Overview

Automated titration presents a multitude of advantages for pharmaceutical laboratories, including:

- Enhanced precision

- Increased efficiency

- Substantial cost savings

These systems not only streamline workflows but also significantly reduce human error, delivering rapid and accurate results. Such capabilities render automated titration systems indispensable for contemporary analytical processes within the pharmaceutical industry. By integrating these advanced technologies, labs can elevate their operational standards, ensuring that they remain at the forefront of innovation and quality in their analytical practices.

Introduction

Automated titration systems are transforming the landscape of pharmaceutical laboratories, providing a combination of precision, efficiency, and cost-effectiveness that traditional methods cannot match. By streamlining workflows and reducing human error, these advanced technologies allow researchers to concentrate on critical analysis rather than laborious manual processes. As the industry embraces automation, it is essential to consider the specific benefits that automated titration offers and how laboratories can fully harness these innovations to enhance their operations.

JM Science Automated Titrators: Precision and Efficiency in Analysis

JM Science presents a diverse array of mechanical titrators, prominently featuring the AQ-300 Coulometric and AQV-300 Volumetric Karl Fischer Titrators. These instruments significantly enhance precision and efficiency in analytical processes, particularly in drug and medicine testing as per the Japanese Pharmacopoeia. By harnessing cutting-edge technology, they provide accurate measurements, effectively reducing variability and enhancing reproducibility.

Incorporating automated titration setups into pharmaceutical laboratories allows researchers to optimize their workflows, enabling a focus on critical tasks rather than being encumbered by manual titration methods. The user-friendly interfaces of these platforms ensure accessibility for personnel across various fields of expertise, facilitating a seamless transition to automation. Laboratory managers have noted that the efficiency gained from automated titration not only accelerates analysis but also improves data integrity, as this automation minimizes the risk of human error.

For example, one manager highlighted the considerable time savings achieved, allowing staff to handle multiple tasks concurrently. This blend of precision, usability, and enhanced positions JM Science's automated titration systems as indispensable instruments within any analytical environment.

Cost Reduction: Lower Sample Analysis Costs with Automation

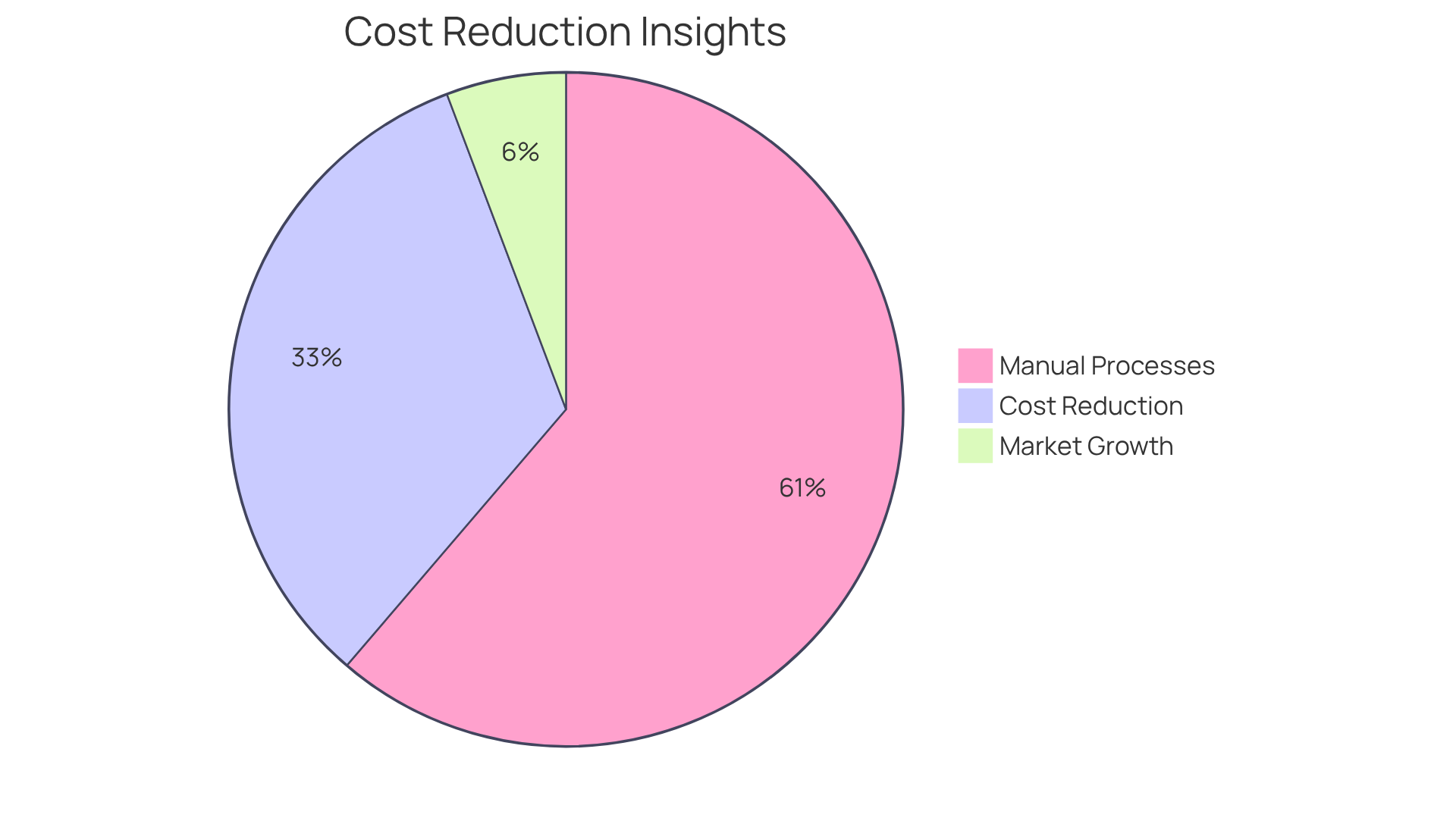

Automated measuring setups offer significant financial advantages for pharmaceutical labs by substantially lowering sample analysis expenses. By reducing reliance on manual labor and optimizing the automated titration process, these systems can lead to a considerable decrease in operational costs. For instance, businesses that have transitioned to mechanized processes report an average operational cost reduction of approximately 35%, as workflows become more efficient and data is seamlessly integrated into production planning frameworks. This statistic is supported by case studies that highlight the .

Moreover, automated titration systems enhance precision in reagent dosing, which minimizes waste and contributes to further cost savings. Financial analysts note that the primary investment in machine-assisted measurement technology, typically ranging from £8,500 to £9,200, is often recouped within a few years due to these ongoing savings. Market analysis indicates that the mechanized measurement segment is projected to grow at a CAGR of 6.1% during the forecast period, underscoring the increasing demand for automation in testing facilities.

As the requirement for high-throughput analysis continues to rise, the financial benefits of mechanization in sample examination, particularly through automated titration, are becoming increasingly apparent, positioning automated titration as a critical investment for forward-thinking pharmaceutical facilities. Insights from financial analysts further reinforce the idea that the return on investment from automated laboratory equipment is compelling, making it a strategic choice for labs aiming to enhance their operations and improve their profitability.

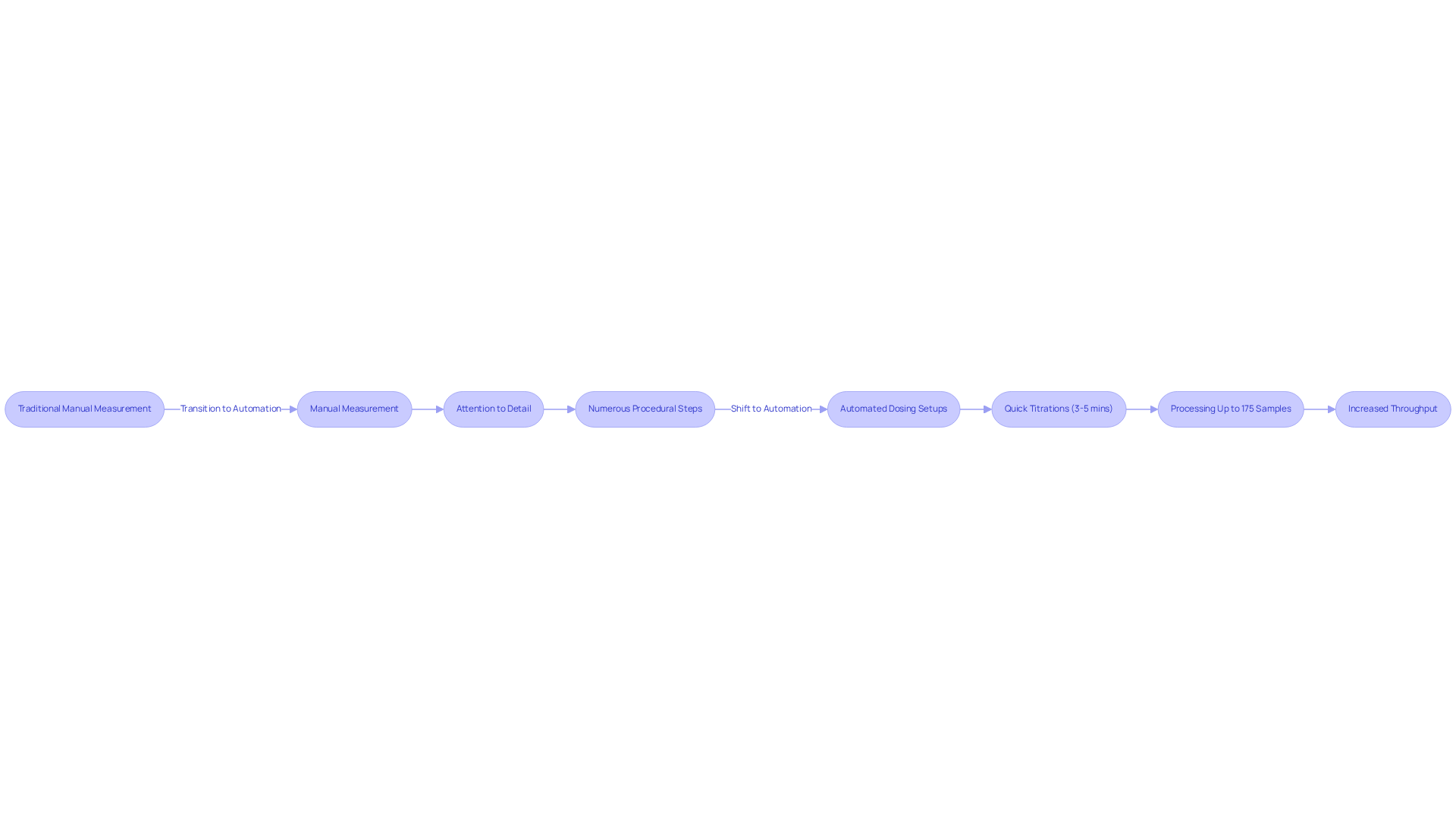

Time Efficiency: Halve Your Analysis Time with Automated Systems

Automated dosing setups offer a transformative advantage by significantly reducing analysis duration. Traditional is often labor-intensive, requiring meticulous attention and numerous procedural steps, which can result in delays. In contrast, automated mechanisms streamline this process, enabling facilities to conduct titrations in as little as 3-5 minutes. This increased efficiency allows laboratories to handle a substantially greater number of samples simultaneously, with certain setups capable of processing up to 175 samples autonomously.

Consequently, laboratories can not only expedite their research timelines but also swiftly adapt to project demands, ensuring they meet stringent deadlines. Indeed, many pharmaceutical lab managers report that automation can reduce their analysis time by half, leading to enhanced productivity and improved operational efficiency. The increased throughput from automated processes not only supports rigorous research but also aligns with the escalating need for rapid results in the fast-paced pharmaceutical sector.

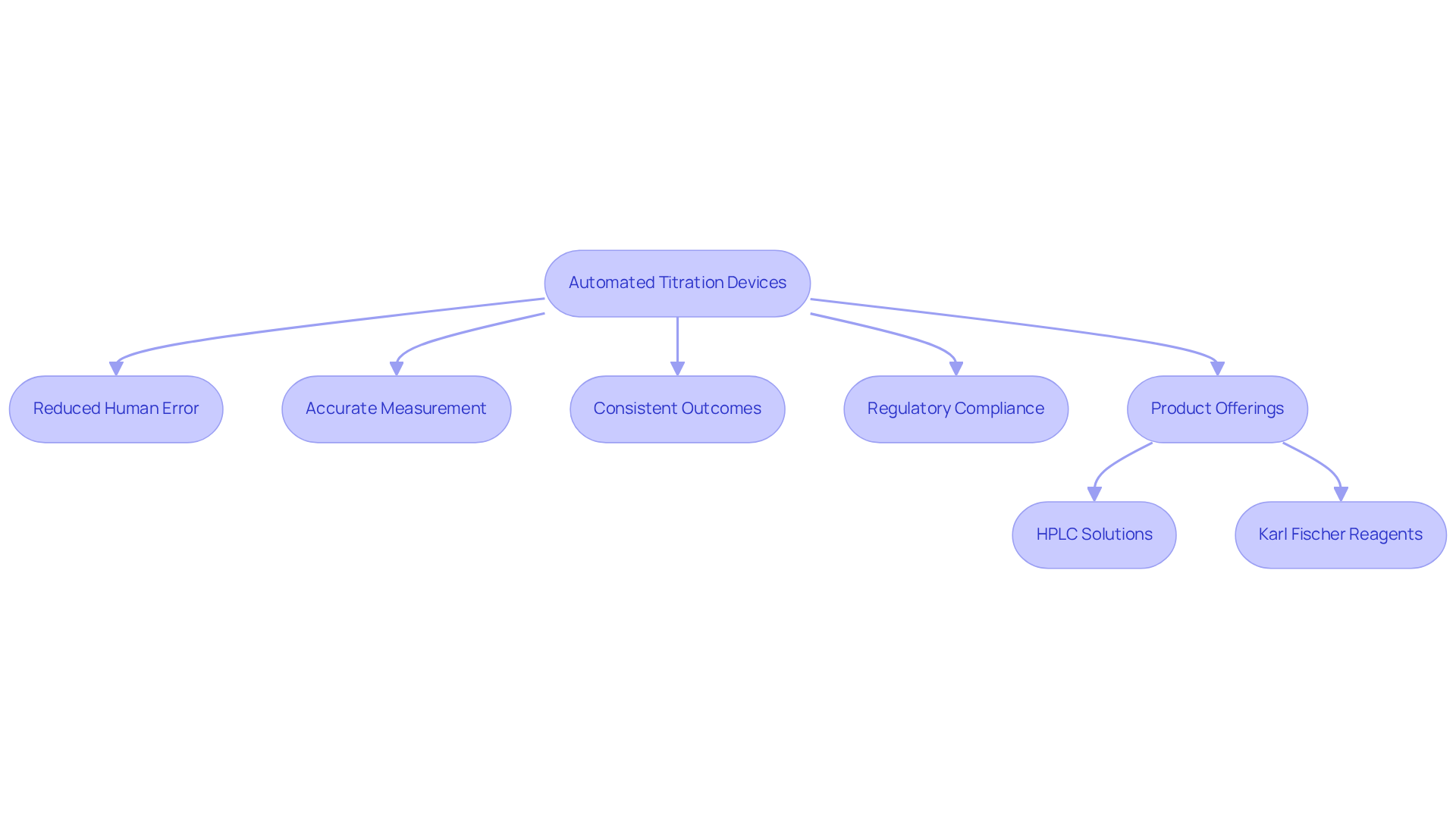

Increased Accuracy: Minimize Human Error in Titration Processes

The automated titration devices from JM Science Inc. are expertly designed to significantly reduce human errors, which are a prevalent challenge in traditional manual titration techniques. By employing precise motor-driven mechanisms and advanced sensors, these devices guarantee accurate measurement and delivery of titrant volumes. This level of precision effectively minimizes manual handling errors, such as misreading endpoints or inconsistent titrant addition. Consequently, research facilities can achieve more reliable and consistent outcomes, which are crucial for adhering to stringent regulatory standards.

In addition to their automated dosing devices, JM Science offers a diverse range of high-quality products, including:

All competitively priced. With JM Science's premium , pharmaceutical laboratories can improve their operational efficiency and accuracy in analytical processes.

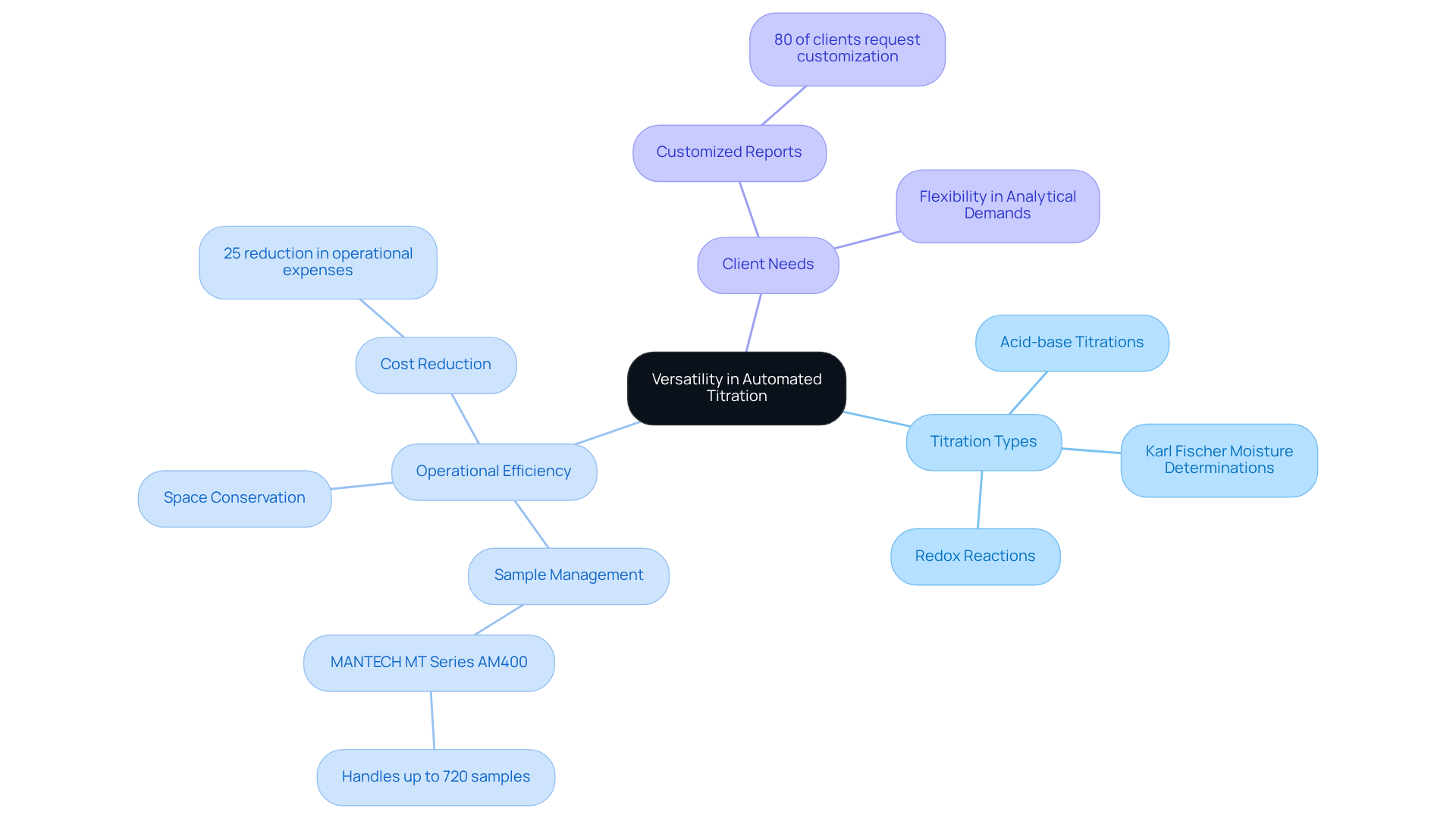

Versatility: Multi-Parameter Analysis for Diverse Laboratory Needs

Automated titration setups exemplify remarkable versatility, adept at conducting multi-parameter evaluations tailored to diverse research needs. JM Science Inc. provides a comprehensive selection of premium titrators, including Karl Fischer titrators, crucial for moisture determinations and other complex analyses. These systems seamlessly perform automated titration for:

- Acid-base titrations

- Karl Fischer moisture determinations

- Intricate redox reactions

This showcases their adaptability across various applications. For instance, the MANTECH MT series AM400 autosamplers can manage up to 720 samples in a single batch, significantly enhancing operational efficiency. This capability in the lab and reduces the necessity for multiple instruments, thereby conserving valuable space and resources. Consequently, research facilities are better equipped to meet evolving research needs and project requirements.

Statistics reveal that 80% of clients request customized reports, highlighting the importance of flexibility in addressing specific analytical demands. Furthermore, facility managers have noted that integrating multi-parameter testing functions can lead to a reduction in operational expenses by as much as 25% through early problem identification, reinforcing the strategic advantage of adopting automated titration solutions.

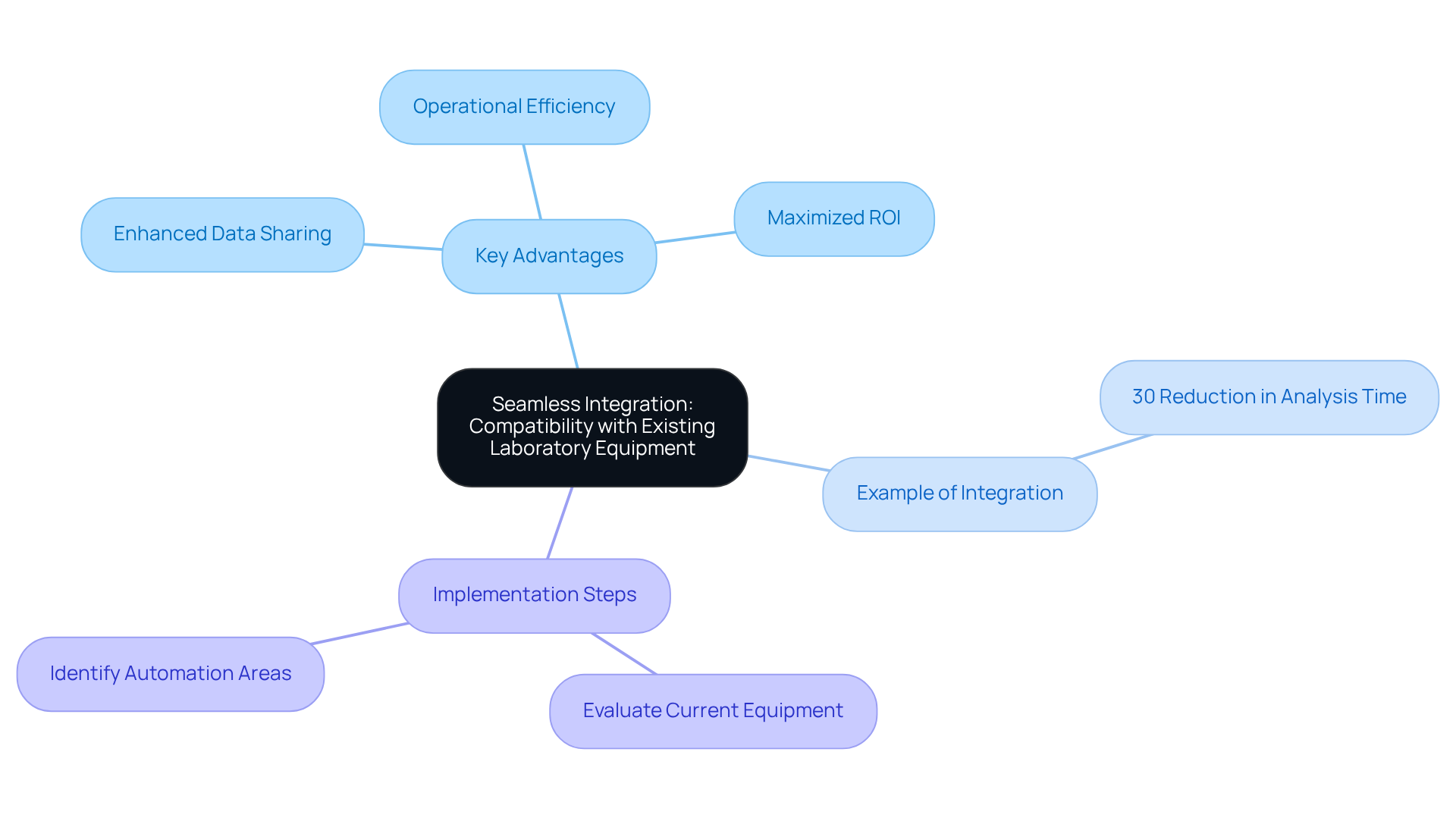

Seamless Integration: Compatibility with Existing Laboratory Equipment

The automated titration setups from JM Science are designed for seamless integration with existing research equipment, enabling facilities to improve their analytical capabilities without the need for a complete overhaul. By linking JM Science's robotic titrators with other analytical devices—such as balances, spectrophotometers, and HPLC systems—facilities can establish a cohesive workflow that significantly improves data sharing and operational efficiency. This streamlined integration not only conserves valuable time but also amplifies the return on investment in laboratory technology, positioning it as a strategic choice for modern pharmaceutical facilities.

Key Advantages of Compatibility in Laboratory Technology Upgrades:

- Enhanced Data Sharing: Seamless integration fosters improved communication between instruments, culminating in more accurate results.

- Operational Efficiency: Streamlined workflows conserve valuable time, enabling lab personnel to concentrate on critical tasks.

- Maximized ROI: By incorporating robotic titrators with existing HPLC columns and accessories, laboratories can elevate their analytical processes, ensuring optimal utilization of their technology investments.

Laboratory managers have remarked, "Incorporating JM Science's mechanized titrators with our current frameworks has revolutionized our workflow, enhancing its efficiency and dependability."

For example, a pharmaceutical laboratory successfully integrated JM Science's automated titration systems with their HPLC systems, leading to a 30% reduction in analysis time and improved accuracy in results. The integration process involved assessing their current equipment, pinpointing key areas for mechanization, and implementing the titrators alongside their existing HPLC columns.

To begin the process of incorporating automated titration systems into your current workflows, consider conducting an evaluation of your existing equipment and identifying key areas where automation can .

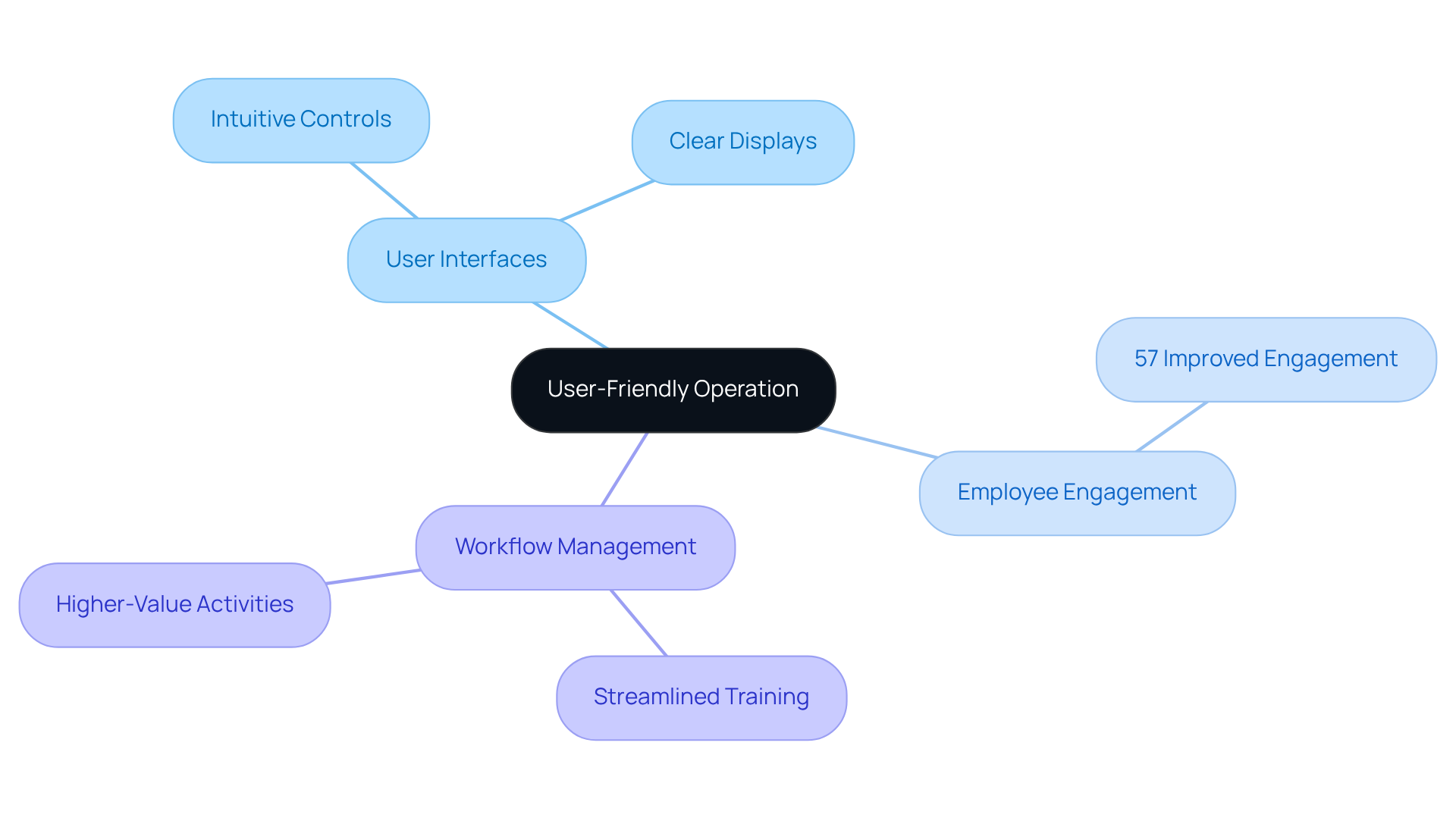

User-Friendly Operation: Simplified Training and Workflow Management

Automated titration systems from JM Science Inc. command attention with their user-friendly interfaces that significantly enhance operations and reduce the learning curve for staff. Equipped with intuitive controls and clear displays, these devices empower users to easily configure and perform analyses, thereby diminishing the need for extensive training.

Research reveals that 57% of companies reported improved employee engagement following the implementation of robotic process automation, highlighting the positive influence of such technologies on workforce satisfaction. This ease of use not only boosts productivity but also enables workspaces to swiftly adapt to new technologies like automated titration, ensuring that staff can efficiently manage workflows and concentrate on essential analysis tasks.

Training specialists assert that through automation fosters more effective training experiences, allowing personnel to prioritize higher-value activities over mundane tasks. By leveraging intuitive dosing technology from JM Science, including our advanced HPLC solutions, facilities can enhance operational efficiency and cultivate a more engaged workforce.

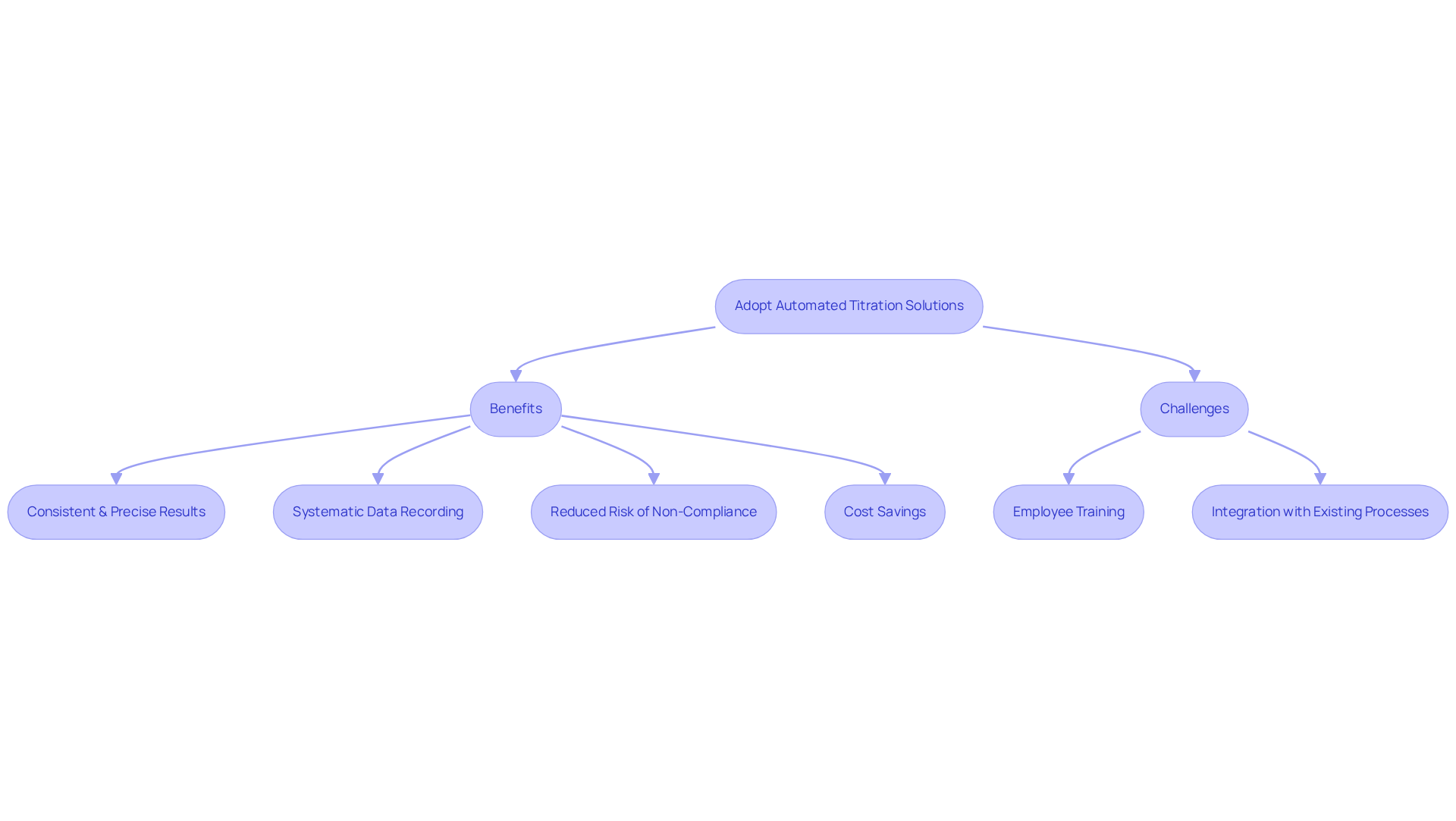

Regulatory Compliance: Meet Industry Standards with Automated Solutions

Automated titration equipment is indispensable for laboratories striving to meet stringent regulatory compliance standards. These advanced systems utilize automated titration to ensure consistent and precise results, which are crucial for adhering to industry regulations. With features such as systematic data recording and intelligent , every automated titration process is thoroughly documented, which simplifies audits and inspections.

By adopting automated titration solutions, laboratories can significantly enhance their compliance efforts, reduce the risk of non-compliance, and maintain the integrity of their analytical results. Notably, laboratories that implement mechanized processes report improved audit preparedness; studies indicate that organizations with compliance automation can save an average of $1.88 million in breach expenses compared to those without it.

As Bill Harrison, CEO of ComplianceBridge, aptly states, "You have to evaluate compliance not as an expense, but as a money saver." However, it is essential to recognize that the introduction of these automated solutions may present challenges, including the need for employee training and integration with existing processes. Overall, the effectiveness of these technologies in maintaining high standards of quality and compliance is unmistakable.

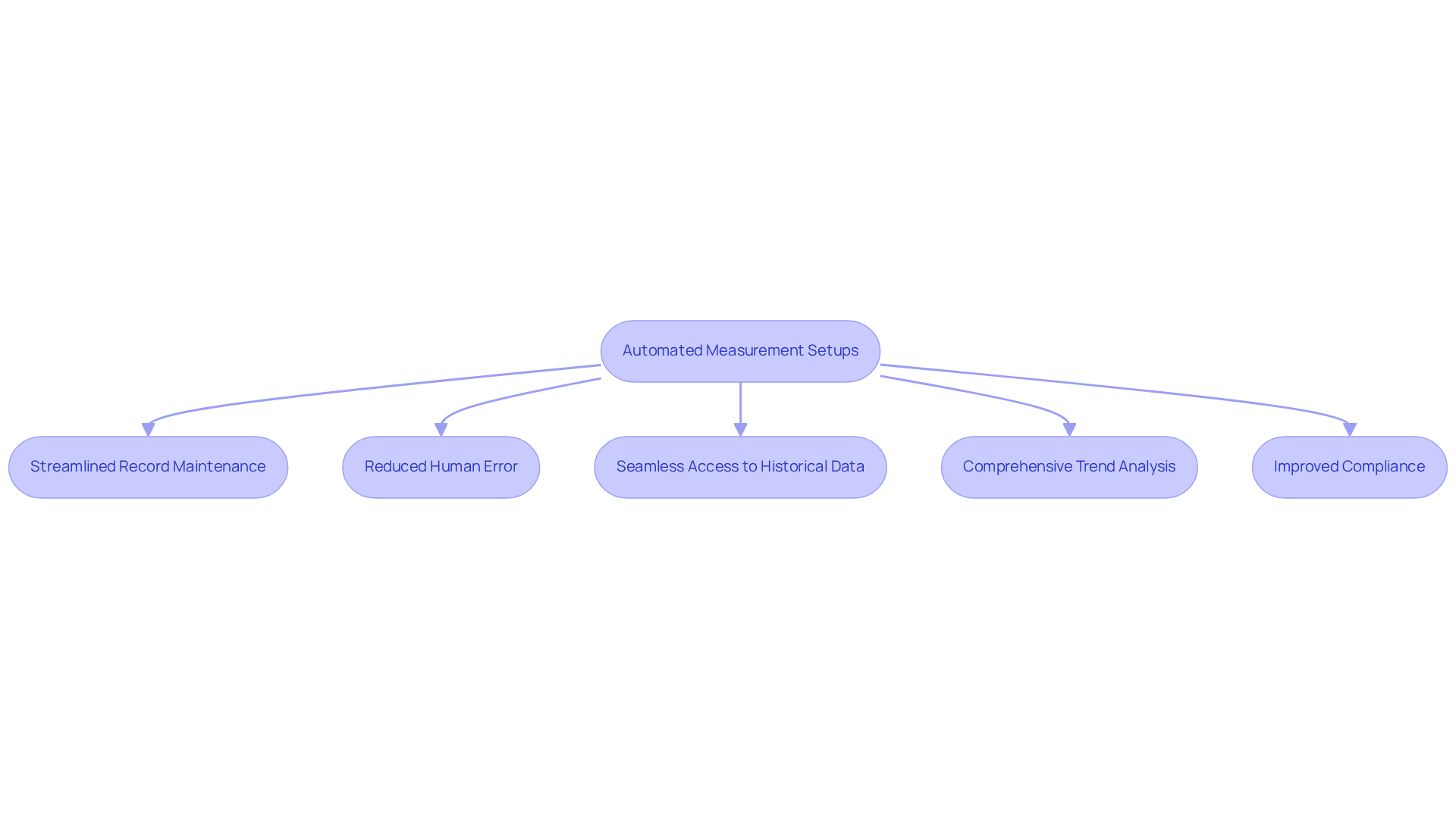

Enhanced Data Management: Streamline Record-Keeping and Reporting

Automated measurement setups significantly enhance data handling, capturing attention with their streamlined record maintenance and reporting procedures. These sophisticated systems perform automated titration to automatically log data, effectively reducing the risk of human error that often accompanies manual data entry. Furthermore, integrated software solutions provide seamless access to historical data, enabling comprehensive trend analysis and reporting. This enhanced capability not only conserves valuable time but also elevates the overall quality of records, thereby supporting informed decision-making and bolstering compliance efforts.

As noted by Stephen Few, 'Numbers have an important story to tell. They rely on you to give them a voice.' This shift towards is essential for facilities aiming to optimize their operations and maintain high standards of accuracy. Moreover, statistics indicate that individuals allocate 60% to 80% of their time attempting to locate information, underscoring the efficiency advantages of mechanized solutions.

A compelling case study on the impact of data analytics in healthcare illustrates how automation can lead to significant improvements in record-keeping practices. Additionally, as Charles Babbage stated, 'Good quality data is ideal, but any data is better than none,' emphasizing the importance of initiating data analytics journeys with whatever data is available.

Lab managers are encouraged to critically evaluate their current data management practices to identify opportunities for automation and improvement.

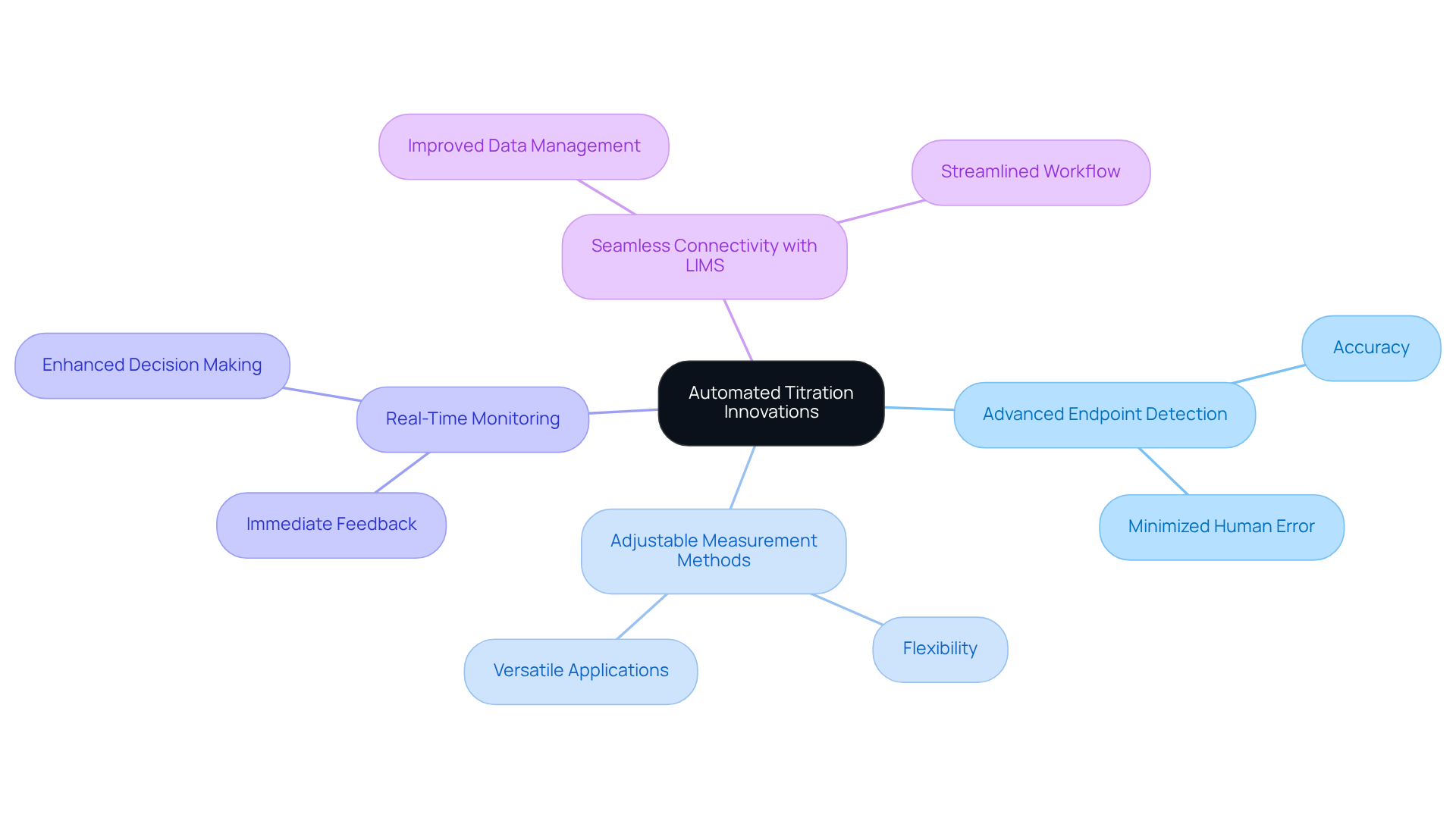

Innovative Features: Cutting-Edge Technology in Automated Titration

Contemporary automated measuring setups are at the forefront of technological advancement, integrating sophisticated features that significantly enhance their capability and efficiency. Key innovations include:

These innovations enable facilities to perform analyses with and flexibility. Furthermore, many of these frameworks offer seamless connectivity options for integration with Laboratory Information Management Systems (LIMS), thereby improving data administration and enhancing workflow effectiveness. Consequently, automated titration has emerged as an essential tool for pharmaceutical laboratories striving to elevate their analytical capabilities and ensure compliance with stringent industry standards.

Conclusion

Automated titration systems signify a transformative shift in the operational landscape of pharmaceutical laboratories, delivering unmatched precision, efficiency, and cost-effectiveness. By embracing these advanced technologies, laboratories can significantly enhance their analytical capabilities and streamline workflows. This shift allows researchers to concentrate on critical tasks instead of navigating the complexities of manual titration.

The advantages of automated titration are compelling. Key benefits include:

- Substantial time savings

- Reduced operational costs

- Heightened accuracy in measurements

With the capacity to process multiple samples simultaneously and minimize human error, automated systems not only enhance productivity but also ensure compliance with stringent regulatory standards. Moreover, the versatility of these titrators facilitates multi-parameter analyses, making them adaptable to a wide range of laboratory needs.

Given these advantages, it is clear that investing in automated titration technology is not merely a trend; it is a strategic decision for pharmaceutical labs striving to excel in a competitive environment. By adopting these innovations, laboratories can optimize operations, improve data integrity, and ultimately advance pharmaceutical research and development. The future of laboratory efficiency is rooted in automation, and now is the opportune moment for facilities to assess their processes and consider the integration of automated titration systems to unlock their full potential.