Overview

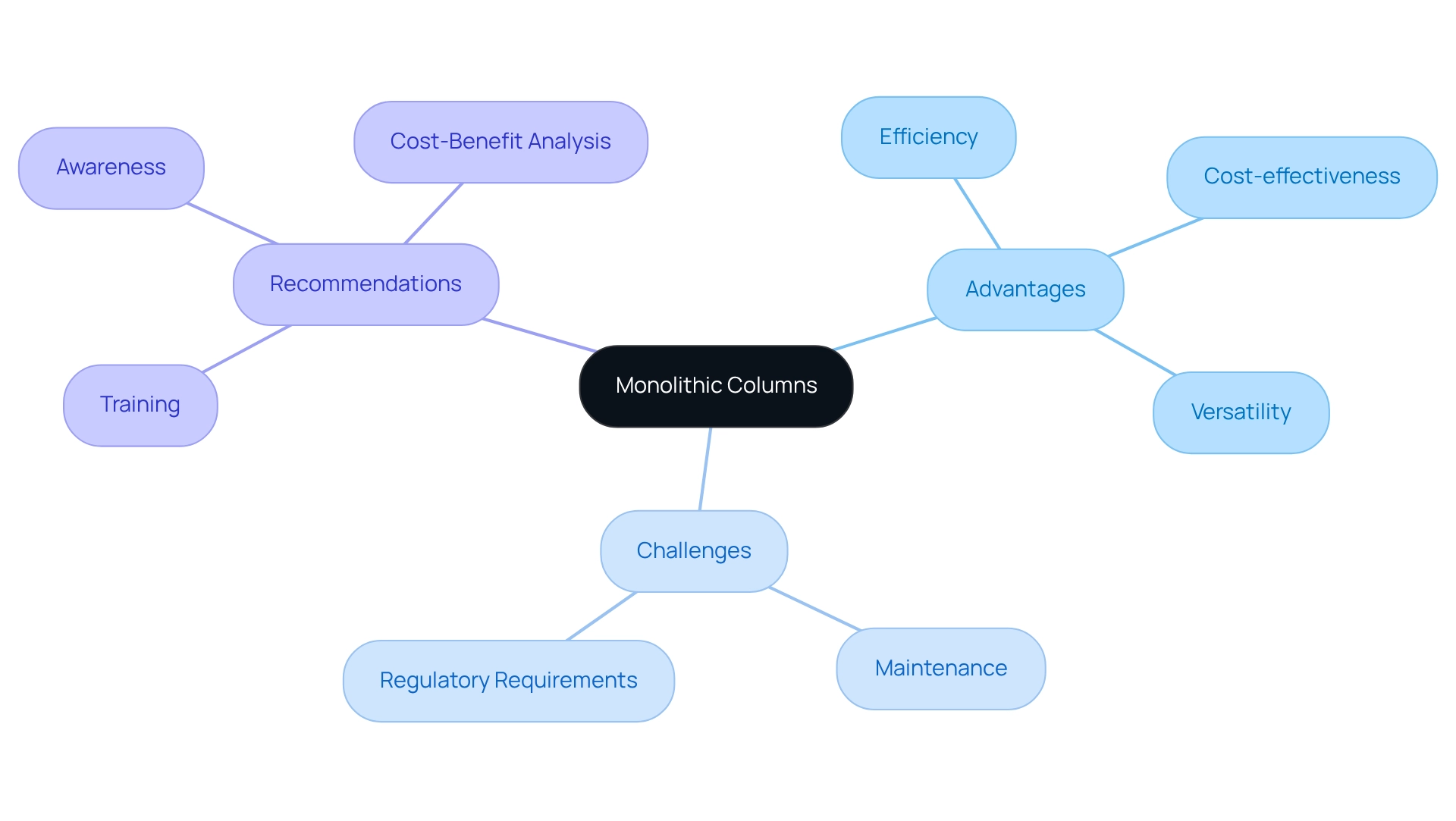

This article offers crucial insights for lab managers regarding the importance of monolith columns, underscoring their efficiency, cost-effectiveness, and versatility across diverse applications in analytical laboratories. It highlights the advantages of monolithic structures, including reduced analysis times and enhanced separation performance. Furthermore, it addresses the challenges associated with their implementation and emphasizes the necessity for proper training to fully leverage their benefits. By understanding these elements, lab managers can optimize their laboratory operations and ensure the effective use of high-quality scientific instruments.

Introduction

In the dynamic landscape of laboratory technology, monolithic columns are emerging as a pivotal advancement in analytical practices. These innovative tools, defined by their unique single-piece structure, promise to revolutionize separation techniques across various industries, including pharmaceuticals and food safety. Their ability to enhance efficiency and reduce analysis times positions monolithic columns not merely as a trend, but as a significant leap forward in chromatography.

As laboratories confront the complexities of compliance and operational demands, comprehending the advantages, challenges, and future trends associated with these columns becomes essential. This article explores the multifaceted world of monolithic columns, examining their impact on laboratory efficiency, cost-effectiveness, and the evolving regulatory landscape.

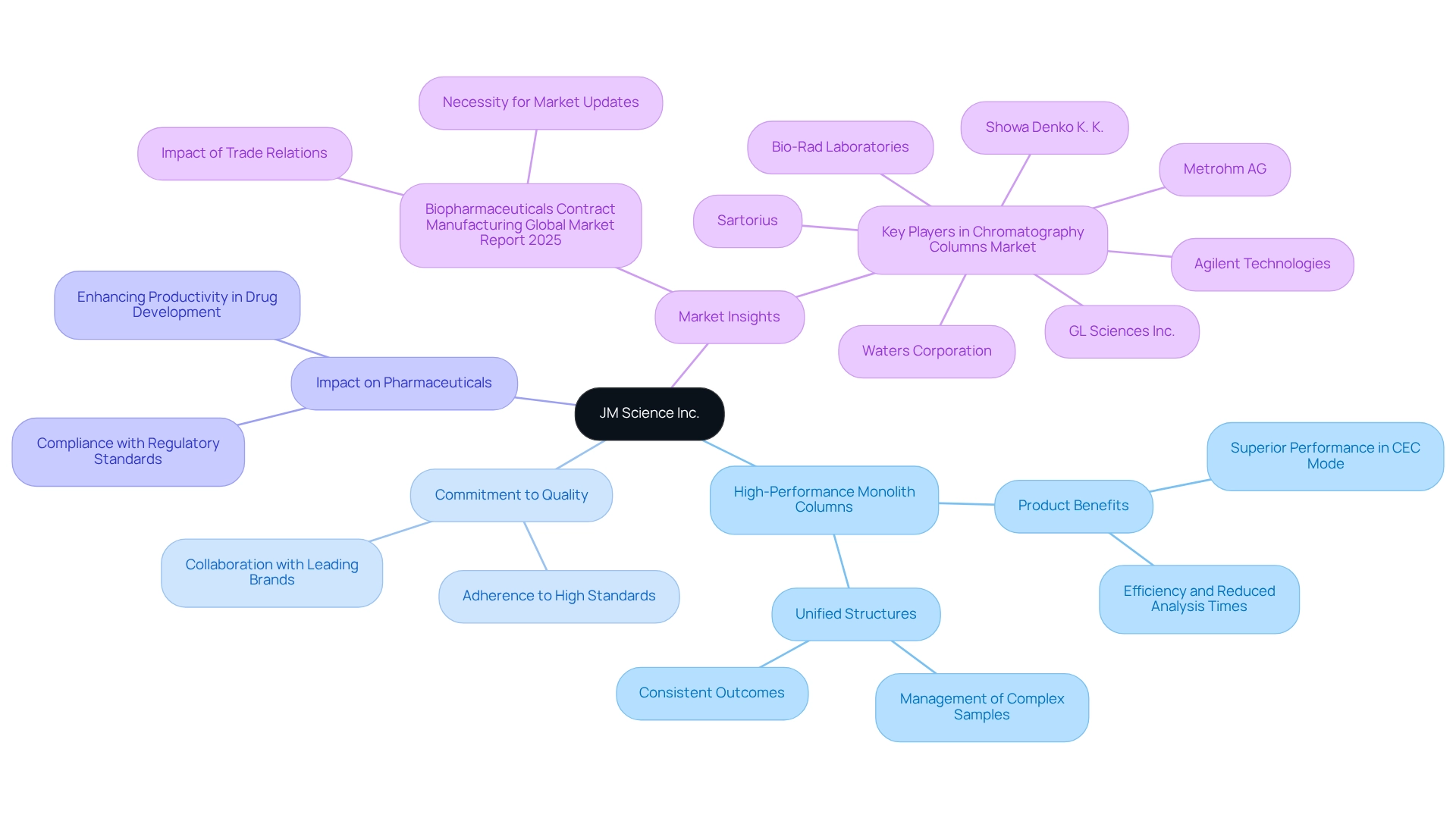

JM Science Inc.: Leading Provider of High-Performance Monolith Columns

JM Science Inc. stands out as a premier importer and distributor of high-performance monolith column structures, which are essential for modern analytical laboratories. Their unwavering commitment to quality and innovation guarantees the delivery of cutting-edge solutions tailored to the diverse needs of various scientific fields, particularly in pharmaceuticals and medical diagnostics. By collaborating with leading brands, JM Science ensures that their monolith column structures adhere to the highest standards of performance and reliability, establishing themselves as a trusted choice for lab managers seeking efficient separation technologies.

Recent statistics reveal that in CEC mode, low-density methacrylate-ester-based monolith columns exhibit superior performance, underscoring their exceptional efficiency and reduced analysis times. Case studies from the Biopharmaceuticals Contract Manufacturing Global Market Report 2025 illustrate the significance of market updates, showcasing how the use of monolith column structures is pivotal in enhancing productivity and precision within drug development processes. Additionally, insights from specialists such as Aaron Acevedo emphasize the benefits of unified structures, including their ability to manage complex samples and deliver consistent outcomes—an essential factor for compliance with regulatory standards in the pharmaceutical industry.

As the chromatography device market continues to evolve, JM Science remains steadfast in its dedication to advancing its product offerings. This commitment ensures that lab managers are equipped with the latest innovations in monolith column technology. Such a strategic focus not only bolsters laboratory capabilities but also propels ongoing advancements in research and healthcare.

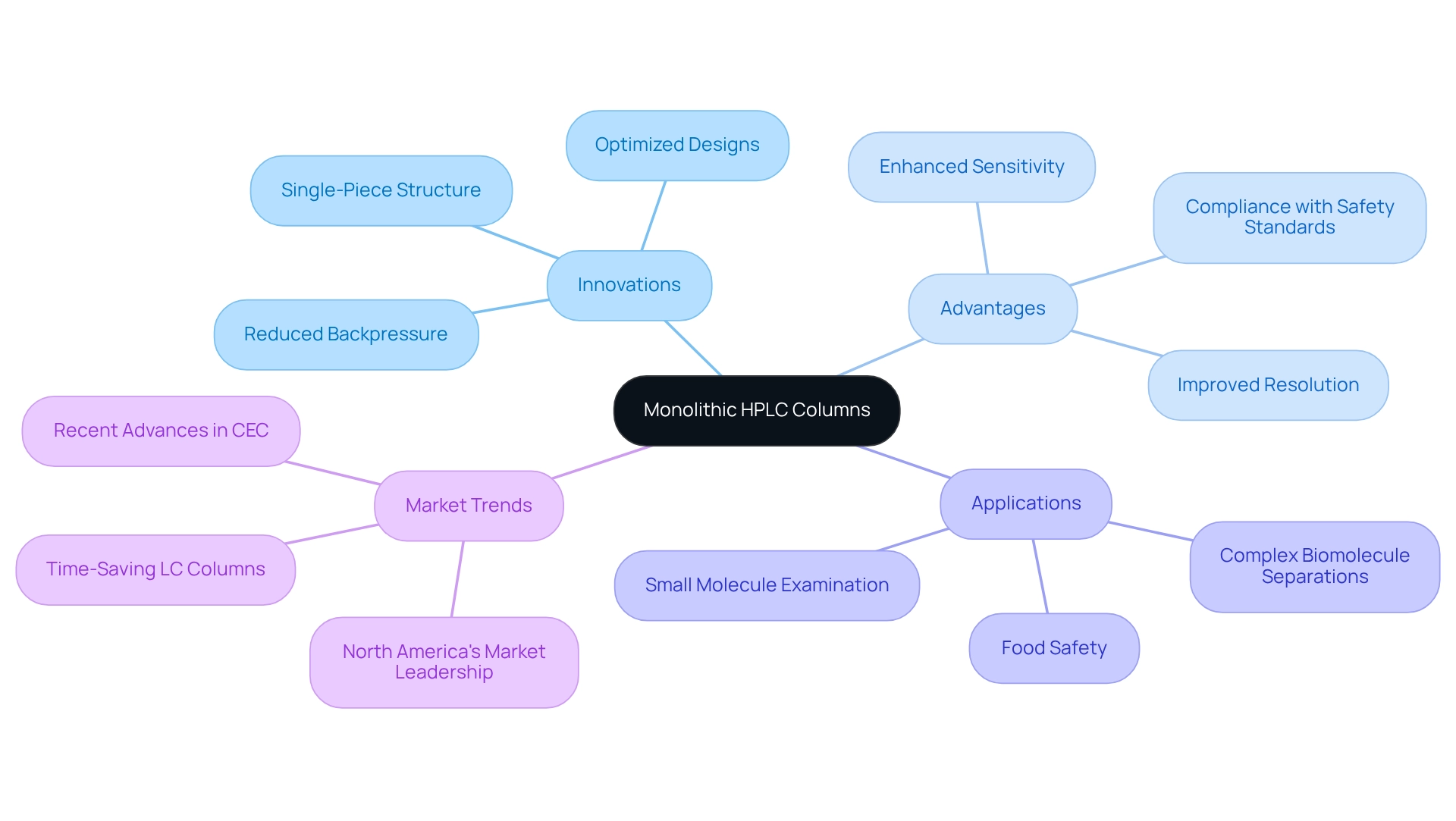

Monolithic HPLC Columns: Innovations in Separation Technology

Monolithic HPLC units, also known as monolith columns, represent a transformative leap in separation technology, characterized by their single-piece structure that eliminates the need for traditional packing materials. This groundbreaking design results in significantly reduced backpressure and increased flow rates, facilitating quicker and more effective separations compared to packed structures, which often encounter greater resistance and slower flow rates. Recent advancements, including optimized channel designs and surface modifications, have further enhanced the performance of these systems, making them ideal for a diverse array of applications—from small molecule examination to complex biomolecule separations.

The advantages of unified structures extend beyond mere efficiency. Their unique design enables enhanced sensitivity and resolution, particularly in capillary electrochromatography (CEC), where the use of solid forms has demonstrated substantial improvements in the analysis of environmental and food safety samples. Research has shown that these structures can achieve compliance with maximum residue limits, thereby safeguarding consumer health. A notable case study on advancements in CEC illustrates how the implementation of unified structures has improved the sensitivity and clarity of analyses, particularly for environmental and food safety applications.

As of 2023, North America leads the chromatography market, reflecting the increasing adoption of innovative technologies such as unified structures. Authorities in the region, including Patricia Regal, have highlighted the recent advancements and applications of these structures, especially in analyzing residues and contaminants in food. The ongoing evolution of the monolith column in monolithic HPLC structures continues to set new benchmarks in separation technology, providing laboratory managers with a reliable solution for their analytical needs.

Applications of Monolithic Columns: From Pharmaceuticals to Food Safety

Monolithic structures, such as the monolith column, are increasingly pivotal across various sectors, particularly in pharmaceuticals, food safety, and environmental testing. In the pharmaceutical sector, the use of monolith columns enables the rapid examination of drug compounds, ensuring compliance with stringent regulatory standards. Recent statistics reveal that over 60% of laboratories are adopting structures like the monolith column, owing to their capacity to deliver reliable results swiftly. In food safety, these monolith columns are essential for identifying contaminants, thereby safeguarding product quality and consumer health. As a sector leader articulates, 'Monolith columns have transformed our approach to food safety testing, offering quicker and more precise results than conventional methods.'

The adaptability of unified structures, particularly the monolith column, makes them indispensable for research supervisors seeking to enhance analytical functions across diverse applications. Recent case studies underscore the efficiency of the monolith column in pharmaceutical analysis, demonstrating how it meets the evolving demands of regulatory compliance, with adherence rates exceeding 90% for facilities utilizing these advanced systems. As the landscape of testing facilities continues to evolve, the role of monolith columns in ensuring safety and quality remains critical.

Advantages of Monolithic Columns: Efficiency and Cost-Effectiveness

Monolithic structures, such as a monolith column, present a multitude of advantages that significantly enhance laboratory operations. Their innovative design facilitates accelerated mass transfer and minimizes backpressure, leading to reduced analysis times and heightened throughput. Research indicates that these structures can achieve plate counts ranging from 10,000 to 800,000, surpassing traditional packed particle systems in terms of efficiency. Notably, the ZIC-pHILIC device exhibits exceptional performance at very high plate counts, underscoring its effectiveness in specialized applications. This increased efficiency translates into shorter run times, allowing laboratories to process more samples in less time.

Moreover, the durability of solid pillars leads to fewer replacements, contributing to substantial cost savings over time. Economic assessments reveal that laboratories utilizing a monolith column can realize significant reductions in operating expenses, making them a cost-effective choice for enhancing laboratory processes. For instance, the analysis of mesopore structures in silica-based solid forms indicates that optimizing pore size distribution can further improve separation kinetics, thereby elevating overall performance. For laboratory supervisors, the combination of enhanced efficiency and diminished operational costs positions large vertical structures, like a monolith column, as a compelling option for streamlining analytical processes. As noted by Haibin Li, the authors declare no conflict of interest, emphasizing the integrity of the findings presented.

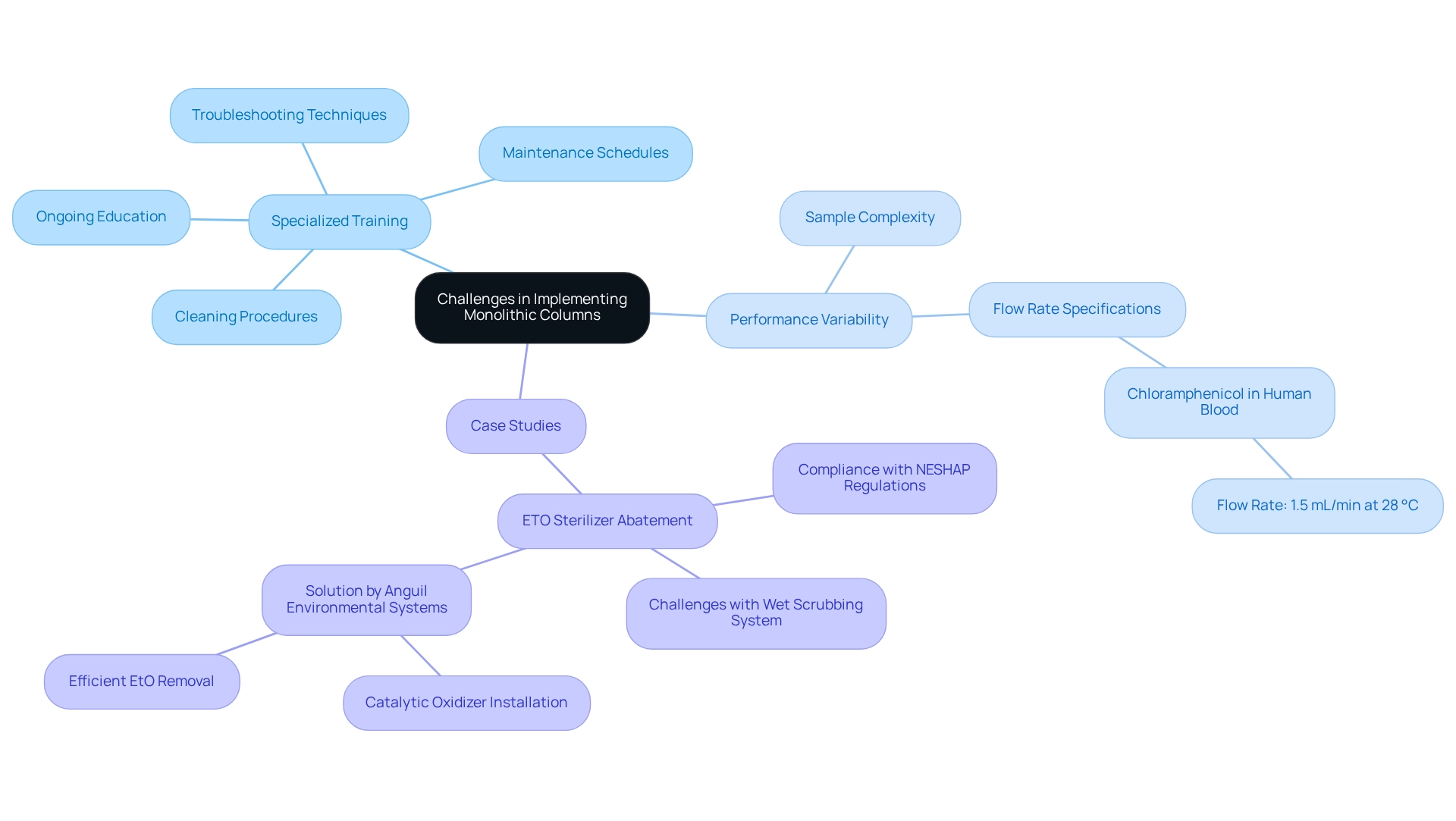

Challenges in Implementing Monolithic Columns: What to Expect

Implementing a monolith column in laboratories presents numerous advantages, along with specific challenges that lab managers must adeptly navigate. A significant hurdle is the necessity for specialized training to fully harness the capabilities of these structures. Staff must be well-versed in unique operational protocols and maintenance requirements to ensure optimal performance and longevity. Variability in separation performance can arise from the complexity of samples, necessitating a comprehensive understanding of the specifications and limitations of the apparatus. For instance, a flow rate of 1.5 mL/min at 28 °C has been documented for chloramphenicol in human blood, underscoring the performance expectations for these devices.

Lab supervisors should anticipate allocating time and resources to develop extensive training programs tailored for large-scale usage. These programs ought to encompass essential topics such as:

- Cleaning procedures

- Maintenance schedules

- Troubleshooting techniques

A case study involving a contract sterilization company, titled "ETO Sterilizer Abatement," highlighted the importance of efficient training and protocol development when integrating new technologies to comply with stringent regulations.

Moreover, feedback from lab managers underscores the critical role of ongoing education in minimizing operational disruptions. Michał Staniak noted that this research received no external funding, emphasizing the value of independent insights within the field. By investing in robust training initiatives, research facilities can enhance staff proficiency, leading to more consistent results and improved analytical outcomes. Ultimately, confronting these challenges directly will facilitate a smoother transition to unified structure technology, utilizing a monolith column to equip facilities for success in their analytical endeavors. JM Science contributes to advancements in research and healthcare through its products and services, further supporting the effective implementation of these technologies.

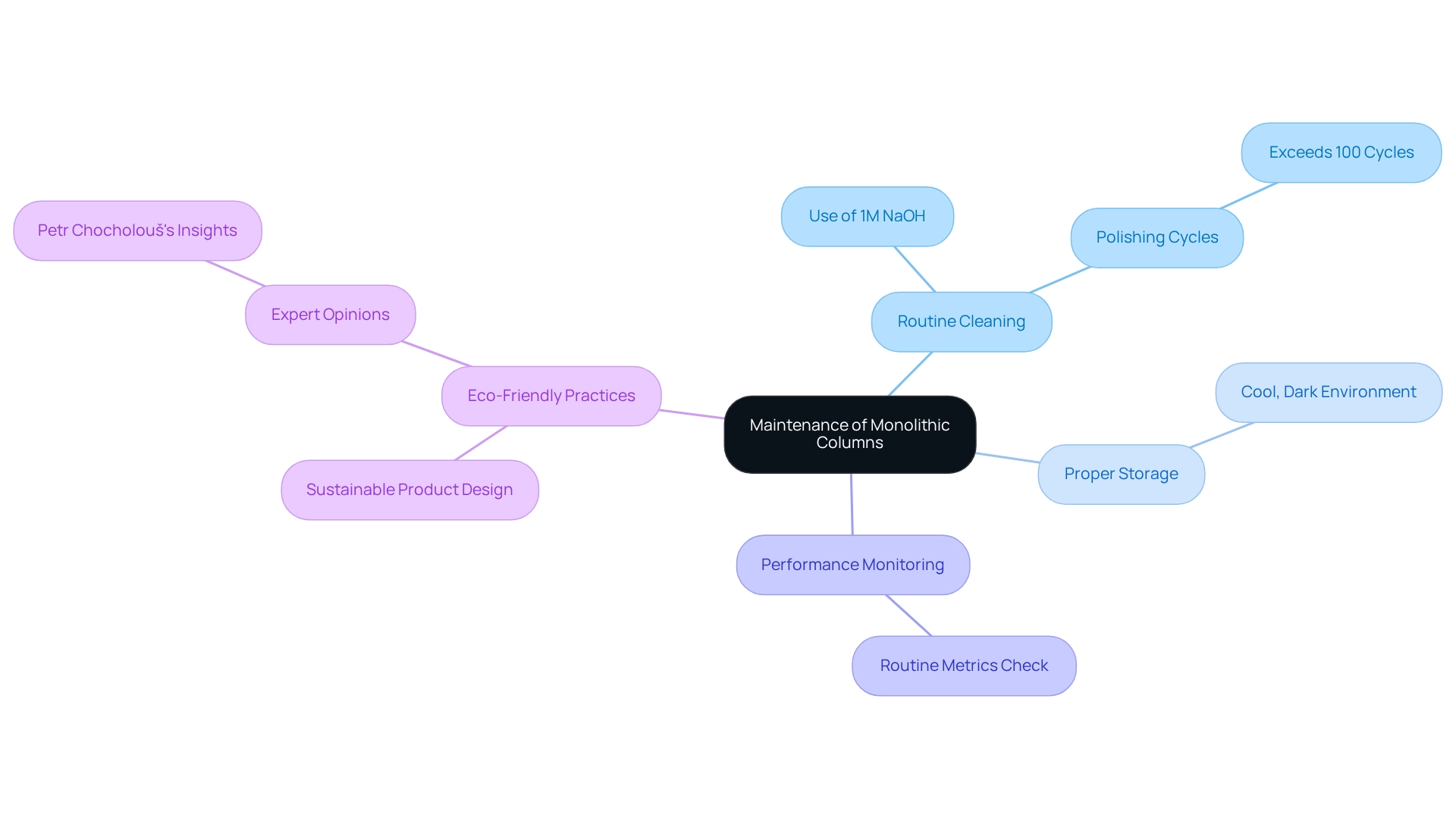

Maintenance of Monolithic Columns: Best Practices for Longevity

To enhance the durability of solid structures, laboratory managers must adopt a set of optimal maintenance practices. Routine cleaning procedures are essential; utilizing suitable solvents, such as 1M NaOH, can effectively prevent contamination and deterioration of the material. Notably, large pillars can exceed 100 cycles for polishing purposes, underscoring the efficiency of these cleaning protocols. A case study on CIMmultus solid structures illustrates their reusability and the effectiveness of cleaning with NaOH, demonstrating that their chromatographic performance remains intact even after multiple cleaning cycles.

Proper storage is equally vital. Columns should be stored in a cool, dark environment when not in use to minimize solvent evaporation and maintain their integrity. Furthermore, routine monitoring of performance metrics is crucial. This proactive strategy facilitates early detection of potential issues, enabling prompt interventions that can extend the durability of the structures.

Expert opinions emphasize that adopting eco-friendly practices in product design, including the maintenance of large vertical structures, can significantly influence sustainability in laboratories. As noted by Petr Chocholouš from Charles University, the updates and new features of novel instruments are critical for enhancing extraction and separation methods. By adhering to these best practices, lab managers can ensure that their unified structures remain effective and reliable, ultimately improving the efficiency of their filtration and extraction systems.

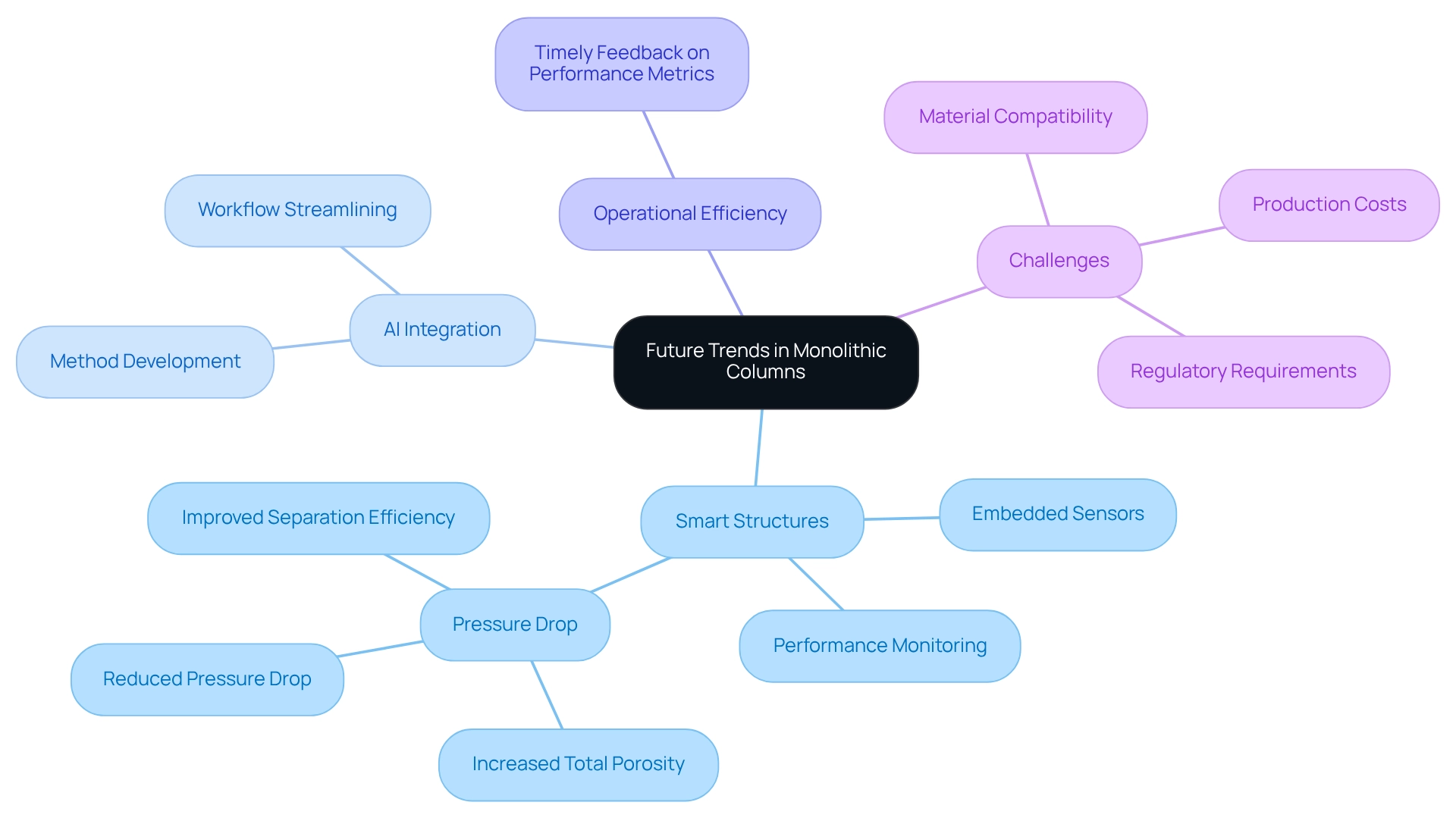

Future Trends in Monolithic Columns: What Lab Managers Should Watch For

As we look ahead, several key trends in monolithic structures warrant the attention of lab managers. Innovations in smart structures lead the way, featuring embedded sensors that enable real-time performance monitoring. This advancement promises to significantly enhance operational efficiency by providing timely feedback on performance metrics. Notably, the use of a monolith column exhibits reduced pressure drop, increased total porosity, and improved separation efficiency compared to traditional particle-packed columns, making them an attractive choice for research facilities.

Moreover, the integration of artificial intelligence into chromatography systems is poised to transform method development and optimization. This allows for more precise and tailored approaches to analysis. For example, AI can assist in identifying optimal separation conditions, thereby streamlining workflows and enhancing outcomes. However, to achieve market success, challenges such as production costs, material compatibility, and regulatory requirements must be addressed, as emphasized by industry experts.

By staying informed about these advancements, lab managers can harness cutting-edge technologies, ultimately driving improvements in laboratory performance and efficiency. Additionally, case studies, such as the application of unified structures in Supercritical Fluid Chromatography (SFC) for analyzing food components, illustrate their effectiveness in achieving efficient separations of complex samples at high flow rates. This highlights the practical applications of unified structures and underscores the importance of adopting these innovations.

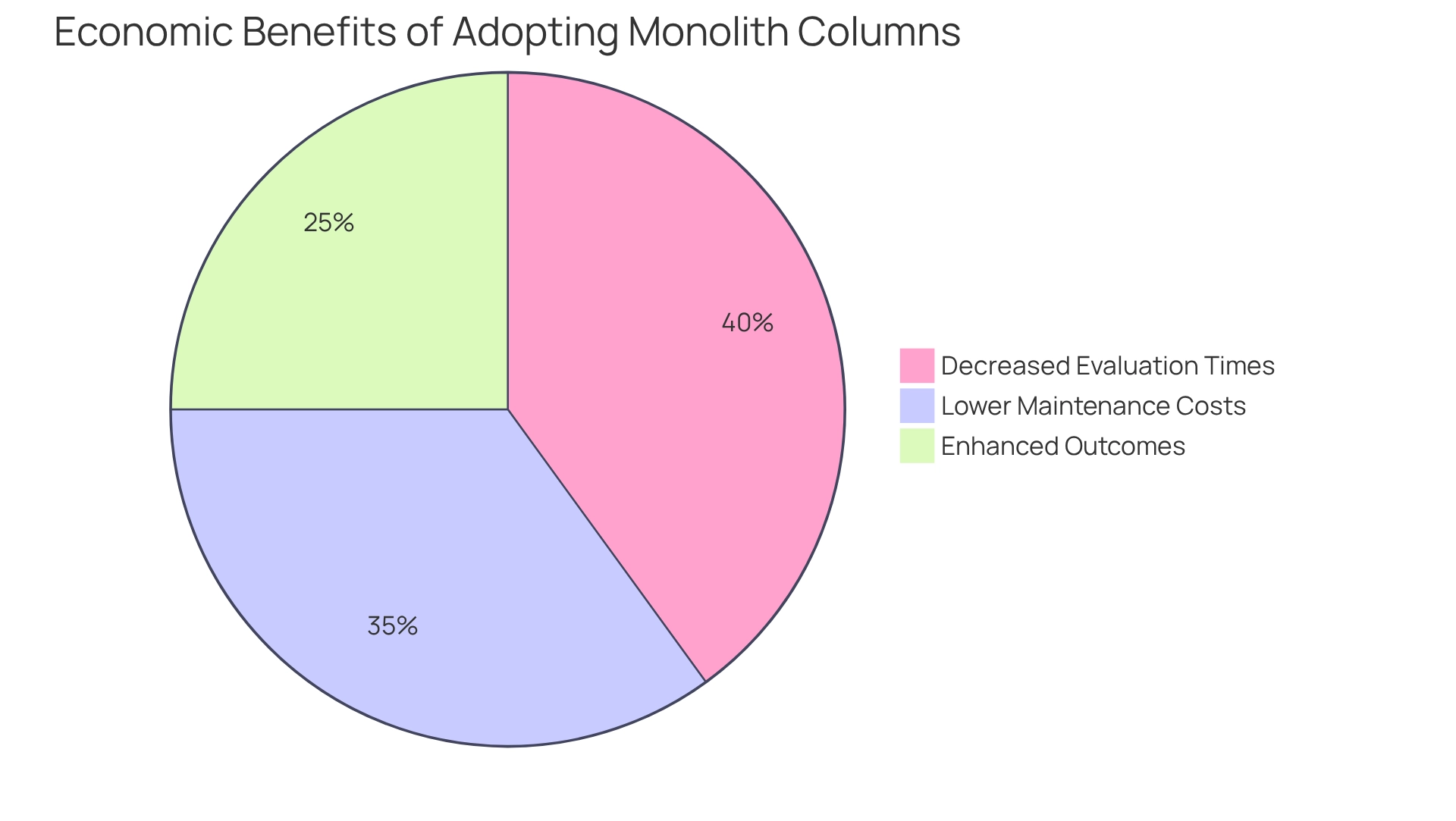

Economic Impact of Monolithic Columns: Cost-Benefit Analysis

The economic effect of adopting monolith columns is substantial. While the initial investment may exceed that of conventional packed systems, the long-term savings in operational expenses, reduced solvent usage, and improved throughput can make this investment advantageous. A comprehensive cost-benefit evaluation must consider several essential factors:

- Decreased evaluation times

- Lower maintenance costs

- The potential for enhanced outcomes, such as the quantitative identification of analytes demonstrated in recent case studies

These improvements not only contribute to heightened compliance but also elevate customer satisfaction. For instance, recent advancements in unified pillar technology, including the successful application of an SBSE method to extract penicillins in milk and honey samples, illustrate their efficiency. Furthermore, as noted by P. Regal, 'All authors read and approved the final manuscript,' underscoring the importance of thorough analysis in chromatography technologies. By investing in monolith columns, laboratories can achieve significant cost reductions while simultaneously enhancing their analytical capabilities.

Regulatory Considerations for Monolithic Columns: Compliance Essentials

Lab managers must prioritize regulatory considerations when implementing monolith column structures, since adherence to Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) standards is essential in pharmaceutical and clinical environments. This entails meticulous documentation of column usage, cleaning protocols, and performance metrics. Regular audits and strict adherence to standard operating procedures (SOPs) are vital for maintaining compliance and minimizing risks associated with regulatory scrutiny.

Statistics reveal that 74% of compliance breaches stem from human error, underscoring the critical need for comprehensive training programs. Effective training fosters a culture of compliance, significantly reducing the likelihood of errors and enhancing research quality. A case study on GLP compliance training demonstrates how well-organized educational initiatives can lead to improved adherence to regulatory standards, ultimately benefiting operational processes.

Furthermore, all personnel in the lab must be vigilant in reporting non-compliance issues to management, as neglecting to do so can lead to serious repercussions, including the inability to complete studies and potential loss of client business. By ensuring that all staff are well-versed in compliance essentials, laboratories can uphold the integrity of their research and maintain their reputations in the scientific community.

Key Takeaways on Monolithic Columns: Essential Facts for Lab Managers

In summary, solid pillars offer significant advantages in terms of efficiency, cost-effectiveness, and versatility across various applications. Their robust design enhances the speed and clarity of separations, making them ideal for complex evaluations.

For example, molecularly-imprinted polymers (MIPs) are synthetic materials featuring recognition sites that selectively bind target molecules, thereby enhancing the selectivity of analytical methods for detecting food contaminants.

Although challenges such as maintenance and adherence to regulatory requirements exist, these can be effectively mitigated through proper training and heightened awareness. Lab supervisors must stay informed about emerging trends and conduct thorough cost-benefit analyses, incorporating customizable pricing options tailored to specific study needs, to make informed decisions regarding the adoption of unified technology.

By leveraging the advantages of the monolith column, laboratories can significantly enhance their analytical capabilities and improve overall operational efficiency.

As P. Regal noted, "All authors read and approved the final manuscript," underscoring the collaborative effort in acknowledging the merits of this technology.

Conclusion

Monolithic columns signify a pivotal advancement in laboratory technology, delivering substantial enhancements in efficiency, speed, and cost-effectiveness across diverse applications. Their distinctive single-piece design facilitates quicker separations, minimizes backpressure, and boosts sensitivity, rendering them especially advantageous in fields such as pharmaceuticals and food safety. The evidence indicates a notable trend, with over 60% of laboratories acknowledging the advantages of these innovative tools, which streamline processes and ensure adherence to stringent regulatory standards.

However, despite these benefits, challenges such as the necessity for specialized training and ongoing maintenance must be addressed. Implementing comprehensive training programs and following best practices for maintenance are crucial for laboratory managers aiming to optimize the longevity and performance of monolithic columns. Moreover, remaining informed about emerging trends, including smart technologies and AI integration, will enable laboratories to enhance their analytical capabilities and foster operational improvements.

Ultimately, investing in monolithic column technology can result in significant long-term savings and improved analytical performance, making them an attractive option for contemporary laboratories. By comprehending the implications of these advancements and tackling potential challenges, laboratories can position themselves at the forefront of analytical innovation, ensuring they meet the evolving demands of the scientific community.