Overview

Column filtration is crucial in pharmaceutical laboratories, serving to ensure the quality and reliability of analytical results. This process effectively separates particulates and contaminants from samples prior to chromatography. Implementing best practices, such as:

- Selecting appropriate filter sizes

- Maintaining equipment

not only enhances data integrity and operational efficiency but also prolongs the lifespan of costly chromatography columns. This, in turn, supports consistent and accurate outcomes in laboratory processes, underscoring the necessity of high-quality scientific instruments in achieving reliable results.

Introduction

In the realm of pharmaceutical laboratories, the significance of effective column filtration is paramount. As the backbone of reliable analytical results, proper filtration practices are essential for safeguarding sample integrity and preventing costly equipment failures. Given the increasing complexity of laboratory processes and the critical need for compliance, understanding the nuances of filtration—from selecting the appropriate materials to implementing innovative technologies—becomes crucial.

This article examines the essential practices laboratories must adopt to enhance filtration efficiency, maintain compliance, and ultimately drive superior outcomes in their analytical endeavors.

Understand the Importance of Column Filtration in Laboratories

Column purification stands as a pivotal procedure within pharmaceutical laboratories, where the quality of specimens directly influences experimental outcomes. Efficient separation of particulates and contaminants prior to the introduction of materials into the chromatography system is essential, as it prevents issues with column filtration and ensures consistent performance. By implementing robust purification practices, laboratories not only enhance the reliability of results but also minimize downtime associated with maintenance issues, ultimately extending the lifespan of costly chromatography columns.

Research underscores that filtering specimens before HPLC analysis can significantly reduce premature clogging and lower back pressure, thereby facilitating more efficient operations and improving data quality. For instance, a study examining the distribution of hydrogen sulfide in the Buzzard field highlighted how enhanced sampling and measurement techniques, including purification, played a crucial role in successfully targeting sweet oil amidst fluctuating H2S distribution. This emphasizes the importance of on-site measurements and meticulous material selection in managing corrosion and ensuring optimal performance in gas wells. As Hani Elshahawi noted, "Identify the beginning and progression of reservoir souring following the application of water injection or other improved recovery methods," illustrating the critical role of proper purification in safeguarding data integrity.

Moreover, recent research has illuminated the significance of the Purnell equation, which correlates resolution to chromatographic factors such as retention, efficiency, and selectivity, further underscoring the necessity for effective substance purification. By ensuring specimens are devoid of particulates, facilities can enhance retention and efficiency, leading to improved selectivity in HPLC analyses.

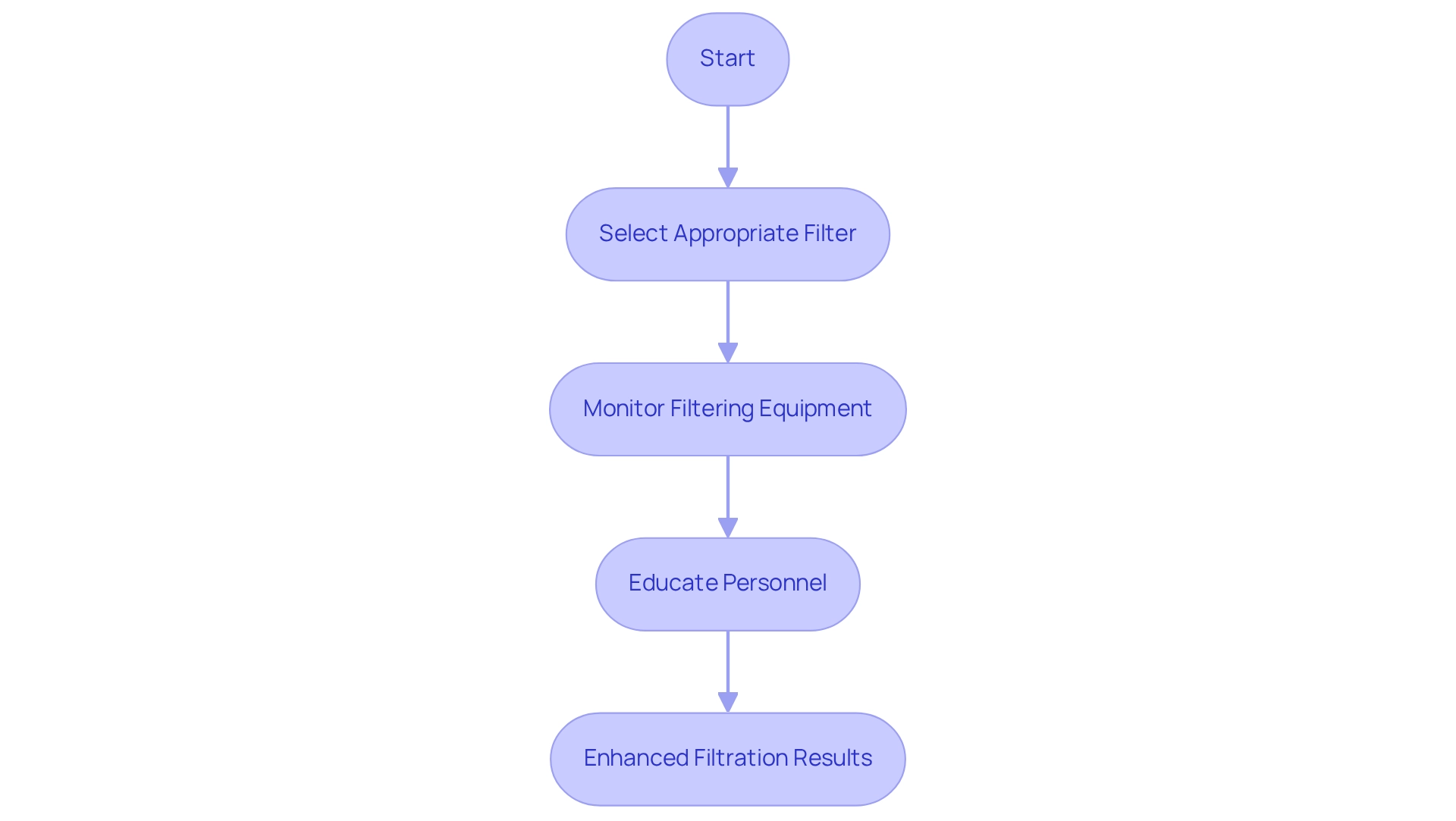

To optimize workflows and achieve superior analytical results, pharmaceutical laboratories should consider the following practical steps for effective filtration:

- Utilize and materials tailored to the sample type.

- Regularly monitor and maintain filtering equipment to avert contamination.

- Educate personnel on optimal methods for sample management and processing techniques.

By prioritizing column filtration, laboratories can reinforce the essential nature of this practice within the pharmaceutical sector, steering clear of common pitfalls that may result in misapplications and compromised results.

Select and Maintain Filtration Columns for Optimal Performance

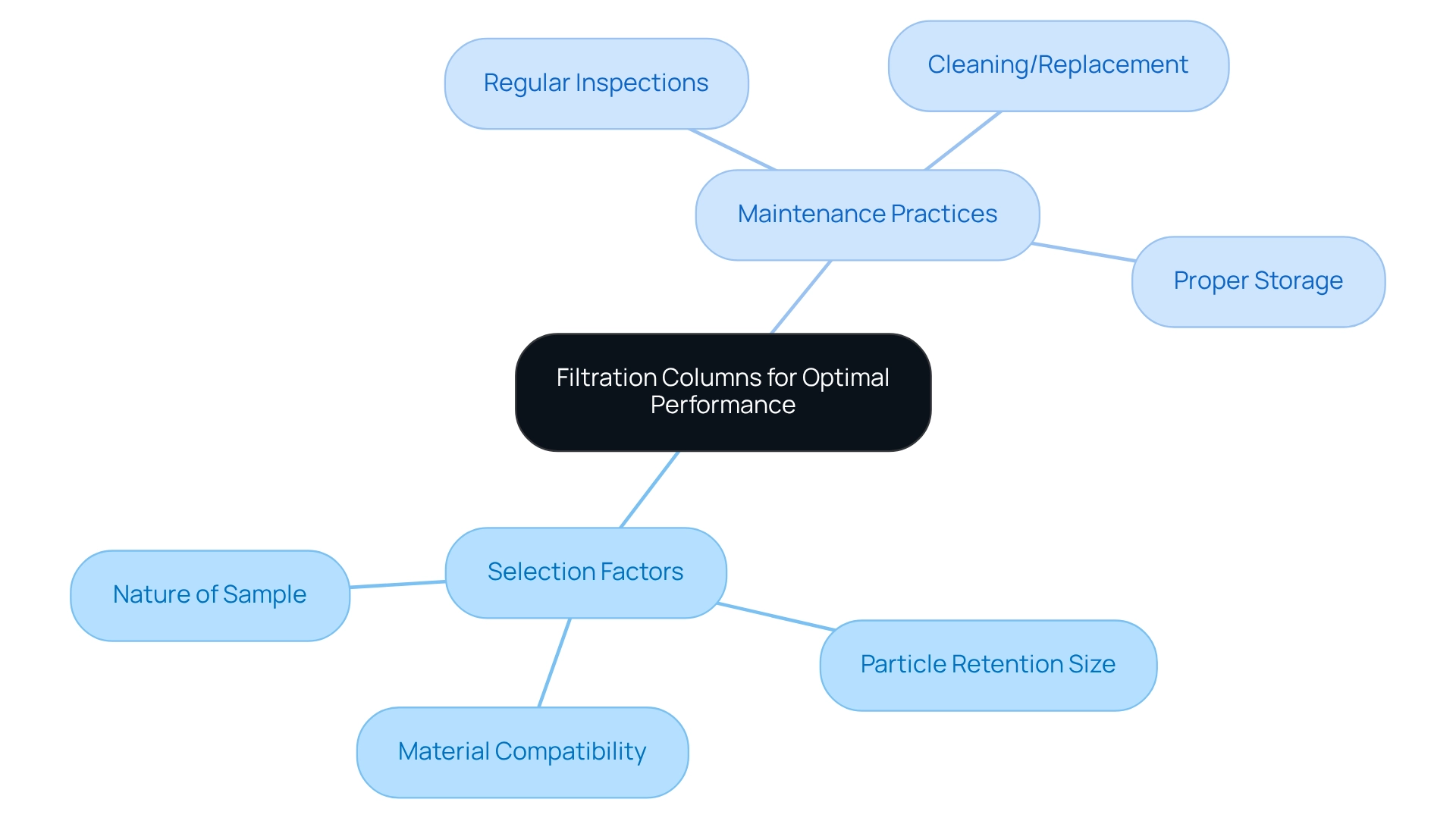

Selecting the right separation columns is essential for achieving optimal performance in chromatographic applications that utilize column filtration. It is important to consider factors such as:

- The nature of the sample

- The required particle retention size

- The compatibility of column materials with the solvents used

In HPLC applications, employing a 0.45 μm filter is generally advised to effectively capture particles, ensuring the integrity of column filtration and preventing contamination.

Routine maintenance of column filtration is critical for sustaining their performance. This includes:

- Regular inspections for wear

- Timely cleaning or replacement of filters

- Proper storage of columns when not in use

By establishing a maintenance schedule, facilities can significantly reduce contamination risks and prolong the lifespan of the columns, which is essential for effective column filtration, ultimately leading to more reliable analytical results.

A recent case analysis revealed that facilities implementing standardized operating procedures for filtering methods experienced a notable improvement in the quality of their filtered solvents. This underscores the importance of fostering a culture of cleanliness and employing skilled staff to maintain efficient filtering systems. The challenges faced by research facilities in executing effective column filtration methods—such as the risk of introducing contaminants during —further highlight the necessity of these procedures.

Moreover, industry experts stress the importance of tailoring practices for column filtration to meet specific analytical requirements. As Frans noted, "If we can achieve that, then we will possess a Freedom EVO platform encompassing the complete sample preparation spectrum which, to me, seems to be a significant paradigm shift for medical facilities." This perspective emphasizes the need for research facilities to adapt their filtering strategies based on particular analytical needs. By adhering to these best practices, facilities can enhance their separation processes with column filtration, ensuring high-quality outcomes in their HPLC applications.

Monitor and Document Filtration Processes for Compliance

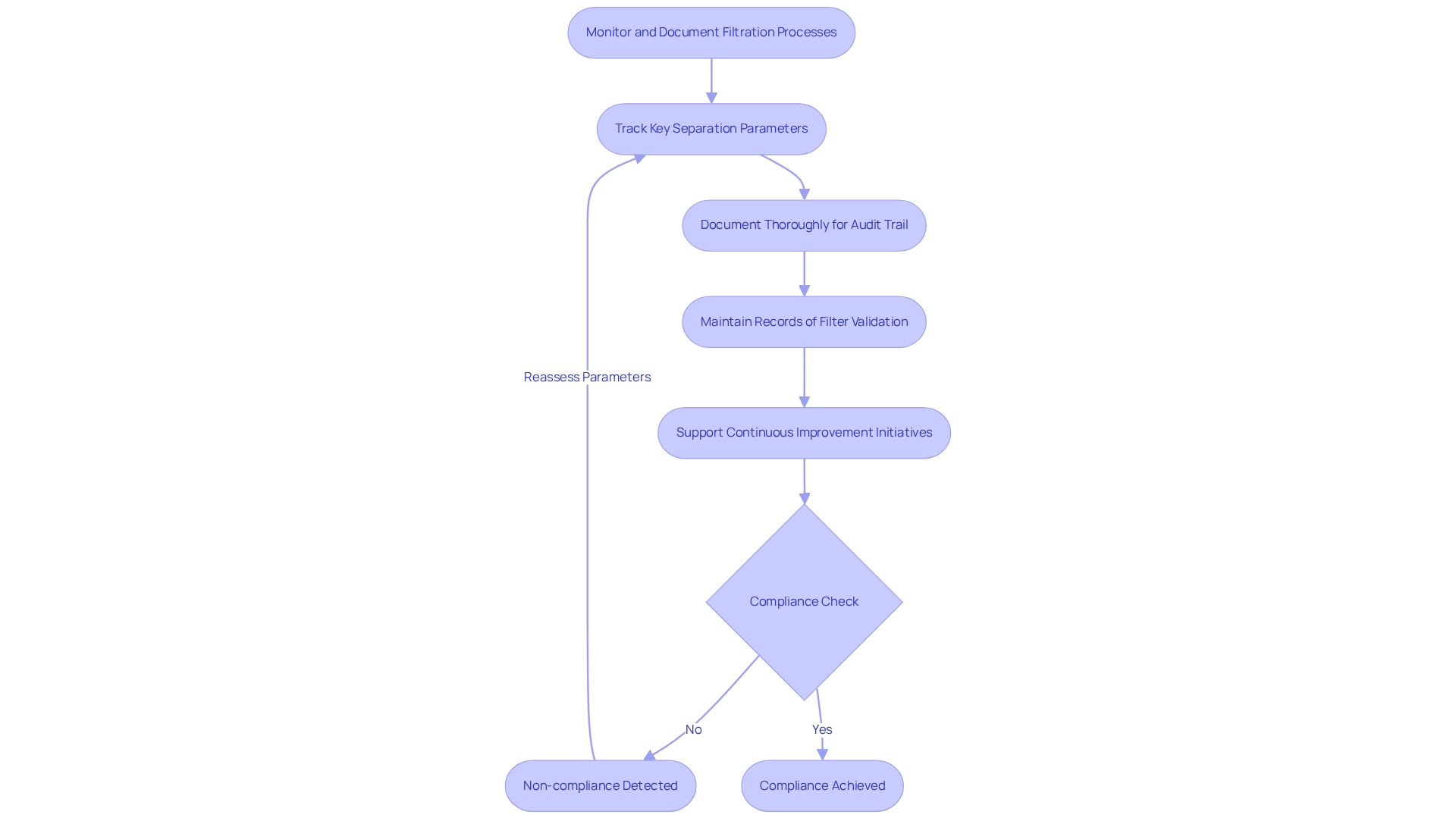

In pharmaceutical facilities, adherence to regulatory standards is vital for ensuring product quality and patient safety. A systematic method for monitoring and documenting column filtration processes is essential for compliance and enhances . Key separation parameters—such as flow rates, filter integrity, and deviations from standard operating procedures—should be meticulously tracked in the context of column filtration. This data must be documented thoroughly to create a clear audit trail, which is vital during inspections by regulatory authorities.

For instance, maintaining comprehensive records of filter validation tests and performance metrics not only demonstrates compliance but also supports continuous improvement initiatives. As Vivianne Arencibia, Vice President of Global Quality Systems and Compliance, states, "You need people. They need to be your nucleus," highlighting the importance of a dedicated team in compliance efforts.

Additionally, insights from the case study titled 'Disaster Recovery in the Pharmaceutical Industry' underscore the dangers linked to non-compliance and the necessity of strong documentation methods. By emphasizing the tracking and recording of purification procedures that utilize column filtration, facilities can effectively reduce risks associated with non-compliance and significantly improve their operational efficiency. Furthermore, awareness of common pitfalls in documentation practices can assist facilities in avoiding missteps in their compliance efforts.

Leverage Innovative Technologies to Enhance Filtration Efficiency

The research facility's purification environment is rapidly advancing, driven by cutting-edge technologies that significantly enhance efficiency and effectiveness. At the forefront of this evolution are automated purification systems, which simplify preparation processes and minimize human error, ultimately boosting throughput. These systems can reduce processing durations by as much as 50%, enabling facilities to manage larger quantities of specimens with improved precision thanks to column filtration, while recent advancements in filtering materials, particularly the development of nanofibers, have further augmented filtering capabilities. These innovative materials facilitate column filtration for the removal of smaller particulates that traditional filters often miss, thereby ensuring higher purity levels in analytical results.

As the global laboratory purification market is projected to grow from $4.1 billion in 2024 to $6.1 billion by 2029, with a compound annual growth rate (CAGR) of 8.3%, the adoption of such technologies is increasingly essential for laboratories striving to remain competitive. Notably, emerging markets such as India, China, Brazil, and Mexico offer significant growth opportunities for pharmaceutical labs seeking to expand their operations.

Pharmaceutical labs, in particular, stand to gain from these innovations. Automated purification systems not only enhance operational efficiency but also yield better analytical results by ensuring consistent specimen quality. For example, a recent deployment of an automated purification system in resulted in a 30% increase in sample throughput and a notable reduction in contamination rates. By integrating these advanced technologies into their workflows, research facilities can optimize their processes, leading to greater productivity and reliability in their outcomes.

Furthermore, in October 2023, Sartorius unveiled its new Grade 175 filter paper for analytical applications, underscoring the ongoing advancements in filtering technologies. Staying abreast of the latest developments in lab purification technologies is crucial for facilities aiming to enhance their capabilities and meet the evolving demands of the scientific community. By concentrating on best practices for implementing column filtration systems, pharmaceutical labs can ensure they are well-prepared to navigate the complexities of modern laboratory environments.

Conclusion

Effective column filtration stands as a cornerstone of success in pharmaceutical laboratories, profoundly influencing both the integrity of analytical results and the longevity of equipment. By prioritizing proper filtration practices—selecting appropriate filter sizes and materials, maintaining filtration columns, and meticulously monitoring processes—laboratories can significantly enhance operational efficiency and ensure compliance with regulatory standards. The integration of innovative technologies, such as automated systems and advanced filter materials, propels laboratories toward achieving superior outcomes.

As the pharmaceutical landscape evolves, it is imperative for laboratories to remain vigilant in adopting best practices that mitigate risks associated with contamination and non-compliance. By fostering a culture of cleanliness, investing in staff training, and leveraging cutting-edge filtration technologies, labs can improve data quality and drive productivity. Ultimately, a steadfast commitment to effective column filtration is essential for laboratories navigating the complexities of analytical processes while upholding the highest standards of quality and safety.