Overview

This article delves into the meaning and applications of Near-Infrared (NIR) technology, with a particular focus on its roles in pharmaceuticals, agriculture, and food science. NIR spectroscopy stands out as a vital analytical technique that facilitates rapid, non-destructive analysis. This capability not only enhances quality control processes but also ensures the authenticity and safety of products across a diverse range of industries. By leveraging NIR technology, organizations can significantly improve operational efficiency and product integrity, making it an indispensable tool in modern scientific applications.

Introduction

The world of spectroscopy is undergoing a transformative shift, particularly through the lens of Near-Infrared Spectroscopy (NIRS) and its applications across various industries. Operating within the near-infrared region of the electromagnetic spectrum, this powerful analytical technique facilitates rapid, non-destructive analysis, establishing itself as indispensable in sectors such as pharmaceuticals, agriculture, and food science. As technological advancements continue to reshape the landscape, the integration of NIR with miniaturized devices and artificial intelligence enhances its precision and efficiency. The implications of these developments are profound, promising to revolutionize quality control processes and ensure the safety and authenticity of products. This article delves into the key concepts, applications, and innovations of NIR spectroscopy, underscoring its critical role in modern analytical practices and its potential to drive significant advancements across multiple fields.

Defining Near-Infrared Spectroscopy: Key Concepts and Principles

Near-Infrared Spectroscopy (NIRS) stands as a formidable analytical technique within the near-infrared region of the electromagnetic spectrum, specifically ranging from 780 nm to 2500 nm. This method is fundamentally based on the principle that molecules absorb light at distinct wavelengths, corresponding to their vibrational modes. The resultant absorption produces overtone and combination bands, which can be detected and analyzed to determine the chemical composition of a sample.

Mastering these essential concepts is crucial for effectively employing NIR methods across various sectors, particularly in pharmaceuticals, agriculture, and food science.

Recent advancements in NIR technology have markedly enhanced its application within the pharmaceutical industry. For example, the advent of miniaturized spectrometers and hyperspectral imaging has expanded the scope of NIRS, facilitating more precise and efficient quality control processes in drug manufacturing. This enhancement is particularly critical, given that approximately 11% of medications sold in emerging markets are counterfeit, resulting in an alarming 144,000 deaths annually.

The ability of NIR analysis to provide rapid and non-destructive evaluations renders it an indispensable tool in tackling this issue, ensuring the authenticity and quality of pharmaceutical products.

A significant case study titled "Advances in Near Infrared Techniques and Related Computational Methods" illustrates the collaborative efforts within the scientific community to investigate the diverse applications of NIR methods. This initiative culminated in a Special Issue in the Molecules journal, featuring 30 publications that explored various applications, particularly in pharmaceuticals and medical fields. The positive responses to this initiative underscore the growing significance of NIR analysis in advancing analytical approaches and innovations.

Moreover, the importance of NIR spectroscopy in pharmaceuticals is highlighted by its role in method validation, which is essential for developing fit-for-purpose analytical methods. As Ivy Das Sarkar aptly notes, "Natural deep eutectic solvents (NADESs) are environmentally friendly green solvents and hold great promise in the pharmaceutical industry." This statement emphasizes the innovative methodologies being explored alongside advancements in NIR technology.

As the industry evolves, the integration of NIR methods into routine quality control processes is becoming increasingly prevalent, reflecting a broader trend toward innovation in pharmaceutical manufacturing.

In conclusion, a thorough understanding of the principles and applications of Near-Infrared Spectroscopy is vital for professionals in the pharmaceutical sector. As advancements continue, its potential to enhance quality control and ensure the safety of pharmaceutical products will only grow, solidifying its role as an essential component of contemporary analytical practices.

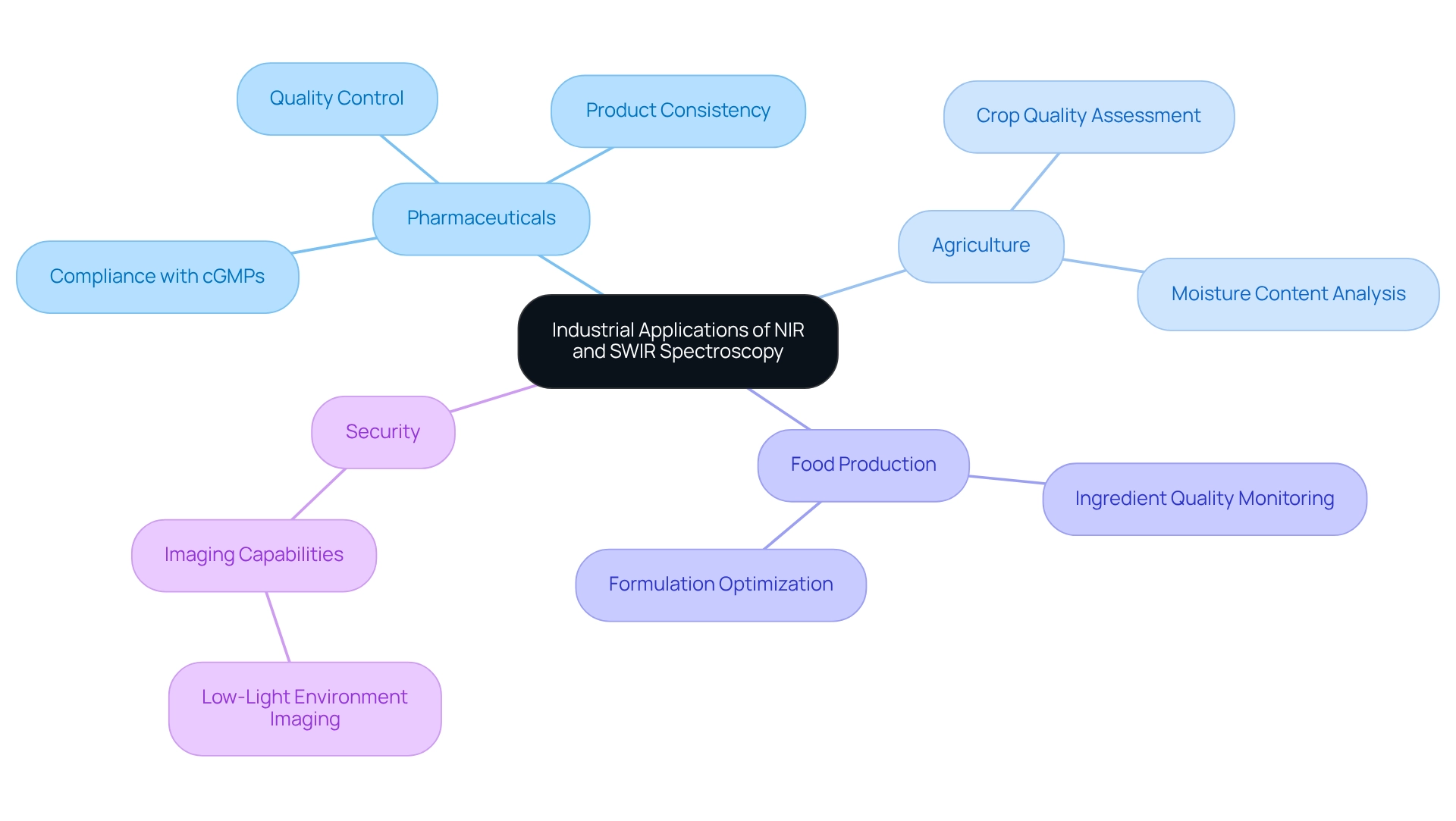

Industrial Applications of NIR and SWIR Spectroscopy: Transforming Industries

The techniques known as NIR, meaning Near-Infrared, and SWIR (Short-Wave Infrared) have revolutionized various sectors by enabling swift, non-destructive analysis. In the pharmaceutical industry, the significance of NIR methods is profound, as they play a crucial role in quality control, ensuring that raw materials meet stringent specifications and that final products maintain consistency. This is particularly important given the FDA's ongoing efforts to update regulations and enhance production methods, as highlighted by the introduction of current Good Manufacturing Practices (cGMPs) for the 21st century, which underscore the importance of advanced analytical techniques, including NIR analysis.

The application of NIR analysis extends beyond pharmaceuticals; it is also vital in agriculture for assessing crop quality and moisture content, as well as in food production, where it aids in monitoring ingredient quality and optimizing formulations. Notably, advancements in SWIR technology are gaining traction in security and surveillance, significantly improving imaging capabilities in low-light environments.

Recent case studies illustrate the effectiveness of NIR analysis within the pharmaceutical sector. For example, a study titled 'Identification and Qualification of Pharmaceutical Products' demonstrated that the implementation of NIR spectroscopy enhances the industry's capacity to ensure product consistency and compliance. The establishment of spectral libraries and the application of mathematical criteria for product identification have proven essential, with quantification of active compounds revealing a relative standard error of prediction below 1.55%. This underscores the accuracy of methods associated with NIR analysis in pharmaceutical applications.

As industries increasingly adopt NIR and SWIR methods, the impact on quality control becomes increasingly apparent. The ability to differentiate among various formulations, such as paracetamol from different manufacturers using potentiometric multisensor systems, exemplifies the precision these methods offer. Expert opinions affirm that integrating NIR and SWIR into industrial applications not only enhances efficiency but also improves the accuracy of analyses, ultimately leading to greater safety and efficacy in pharmaceutical products.

Robbe C Lyon emphasizes that this trend is expected to continue evolving, with NIR and SWIR technologies becoming integral to quality assurance processes across multiple sectors.

Advantages of NIR and SWIR Spectroscopy: Enhancing Efficiency and Accuracy

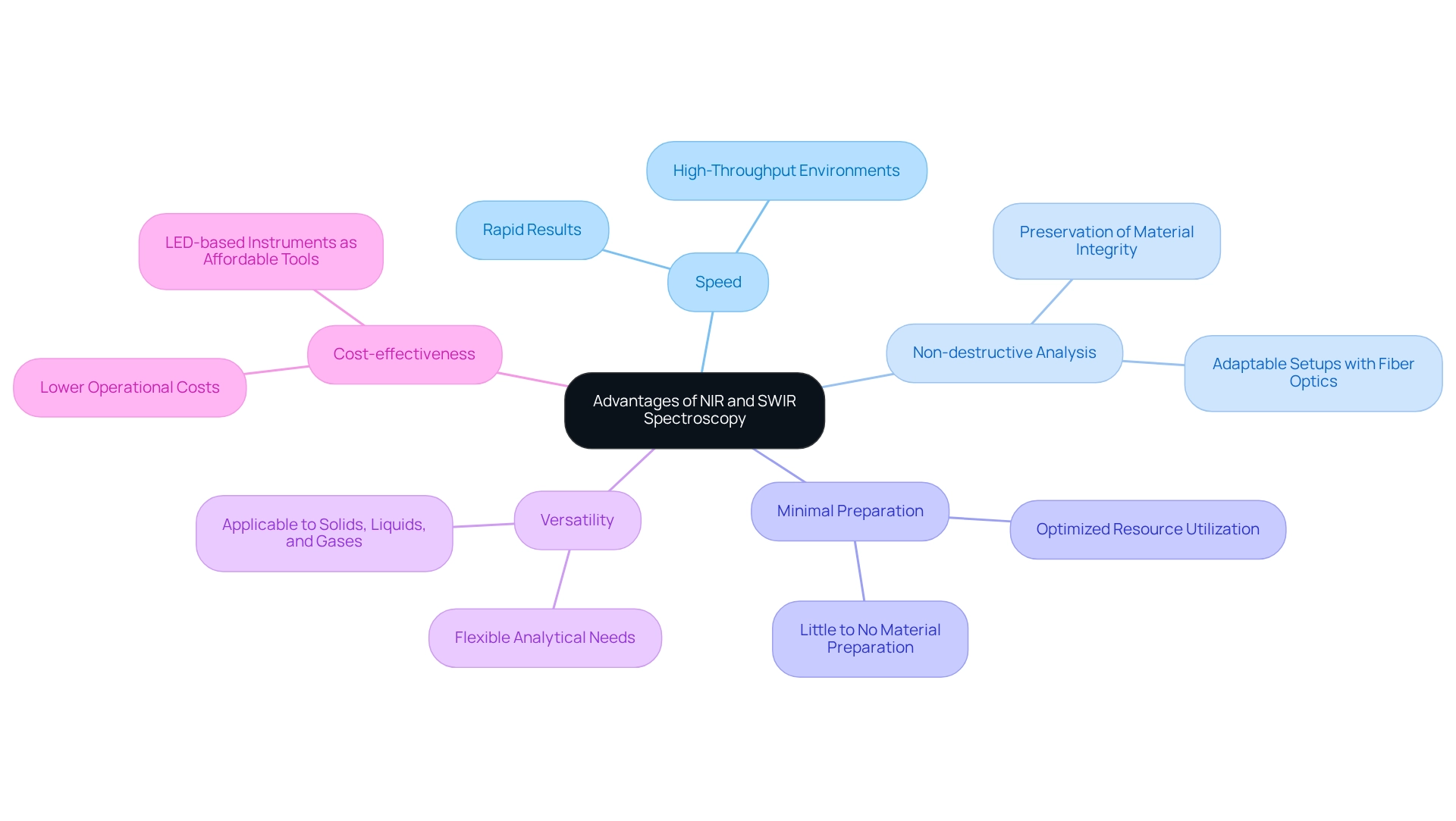

NIR and SWIR techniques present a multitude of advantages that significantly enhance laboratory operations.

- Speed: These methods yield rapid results, often within a minute, making them indispensable in high-throughput environments where time is of the essence.

- Non-destructive analysis: A key feature of NIR and SWIR is their ability to evaluate materials without altering them, thereby preserving their integrity for subsequent testing. As noted by Silvia Serranti, this non-contact capability facilitates adaptable setups, employing fiber optics to efficiently power and collect spectral responses.

- Minimal preparation of materials: In contrast to traditional analytical methods, NIR requires little to no material preparation. This efficiency not only saves valuable time but also optimizes resource utilization within laboratory settings.

- Versatility: NIR and SWIR techniques are applicable to a diverse array of materials—solids, liquids, and gases—rendering them exceptionally flexible for various analytical needs.

- Cost-effectiveness: The reduction in both preparation and analysis time leads to lower operational costs, establishing these methods as economically advantageous for laboratories. Notably, LED-driven devices are recognized as the most affordable tools, further emphasizing their significance in this context.

Recent advancements in deep learning frameworks have further accelerated the speed and efficiency of NIR analysis, which is vital for comprehending nir meaning, enabling precise quality assessments of solid materials, including pharmaceuticals and food products. The swift detection capabilities of NIR are primarily due to its non-contact nature and the utilization of fiber optics for adaptable analysis configurations. This adaptability fosters high detection speeds and the capacity to perform multiple assessments on the same sample without interference from color variations.

Moreover, case studies, such as the implementation of Bootstrapping Soft Shrinkage (BOSS) for feature selection in olive oil adulteration detection, highlight NIR's effectiveness in identifying informative wavenumbers, further showcasing its analytical strength.

Differences in NIR spectra based on particle sizes have also been documented, with larger particles exhibiting higher absorbance due to variations in light penetration and reflection properties. With LED-based instruments emerging as the most cost-effective solution within the NIR spectrum, laboratories can realize significant cost savings while simultaneously enhancing their analytical capabilities.

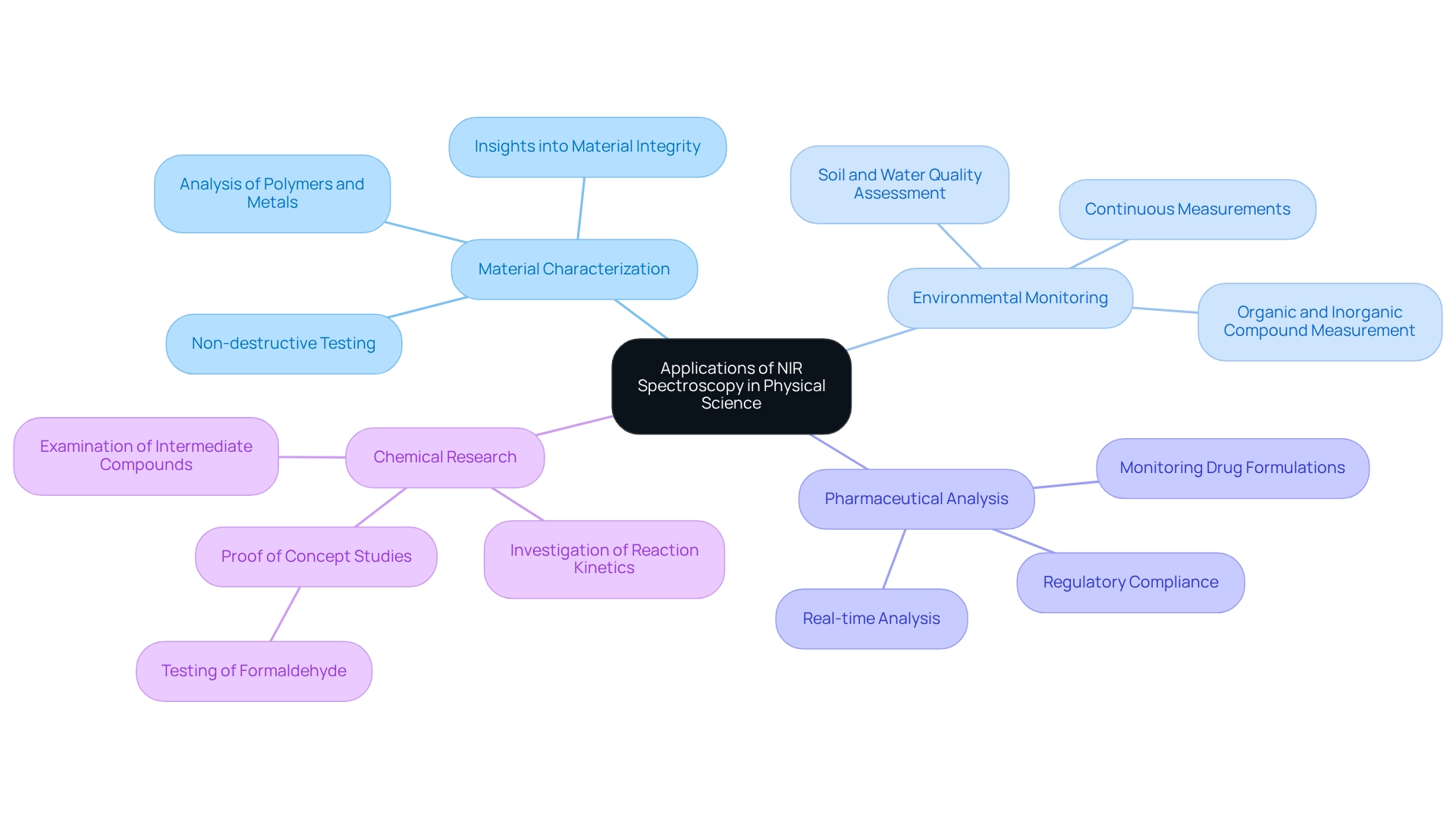

Applications of NIR Spectroscopy in Physical Science: A Comprehensive Overview

NIR analysis plays a pivotal role across various domains of physical sciences, showcasing its versatility and importance in advancing research and development. Its key applications are numerous and impactful:

-

Material Characterization: NIR spectroscopy is instrumental in analyzing the composition and properties of materials, including polymers and metals. This technique allows for non-destructive testing, providing crucial insights into material integrity and performance.

-

Environmental Monitoring: The innovation is essential for assessing soil and water quality, enabling the measurement of both organic and inorganic compounds. Recent advancements in NIR analysis have enhanced its capability to deliver continuous measurements, which are vital for effective environmental management and sustainability initiatives. This aligns with the necessity of continuous measurements enabled by NIR technology for a circular economy, emphasizing its relevance in modern environmental practices.

-

Pharmaceutical Analysis: In the pharmaceutical sector, NIR techniques are utilized to monitor the composition of drug formulations, ensuring compliance with stringent regulatory standards. This method facilitates real-time analysis, which is crucial for maintaining quality control throughout the manufacturing process.

-

Chemical Research: NIR analysis aids in investigating reaction kinetics and mechanisms by examining intermediate compounds in real-time. This application is particularly valuable in understanding complex chemical processes and optimizing reaction conditions. Notably, a recent study demonstrated the proof of concept by testing formaldehyde, highlighting the innovative applications of NIR in chemical research.

Recent developments in NIR technology have further expanded its applications. For instance, a case study titled "NIRS Technology: The Green Analytical Choice for Sustainable Food Production" highlights its role in sustainable food production, demonstrating how it can enhance precision agriculture and contribute to a circular economy. This underscores the growing recognition of NIR as a green analytical choice across various sectors.

Furthermore, expert insights suggest that NIR analysis is becoming increasingly significant in environmental monitoring and pharmaceutical evaluation, with trends indicating its wider acceptance in these domains. As the global fast fashion market is projected to expand by USD 79.2 billion from 2025-2029, the need for effective monitoring solutions such as NIR technology will likely rise, underscoring its significance in addressing modern challenges.

In summary, the applications of NIR analysis in physical sciences not only advance research but also play a critical role in promoting sustainability and compliance across industries.

How NIR Spectroscopy Works: Understanding the Technology Behind the Technique

NIR spectroscopy is fundamentally based on the principle of light-matter interaction. When near-infrared light targets a specimen, specific wavelengths are absorbed by the molecular bonds within the material. This absorption of energy triggers molecular vibrations, resulting in overtone and combination bands that are characteristic of particular chemical bonds.

The subsequent spectrum is meticulously analyzed to identify and quantify the constituents present. This process comprises several critical steps:

- Sample Preparation: Proper preparation is crucial to ensure that the specimen is suitable for analysis, which may involve grinding, mixing, or conditioning the material to achieve homogeneity.

- Spectral Acquisition: A spectrometer is employed to collect the NIR spectrum, capturing the light transmitted or reflected from the specimen.

- Data Analysis: Chemometric techniques are utilized to interpret the spectral data, facilitating the extraction of meaningful information regarding the sample's composition.

Recent advancements in NIR analysis technology have significantly broadened its application across various fields, notably in the food and pharmaceutical industries. A review titled 'Challenges and Opportunities in NIR Analysis' discusses the extensive use of NIR analysis in the food sector, particularly for measuring proximate composition and functional properties. However, it also underscores that the integration of NIR analysis into routine monitoring of food functionality remains a challenge, indicating a pressing need for further research and training.

Moreover, studies have demonstrated robust correlations between specific chemical components and measurable attributes. For instance, the β coefficients from calibration equations have revealed strong relationships between phenolic compounds and metal content in tea samples, emphasizing the technique's efficacy in chemical analysis. Furthermore, a Pearson correlation of 0.96 was observed between fat content and the altitude of coffee plantations, showcasing the accuracy of NIR analysis in agricultural applications.

As we approach 2025, advancements in NIR spectrometer technology continue to evolve, enhancing the capabilities of spectral acquisition and analysis. These developments are essential for improving the precision and effectiveness of NIR analysis, establishing it as a critical instrument in both research and practical applications across numerous scientific fields. Author MT noted that while NIR analysis holds great potential, its full capabilities are yet to be fully realized, stressing the importance of ongoing research and development in this domain.

Additionally, unsupervised pattern recognition utilizing PCA has been effectively applied to detect heavy metals as indicators to distinguish between various tea types, further highlighting the analytical potential of NIR techniques in complex analyses.

NIR Calibration: Ensuring Accuracy in Spectroscopic Measurements

Calibration in near-infrared (NIR) spectroscopy is a fundamental process that establishes a reliable relationship between the spectral data obtained from the instrument and the known concentrations of analytes. This relationship provides critical insight into the meaning of these measurements in reference materials. The meticulous calibration process encompasses several key steps:

- Selection of Calibration Standards: Choosing appropriate reference materials that closely resemble the samples to be analyzed is crucial. The accuracy of the calibration model heavily relies on the quality and relevance of these standards.

- Data Collection: The subsequent step involves measuring the spectra of the calibration standards under controlled conditions. Consistency in data collection is vital to ensure that the spectral data accurately reflects the properties of the analytes.

- Model Development: Statistical methods, such as Partial Least Squares (PLS) regression, are employed to create a calibration model that correlates spectral data with analyte concentrations. This model serves as the backbone for interpreting unfamiliar specimens.

- Validation: To ensure the accuracy and reliability of the calibration model, it must be tested with separate datasets. This validation step is crucial for verifying that the model operates effectively under various conditions and types.

Routine calibration is essential to account for instrument drift and changes in specimen characteristics over time. Recent discussions within the scientific community have underscored the importance of calibration standards, which provide a benchmark for accuracy, ensuring that measurements remain consistent and reliable.

In 2025, current best practices for NIR calibration in laboratories emphasize the need for robust calibration techniques, essential for understanding the meaning of NIR. These practices include the use of advanced statistical methods and the incorporation of diverse sample types to enhance model robustness. Ongoing research indicates that well-developed calibration models can achieve accuracy levels exceeding 95%, significantly improving the reliability of analytical results.

Real-world examples illustrate the practical implications of effective calibration. A recent case study titled "New NIR for Feed: Hard Work or a Smart Move?" regarding the introduction of new NIR analyzers in feed mills demonstrated excellent analytical performance and low operational costs. However, it also highlighted the challenges associated with installation and the necessity for recalibrating existing solutions to ensure a seamless transition.

Expert opinions support the notion that advanced methods such as NIR analysis enhance quality control by offering quick, nondestructive evaluations. Dr. Dave Van Staveren, Head of Competence Center Spectroscopy, states, "Advanced techniques like Raman and near-infrared (NIR) methods enhance QC by providing rapid, nondestructive analysis." As the field continues to evolve, the integration of innovative calibration methods will be pivotal in advancing the accuracy and efficiency of NIR spectroscopy across various applications.

The Rise of NIR Imaging: Trends and Technological Advancements

The advancements in NIR imaging methods underscore the importance of nir meaning, primarily driven by the growing demand for real-time, non-invasive analysis across various sectors. Notable trends shaping the landscape of NIR imaging include:

- Miniaturization: The emergence of compact, portable NIR imaging devices has revolutionized field applications, enabling on-site analysis in diverse environments. The integration with AI enhances image analysis and interpretation, reflecting the nir meaning of improved accuracy and operational efficiency through the incorporation of machine learning algorithms. This integration facilitates sophisticated data processing, allowing for easier derivation of actionable insights from complex datasets.

- Enhanced Resolution: Recent progress in sensor advancements has led to higher resolution images, enabling more detailed examinations of samples. This improvement is crucial for applications requiring precision, such as medical diagnostics and quality control in food safety.

- Broader Applications: NIR imaging is increasingly utilized in medical diagnostics, food safety, and environmental monitoring, highlighting the nir meaning across multiple industries. For instance, in the agricultural sector, NIR imaging assesses crop health and optimizes irrigation practices, demonstrating its versatility and effectiveness. This trend is supported by the growing adoption of infrared imaging in Latin America, where it is being used to monitor crop health and enhance agricultural practices.

Industry leaders such as Qualcomm Technologies, Sony, and GE Healthcare are at the forefront of next-generation imaging innovations, significantly influencing advancements in NIR imaging. A recent client noted, "The report is excellent and has a good amount of data, and our team is extremely happy with the information provided," underscoring the value of comprehensive data in this field. Furthermore, the recent introduction of the TS005 thermal monocular camera emphasizes ongoing advancements in imaging methods that may pertain to NIR applications.

These trends not only highlight the current direction of NIR imaging methods but also indicate a promising future brimming with possibilities for further innovation and application across various fields.

Innovations in NIR Technology: Exploring Related Products and Solutions

Recent innovations in Near-Infrared (NIR) methods are transforming the landscape of material analysis and monitoring, illustrating the significance of NIR across various industries. Key advancements include:

- Portable NIR Analyzers: These devices facilitate on-site analysis, significantly enhancing convenience and accessibility for users. Their compact design allows for immediate data collection and analysis, making them invaluable in settings such as agricultural assessments and quality control in food production. Experts emphasize the importance of these portable and miniaturized NIR analyzers, particularly in industries like dairy processing, where they can streamline operations and enhance product quality.

- Hyperspectral Imaging: This cutting-edge technique merges NIR spectroscopy with imaging capabilities, providing detailed spatial information about samples. By capturing a wide range of wavelengths, hyperspectral imaging enables more comprehensive assessments of material composition and quality, which is particularly beneficial in sectors like environmental monitoring and food safety.

- Advanced Chemometric Software: The development of sophisticated chemometric tools has greatly improved data analysis capabilities. These software solutions allow for more nuanced interpretation of spectral data, enabling users to derive actionable insights from complex datasets, thus enhancing decision-making processes in research and industrial applications.

- Integration with IoT: The connection of NIR devices to the Internet of Things (IoT) is revolutionizing real-time monitoring and data sharing. This integration facilitates immediate access to analytical results, allowing for timely interventions and optimized operational efficiency in industrial processes. As industries increasingly adopt IoT solutions, the role of NIR systems in enhancing productivity and quality assurance becomes even more pronounced. Nevertheless, the use of cloud computing services for data processing raises concerns regarding data security and ownership, which must be addressed to ensure user trust.

These innovations highlight the evolving characteristics of NIR solutions, demonstrating their ability to propel substantial progress across multiple sectors, such as agriculture, food processing, and pharmaceuticals. For instance, a recent study utilizing a handheld NIR device, the Phazir 1624, demonstrated its effectiveness in analyzing fatty acid profiles in raw milk, achieving coefficients of determination between 0.87 and 0.92 when compared to traditional gas chromatography mass spectrometry methods. Such real-world applications underscore the growing reliance on portable NIR analyzers for accurate and efficient on-site analysis. Furthermore, a recent development by Liang et al. introduced a NIR approach for assessing slurry traits in livestock and poultry breeding, highlighting the adaptability of NIR methods in agricultural applications. As the technology continues to evolve, the integration of IoT and advanced analytical tools will likely further expand the capabilities and applications of NIR technology. Therefore, this review aims to provide an overview targeted at dairy processors, researchers, technologists, and engineers regarding portable and miniaturized NIR analyzers and their potential in the dairy industry.

Conclusion

The advancements in Near-Infrared Spectroscopy (NIRS) have established it as a transformative tool across diverse industries, including pharmaceuticals, agriculture, and food science. By harnessing the principles of light absorption and molecular vibrations, NIR technology facilitates rapid, non-destructive analysis that is essential for maintaining product quality and safety. The integration of miniaturized devices and artificial intelligence has further augmented its capabilities, enabling more precise and efficient processes.

As discussed throughout this article, NIRS is revolutionizing quality control in pharmaceuticals by combating counterfeit drugs and ensuring compliance with stringent regulations. Its applications extend to agriculture, where it plays a vital role in evaluating crop quality, and in food production, where it optimizes ingredient formulations. The versatility of NIR and SWIR technologies underscores their potential to enhance operational efficiency and accuracy across various sectors.

Looking ahead, the future of NIR technology is promising. With ongoing innovations such as portable analyzers, hyperspectral imaging, and IoT integration, the landscape of material analysis is evolving. These advancements not only bolster analytical capabilities but also support sustainable practices and real-time monitoring, addressing contemporary challenges in multiple fields. Embracing these technologies will be critical for industries striving to enhance quality assurance and operational efficiency in an increasingly competitive market.