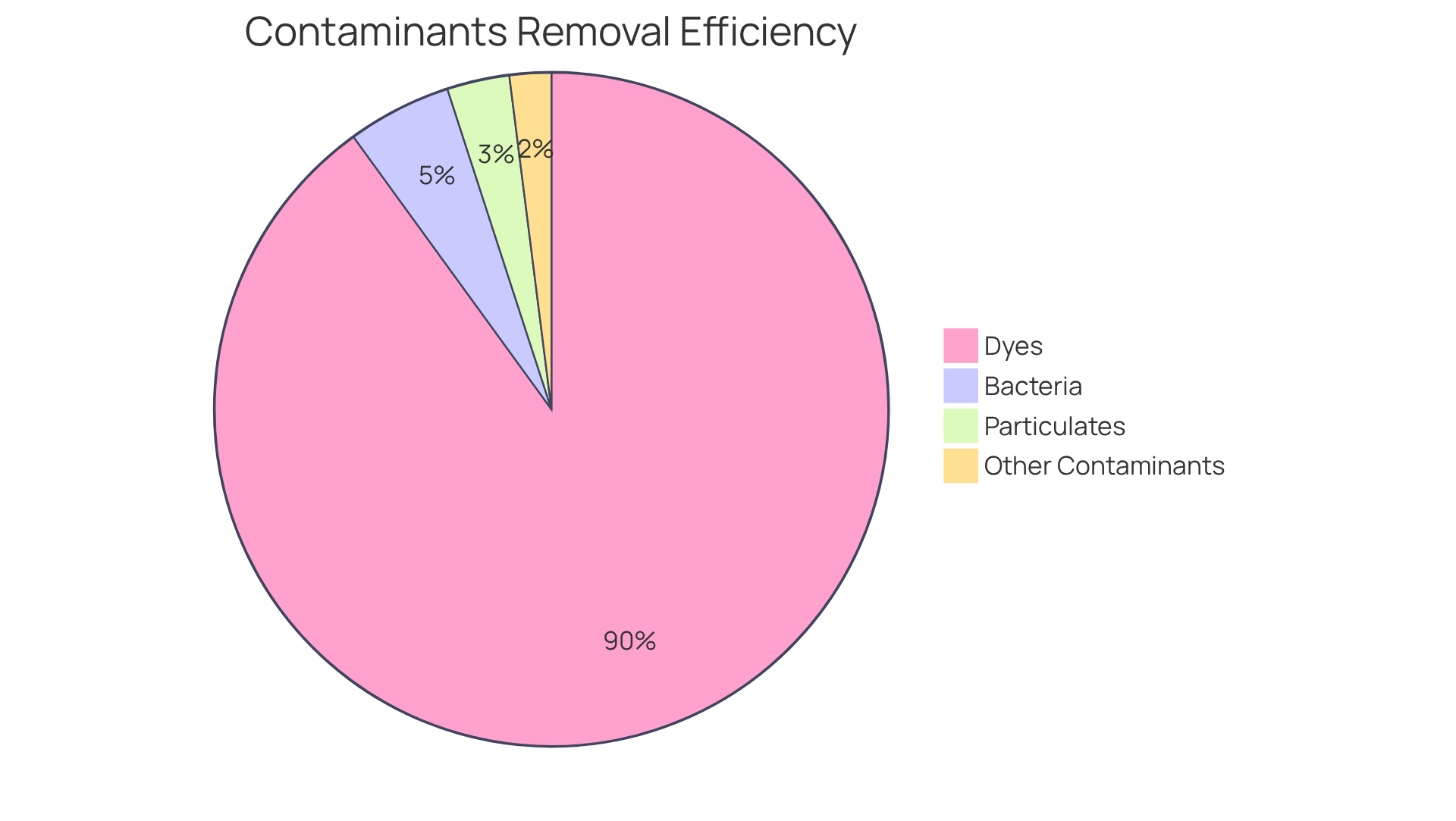

Filtration Efficiency: Achieve High Purity in Laboratory Applications

Fluoropolymer films stand out for their exceptional filtration efficiency, empowering laboratories to achieve remarkable purity levels in their samples. These layers excel at , bacteria, and a variety of contaminants, ensuring that final products adhere to stringent quality standards. Notably, studies have shown that pvdf filter membranes can achieve over 90% removal efficiency for both anionic and cationic dyes, underscoring their effectiveness in preserving sample integrity. By integrating fluoropolymer films into their processes, research facilities significantly enhance their analytical capabilities, ensuring that findings are not only precise but also repeatable—an essential requirement in pharmaceutical research and development.

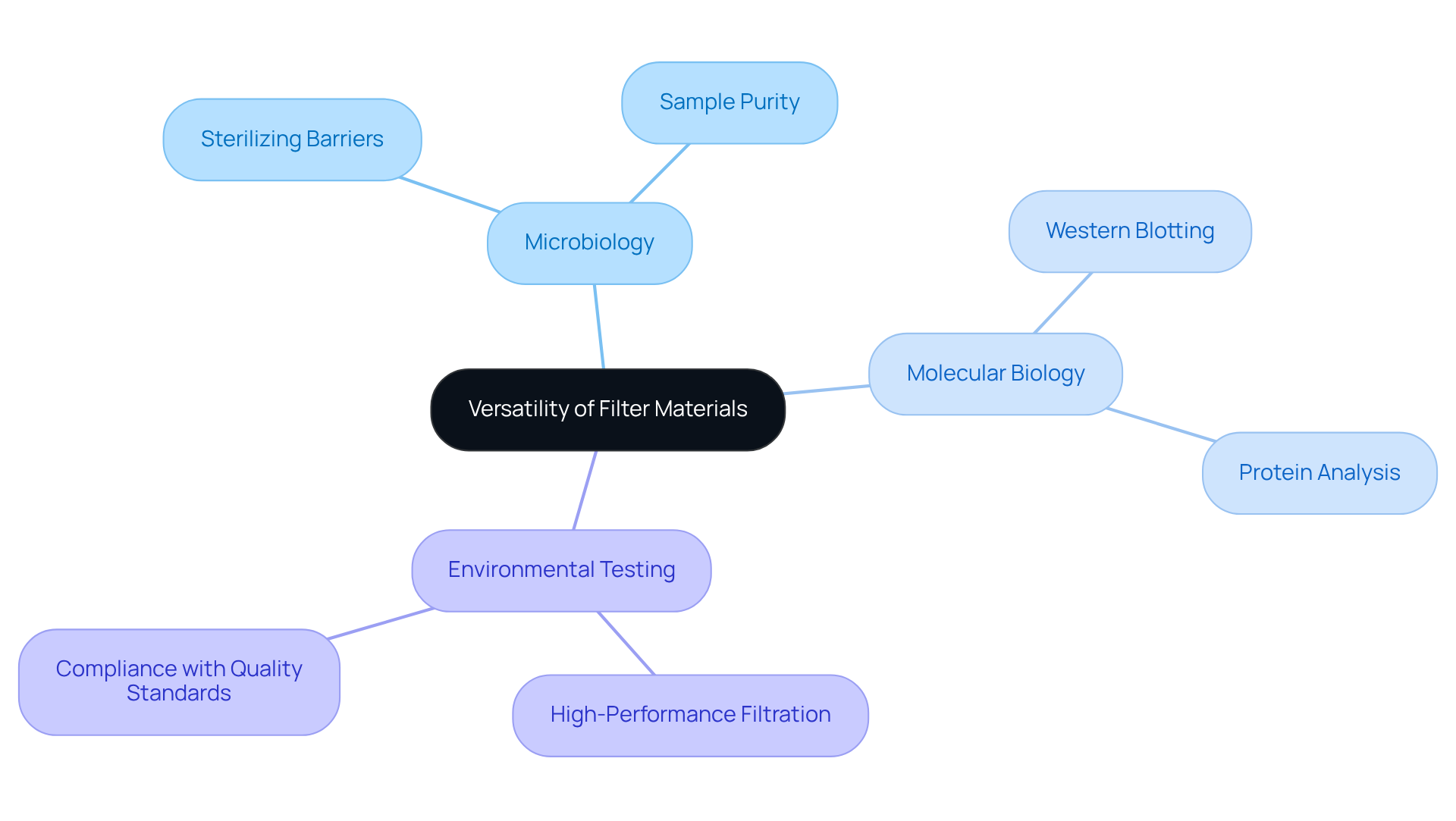

Versatility: Suitable for Diverse Applications in Scientific Research

Filter materials are celebrated for their versatility, finding applications in microbiology, molecular biology, and environmental testing. Their robust performance across diverse settings renders them indispensable tools for researchers and laboratory technicians. In microbiology, pvdf filter membranes serve as efficient sterilizing barriers, ensuring the purity and sterility of samples—an essential factor for achieving precise results. In molecular biology, pvdf filter membranes are employed for Western blotting and protein analysis, where their low protein binding characteristics significantly enhance the reliability of experimental outcomes. Furthermore, fluoropolymer filters excel in environmental testing, providing high-performance filtration solutions that comply with stringent quality standards.

The fluoropolymer market is projected to expand at a compound annual growth rate (CAGR) of 7.4% from 2023 to 2032, underscoring their increasing utilization in scientific research. This growth is propelled by the unique characteristics of these structures, which include high mechanical strength, chemical resistance, and a crystallinity level reaching 50-70%. These attributes enable their application in various processes, such as . Additionally, the high melting point of 171-180 °C ensures reliability in challenging research environments. Consequently, fluoropolymer films significantly enhance research processes, guaranteeing consistent and dependable performance across multiple scientific domains.

As noted by Victor Tcherdyntsev, an academic editor, "The unique combination of physicochemical characteristics allowed this polymer to be included in the so-called NASA list of materials promising for use in space." This statement highlights the advanced characteristics of these films, further reinforcing their critical role in diverse applications.

Ease of Use: Streamline Laboratory Processes with PVDF Membranes

These films are engineered for seamless integration into research processes, empowering staff to utilize them with minimal disruption. Their compatibility with standard scientific apparatus and established protocols enables researchers to apply these films swiftly, eliminating the need for extensive training or procedural alterations.

Prior to usage, fluoropolymer sheets require pre-activation by soaking them in 100% methanol or ethanol for 3 minutes, ensuring optimal effectiveness during separation processes. This intuitive design and minimizes the likelihood of errors, significantly enhancing overall efficiency in the laboratory environment.

Laboratories employing fluoropolymer filtration materials have reported substantial time savings, allowing them to focus on critical research tasks rather than troubleshooting filtration issues. Moreover, these fluoropolymer sheets are noted for their durability, lasting over 50 years without significant property degradation, making them a sustainable investment for research facilities.

As one researcher noted, 'The smooth incorporation of fluoropolymer films into our current processes has transformed our workflow, enabling us to achieve results more rapidly and with greater precision.'

By optimizing research operations and leveraging their hydrophilic properties for efficient filtration in aqueous systems, these materials foster a more productive research environment, establishing them as invaluable assets in pharmaceutical facilities.

Tip for Implementation: To fully leverage the benefits of these films, ensure they are pre-activated according to the guidelines before integrating them into your testing processes.

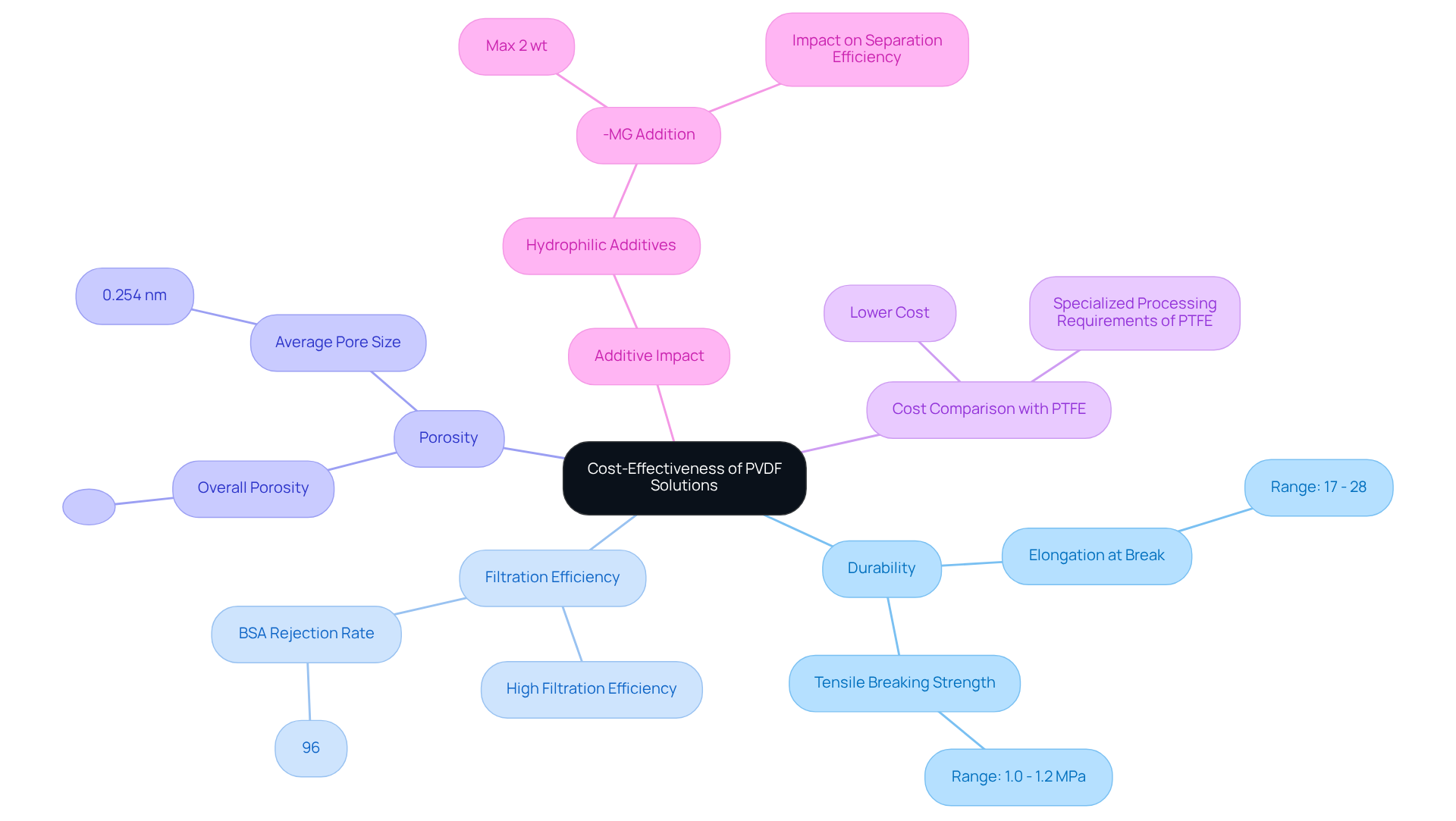

Cost-Effectiveness: Optimize Laboratory Budgets with PVDF Solutions

Investing in filter materials presents laboratories with substantial cost reductions. Their robust durability—characterized by an elongation at break ranging from 17% to 28% and a tensile breaking strength of 1.0 to 1.2 MPa—coupled with high filtration efficiency, minimizes the necessity for frequent replacements and maintenance. This allows laboratories to allocate resources more strategically.

With an and an average pore size of 0.254 nm, these films not only endure operational demands but also enhance performance outcomes. Notably, the introduction of hydrophilic additives such as -MG, with a maximum addition of 2 wt%, has been shown to improve separation efficiency, underscoring the importance of optimal additive concentration to prevent pore clogging.

By opting for pvdf filter membranes as fluoropolymer solutions, laboratories can effectively enhance their budgets while upholding stringent quality and performance standards. This positions them as a prudent choice in the competitive pharmaceutical landscape, particularly when compared to the elevated costs associated with PTFE products.

Equipment Compatibility: Integrate PVDF Membranes with Existing Laboratory Tools

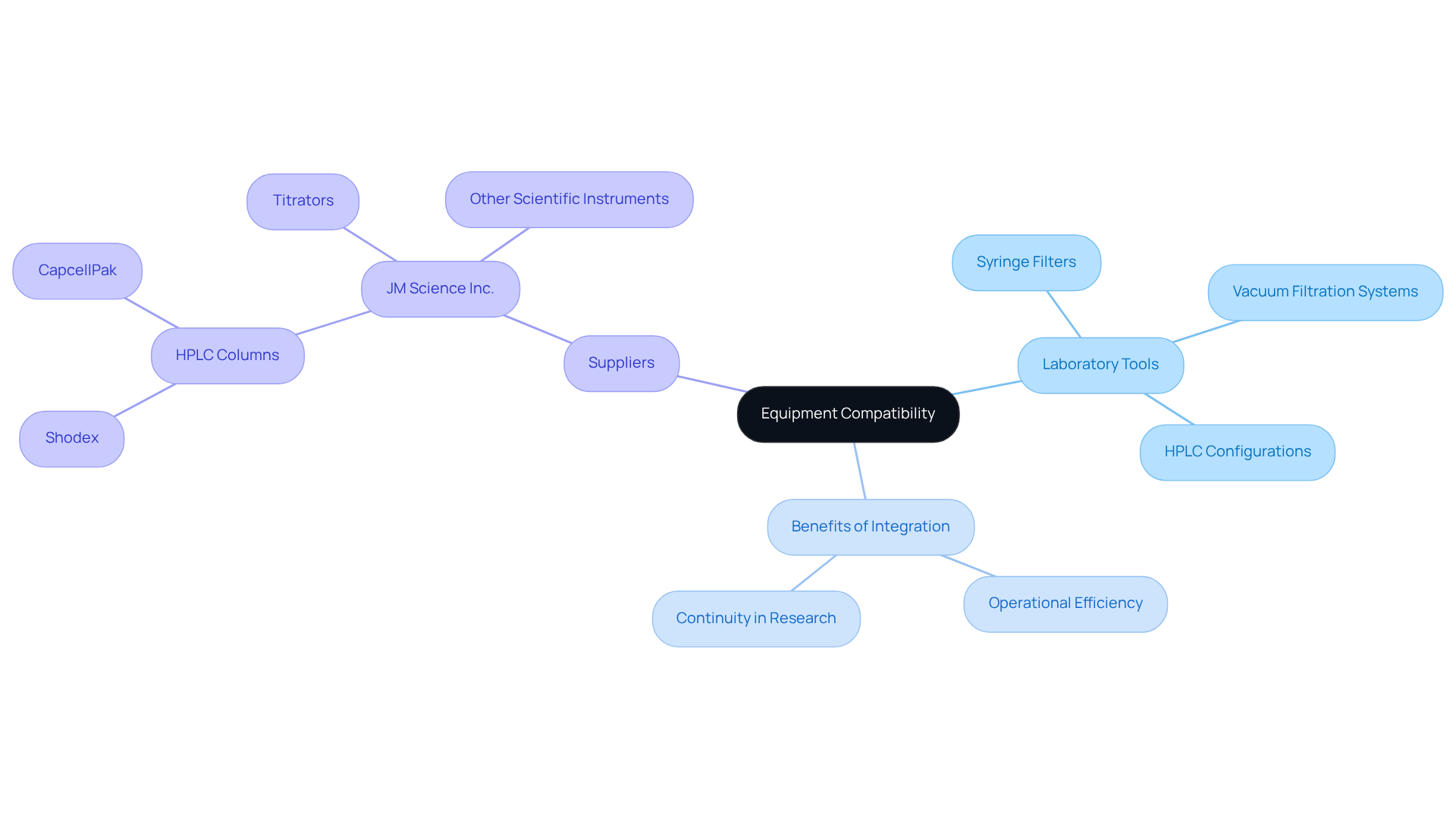

These filtration materials are designed to be compatible with a diverse array of laboratory apparatus, including syringe filters, vacuum filtration systems, and HPLC configurations. This compatibility allows facilities to seamlessly integrate fluoropolymer sheets into their existing processes without incurring costly enhancements or alterations. By utilizing barriers that align with their current tools, laboratories can enhance operational efficiency and maintain continuity in their research activities.

JM Science Inc. provides a wide selection of HPLC columns, such as Shodex and CapcellPak, in addition to titrators and other scientific instruments that facilitate these integrations. This comprehensive offering simplifies the optimization of laboratory processes, reinforcing the importance of in achieving research excellence.

Low Protein Binding: Preserve Sample Integrity in Biological Applications

Polyvinylidene fluoride sheets are distinguished by their low protein binding capability, a critical feature for applications involving biological samples. This characteristic minimizes sample loss and ensures the is preserved throughout the filtering process. Laboratories can rely on fluoropolymer films to deliver precise and consistent results, making them an ideal choice for biochemistry, molecular biology, and pharmaceutical research. The reliability of these materials underscores their importance in high-quality scientific instruments, reinforcing their value in laboratory settings.

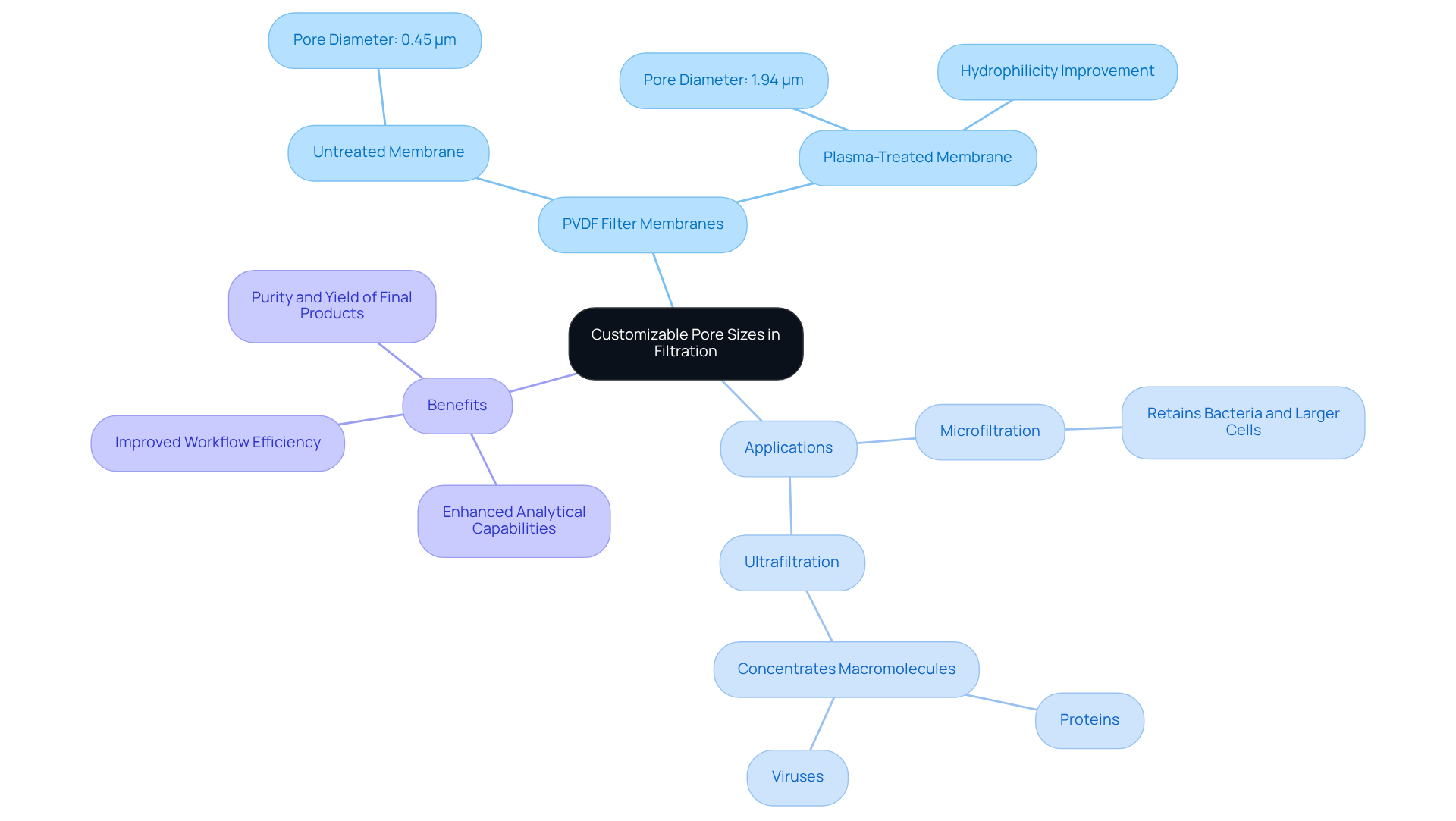

Customizable Pore Sizes: Tailor Filtration Solutions to Laboratory Requirements

Fluoropolymer sheets, such as PVDF filter membranes, present adjustable pore dimensions, empowering research facilities to select the optimal filtration standard tailored to their specific applications. Typically, untreated PVDF filter membranes feature a of 0.45 µm, which can expand to 1.94 µm following plasma treatment. This capability allows researchers to refine their processes, whether they are filtering particulates from solutions or isolating biomolecules. By customizing pore sizes to meet distinct requirements, facilities can significantly enhance their analytical capabilities and improve overall workflow efficiency.

For example, microfiltration barriers with precise pore sizes effectively retain bacteria and larger cells, while ultrafiltration structures are specifically designed to concentrate macromolecules such as proteins and viruses. This flexibility in separation solutions involving PVDF filter membranes not only optimizes scientific operations but also ensures the purity and yield of the final products, ultimately supporting more reliable and precise outcomes in pharmaceutical research.

As highlighted by Jiayun Zhu, long-term purification and pH-stability studies demonstrate the remarkable durability, reusability, and effectiveness of these materials under both typical and extreme conditions. Such attributes underscore the importance of high-quality scientific instruments in laboratory settings, making fluoropolymer sheets an invaluable asset for advancing research.

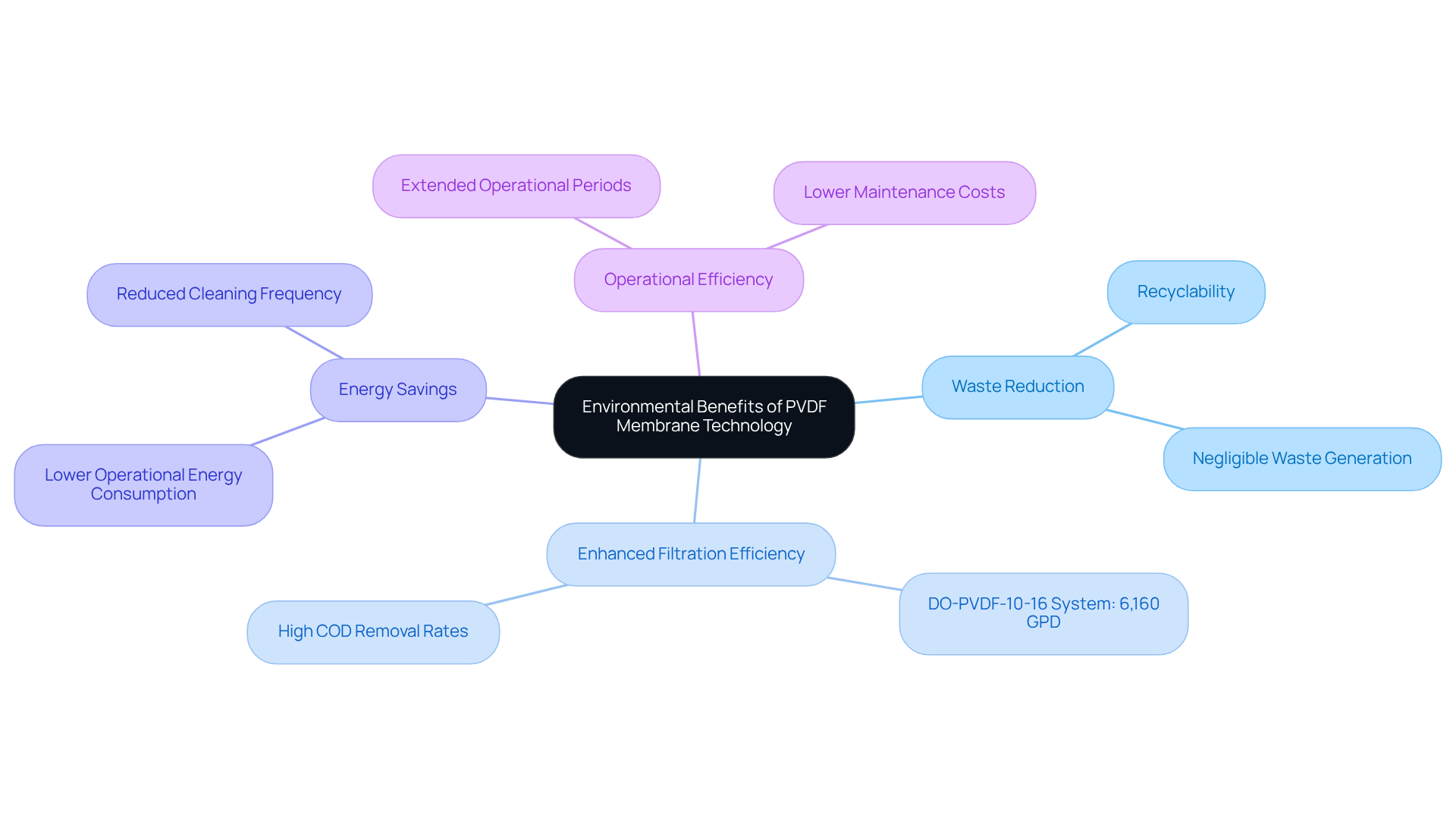

Environmental Benefits: Sustainable Practices with PVDF Membrane Technology

Fluoropolymer sheets are pivotal in advancing sustainable laboratory methods, significantly reducing waste and enhancing filtration efficiency. Their robust design minimizes the need for replacements, thereby lowering environmental impact. For example, the achieves a remarkable permeate rate of 6,160 GPD, showcasing its high operational efficiency.

Recent advancements in polymer technology focus on reducing energy consumption during both manufacturing and operational phases, aligning with the overarching sustainability goals in scientific research. Additionally, these fluoropolymer sheets are reusable and generate negligible waste during production and use, underscoring their eco-friendliness.

By integrating pvdf filter membranes into their workflows, laboratories enhance operational efficiency while also contributing to environmental conservation efforts. As industry leader Tao Hu asserts, "The fundamental properties that make PVDF exceptional today provide the foundation for innovations that will shape the future of separation technology.

Conclusion

The advantages of PVDF filter membranes in pharmaceutical laboratories are substantial, underscoring their essential role in enhancing laboratory efficiency and reliability. These membranes provide exceptional filtration capabilities, outstanding chemical resistance, and low protein binding properties, rendering them indispensable tools for researchers dedicated to maintaining high purity standards in their processes.

Key points have emerged throughout this discussion, including the membranes' remarkable filtration efficiency, their versatility across various applications, and their durability under challenging conditions. Furthermore, their cost-effectiveness and ease of integration with existing laboratory equipment reinforce their status as a preferred choice for pharmaceutical facilities. Laboratories can confidently depend on PVDF membranes to optimize workflows, minimize downtime, and ensure precise results.

Given these insights, investing in high-quality PVDF filter membranes not only supports rigorous scientific standards but also aligns with sustainable research practices. As the demand for reliable and efficient filtration solutions continues to rise, embracing these advanced materials will be crucial for laboratories striving for excellence in pharmaceutical research and development. The adoption of PVDF membranes represents a forward-thinking approach that can significantly influence the future of laboratory operations.