Overview

Mercury vapor lamps represent a high-intensity discharge lighting solution, distinguished by their bright, bluish-white illumination and extended operational lifespan. These features render them particularly suitable for industrial and outdoor applications. However, it is imperative to acknowledge both their advantages and drawbacks:

- Efficiency

- Durability

- Health risks associated with mercury exposure

- Environmental concerns regarding disposal

These factors underscore the necessity for careful handling. Furthermore, the exploration of safer alternatives, such as LED technology, is essential. This consideration not only addresses the potential hazards but also aligns with contemporary environmental standards, prompting a shift towards more sustainable lighting solutions.

Introduction

In the realm of lighting technology, few innovations have made as significant an impact as mercury vapor lamps. Introduced over a century ago, these high-intensity discharge lamps have illuminated everything from bustling city streets to expansive industrial spaces. Their striking bluish-white glow and impressive lifespan have established them as a staple in applications demanding bright, reliable light.

However, as discussions around environmental sustainability and health risks intensify, the future of mercury vapor lamps hangs in the balance. This article delves into the mechanics, benefits, and drawbacks of these lamps while exploring the evolving landscape of lighting alternatives that promise to redefine the industry.

As cities and industries seek more efficient and safer solutions, understanding the role of mercury vapor lamps becomes crucial for informed decision-making in lighting technology.

What Are Mercury Vapor Lamps?

The mercury vapor lamp represents a sophisticated type of gas-discharge device that generates light through an electric arc ignited in vaporized metal. This innovative process yields a bright, bluish-white illumination, making it particularly advantageous for various applications, such as street lighting and industrial environments. Classified as high-intensity discharge (HID) fixtures, mercury vapor lamps are celebrated for their exceptional efficiency and longevity, typically lasting between 16,000 to 24,000 hours.

In industrial settings, mercury vapor lamps are widely utilized as high-intensity discharge lights due to their ability to produce significant brightness, rendering them ideal for expansive areas such as warehouses, factories, and outdoor spaces. Their effectiveness is underscored by recent data indicating that the use of a 5 mg NSE reactive barrier can effectively inhibit nearly all harmful emissions released into indoor environments for at least 48 hours, thereby enhancing safety and reducing environmental impact. This is especially pertinent for pharmaceutical lab managers who must ensure a secure working environment while minimizing exposure to hazardous substances.

Case studies, including the analysis of leachate concentrations from various barrier and bulb combinations using the Toxicity Characteristic Leaching Procedure (TCLP), reveal critical insights into the environmental ramifications of harmful discharge lighting. The findings demonstrate that leachable heavy metals were more prevalent in spent bulbs compared to new ones, while selenium leachate concentrations remained below detection limits, affirming the minimal environmental risk associated with the application of nano-selenium in reactive barriers.

Recent advancements in gas discharge lighting technology, particularly concerning mercury vapor lamps, have focused on enhancing efficiency and reducing harmful emissions. Authorities within the illumination sector emphasize the importance of these developments, noting that innovative designs and materials can yield products tailored for different phases of the bulb lifecycle. For instance, the integration of reactive barriers not only mitigates exposure to harmful gases but also boosts the overall efficiency of the lighting solutions.

Professor Steven Hamburg remarked, "The technical contributions of Indrek Kulaots, Aihui Yan, Shin Bowers, and myself are gratefully acknowledged," highlighting the collaborative efforts that have propelled this technology forward.

Practical applications of discharge fixtures, specifically mercury vapor lamps, in street lighting exemplify their efficiency in providing reliable illumination for urban environments. As cities continue to seek eco-friendly lighting alternatives, the role of mercury vapor lamps remains crucial, particularly in scenarios where intense brightness is essential.

In conclusion, the mercury vapor lamp as a type of discharge fixture signifies a pivotal innovation in the realm of industrial and street illumination, merging efficiency, durability, and advancements addressing both performance and ecological challenges. This renders them a significant consideration for pharmaceutical lab managers.

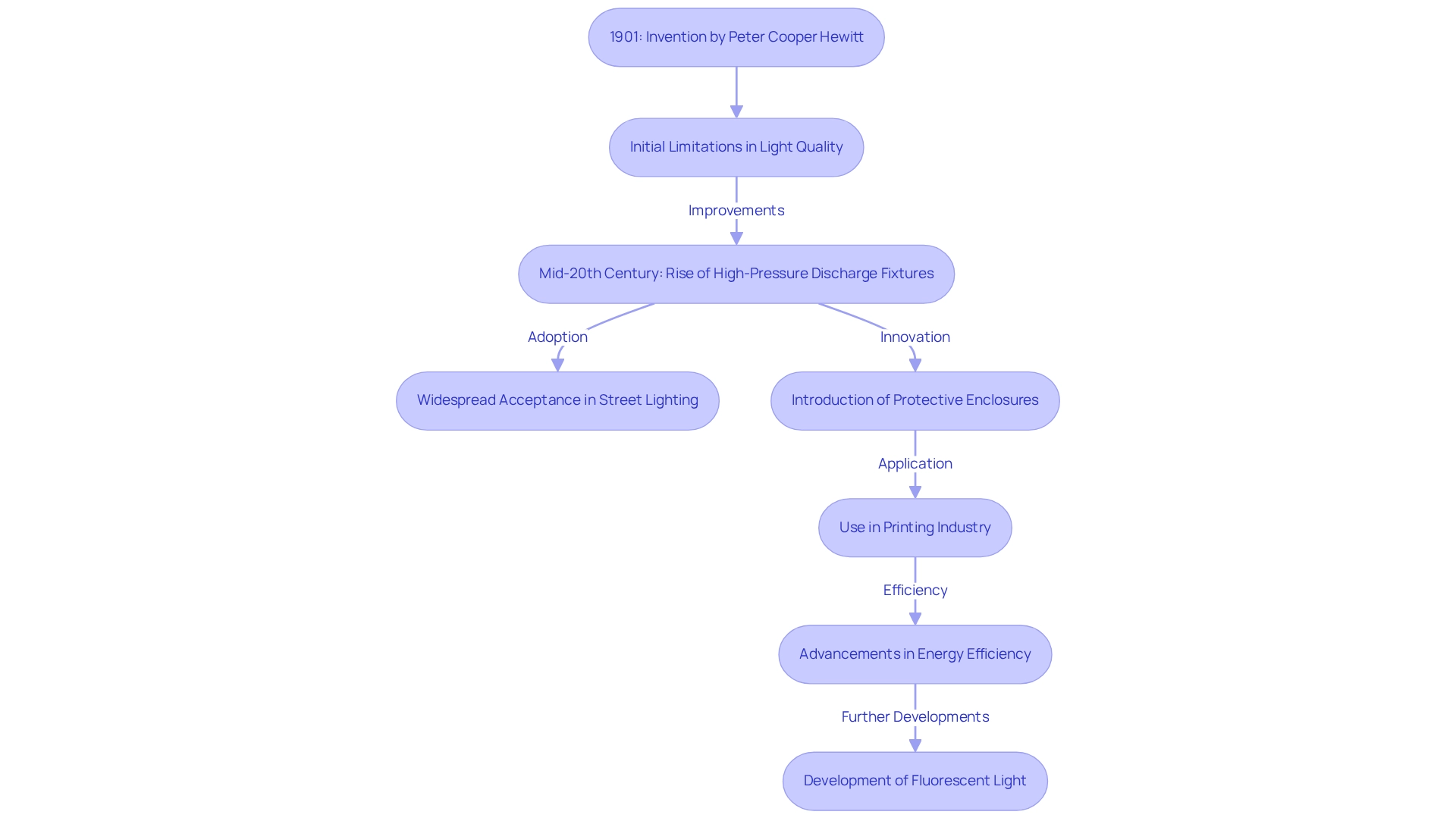

The History of Mercury Vapor Lamps

The vapor light source, developed in 1901 by American engineer Peter Cooper Hewitt, represents a pivotal moment in the evolution of artificial lighting technology. This innovative light source, known as the mercury vapor lamp, was among the first to employ vaporized quicksilver for illumination, setting the stage for future advancements in lighting. Initially, the quality of light produced by these devices was limited, restricting their applications.

As design and efficiency improved, high-pressure discharge fixtures emerged, gaining widespread acceptance in street lighting and industrial settings by the mid-20th century.

The historical significance of the mercury vapor lamp cannot be overstated; it marked a notable progression from traditional lighting methods, facilitating the development of more complex electric lighting systems. As Peter Cooper Hewitt remarked, "I created a light source based on gaseous discharge, leading to significant advancements such as the fluorescent light." This invention laid the foundation for further innovations, including the fluorescent light, which dramatically reshaped the lighting industry.

Throughout the years, various milestones have highlighted the evolution of fixtures, particularly those utilizing mercury vapor lamp technology. For instance, the introduction of protective enclosures and exhaust systems in the printing industry allowed for the safe application of these devices in curing inks, showcasing their versatility and adaptability. Moreover, advancements in technology have led to improved energy efficiency and light quality, establishing gas discharge lights as essential components in numerous applications.

As we trace the history of discharge fixtures, it becomes apparent that each innovation builds upon its predecessor, reflecting a continuous pursuit of enhanced lighting solutions. From Hewitt's original concept to modern applications, the progression of gas discharge fixtures illustrates the dynamic nature of lighting technology and its profound impact on both industrial and everyday environments.

How Mercury Vapor Lamps Work

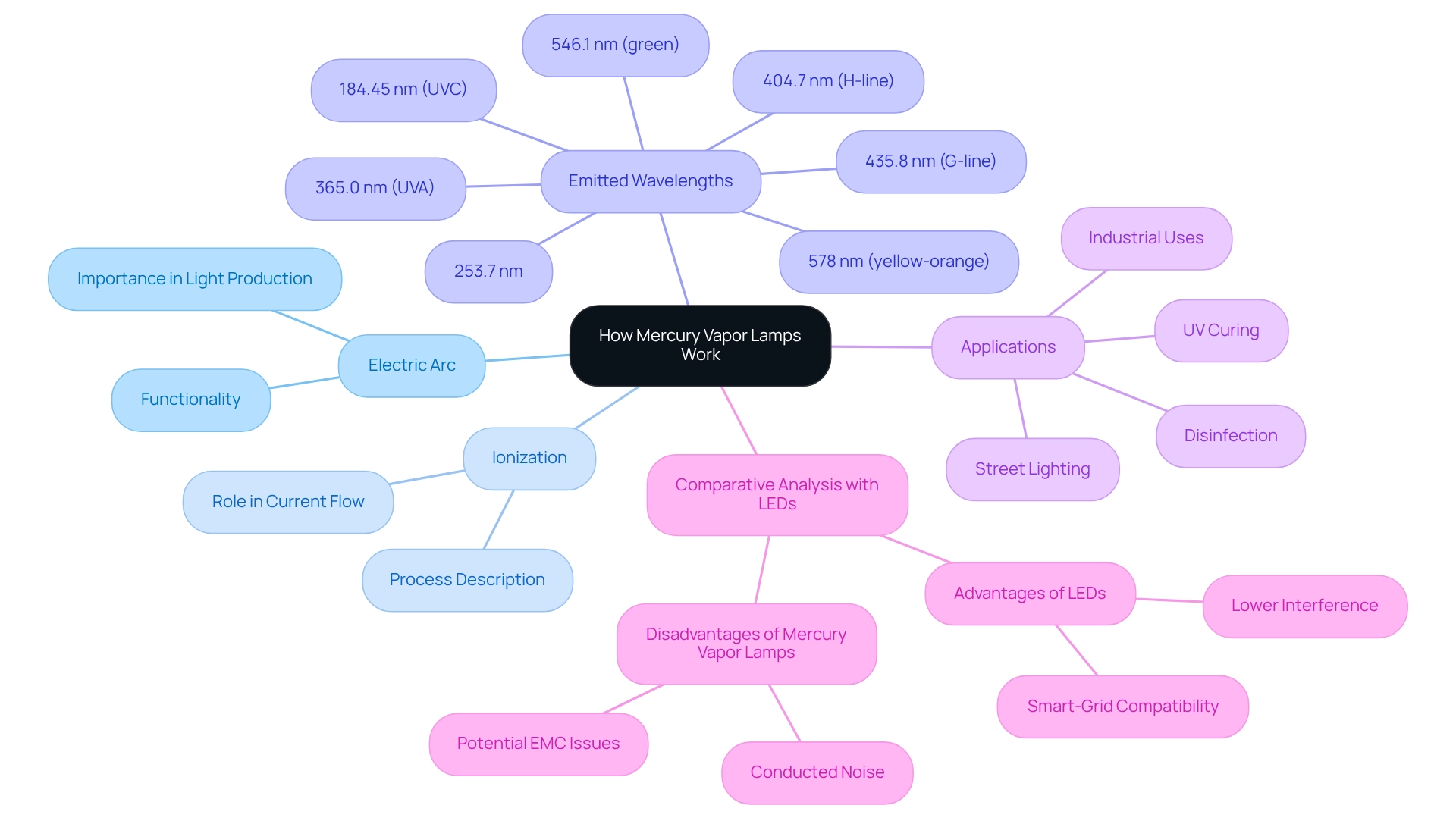

Mercury vapor lamps function by generating an electric arc between two electrodes within a sealed glass tube filled with vapor. Upon activation, a high voltage is applied, ionizing the mercury gas and allowing current to flow. This ionization generates ultraviolet (UV) light, which energizes a phosphor coating on the fixture's interior, resulting in the emission of visible light.

The high pressure maintained within the device significantly enhances its efficiency and brightness, establishing it as a favored choice for various applications.

The operational principles of gas discharge lamps rely on electric arc technology, which is crucial for their functionality. Specialists in the field emphasize that this technology facilitates the efficient production of light through the excitation of specific atoms. The most intense peaks of the emission line spectrum for mercury (Hg) occur at distinct wavelengths, including:

- 184.45 nm (UVC)

- 253.7 nm

- 365.0 nm (UVA)

- 404.7 nm (H-line)

- 435.8 nm (G-line)

- 546.1 nm (green)

- 578 nm (yellow-orange)

These wavelengths are particularly valuable in applications such as disinfection and UV curing, where precise UV output is critical. Peter Cooper Hewitt noted, "One characteristic of the mercury-based fixture is that in addition to certain wavelengths of visible light, it emits large amounts of ultraviolet light," underscoring the significance of these devices across various applications.

Recent research highlights the efficiency ratings of mercury vapor lamp sources relative to other illumination technologies. Although they produce conducted noise that may disrupt power line communication (PLC) channels, studies reveal that their interference levels typically remain within safe limits for most applications. Nevertheless, the potential for exceeding electromagnetic compatibility (EMC) levels in the broadband spectrum necessitates careful consideration when integrating these devices into smart-grid environments.

Notably, Light Emitting Diodes (LEDs) are recommended as a more advantageous illumination solution for smart-grid applications due to their reduced interference.

Real-world applications of mercury vapor lamp fixtures demonstrate their efficacy in diverse settings, from street lighting to industrial uses. For example, medium-pressure vapor sources can be optimized to emit either UV-A or UV-C light, showcasing their versatility. The case study titled "Conclusion on Mercury Vapor Light Interference" stresses the importance of considering the noise levels produced by these devices concerning smart-grid applications.

As the demand for effective illumination solutions continues to grow, understanding the operational mechanisms and performance characteristics of mercury vapor lamps remains essential for experts in the field.

Benefits of Mercury Vapor Lamps

Mercury vapor lamps exhibit exceptional luminous efficiency, typically ranging from 35 to 55 lumens per watt. This high efficiency results in bright, clear illumination, making them particularly suitable for outdoor and industrial applications. Their extended operational life significantly diminishes the need for frequent replacements, leading to considerable maintenance cost savings over time.

This durability proves advantageous in environments such as street illumination and sports venues, where consistent and reliable lighting is essential.

In industrial settings, the advantages of fluorescent lighting extend beyond mere illumination. They effectively light expansive areas, crucial for safety and productivity in large workspaces. Moreover, the cost savings associated with their prolonged lifespan can be substantial; for example, the estimated yearly expenses for a typical multiplex usage pattern are around $1,000, underscoring the economic benefits of investing in these lighting solutions.

Expert opinions highlight the growing recognition of these light sources across various industries. James Gardiner noted a global resistance to fluorescent lights, particularly among small cinemas utilizing models like the NC900/1000, amid discussions regarding potential prohibitions in the EU by 2025. This contemporary viewpoint contributes to the ongoing dialogue about the challenges and considerations facing the industry.

Despite these regulatory concerns, mercury vapor lamps' ability to deliver high-quality illumination while minimizing operational costs positions them as a preferred choice for numerous applications.

JM Science Inc. distinguishes itself in the market through its commitment to quality and customer support, as demonstrated in the case study titled "Market Positioning and Customer Support." The company consistently updates its product offerings and nurtures strong relationships with leading manufacturers, ensuring it meets the evolving needs of the scientific community. As the industry advances, the continued application of mercury vapor lamps remains a topic of discussion; however, their advantages in efficiency and cost-effectiveness render them a valuable asset in both industrial and outdoor illumination contexts.

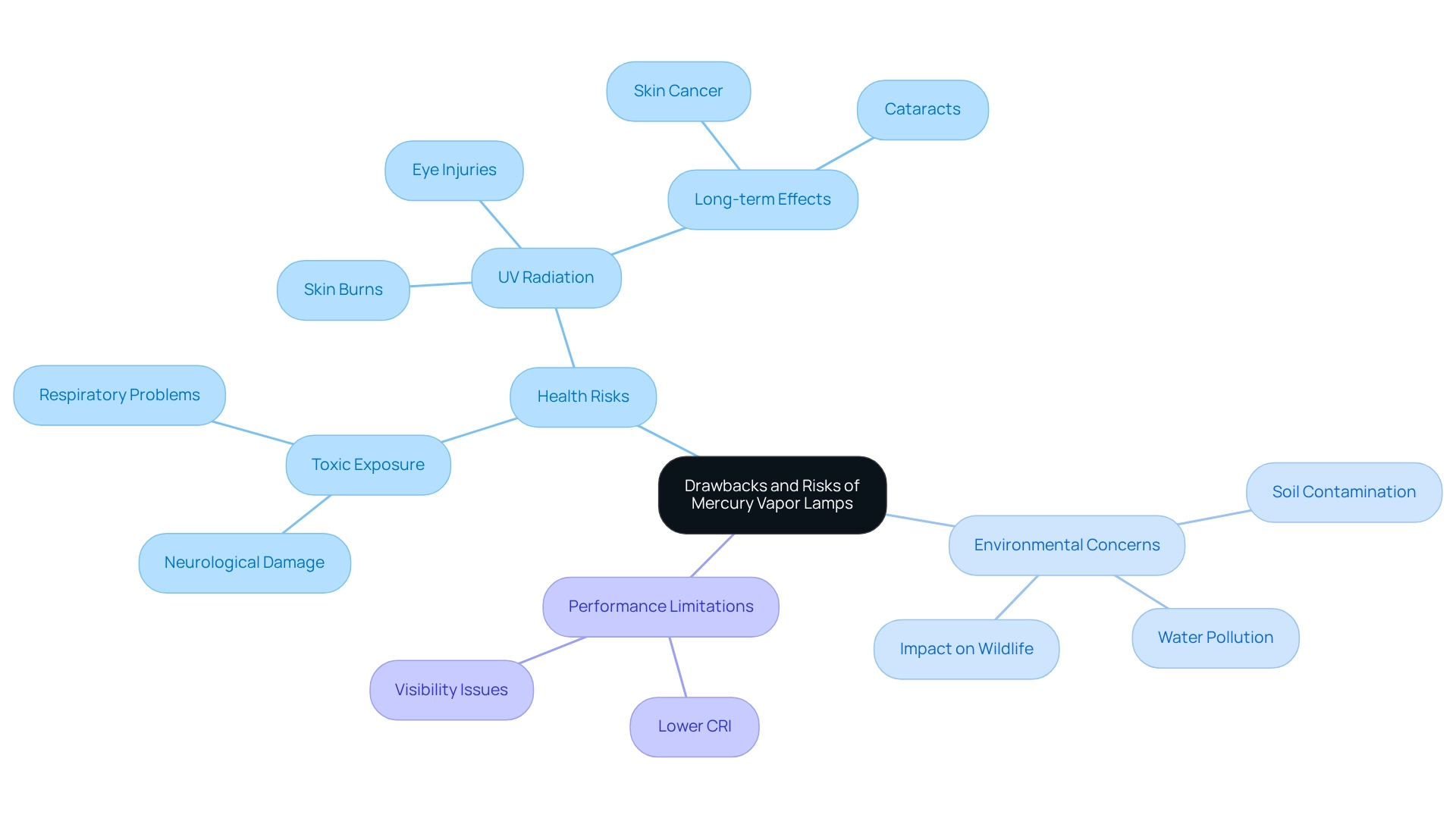

Drawbacks and Risks of Mercury Vapor Lamps

While mercury vapor lamps offer certain advantages, they also present considerable disadvantages that warrant careful evaluation. A primary concern with mercury vapor lamps is their toxic content, which poses significant environmental and health risks if the light fixture is damaged. Exposure to this heavy metal can lead to various health issues, including neurological damage and respiratory problems, particularly in workplace settings.

For instance, a recent study highlighted the hazards of workplace exposure at recycling facilities, with Shi DS emphasizing the risks associated with handling these items. This underscores the urgent need for stringent safety protocols to mitigate such dangers.

Furthermore, gas discharge sources emit ultraviolet (UV) radiation, which can cause skin burns and eye injuries with prolonged exposure. This risk is especially concerning in environments where individuals may be exposed to the light for extended periods, such as laboratories and industrial settings. The health effects of UV radiation are well-documented, with potential long-term consequences that include skin cancer and cataracts.

In addition to health risks, mercury vapor lamp sources exhibit a lower color rendering index (CRI) compared to other lighting technologies. This limitation can negatively impact visibility and color perception, which is crucial in applications requiring precise color differentiation, such as pharmaceutical laboratories and quality control processes.

Environmental concerns related to hazardous substances, particularly from mercury vapor lamps in lighting technology, are also significant. Improper disposal of broken light fixtures can lead to toxic contamination of soil and water, posing threats to ecosystems and human health. Case studies indicate that even small amounts of mercury can have detrimental effects on wildlife and plant life, highlighting the importance of responsible handling and disposal practices.

For example, the case study titled "Impact of Light on Strawberry Production" illustrates how manipulating light intensity and spectral composition can improve strawberry quality and yield, emphasizing the need for further research on light effects in fruit production.

Recent advancements in LED technology provide a safer alternative to traditional gas lights, particularly in regulated plant production environments. Research has focused on the effects of light spectra on fruit quality and secondary metabolism, demonstrating that LED technology can optimize growth while minimizing health and environmental risks.

Moreover, air quality issues related to hazardous discharge fixtures are underscored by data revealing average levels of xylenes at 12.3 μg/m³, which can be exacerbated by the use of these devices.

In conclusion, while these discharge bulbs may be utilized across various applications, the associated health hazards, ecological impacts, and performance limitations underscore the necessity for thorough assessment and consideration of safer alternatives.

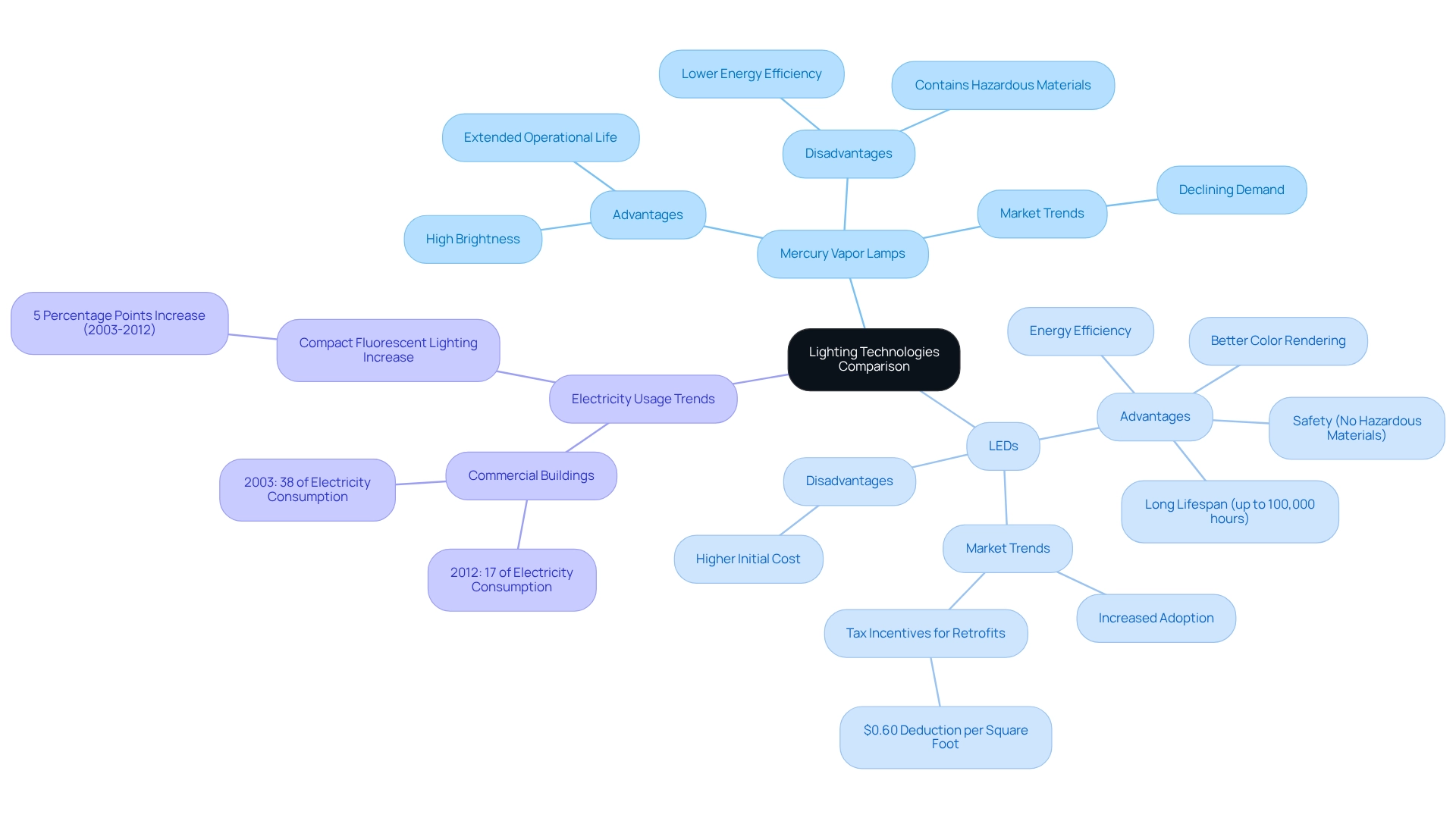

Mercury Vapor Lamps vs. Other Lighting Technologies

Mercury vapor lamp light sources present a unique set of benefits and drawbacks when compared to fluorescent and LED fixtures. One of the primary advantages of these gas discharge lights is their high brightness and extended operational life, rendering them suitable for large outdoor areas where intense illumination is essential. However, their energy efficiency is significantly lower than that of LEDs, which can last up to 100,000 hours while consuming considerably less power.

The transition from vapor to LED illumination has been further encouraged by new tax incentives introduced in 2019. These incentives allow businesses to benefit from deductions based on energy savings achieved through such retrofits, specifically qualifying for a $0.60 deduction per square foot.

In terms of color rendering, LEDs surpass vapor lamps by offering a more accurate representation of colors, which is vital in numerous applications. Additionally, LEDs do not contain hazardous materials like mercury, making them a safer choice for both the environment and public health. Market trends indicate a substantial shift towards energy-efficient illumination solutions, with LED technology leading the charge.

In 2012, illumination accounted for 17% of electricity usage in commercial structures, a notable decrease from 38% in 2003. This decline underscores the increasing adoption of more efficient illumination technologies. The rise in compact fluorescent illumination usage by five percentage points during this timeframe further highlights this trend. As companies increasingly recognize the financial and ecological advantages of LED upgrades, the demand for mercury-based fixtures is expected to decline.

In conclusion, while mercury vapor lamps may still be favored for specific high-intensity applications, the advantages of LEDs regarding energy efficiency, durability, and safety are driving a significant transformation in the lighting sector. As Greg Keoleian, co-director of the Center for Sustainable Systems at the School for Environment and Sustainability, notes, the implications of these trends extend to residential structures where T8 fixtures and troffers are commonly utilized. Moreover, a case study on the tax benefits of LED retrofits illustrates how businesses can achieve financial gains from these transitions, reinforcing the case for energy-efficient solutions.

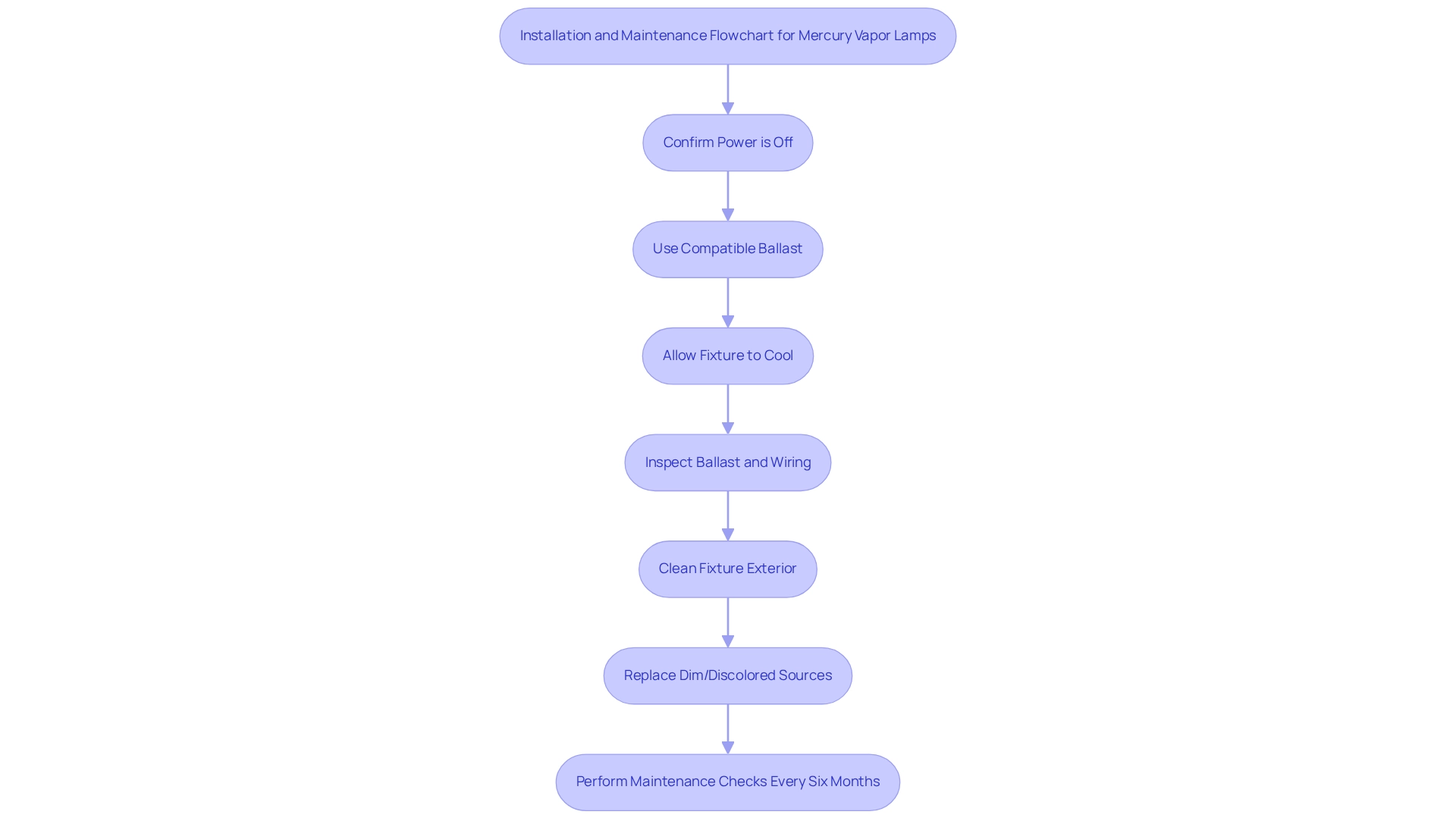

Installation and Maintenance Tips for Mercury Vapor Lamps

To successfully set up a gas discharge light, begin by confirming that the power source is completely switched off. It is crucial to utilize a compatible ballast designed to regulate the electrical current, as these fixtures operate at specific voltage levels. When replacing an existing light fixture, allow it to cool down sufficiently before handling to prevent burns or injuries.

Regular maintenance is vital for the optimal performance and longevity of mercury vapor lamps. This includes routinely inspecting the ballast and wiring for any signs of wear or damage, which can adversely affect the light's efficiency. Additionally, cleaning the fixture's exterior is essential to ensure maximum light output and to prevent dust accumulation that may hinder performance.

It is advisable to replace light sources that exhibit signs of dimming or discoloration, as these may indicate a decline in light quality and efficiency. Industry experts recommend performing maintenance checks every six months to verify that all components are functioning correctly and to address any potential issues before they escalate. Notably, signs of detrimental UV exposure can take several hours to appear, underscoring the importance of vigilance during maintenance.

Practical examples highlight common maintenance challenges faced by facilities using high-intensity discharge lights. For instance, in a large retail environment, a broken outer bulb resulted in the inner tube emitting intense UV radiation, posing health risks to employees. This incident emphasizes the necessity of regular inspections and prompt action when any damage related to the mercury vapor lamp is identified.

The health risks associated with such incidents are significant, as exposure can lead to eye and skin burns, headaches, and nausea.

Moreover, recent proposed changes aim to reduce the release of harmful substances and energy costs, underscoring the importance of proper maintenance and installation practices in accordance with regulatory standards. By adhering to these best practices for installation and maintenance, facilities can enhance the safety and efficiency of their gas discharge lighting systems, ultimately leading to a more effective illumination solution. As noted by A.J. Han, understanding the implications of utilizing these fixtures is crucial, particularly regarding their impact on power lines and overall energy management.

In terms of financial efficiency, the non-rounded net reduction in annualized average expenses is projected to be $642, or $5.84 per stakeholder, highlighting the economic benefits of employing gas-discharge lights across various applications.

Environmental Considerations and Disposal of Mercury Vapor Lamps

The disposal of mercury vapor lamps presents a critical environmental concern due to their mercury content, which poses significant risks if not managed properly. It is essential that these lights are never discarded with regular waste. Instead, they should be taken to designated recycling centers equipped to handle hazardous waste.

Numerous local authorities have established recycling initiatives specifically for fluorescent and mercury-containing bulbs. These initiatives enable safe disposal and significantly reduce environmental impact. Furthermore, the lighting sector should develop accessible collection programs for bulb waste and label items with hazardous content alerts to enhance recycling efforts.

Complying with local guidelines regarding the disposal of mercury vapor lamps is crucial for ensuring both safety and environmental protection. Improper disposal can lead to severe mercury pollution, with data indicating that approximately 14.2 million fluorescent bulbs, containing an estimated 23 kg of mercury, are expected to be discarded. This underscores the urgent need for effective recycling initiatives to mitigate potential hazards.

Expert insights emphasize the importance of awareness and adherence to hazardous waste management laws. A study by the EcoWaste Coalition revealed that the Philippines generates around 50 million pieces of lighting waste annually, with a significant portion disposed of improperly, resulting in environmental and health hazards. The findings highlighted the necessity for government intervention, including the establishment of collection initiatives for light waste and compliance with global accords such as the Minamata Convention on Mercury.

In the United States, various recycling initiatives have been implemented to address the disposal of mercury vapor lamps. These programs not only promote proper disposal methods but also educate the public on the environmental consequences of improper disposal. Notably, disposal rates of harmful substances in fluorescent bulbs in South Korea are lower than those in the USA and China, indicating varying effectiveness of recycling programs across nations.

Real-world examples of successful recycling initiatives illustrate the effectiveness of community engagement in reducing hazardous waste and protecting the environment. By participating in these programs, individuals and organizations can contribute to a safer and more sustainable future. As Claudio Raposo pointed out, the effects of exposure to the toxic element are severe, with historical instances such as the Minamata disease highlighting the urgent need for responsible disposal practices.

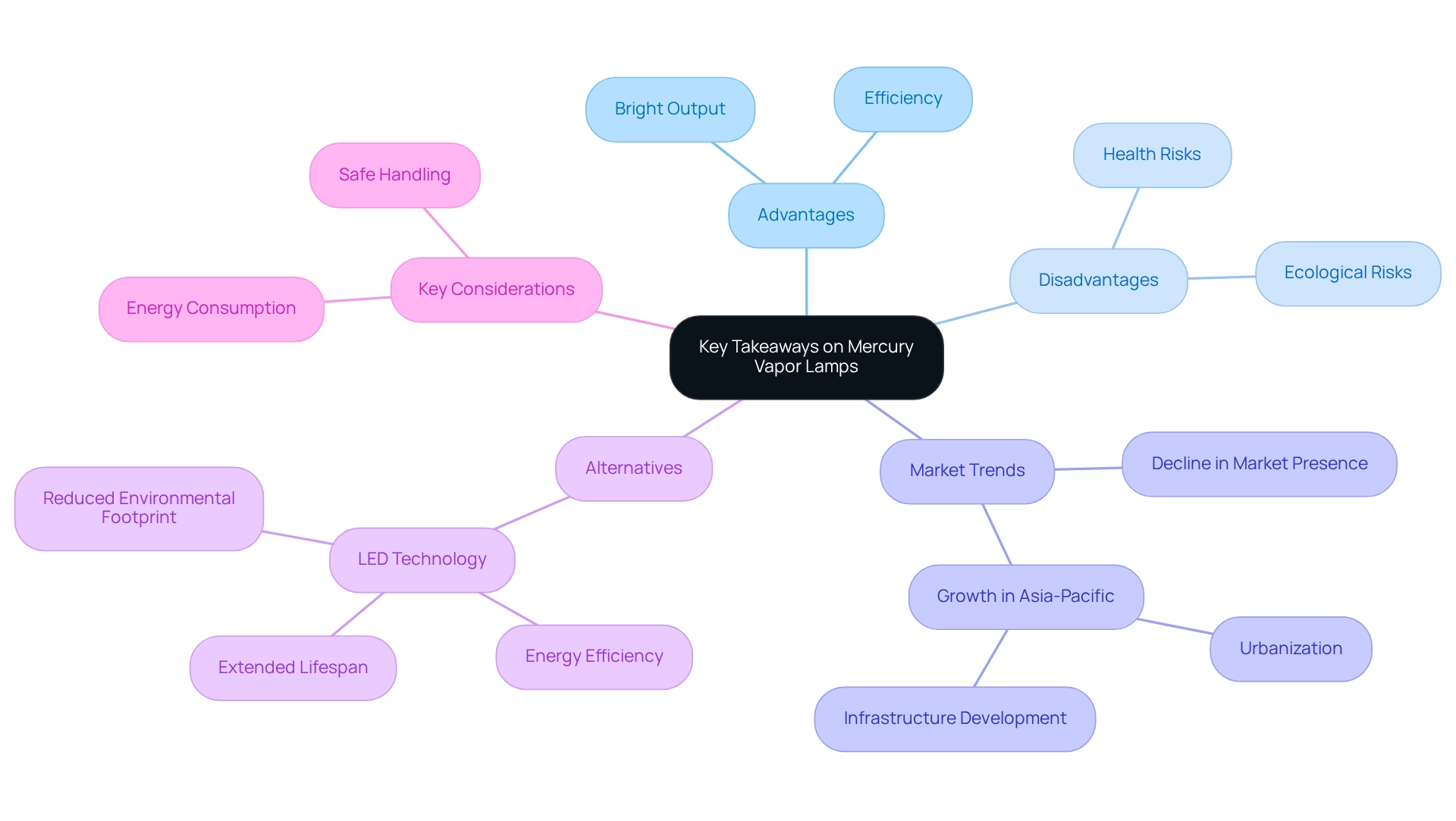

Key Takeaways on Mercury Vapor Lamps

Mercury vapor lamps represent a pivotal lighting technology, distinguished by their bright output and efficiency across various applications. These fixtures function by transmitting an electric current through a mercury vapor lamp, producing high-intensity illumination that proves especially beneficial for outdoor and industrial settings. However, despite their advantages, these gas discharge devices pose significant ecological and health risks due to the toxic nature of mercury.

Proper installation, usage, and disposal methods are essential to mitigate these hazards and ensure responsible application.

As we approach 2025, the landscape for discharge fixtures is evolving. While they continue to deliver substantial illumination, the increasing focus on sustainability and energy efficiency has resulted in a decline in their overall market presence. Notably, the Asia-Pacific region is projected to experience significant growth driven by urbanization and infrastructure development, particularly in India and China.

Nevertheless, niche applications still exhibit limited demand for these light sources, particularly in scenarios that require high-intensity illumination. This trend underscores the importance of understanding both the operational benefits and the environmental impacts associated with specific gas technologies.

Key considerations for utilizing these lighting sources include their energy consumption and the imperative for careful handling due to the hazardous materials involved. As the illumination sector transitions toward more sustainable solutions, alternatives such as LED technology are emerging as viable options. LEDs provide enhanced energy efficiency, extended lifespans, and a reduced environmental footprint, making them an attractive choice for a variety of applications.

As Oleg Shchekin remarked, "As novel as LEDs may seem, the related discoveries and technology development have over a century-long history, with generations of researchers working on fundamental exploration without which the present day successes would not have been possible."

Practical examples illustrate the shift from mercury-based illumination to LED technology, showcasing successful applications across different industries. These transitions not only enhance energy efficiency but also align with contemporary sustainability objectives. Industry leaders emphasize that while certain gas fixtures have played a crucial role in the history of illumination, the future lies in innovative technologies that prioritize safety and environmental responsibility.

The case study titled 'Future Outlook for Energy-Efficient Illumination Technologies' offers insights into emerging trends and innovative applications poised to transform the illumination industry.

In conclusion, while the use of mercury vapor lamps presents specific advantages, their drawbacks and the changing landscape of illumination technology necessitate a comprehensive evaluation of their application. It is also crucial to note that the market value discussed does not encompass revenues from resales along the supply chain. As the industry advances, remaining informed about the latest trends and alternatives will be vital for making responsible lighting choices.

Conclusion

Mercury vapor lamps have undeniably made a significant mark in the lighting industry, delivering bright, efficient illumination for various applications, particularly in outdoor and industrial settings. Their operational mechanisms and historical significance underscore their role as a foundational technology that paved the way for modern lighting solutions. However, the environmental and health risks associated with mercury content, including potential exposure and improper disposal, must not be overlooked.

As the industry shifts towards sustainability, the advantages of alternative lighting technologies like LEDs become increasingly compelling. LEDs not only provide superior energy efficiency and longer lifespans but also eliminate the hazardous materials present in mercury vapor lamps. This growing emphasis on eco-friendly solutions reflects a broader commitment to reducing environmental impact and enhancing public safety.

In conclusion, while mercury vapor lamps continue to serve niche markets, the future of lighting technology is clearly leaning towards innovations that prioritize both efficiency and safety. Understanding the implications of using mercury vapor lamps, alongside awareness of emerging alternatives, is essential for making informed decisions in lighting technology. As the landscape evolves, embracing sustainable practices and responsible usage will be crucial in shaping a safer and more efficient future for the industry.