Overview

This article examines best practices for tube centrifuge usage, underscoring the critical importance of safety and accuracy within laboratory environments. It begins by addressing the necessity of selecting the appropriate centrifuge tube, a fundamental factor that directly impacts experimental outcomes. Following this, adherence to established safety protocols is highlighted, serving as a vital measure to mitigate risks associated with centrifuge operations. Furthermore, the implementation of proper maintenance and cleaning procedures is discussed, as these practices are essential for ensuring reliable results. Collectively, these elements form the backbone of effective laboratory operations, ultimately fostering a culture of safety and precision.

Introduction

In the realm of scientific research, centrifuge tubes are indispensable for the precise separation and analysis of samples. As technology progresses, these essential laboratory tools have evolved, demonstrating remarkable versatility across applications ranging from blood analysis to DNA extraction.

It is imperative for laboratory professionals to understand the nuances of centrifuge tube selection, operation, and maintenance to enhance their research outcomes. With emerging innovations and a steadfast focus on safety protocols, the landscape of centrifuge tube usage is continuously transforming. This underscores the necessity of staying informed and adopting best practices in an ever-evolving field.

Understanding Centrifuge Tubes: Purpose and Applications

Tube centrifuge containers are essential instruments in laboratory settings, specifically engineered to hold samples during centrifugation—a technique that separates components based on their density. In 2025, these containers are pivotal in a variety of applications, including blood analysis, DNA extraction, and cell culture, reflecting their versatility and critical role in scientific research.

The purpose of centrifuge vessels varies significantly depending on their design. For instance, conical containers are particularly effective for sedimentation processes, allowing for efficient separation of cellular components. Microcentrifuge vials, on the other hand, cater to small-volume applications, making them ideal for tasks such as DNA extraction where precision is paramount. PCR containers are specifically crafted for polymerase chain reaction processes, ensuring optimal thermal cycling and sample integrity.

Recent advancements in technology for spin containers have concentrated on enhancing performance and sustainability. Manufacturers are increasingly innovating to meet the growing demand for high-quality laboratory supplies, as evidenced by competitive players like Bioplastic and Sarstedt, who are advancing their market positions through strategic collaborations and product innovations. This competitive environment is defined by an emphasis on innovation and sustainability, which is essential for addressing the changing requirements of laboratories.

Expert insights highlight the significance of choosing the appropriate container for particular applications. Laboratory professionals emphasize that using the correct container type not only ensures optimal results but also maintains sample integrity, which is crucial for accurate analysis. Statistics show that hospitals represent the largest portion of the medical spinning device market, emphasizing the essential function these instruments serve in clinical environments. This statistic underscores the importance for lab managers to prioritize quality and precision in their decisions.

In blood analysis, the use of a tube centrifuge is essential for separation containers to isolate plasma from blood cells, a process that is crucial for various diagnostic tests. Likewise, in DNA extraction, the selection of a tube centrifuge as the collection vessel can greatly influence yield and purity, making it crucial for researchers to remain updated on the latest varieties and applications of these containers.

In general, the scope of collection vessel applications keeps changing, propelled by technological progress and a greater comprehension of research requirements. As the market expands, the focus on quality and accuracy in choosing test vessels continues to be a key priority for managers striving to improve their operational efficiency. As highlighted by the IMARC Team, the report on lab spinning machine trends is excellent and offers a wealth of data, further underscoring the significance of remaining informed in this area.

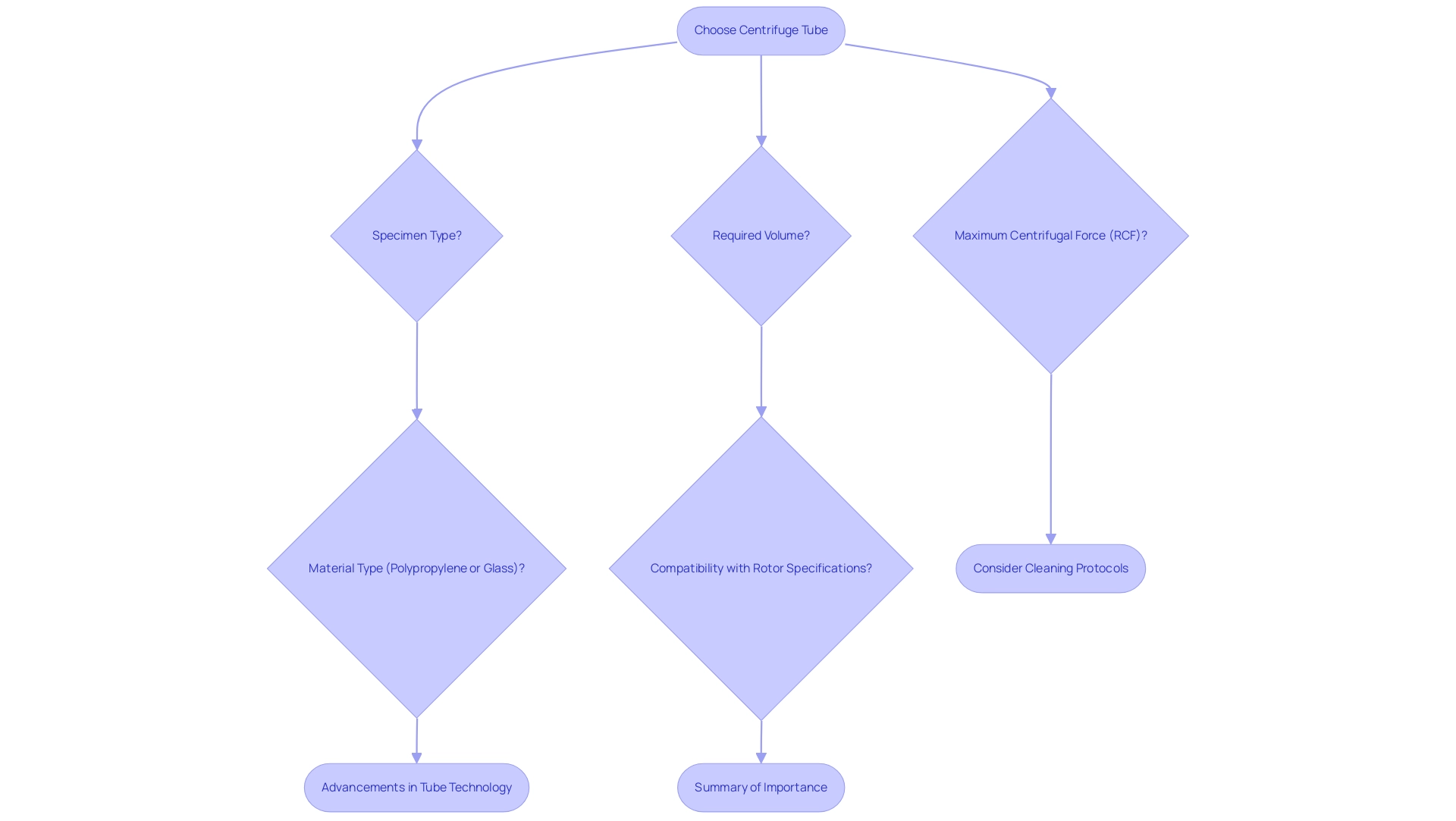

Choosing the Right Centrifuge Tube for Your Application

Choosing the appropriate tube centrifuge container is crucial for achieving optimal outcomes in laboratory applications. Key factors to consider include the specimen type, required volume, and the maximum centrifugal force (relative centrifugal force, RCF) that the container can endure. For example, polypropylene cylinders are preferred for biological samples due to their superior chemical resistance, whereas glass containers are often selected for applications that demand high optical clarity.

Test vessels play a significant role in medication formulation and evaluation processes within pharmaceutical studies, where exceptional clarity and chemical resilience are paramount. It is essential to ensure that the chosen vessel's dimensions align with the rotor specifications. This compatibility is critical, as an improper fit can lead to suboptimal separation outcomes and potential damage to both the containers and the centrifuge. Always consult the manufacturer's guidelines regarding maximum velocity and temperature limits to minimize the risk of operational failure.

Recent advancements underscore the importance of tube centrifuge devices, particularly for delicate specimens that may degrade due to oxidation or evaporation during the spinning process. These devices help preserve sample integrity by preventing oxidation and evaporation, making them invaluable in pharmaceutical research.

A case study on cleaning protocols for reusable containers highlights the necessity of proper maintenance. It emphasizes hand-washing with mild detergents and avoiding commercial dishwashers, which can compromise integrity. Adhering to specific cleaning protocols is essential for ensuring the longevity and efficiency of reusable containers in research settings.

Looking ahead to 2025, optimal methods for selecting spinning devices will continue to evolve, focusing on the impact of container material on performance. The choice of piping material can significantly affect the clarity and chemical resistance required for various applications. By following these guidelines and considering the compatibility of sample containers with different rotor types, laboratory managers can enhance the precision and safety of their tube centrifuge spinning processes.

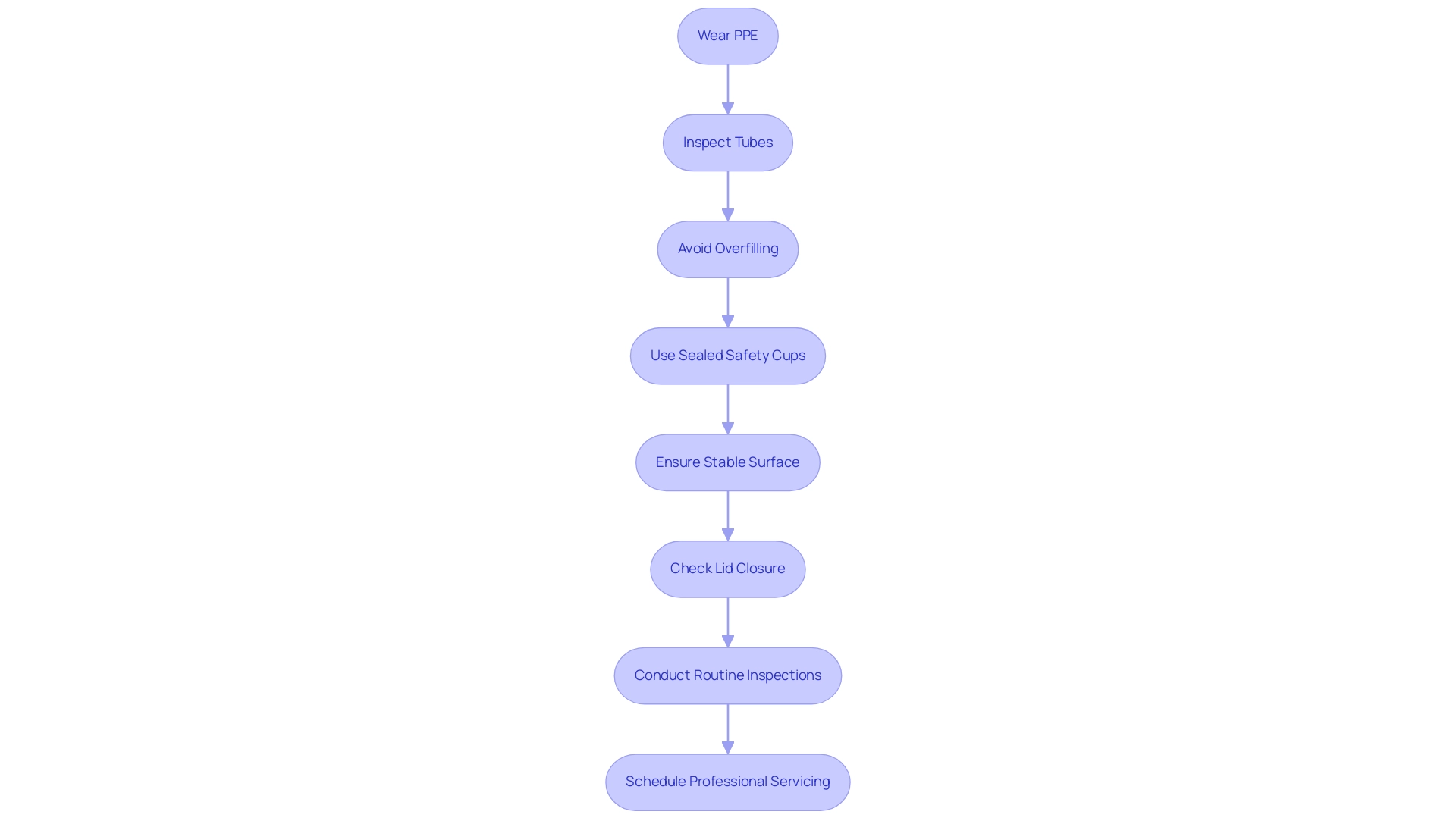

Safety Protocols for Handling Centrifuge Tubes

To ensure safety while handling tube centrifuge containers, it is imperative to wear appropriate personal protective equipment (PPE), including gloves, lab coats, and safety goggles. Prior to use, inspect the containers meticulously for any cracks or defects, as these can jeopardize integrity during centrifugation. To avoid spillage, which can result in contamination or accidents, overfilling the tube centrifuge must be strictly avoided.

When working with hazardous materials, utilizing sealed safety cups or buckets is essential to effectively contain any potential leaks. Furthermore, always confirm that the device is operated on a stable, level surface, and ensure that the lid is securely closed during operation to mitigate the risk of accidents. Routine inspections of the tube centrifuge should be conducted before each use, with professional servicing and calibration scheduled at least once annually to uphold optimal performance and safety standards.

Recent findings highlight the necessity for enhanced training programs aimed at reducing pre-analytical errors and improving overall performance, underscoring the critical importance of adhering to established centrifugation protocols. For instance, a survey evaluating rotor operation knowledge demonstrated strong reliability and validity, affirming the significance of adequate training in research environments. This survey serves as a valuable tool for future studies in training, emphasizing the need for continuous education in safety protocols.

In 2025, safety data regarding tube handling in research facilities indicate a pressing need for strict adherence to safety protocols. Common PPE utilized in research environments for spinning operations includes not only gloves and lab coats but also face shields and respiratory protection when necessary. Expert advice emphasizes that proper training and compliance with safety protocols are paramount in preventing accidents and ensuring a secure working environment.

As noted by Kübra Nur Köyüstü, "the authors declare that there are no conflicts of interest regarding this research or manuscript," reinforcing the importance of transparency and ethical considerations in scientific practices. Additionally, referencing the 2025 laboratory safety standards for rotor usage ensures that the content aligns with current regulations and practices.

Best Practices for Operating Centrifuge Tubes

To guarantee the efficient functioning of spinning containers, it is essential to balance the rotor by placing containers of equal weight directly opposite one another. This practice significantly reduces vibrations, which can potentially harm the apparatus and jeopardize the integrity of the specimens. Furthermore, it is crucial to fill the tubes to the recommended levels, allowing adequate space for material expansion during centrifugation.

Adjusting the device to the appropriate speed is vital for optimal separation. Suggested rotation speeds for compound rotor devices typically encompass 4000 rpm, 6000 rpm, and 7000 rpm, depending on the specific type of material and intended results. Adhering to these guidelines not only enhances the efficiency of the separation process but also preserves the integrity of the samples being processed.

Regular monitoring of the equipment during operation is imperative. Laboratory managers emphasize the importance of vigilance for any unusual noises or vibrations, which could indicate an imbalance or malfunction. Immediate cessation of operation is advised if any issues arise, ensuring both safety and accuracy in laboratory practices.

Recent case studies highlight best practices for operating tube centrifuge systems in research labs, showcasing innovative rotor balancing methods that enhance operational efficiency. For instance, a novel balancing technique utilizing unsupervised deep learning has demonstrated effectiveness in addressing preset imbalances without the need for additional weight trials, thereby enhancing both cost-effectiveness and accuracy. A case study on a rotor with two discs supported by sliding bearings illustrates this method, emphasizing its potential to balance imbalances efficiently.

Expert insights underscore the importance of rotor balancing in spinning machine operations. Statistics indicate that improper balancing can lead to increased wear and tear on equipment, ultimately affecting the reliability of results. As noted by a US TPS Business Development Manager, "The response was good, and I got what I was looking for as far as the report. Thank you for that," emphasizing the significance of efficient operation of the device in achieving desired outcomes.

Additionally, it is important to consider the disadvantages of the MBM, which include potential invalidity of the planar mode assumption in damped systems and reliance on limited sensor data. By applying optimal methods for operating tube centrifuges efficiently, laboratories can ensure high-quality results and maintain the integrity of their research.

Maintenance and Cleaning of Centrifuge Tubes

To ensure the integrity of tube centrifuge containers and prevent cross-contamination, implementing rigorous cleaning protocols after each use is essential. Begin by thoroughly rinsing the containers under running tap water, followed by rinsing in deionized or distilled water to eliminate any traces of detergent. Next, apply a mild detergent to remove any stubborn residues. It is crucial to avoid harsh substances that could damage the surface, as this can undermine efficiency and result in contamination hazards.

For containers exposed to dangerous materials, strictly adhere to your facility's decontamination procedures. These guidelines are designed to mitigate risks associated with hazardous substances and ensure the safety of laboratory personnel. Regular examinations of containers for signs of deterioration, such as fractures or chips, are vital.

Promptly replace any damaged pipes to maintain reliable performance and compliance with safety standards.

Expert recommendations emphasize the significance of preventive maintenance. For instance, Eppendorf advises an annual preventive maintenance check by a qualified service technician for the device, rotor, and accessories to ensure operational safety and extend the service life of your instrument. This practice not only guarantees safety but also enhances the lifespan of the equipment.

Statistics reveal that inadequate upkeep of scientific apparatus, including tube centrifuges and spinning vessels, can lead to significant cross-contamination events. Recent studies indicate that facilities adhering to stringent cleaning validation protocols, such as those outlined in ASTM E3106 – 18e1, have reported a marked reduction in cleaning validation failures. This underscores the effectiveness of data-driven approaches in assessing cleaning efficacy and highlights the necessity of maintaining high standards in experimental practices.

Moreover, adherence to regulations from Health Canada and TGA regarding dynamic revalidation mechanisms and real-time documentation is crucial for upholding standards in testing facilities. In conclusion, comprehensive cleaning and routine maintenance of tube centrifuge containers are vital for ensuring safety and precision in testing environments. By following established protocols and guidelines, facilities can significantly reduce the risk of cross-contamination and enhance the reliability of their analytical results.

Common Mistakes to Avoid When Using Centrifuge Tubes

Frequent errors in the utilization of containers can significantly impact laboratory outcomes and safety. Key errors when operating a tube centrifuge include:

- Overfilling containers

- Using damaged or compromised containers

- Failing to properly balance the rotor

Overfilling tubes can lead to spillage and contamination, jeopardizing the integrity and accuracy of samples.

Studies indicate that improper billing practices are among the most frequently reported issues in testing environments, with a notable percentage of technicians acknowledging the risks associated with overfilling. Significantly, only 17% of participants reported the existence of ultracentrifuges in their facilities, underscoring the necessity for appropriate usage of these devices across various environments.

Utilizing compromised containers presents another critical risk; such items may break during the operation of a tube centrifuge, resulting in sample loss and potential injury to laboratory personnel. Furthermore, neglecting to balance the tube centrifuge rotor correctly can cause excessive vibrations, risking damage to the equipment and leading to inaccurate results. It is essential to ensure that all containers are labeled correctly and that the appropriate speed and time settings for the tube centrifuge are applied for each specific application.

After stopping a wobbling tube centrifuge, users should check if the tubes or plates in the rotor or buckets are correctly balanced; if the issue persists, it is advisable to contact the manufacturer or dealer for servicing.

Real-world examples illustrate the consequences of these mistakes. For instance, a research facility reported a significant loss of specimens due to overfilling the tube centrifuge, which led to costly delays and compromised research outcomes. Laboratory technicians emphasize the importance of vigilance, stating that "the integrity of our samples is paramount; even minor oversights can lead to major setbacks."

T. Kanno observes that as professionals in the field, we must be capable of predicting and reacting to current shifts in health requirements, highlighting the importance of appropriate spinning device practices in response to changing demands.

To mitigate these risks, facilities should adopt best practices, including:

- Regular training on appropriate rotor usage

- Routine checks for the integrity of the tube centrifuge

By fostering a culture of safety and accuracy, research facilities can enhance their operational efficiency and ensure reliable results. JM Science Inc.'s collaborations with prominent brands such as Agilent Technologies and Thermo Fisher Scientific further demonstrate a commitment to quality and innovation in scientific practices, emphasizing the significance of utilizing dependable equipment and methods in spinning operations.

Innovations in Centrifuge Tube Technology

Recent advancements in container technology have significantly transformed research practices, focusing on enhanced chemical resistance, leak-proof seals, and improved clarity for optimal sample visibility. The market for single-use containers is projected to experience substantial growth from 2025 to 2033, driven by factors such as an aging demographic and increasing healthcare expenditures. This growth underscores the critical need for innovative solutions within laboratory environments.

Manufacturers are increasingly adopting innovative materials, particularly eco-friendly plastics, reflecting a broader commitment to sustainability within the scientific community. Laboratories are aligning their practices with environmental considerations while upholding performance standards by embracing these eco-friendly container materials. Recent case studies have illuminated regional market trends, demonstrating how specific areas are at the forefront of adopting these advanced materials and designs.

Moreover, the integration of intelligent technology into containers is revolutionizing specimen monitoring. These advancements facilitate real-time monitoring of conditions during centrifugation, enhancing both safety and precision in scientific processes. Experts assert that such innovations not only bolster operational efficiency but also yield better outcomes in research and diagnostics.

The significance of improved chemical resistance in containers is paramount, as it ensures the integrity of samples, especially when handling aggressive solvents or reactive materials. Manufacturers are prioritizing advancements in leak-proof seals, which are essential for preventing contamination and ensuring reliable results. As the industry evolves, staying informed about these innovations will empower facilities to refine their processes and maintain the highest standards of safety and accuracy.

As noted in a quote from Deloitte, "We have been working with MarkWide Research for a number of years now, and we have found their market research reports to be invaluable in helping us make strategic decisions for our business." This underscores the importance of accessing reliable market research to navigate the evolving landscape of tube centrifuge technology. Additionally, sample reports for the tube centrifuge market can be requested, with 24/7 support for procurement, providing valuable resources for laboratory managers to make informed decisions.

Conclusion

The exploration of centrifuge tubes underscores their pivotal role in modern laboratory practices, highlighting the necessity for meticulous selection and usage to achieve optimal results. A comprehensive understanding of the various types of centrifuge tubes and their specific applications is essential for laboratory professionals, as it directly influences the efficiency of processes such as blood analysis and DNA extraction. Technological advancements not only enhance the performance of these tubes but also emphasize the critical importance of sustainability within laboratory environments.

Safety protocols regarding the handling of centrifuge tubes are of utmost importance. Proper training, regular maintenance, and strict adherence to established guidelines can significantly mitigate the risk of accidents and ensure the accuracy of results. Common pitfalls, such as overfilling and neglecting rotor balance, can lead to severe consequences, reinforcing the necessity of vigilance in laboratory settings.

Innovations in centrifuge tube technology are continually reshaping the landscape of scientific research, with an emphasis on improved materials and smart technologies that bolster sample integrity and operational efficiency. As the demand for high-quality laboratory supplies escalates, remaining informed about these trends and adopting best practices will empower laboratories to uphold high standards of safety and precision.

In conclusion, the effective utilization of centrifuge tubes is vital for propelling scientific research forward. By prioritizing quality, safety, and innovation, laboratory professionals can enhance their operational efficiency and contribute to the reliability of their findings. As the field evolves, embracing these principles will ensure that laboratories remain at the forefront of scientific discovery.