Overview

Selecting the appropriate metal analyzer for your laboratory is a critical decision that demands careful evaluation. Begin by assessing the specific types of metals you intend to analyze, as well as the regulatory standards that must be met. Key features such as sensitivity, accuracy, and usability play a significant role in this selection process. Understanding these factors is paramount; it allows laboratories to compare various models effectively.

Furthermore, considering the level of manufacturer support available ensures that your choice enhances analytical capabilities while adhering to stringent quality benchmarks. By prioritizing these elements, laboratories can make informed decisions that significantly impact their operational efficiency.

Introduction

In the realm of analytical chemistry, metal analyzers are indispensable instruments, each specifically designed to meet the unique needs of laboratories. From the non-destructive capabilities of X-ray Fluorescence (XRF) to the unmatched sensitivity of Inductively Coupled Plasma Mass Spectrometry (ICP-MS), these devices provide a wide array of functionalities that cater to diverse applications.

As industries evolve and regulatory standards tighten, grasping the nuances of these technologies becomes essential for laboratories seeking to enhance their analytical capabilities. This article explores the various types of metal analyzers, highlighting their distinctive features and critical considerations for selecting the appropriate model, ensuring that laboratories can confidently and precisely navigate the complexities of modern metal analysis.

Understand Metal Analyzers: Types and Functions

Metal analyzers serve as essential tools in laboratories, with each one tailored for specific applications and offering distinct advantages. The primary types include:

- X-ray Fluorescence (XRF) Analyzers: Renowned for their non-destructive testing capabilities, XRF analyzers assess a broad spectrum of metals and alloys. By directing X-rays onto a specimen, they induce the emission of secondary X-rays, which are subsequently analyzed to determine the elemental composition. This makes XRF ideal for applications where the integrity of the material is paramount. Recent advancements indicate that XRF technologies are gaining significant market share, reflecting their increasing adoption across various industrial applications.

- Optical Emission Spectroscopy (OES): OES excels in bulk material analysis. This method excites the atoms within a specimen using a high-energy source, measuring the emitted light to identify elemental composition. OES is favored for its rapid results and is widely utilized in quality control processes. Current statistics suggest that OES is becoming increasingly popular due to its efficiency in analyzing multiple elements simultaneously.

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS): Known for its exceptional sensitivity, ICP-MS is the preferred method for trace metal analysis. It ionizes the material and measures the mass-to-charge ratio of the ions, allowing for precise determination of elemental concentrations, even at very low levels. As of 2025, advancements in ICP-MS technologies continue to enhance their functionality, solidifying their indispensability in modern analytical laboratories.

- Laser-Induced Breakdown Spectroscopy (LIBS): LIBS employs a laser to vaporize a small amount of material, creating a plasma that emits light. The emitted light is then analyzed to identify the elemental composition. This technique is valued for its speed and ability to analyze solid samples without extensive preparation. Notably, the optical advantages of curved sensors in LIBS systems have been observed to offer more direct illumination for edge pixels, thereby improving measurement precision.

Understanding these varieties of metal analyzers is crucial for facilities to select suitable equipment based on their specific needs, such as sensitivity, analysis speed, and the types of materials involved, including metals. Expert insights, such as those from Philippe Sarrazin of the SETI Institute, underscore the importance of developing advanced imaging technologies that can be integrated into various analytical processes. Furthermore, the case study on the Neptec Vision System for the ISS illustrates practical applications of advanced imaging technologies, connecting them to the broader context of material analysis in research environments. As of 2025, the expanding market share for XRF and ICP-MS technologies highlights their rising acceptance in numerous industrial applications, emphasizing the importance of staying informed about current trends in elemental analysis.

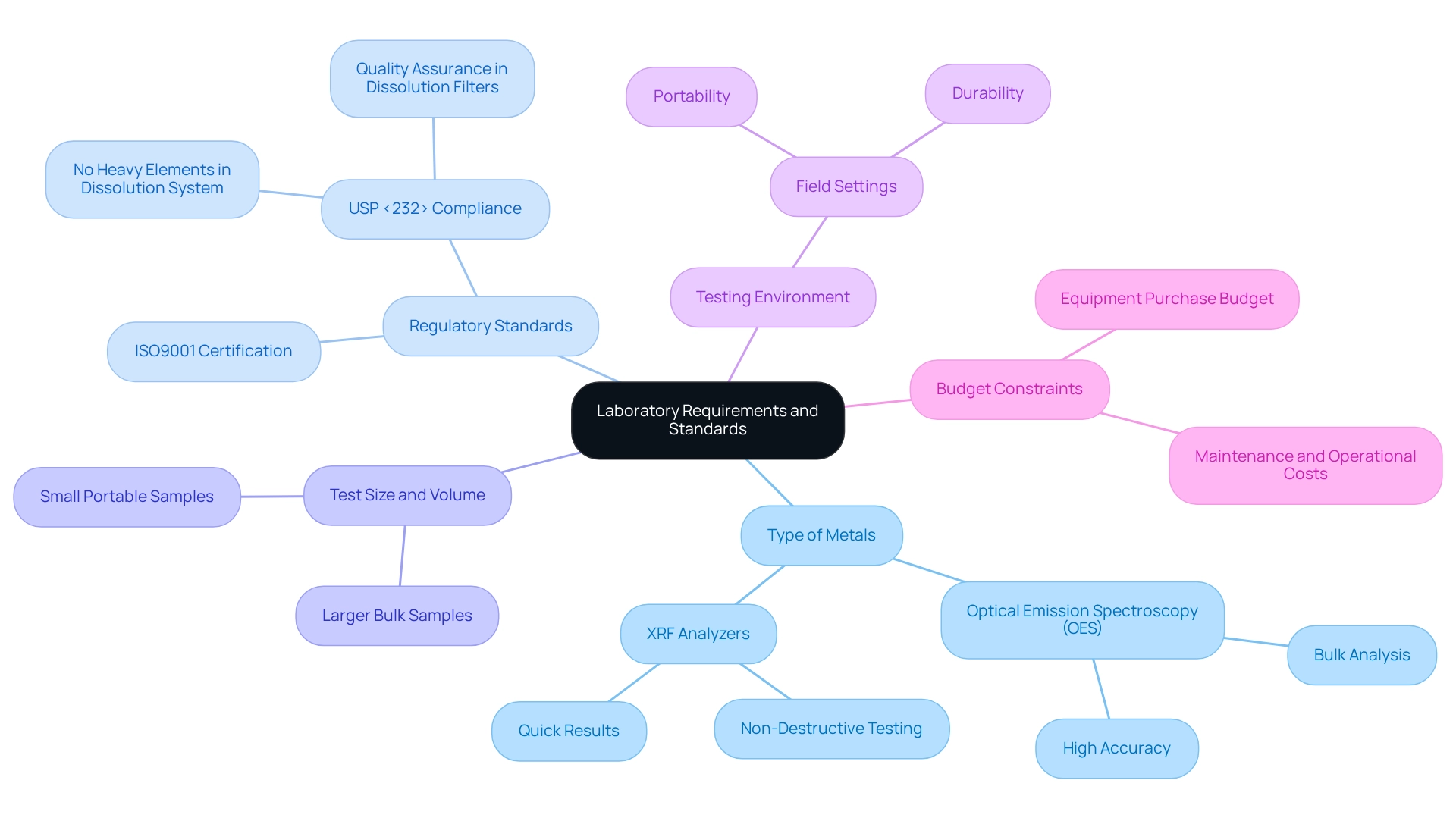

Identify Your Laboratory's Requirements and Standards

Evaluating your laboratory's specific needs for a metal analyzer is vital for ensuring adherence and precision in examinations. Key considerations include:

- Type of Metals: Identify the specific metals and alloys you will examine; different testing devices are optimized for various materials. For instance, Optical Emission Spectroscopy (OES) instruments excel in bulk analysis, detecting a wide range of elements with high accuracy. Additionally, metal analyzers like XRF offer the advantage of being non-destructive and providing quick results, making them suitable for diverse applications.

- Regulatory Standards: Stay informed about industry-specific regulations, such as the enforcement of USP <232> in 2015, which mandates that no part of the dissolution system contributes heavy elements. Compliance with these standards is essential for pharmaceutical applications, ensuring your laboratory meets the highest quality benchmarks. A relevant case study is the Quality Assurance in Dissolution Filters, where QLA recognized the need for high-quality filters to meet these standards, resulting in their filters being certified heavy metal free and achieving ISO9001 certification.

- Test Size and Volume: Assess the dimensions and capacity of the specimens you will be examining. Some instruments are designed for small, portable samples, while others cater to larger bulk samples, influencing your choice of equipment.

- Testing Environment: Consider the conditions in which the assessment tool will operate. If portability and durability are essential—such as in field settings—these factors will significantly influence your selection.

- Budget Constraints: Establish a clear budget for your equipment purchase, factoring in maintenance and operational costs. This financial framework will assist you in refining your choices efficiently by thoughtfully evaluating these factors, enabling facilities to select instruments, such as a metal analyzer, that not only comply with regulatory standards but also enhance their analytical capabilities, ultimately contributing to improved quality assurance in their procedures. As David Bradley emphasized, the perspectives presented in this article underscore the significance of adherence and quality in scientific practices.

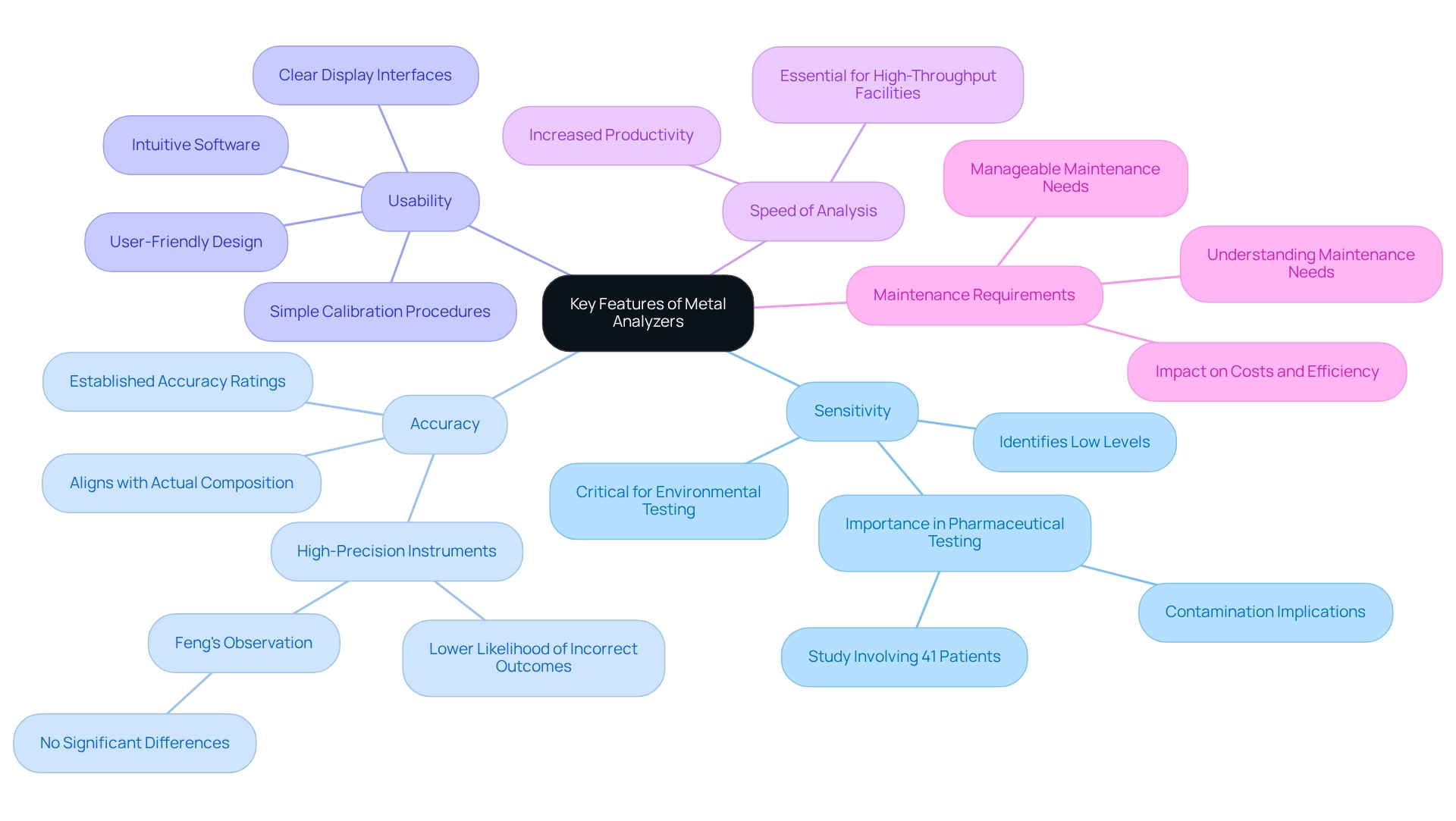

Evaluate Key Features: Sensitivity, Accuracy, and Usability

When assessing a metal analyzer for metals, several key features should be prioritized to ensure optimal performance in laboratory settings:

- Sensitivity: The capability to identify low levels of elements is crucial, particularly in areas such as environmental testing and valuable substance analysis. High sensitivity in a metal analyzer ensures that even trace amounts of metals can be accurately identified, which is critical in pharmaceutical testing where contamination can have serious implications. A recent study involving 41 patients highlighted the importance of sensitivity in decision-making processes, emphasizing that accurate detection is crucial for informed choices in laboratory settings.

- Accuracy: This feature indicates how closely the results from the assessment align with the actual composition of the sample. For critical applications in pharmaceuticals, it is essential to choose a metal analyzer that has established accuracy ratings. Research has indicated that high-precision instruments considerably lower the likelihood of incorrect outcomes, thus improving the dependability of test results. As noted by Feng, there were no significant differences between intervention and control groups, underscoring the necessity for precise measurements in achieving consistent outcomes.

- Usability: A user-friendly design can greatly enhance operational efficiency. Look for devices featuring intuitive software, simple calibration procedures, and clear display interfaces. These features not only streamline the workflow but also reduce the likelihood of user error, which is vital in high-stakes environments.

- Speed of Analysis: In high-throughput facilities, the rate at which a testing device can provide results is essential. Quicker analysis durations lead to heightened productivity, enabling facilities to manage more samples without sacrificing quality.

- Maintenance Requirements: Understanding the maintenance needs of a testing device is essential for long-term operational planning. Some models may necessitate more frequent calibration or servicing, which can affect overall costs and efficiency. Selecting a metal analyzer with manageable maintenance needs can lead to improved resource distribution and minimized downtime.

By focusing on these characteristics, laboratories can select metal analyzers that not only meet their analytical requirements but also enhance the overall quality and reliability of their testing procedures. The case study on nurse-led immunotherapy decision coaching illustrates how informed decision-making, supported by accurate and reliable data, can significantly impact patient outcomes, reinforcing the importance of selecting high-quality metal analyzers from reputable suppliers such as JM Science Inc.

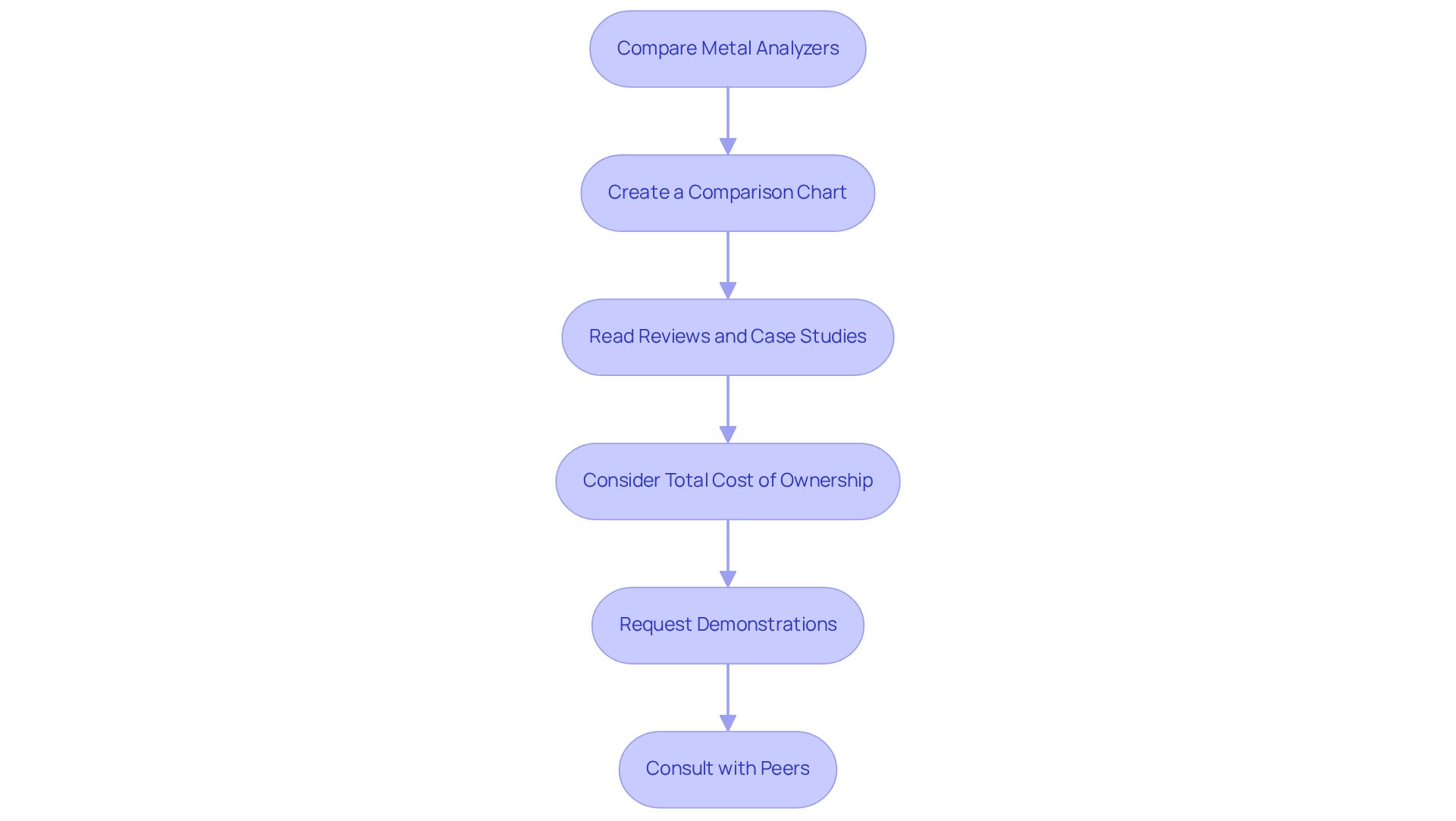

Compare Models: Analyze Performance and Cost-Effectiveness

To effectively compare metal analyzers, follow these essential steps:

- Create a Comparison Chart: Compile a comprehensive list of the models under consideration, detailing their key specifications such as sensitivity, accuracy, speed, and price. This visual representation is crucial for making informed decisions.

- Read Reviews and Case Studies: Actively seek out user reviews and case studies that emphasize the real-world performance and reliability of the testing devices. Systematic reviews have shown that many diagnostic tests provide good value for money, highlighting the necessity of thorough evaluation. Furthermore, insights from case studies on the growth factors in the clinical chemistry testing equipment market can offer valuable context on market trends and challenges.

- Consider Total Cost of Ownership: Evaluate not only the initial purchase price but also maintenance costs, consumables, and potential downtime. The average cost of acquiring basic diagnostic equipment for a medical analysis laboratory ranges from $50,000 to $100,000. Understanding these financial implications is vital for assessing the feasibility and advantages of upgrading to advanced instruments.

- Request Demonstrations: Whenever feasible, organize demonstrations of the testing devices. Observing the equipment in action can yield invaluable insights into usability and performance, helping to clarify any uncertainties.

- Consult with Peers: Engage with fellow professionals in the field to gather recommendations and insights based on their experiences with specific models. This peer feedback can be instrumental in guiding your decision-making process.

By adhering to these procedures, facilities can ensure they select the most appropriate metal analyzer and materials testing devices, balancing performance with affordability, ultimately enhancing their analytical capabilities. As ChiHui Fang noted, "The literature reveals many areas in which testing represents good value for money," reinforcing the importance of thorough evaluation in the selection process.

Consider Support and Maintenance: Ensure Long-Term Reliability

When selecting a metal analyzer, it is crucial to consider several aspects of support and maintenance to ensure long-term reliability.

- Manufacturer Support: Begin by assessing the level of support offered by the manufacturer, which includes technical assistance, training, and warranty options. Robust manufacturer support is essential for addressing any operational challenges that may arise. Notably, 85% of laboratory managers indicate that effective manufacturer support significantly enhances equipment reliability.

- Availability of Spare Parts: Next, confirm that spare parts are readily available and that the manufacturer is renowned for its service and support. By 2025, the accessibility of spare parts will be vital for minimizing downtime and maintaining operational efficiency. A recent survey revealed that 90% of labs prioritize manufacturers with a proven track record in spare parts availability.

- Preventive Maintenance Plans: It is also advisable to seek manufacturers that offer preventive maintenance plans designed to keep your equipment in optimal condition. Such plans can significantly reduce the risk of unexpected failures, ensuring consistent performance. For instance, Struers services focus on delivering high-quality results and enhancing efficiency through regular maintenance checks.

- User Training: Additionally, evaluate whether the manufacturer provides comprehensive training for your staff. Proper training equips users to operate the device effectively and troubleshoot common issues, ultimately enhancing overall productivity. Research shows that labs with trained personnel experience 30% fewer operational disruptions.

- Community and Resources: Finally, investigate the presence of an active user community or online resources, such as forums or knowledge bases. These platforms can be invaluable for seeking guidance and sharing experiences with other users, fostering a collaborative environment for problem-solving.

In a recent case study, JM Science's handheld LIBS devices showcased their effectiveness in soil organic carbon measurement and food authentication. The success of these applications was largely attributed to the robust support and maintenance provided by JM Science, which ensured accurate results and operational reliability. This innovation not only bolsters agricultural practices but also highlights the versatility of metal analyzers in various applications.

Conclusion

Selecting the right metal analyzer is a pivotal decision for laboratories aiming to enhance their analytical capabilities. This article has illuminated the diverse types of metal analyzers available, including XRF, OES, ICP-MS, and LIBS, each offering unique advantages tailored to specific applications. Understanding the strengths and functionalities of these technologies is essential, especially as industries face evolving regulatory standards and the need for precision in testing.

Key considerations for laboratories include a thorough assessment of their specific needs, such as:

- The types of metals to be analyzed

- Compliance with relevant regulations

- The operational environment

Additionally, prioritizing features like:

- Sensitivity

- Accuracy

- Usability

- Maintenance requirements

can significantly impact the effectiveness of metal analysis. By evaluating these factors and comparing different models comprehensively, laboratories can make informed decisions that balance performance with cost-effectiveness.

Ultimately, the choice of a metal analyzer should not only focus on immediate needs but also consider long-term reliability through robust manufacturer support and maintenance plans. As the field of analytical chemistry continues to advance, staying abreast of the latest technologies and best practices will empower laboratories to navigate the complexities of metal analysis confidently. By investing in the right tools and knowledge, laboratories can ensure high-quality results, enhance their operational efficiency, and uphold the standards required in today's competitive landscape.