Overview

This article delves into the critical role of essential reagent reservoirs within pharmaceutical laboratories, emphasizing their significance in enhancing accuracy, efficiency, and safety in laboratory operations. By spotlighting various brands, such as JM Science with its precision design, Thermo Fisher known for its innovative accessibility, and Axygen’s unwavering commitment to traceability, the discussion underscores the necessity of high-quality containers. These features collectively optimize laboratory workflows and ensure compliance with industry standards, demonstrating that the right tools are indispensable for achieving excellence in scientific research.

As the landscape of pharmaceutical labs continues to evolve, the importance of selecting superior reagent reservoirs becomes increasingly clear, prompting laboratory professionals to prioritize quality in their operational choices.

Introduction

In the ever-evolving realm of pharmaceutical laboratories, the selection of reagent reservoirs is pivotal in achieving precision, efficiency, and safety. As laboratories work diligently to optimize their workflows and comply with rigorous standards, prominent manufacturers such as JM Science, Thermo Fisher Scientific, and Corning are at the forefront, offering innovative solutions designed to meet these critical needs.

These reservoirs, crafted from high-quality materials that endure chemical interactions, feature designs that significantly reduce waste and enhance accessibility. They are essential instruments in contemporary laboratory environments. This article examines the diverse offerings from these companies, highlighting how their distinctive features bolster operational efficiency and reliability in pharmaceutical applications.

JM Science Reagent Reservoirs: Precision and Reliability for Pharmaceutical Applications

JM Science presents a comprehensive range of chemical containers specifically designed for pharmaceutical laboratories, underscoring the importance of accuracy and reliability in liquid management. Crafted from premium materials, these storage tanks are engineered to withstand various chemical interactions, making them ideal for sensitive applications. Notable design features, such as graduated markings and a V-shaped bottom, facilitate optimal recovery from the reagent reservoir, significantly minimizing waste and enhancing workflow efficiency. In high-throughput environments where precision is paramount, these reagent reservoirs emerge as indispensable tools, reflecting JM Science's steadfast commitment to quality and exemplary customer support.

The AQ-300 Coulometric Karl Fischer Titrator, paired with the Hiranuma Aquacounter AQV-300 Volumetric Titrator, plays a crucial role in drug and medicine testing, ensuring adherence to the Japanese Pharmacopoeia. The AQV-300 is meticulously designed for volumetric titration, delivering high precision and reliability in moisture content analysis, which is vital for the quality control of medicinal products. Alán Aspuru-Guzik, a professor at the University of Toronto, emphasizes the significance of high-quality materials in laboratory settings, stating, "The integrity of laboratory tools directly impacts the reliability of experimental results." Recent advancements in chemical storage technology illustrate that employing high-quality materials can enhance performance metrics, further solidifying their role in modern pharmaceutical applications. For instance, research indicates that integrating calibration models with bioprocess models can deepen the understanding of growth dynamics in biotechnological research, showcasing the capabilities of advanced tools like JM Science's chemical storage systems. As the sector evolves, the integration of these storage systems into testing protocols continues to receive positive feedback from experts, underscoring their importance in achieving reliable outcomes.

Thermo Fisher Scientific Reagent Reservoirs: Trusted Solutions for Laboratory Efficiency

Thermo Fisher Scientific's reagent reservoir containers are meticulously engineered to enhance workflow efficiency, catering to both manual and automated pipetting systems. Available in a variety of sizes and configurations, including sterile options, these containers are indispensable for compliance in pharmaceutical environments. Their innovative trough-within-a-trough design maximizes liquid accessibility, ensuring pipetting is executed with both efficiency and precision. This thoughtful design not only minimizes waste but also streamlines workflows, establishing these storage tanks as essential assets in numerous research facilities.

The reliability of Thermo Fisher products is further reinforced by comprehensive support resources, which solidify their reputation as trusted solutions within the industry. Recent case analyses reveal that the utilization of Thermo Fisher chemical containers has led to marked improvements in productivity, underscoring their effectiveness in real-world applications. As Jennifer Honeycutt observes, the advent of new protein purification platforms empowers biopharma scientists to design experiments and analyze results with greater efficiency, aligning perfectly with the enhancements offered by Thermo Fisher's products.

Moreover, the Eppendorf Pipette Manager exemplifies how interconnected pipette systems elevate efficiency and reproducibility in liquid handling workflows, facilitating digital documentation and rapid input of pipetting parameters. As pharmaceutical laboratories increasingly adopt automated pipetting systems, the market share of Thermo Fisher Scientific's reagent reservoir containers continues to grow, highlighting their essential role in enhancing operational efficiency.

Corning Reagent Reservoirs: Versatile Options for Diverse Laboratory Applications

Corning reagent reservoirs are distinguished by their exceptional flexibility, making them suitable for a wide range of experimental applications. These containers, available in both sterile and non-sterile formats, function as a reagent reservoir that accommodates various pipetting techniques, including multichannel pipetting. Their robust construction guarantees durability, while the transparent material of the reagent reservoir facilitates easy monitoring of liquid levels. Corning's unwavering commitment to quality and innovation positions their containers as the preferred choice for laboratories seeking reliable and versatile solutions.

Gilson Reagent Reservoirs: Optimized Design for Efficient Reagent Use

Gilson solution containers are meticulously designed with an enhanced layout that significantly increases solution use efficiency. Key features, such as broad stable bases and sloped sides, facilitate easy access and thorough aspiration of substances, thereby effectively minimizing waste. Available in various sizes, these reagent reservoirs are compatible with both manual and automated pipetting systems, making them a versatile choice for facilities aiming to optimize productivity.

In practical applications, selecting appropriate elution buffers, especially those used in conjunction with Gilson reagent reservoirs, is crucial for downstream processes. The choice of elution buffer can profoundly influence nucleic acid stability, as evidenced by studies evaluating components like EDTA for their effects on downstream applications. Laboratories employing Gilson containers have reported significant reductions in chemical waste, showcasing practical efficiency improvements.

Expert insights highlight that the design features of Gilson containers not only enhance workflows but also contribute to substantial cost savings in chemical consumption. As of 2025, efficiency data indicates that facilities utilizing Gilson products experience improved chemical usage, with reports revealing up to a 30% reduction in waste compared to conventional containers. This underscores Gilson's commitment to quality and innovation within medical applications.

Heathrow Scientific Reagent Reservoirs: Sterile and Non-Sterile Options for Safety and Compliance

Heathrow Scientific provides an extensive selection of reagent containers, encompassing both sterile and non-sterile options tailored to meet the varied demands of research facilities. The sterile containers are meticulously crafted for applications necessitating stringent contamination control, rendering them indispensable for pharmaceutical laboratories where precision is essential. Conversely, the non-sterile containers offer versatility for less sensitive tasks, empowering facilities to optimize their workflows.

User safety is paramount in the design of these reservoirs. They are equipped with a reagent reservoir that has clear graduation markings for precise measurement and a construction that significantly mitigates the risk of spills, thereby enhancing operational safety. This commitment to safety and compliance positions Heathrow Scientific as a trusted partner for pharmaceutical facilities.

Recent statistics underscore the vital role of contamination control in research settings. Laboratories that implement rigorous safety protocols, including the utilization of sterile containers, have observed a marked decrease in contamination incidents. Notably, individuals eligible under specific regulations must have engaged in high complexity testing consistently since December 28, 2024, underscoring the necessity of adherence in testing environments. Additionally, case studies reveal that the adoption of Heathrow Scientific's sterile solutions has fostered a culture of safety, aligning with the OSHA Laboratory standard and promoting responsible chemical handling practices among staff.

As the testing landscape evolves, particularly with new compliance mandates set for December 2024, the necessity for dependable tools such as Heathrow Scientific's chemical containers to ensure regulatory compliance and uphold safety standards becomes increasingly clear. Emily H. Xiong articulates, "We then outline the computational examination of data to ascertain effect size and statistical significance," highlighting the critical role of data analysis in sustaining safety and compliance within research environments.

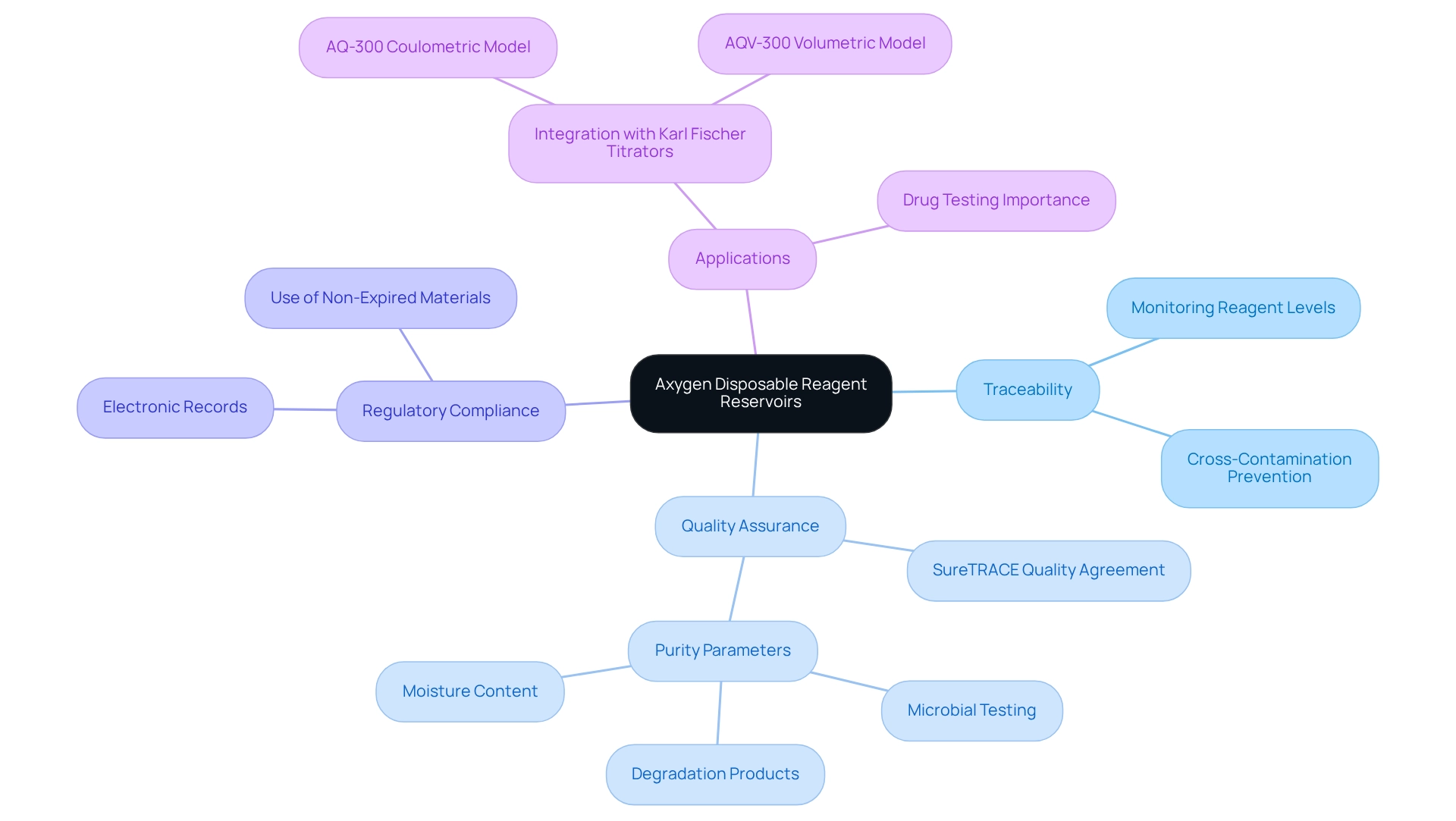

Axygen Disposable Reagent Reservoirs: Ensuring Traceability and Quality Control

Axygen disposable chemical containers are meticulously crafted to prioritize traceability and quality assurance, making them an ideal choice for laboratories in the pharmaceutical industry. Each reagent reservoir is manufactured under stringent quality standards, ensuring compliance with the latest regulatory requirements, including those pertaining to electronic records and cloud computing services. The transparent design of the reagent reservoir allows for easy monitoring of reagent levels, while the disposable nature significantly reduces the risk of cross-contamination—a critical concern in medical environments—by adhering to guidelines against using raw materials that have surpassed their established expiry dates.

Axygen's commitment to quality and traceability is exemplified by the SureTRACE quality agreement, which guarantees that all products meet rigorous purity parameters, including microbial testing, degradation products, and moisture content. This focus on quality assurance is essential for facilities striving to uphold high standards throughout their workflows. Trust our selected supplier partners, who are committed to the SureTRACE quality agreement, to deliver the finest products and services to support your operations.

Real-world applications of Axygen products highlight their effectiveness in enhancing traceability within laboratories. The integration of Karl Fischer titrators, such as the AQ-300 Coulometric and AQV-300 Volumetric models, underscores their importance in drug and medicine testing, particularly in adherence to the Japanese Pharmacopoeia. These titrators are vital for accurately assessing moisture content in medications, ensuring product quality and safety. The AQ-300 features advanced coulometric titration technology, while the AQV-300 offers volumetric precision, both designed to meet the stringent demands of drug testing.

As we approach 2025, the emphasis on regulatory compliance and quality assurance standards for chemical containers remains paramount. Axygen's single-use chemical containers not only fulfill these criteria but also provide facilities with a reagent reservoir and the necessary tools to ensure traceability throughout their processes. By integrating these storage systems into their workflows, alongside advanced titration techniques, pharmaceutical laboratories can enhance their operational efficiency and maintain the integrity of their research. For further information on acquiring these titrators, please visit our e-commerce platform.

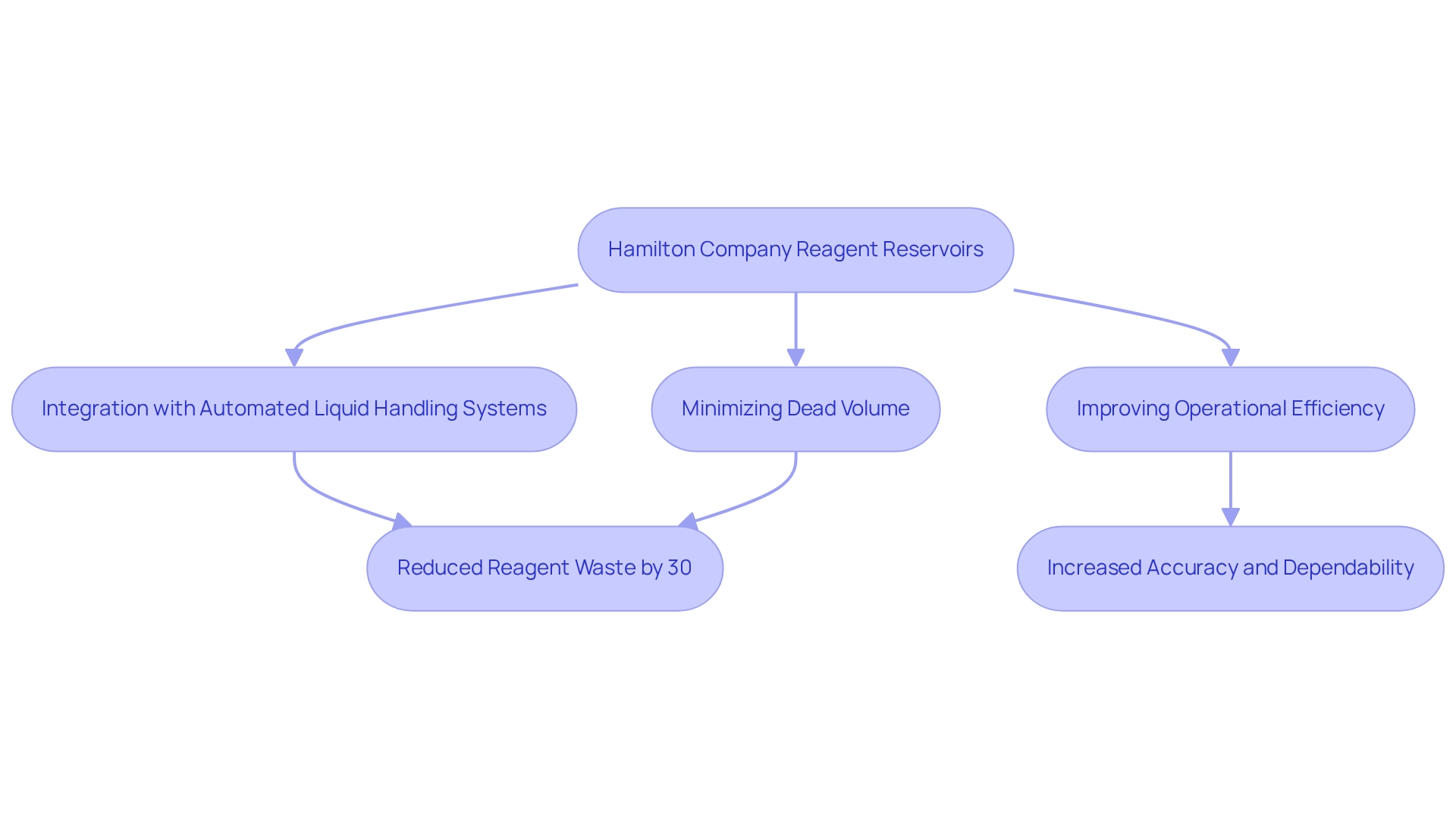

Hamilton Company Reagent Reservoirs: Enhancing Automation in Laboratory Settings

Hamilton Company chemical containers are meticulously designed to enhance automation in research settings. These containers integrate seamlessly with various automated liquid handling systems, facilitating smooth incorporation into existing workflows. Essential design characteristics, such as minimal dead volume and easy access for pipetting, empower facilities to improve operational efficiency while significantly minimizing material waste. Recent statistics indicate that automation can lead to a reduction in reagent waste by up to 30%, underscoring the critical role of the reagent reservoir in modern lab environments.

A prime example of automation in action is the Nucleus FlexPod, a mobile robotic base that enables users to swiftly and effortlessly integrate current lab devices, thereby enhancing workflow efficiency. Hamilton's unwavering commitment to innovation and quality positions them as a leader in process automation, with real-world examples illustrating substantial efficiency improvements in liquid handling. As research facilities increasingly embrace automated solutions, Hamilton's containers are emerging as vital instruments for achieving accuracy and dependability in scientific inquiry.

According to an affiliate of Hamilton Company, "By doing so, users may re-focus their attention to high-value tasks while remaining confident that results are accurate and robust." This sentiment encapsulates the growing trend of integrating devices like Waters Corporation's Andrew+ pipetting robot, which automates liquid handling and connects with other scientific instruments. Consequently, Hamilton's water storage systems, including the reagent reservoir, are pivotal in facilitating these advancements, ensuring that research facilities can meet the demands of contemporary scientific inquiry.

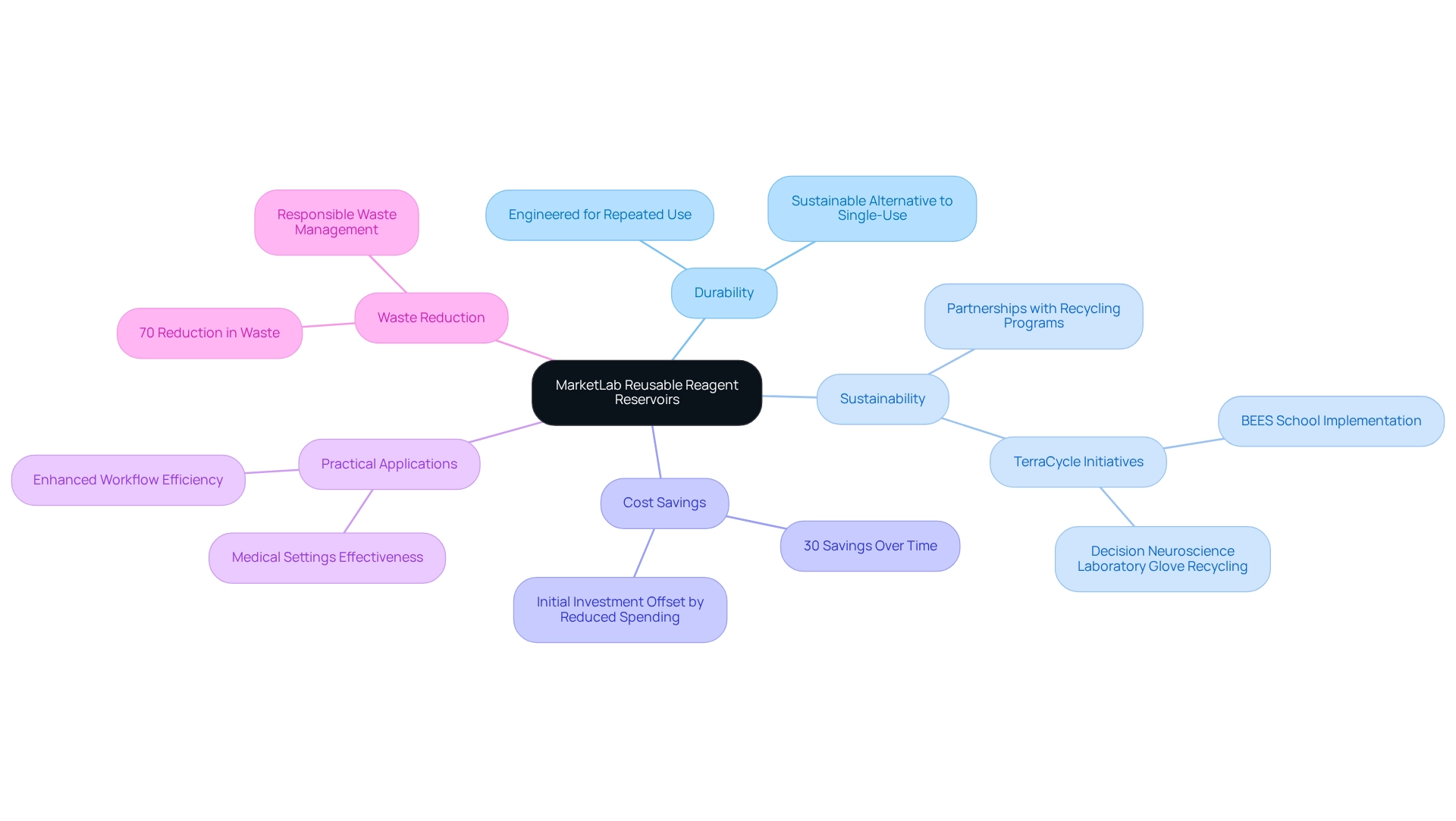

MarketLab Reusable Reagent Reservoirs: Versatile Solutions for Laboratory Use

MarketLab presents a diverse array of reusable reagent reservoirs, designed as adaptable solutions for various scientific applications. Engineered for durability, these containers withstand repeated use, establishing them as a sustainable alternative to single-use options. Their transparent design allows for easy monitoring of liquid levels, thus enhancing operational efficiency. By integrating a reagent reservoir and reusable containers into research workflows, facilities can significantly reduce waste and operational costs, aligning with broader sustainability initiatives. Research indicates that shifting from disposable to reusable alternatives can lead to a waste reduction of up to 70%. Additionally, facilities that adopt reusable containers, such as a reagent reservoir, have reported savings of approximately 30% over time, as the initial investment is offset by decreased spending on disposables.

Practical examples illustrate the effectiveness of these containers in medical settings. A recent initiative at a prominent pharmaceutical lab showcased that the implementation of a reagent reservoir along with reusable containers not only minimized waste but also enhanced workflow efficiency, facilitating more streamlined operations. Moreover, the Decision Neuroscience Laboratory's glove recycling initiative, which employed TerraCycle containers, successfully diverted around 15 boxes of gloves from incineration in less than two months, underscoring the potential for responsible waste management in research environments.

Beyond their practical benefits, MarketLab's reusable chemical containers align with sustainability goals. The company's dedication to eco-friendly practices is reflected in initiatives such as partnerships with recycling programs that advocate for responsible waste management. For instance, the BEES school has adopted TerraCycle boxes across multiple labs, further fostering recycling efforts and reducing landfill waste. As research facilities increasingly prioritize sustainability, the adoption of reusable items like these containers becomes essential for minimizing environmental impacts while maintaining high standards of quality and performance.

Sigma-Aldrich Reagent Reservoirs: High-Quality Standards for Pharmaceutical Laboratories

Sigma-Aldrich chemical containers are synonymous with high-quality standards, establishing them as a preferred choice for pharmaceutical facilities. Engineered to meet the stringent demands of research environments, these containers ensure reliability and precision in fluid management. Crafted from materials that demonstrate exceptional chemical compatibility, they significantly mitigate the risk of adverse chemical interactions, which is vital for preserving the integrity of sensitive reagents. As noted by Sax, N.I., substances utilized in laboratory settings must be carefully selected to prevent transfer from packaging materials, underscoring the importance of material integrity in laboratory applications. By 2025, the relevance of these containers is underscored by their ability to aid laboratories in achieving both research and compliance objectives. For example, a standard 250 x 25 mm column operates at a flow rate of 10 to 60 mL/min, accommodating a maximum sample size of 2.5 mg, illustrating the efficiency of Sigma-Aldrich products in high-performance applications.

Real-world examples further demonstrate the efficacy of Sigma-Aldrich containers in upholding high-quality standards. Regular maintenance and systematic checks are imperative, as evidenced by case studies that highlight detector issues stemming from lamp failures or contamination, which resulted in inaccurate readings. Such challenges accentuate the necessity for reliable liquid handling solutions, and Sigma-Aldrich containers serve as effective reagent reservoirs. Moreover, ensuring that columns are securely capped when not in use can prevent potential issues, reinforcing the importance of proper storage techniques to maintain the quality of Sigma-Aldrich products.

Expert insights bolster the reliability of these containers in pharmaceutical settings, where adherence to stringent quality standards is paramount. By merging innovative design with robust materials, Sigma-Aldrich sets the benchmark for excellence in liquid handling, empowering research facilities to confidently advance their scientific pursuits. Routine system evaluations and adherence to maintenance schedules are essential for optimal chromatographic performance, highlighting the proactive measures necessary for success in research environments.

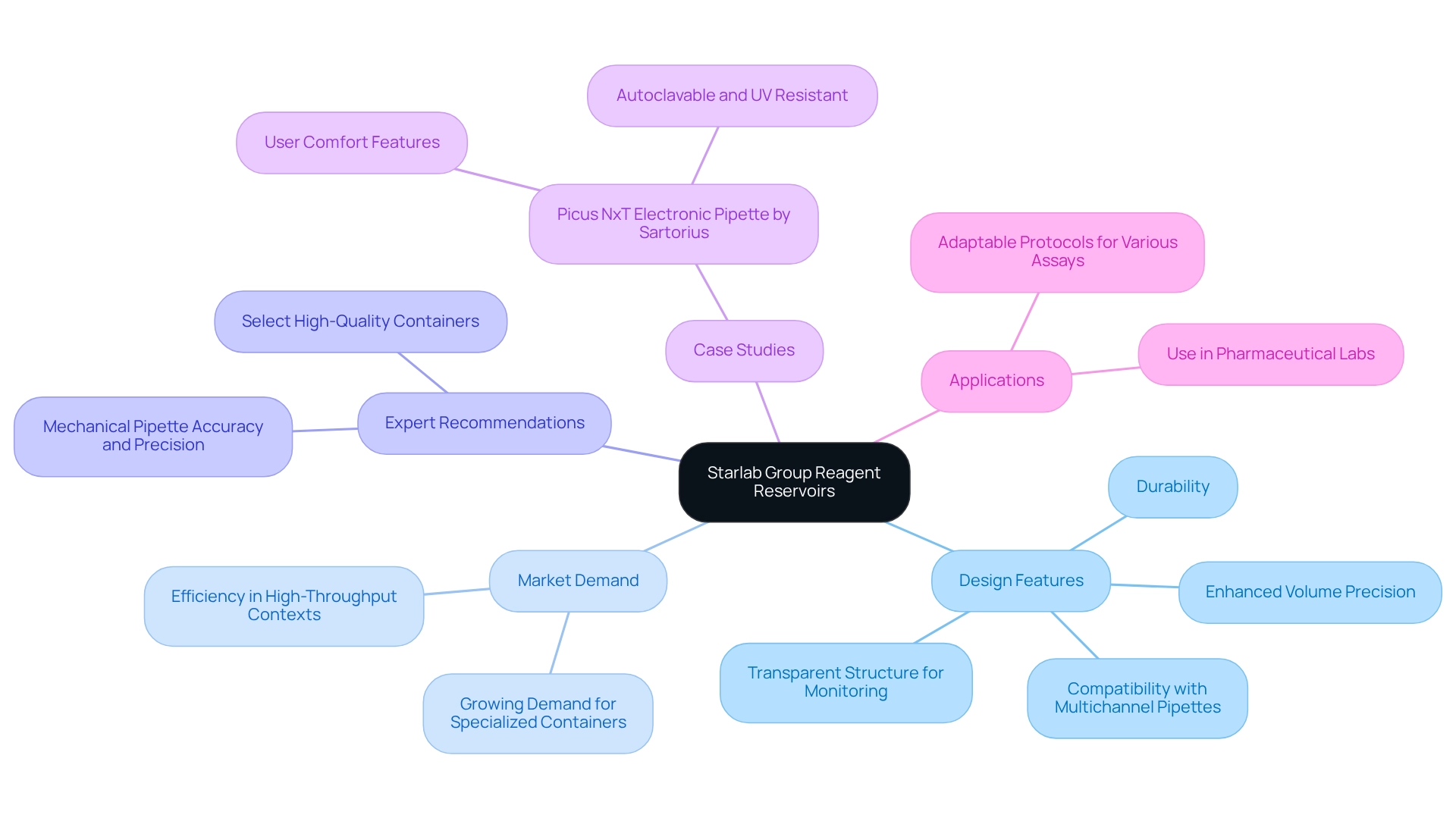

Starlab Group Reagent Reservoirs: Specialized Solutions for Multichannel Pipetting

Starlab Group solution containers are expertly crafted for multichannel pipetting, presenting tailored options that significantly enhance efficiency in high-throughput environments. Their unique design is customized to accommodate various pipetting methods, ensuring users achieve precise and reliable results. With a transparent structure that allows for easy monitoring of chemical levels, these containers are built to last, providing durability and reliability even in demanding experimental conditions.

Recent advancements in 2025 highlight a growing market demand for specialized chemical containers, particularly in high-throughput contexts where efficiency is paramount. Starlab's innovative approach not only meets these needs but also integrates seamlessly into existing laboratory workflows. Real-world examples underscore the efficiency improvements observed in high-throughput facilities utilizing Starlab products, demonstrating their practical value.

Experts stress the importance of selecting high-quality chemical containers, with numerous professionals noting that Starlab's design features—such as compatibility with multichannel pipettes and enhanced volume precision—set them apart in the marketplace. As CAPP points out, choosing a mechanical pipette with superior accuracy and precision is essential for optimal performance. Case studies further validate the effectiveness of Starlab Group solution containers, including the Picus NxT Electronic Pipette by Sartorius, designed with user comfort in mind and equipped with an adjustment wheel for rapid volume setting. This pipette is fully autoclavable and UV resistant, making it a durable and reliable choice for scientific applications.

Moreover, the same protocol can be adapted for diluted whole blood or endothelial: PBMC co-cultures, showcasing the versatility of Starlab's containers across various scientific applications. As laboratories increasingly focus on productivity, Starlab's commitment to innovation makes their reagent reservoirs indispensable tools for pharmaceutical labs aiming to optimize their processes.

Conclusion

The exploration of reagent reservoirs from leading manufacturers underscores their critical role in enhancing the efficiency, reliability, and safety of pharmaceutical laboratories. JM Science distinguishes itself with precision-engineered reservoirs that minimize waste and optimize reagent recovery. In contrast, Thermo Fisher Scientific offers innovative designs that enhance liquid accessibility and streamline workflows. Corning, Gilson, and Heathrow Scientific present versatile and robust options tailored to diverse laboratory needs, ensuring compliance and safety standards are consistently met.

The emphasis on quality and traceability is further highlighted by Axygen's disposable reservoirs, meticulously designed to mitigate cross-contamination risks. Hamilton Company’s commitment to automation illustrates how the integration of advanced reservoir technologies can yield significant operational efficiencies. Meanwhile, MarketLab’s reusable solutions advocate for a sustainable approach, empowering laboratories to effectively cut costs and minimize waste.

Ultimately, selecting the right reagent reservoirs transcends mere convenience; it is a foundational element in upholding high standards of quality and compliance within pharmaceutical applications. As the industry evolves, embracing these innovative solutions becomes essential for laboratories striving for excellence in research and operational outcomes. The commitment of these manufacturers to quality, safety, and efficiency accentuates the vital role these reservoirs play in advancing pharmaceutical science and ensuring reliable laboratory practices.