Overview

This article delves into the critical process of selecting a peristaltic pump head that is specifically tailored to meet the unique needs of laboratory environments. It underscores essential factors such as:

- Flow rate

- Roller count

- Material compatibility

- Channel configuration

By emphasizing the importance of these elements, the article illustrates that meticulous consideration is vital for optimizing performance and ensuring reliable operation across various laboratory applications. Understanding these components not only enhances functionality but also fosters confidence in the equipment's reliability.

Introduction

In the realm of laboratory technology, peristaltic pumps emerge as indispensable tools, celebrated for their exceptional capability to manage a wide range of fluids, from corrosive chemicals to thick viscous substances. Their innovative design—compressing and releasing flexible tubing—ensures efficient fluid transfer while significantly reducing contamination risks, a crucial consideration in sensitive scientific environments.

As laboratories increasingly adopt cutting-edge advancements, the importance of peristaltic pumps continues to grow, with their precision and reliability being vital in applications such as chemical dosing and cell culture.

This article explores the intricacies of peristaltic pumps, examining their operational mechanisms, essential components, and the key factors to consider when selecting the appropriate pump head for specific laboratory needs.

Explore the Basics of Peristaltic Pumps

Peristaltic devices stand as a cornerstone in laboratory environments, recognized for their positive displacement mechanism that adeptly manages a wide range of liquids, including corrosive and viscous materials. These devices function by compressing and releasing a flexible tube, which generates a vacuum that draws fluid in and subsequently expels it. This unique operation significantly minimizes contamination risks, making these devices particularly suitable for sensitive applications such as chemical dosing, cell culture, and chromatography.

The benefits of these devices extend beyond mere operational efficiency. They are engineered to minimize interaction between the fluid and the device components, a crucial factor in preventing contamination—a major concern for facility managers. Recent advancements in pumping technology, exemplified by NETZSCH's NEMO® MY device with its magnetic coupling, enhance both safety and operational efficiency. This marks a pivotal advancement in pumping innovation, further solidifying the role of peristaltic systems in .

Expert opinions underscore the importance of these devices in laboratory settings. Laboratory supervisors frequently highlight the necessity of contamination prevention in fluid management. One supervisor remarked, "Peristaltic devices are crucial for preserving the integrity of our samples; they offer a dependable solution to contamination risks." In applications involving chemical dosing, the accuracy and reliability of these devices have been shown to significantly improve outcomes.

Recent data indicate a growing acceptance of specific types of fluid delivery systems within research facilities, with a notable 15% increase in utilization over the past year, underscoring their efficiency and reliability. As research facilities continue to evolve, the integration of advanced technologies in fluid transfer devices is expected to enhance their functionality, ensuring they remain indispensable tools in scientific inquiry and applications. Furthermore, the validation process for ensuring the accuracy and reliability of data through expert consultations bolsters the credibility of claims regarding these devices, reinforcing their significance in laboratory applications.

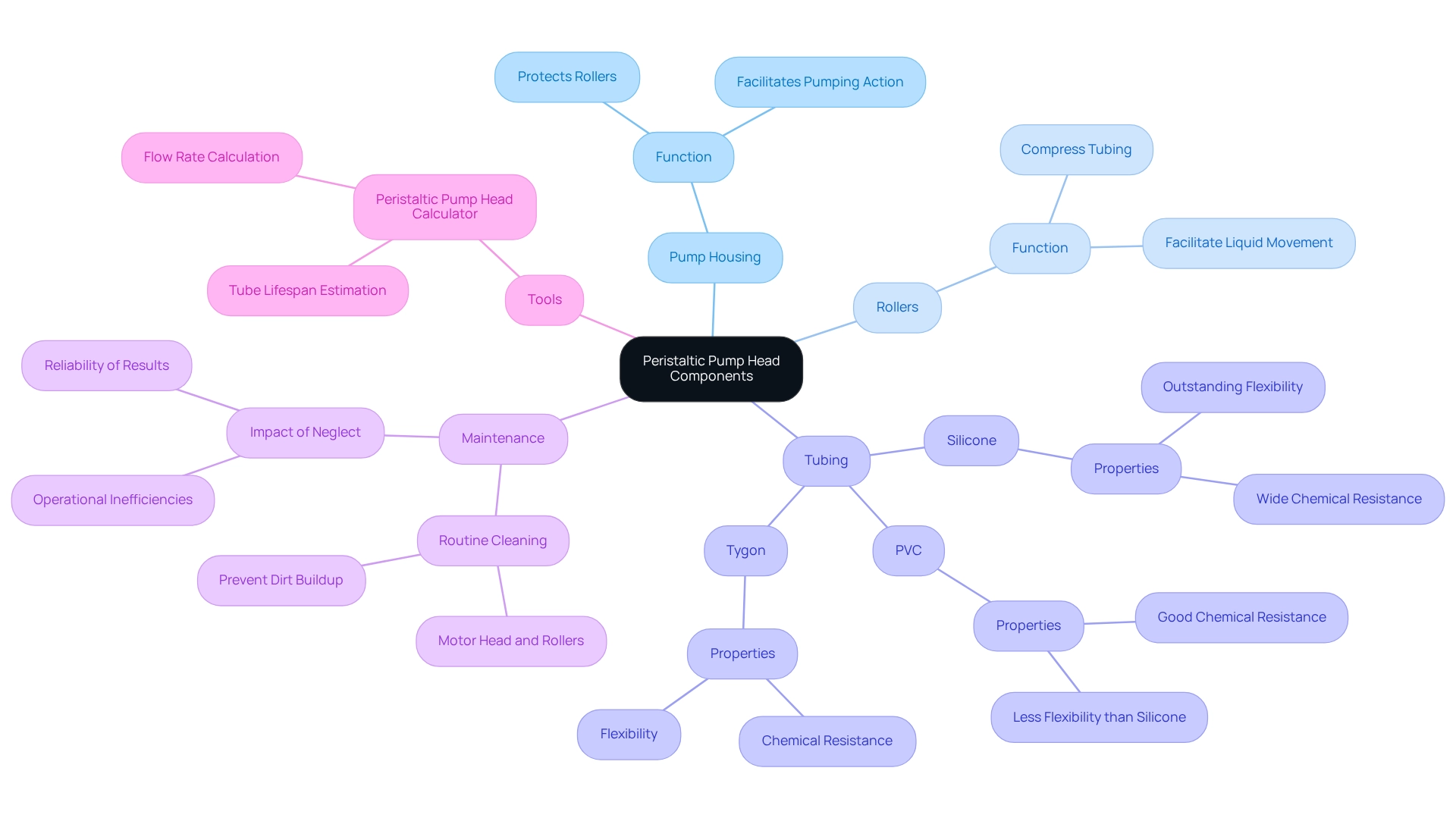

Understand Peristaltic Pump Head Components

Several essential components make up a peristaltic pump head, including the pump housing, rollers, and tubing. The housing serves to protect the rollers, which compress the tubing to facilitate the pumping action. The choice of tubing material is critical, as it must withstand the chemical properties of the fluids being pumped. Common materials include silicone, PVC, and Tygon, each offering varying degrees of chemical resistance and flexibility. For instance, silicone tubing is recognized for its outstanding flexibility and resistance to a wide variety of chemicals, making it suitable for numerous scientific applications. Conversely, PVC offers good chemical resistance but may not match the flexibility of silicone.

Understanding these components is vital for selecting the appropriate peristaltic pump head for specific laboratory needs, which ensures optimal performance and durability. Routine maintenance, including regular cleaning of the motor head and rollers, is crucial to prevent dirt buildup that could disrupt operations. Neglecting maintenance can lead to operational inefficiencies, ultimately impacting the reliability of results.

Utilizing tools such as calculator can aid in calculating flow rates and estimating tube lifespan under specific conditions, thereby enhancing operational efficiency. For example, in the case study 'Water and Wastewater Treatment Using Hose Pumps,' precise dosing by hose systems was shown to improve treatment efficiency, underscoring the importance of selecting the appropriate peristaltic pump head and tubing material. Moreover, the peristaltic pump head facilitates smooth and steady liquid movement when transferring thick substances like adhesives and greases, emphasizing its significance in research environments. As Adam Magnuski, Business Development Manager (Pumps), states, "If you need any assistance in selecting the appropriate head, please feel free to get in touch with our expert engineers at sales@pctflow.com or call 01953 609930." By choosing the right materials and maintaining the peristaltic pump head properly, laboratories can achieve reliable and consistent outcomes in their applications.

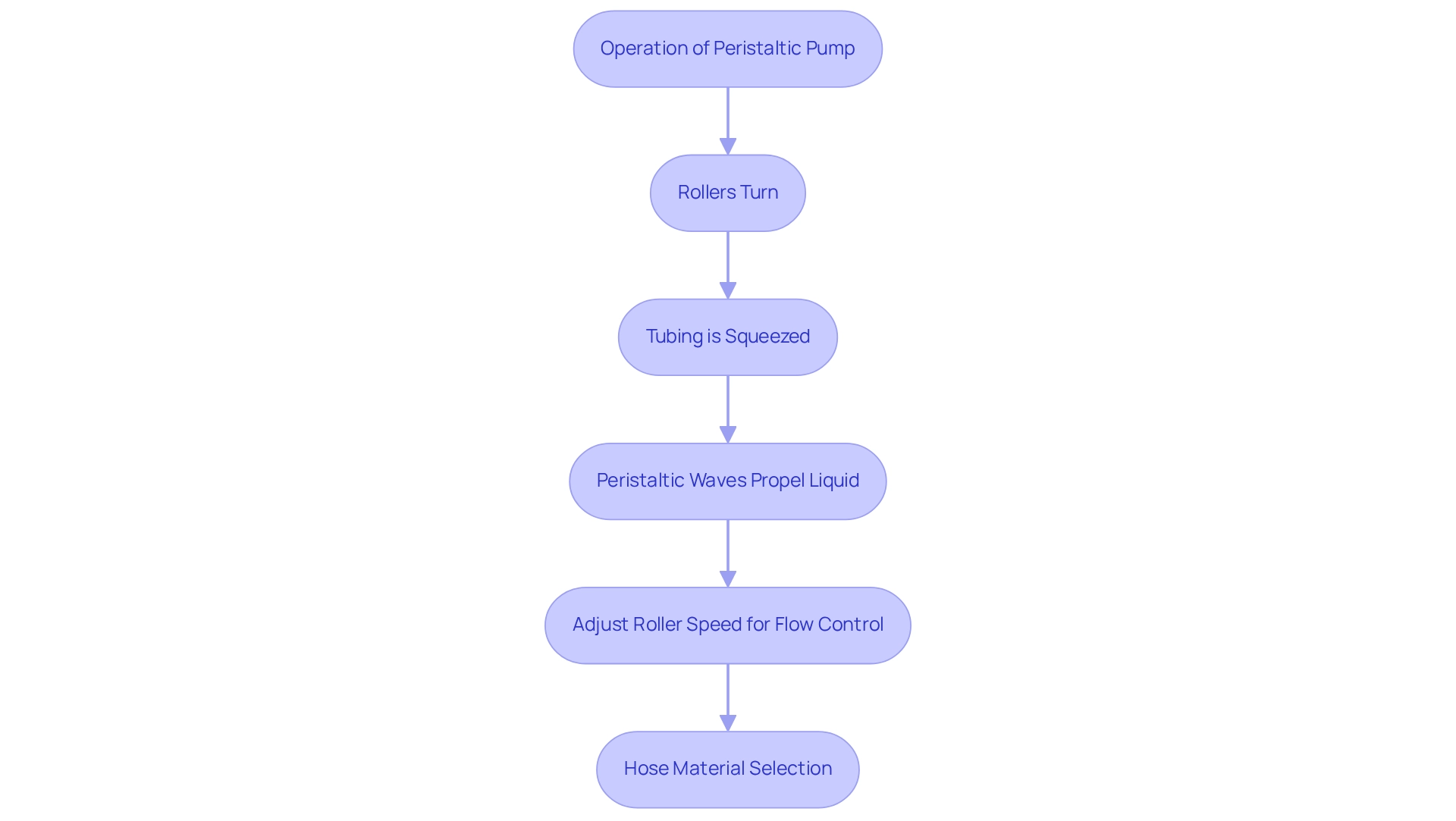

Examine How Peristaltic Pumps Operate

Peristaltic pump heads operate through a simple yet highly efficient mechanism. As rollers turn, they squeeze the tubing, generating a series of peristaltic waves that propel the liquid forward. This design allows for precise flow rate control via the peristaltic pump head, which can be easily adjusted by varying the roller speed. Notably, the peristaltic pump head devices are self-priming, enabling them to handle various viscosities without compromising efficiency, making them ideal for diverse research applications, from liquid transfer to precise dosing.

Flow rate control is critical in laboratory environments, where precision is essential. for systems like the LAMBDA MAXIFLOW laboratory device illustrate performance capabilities, demonstrating how adjustments in roller speed can enhance liquid delivery. Additionally, programmable fluid delivery devices equipped with digital displays and remote communication enhance flow rate management, facilitating more accurate control across various applications.

The ability of these devices to manage different viscosities is supported by case studies that underscore the importance of selecting appropriate hose materials, such as silicone and PTFE, to prevent contamination and ensure compatibility with a range of substances. In terms of operational efficiency, the peristaltic pump head is highly regarded for its versatility across multiple applications. In hygienic medical settings, for instance, these devices excel by not contaminating sterile liquids and eliminating the need for cleaning, thereby enhancing operational efficiency.

The careful selection of hose materials, highlighted in the case study titled 'Choosing Hose Materials for the Peristaltic Pump Head,' emphasizes the significance of material compatibility in experimental applications. This combination of features, supported by operational efficiency ratings for various viscosities, positions these devices as a reliable choice for laboratories seeking both precision and flexibility in their fluid handling processes.

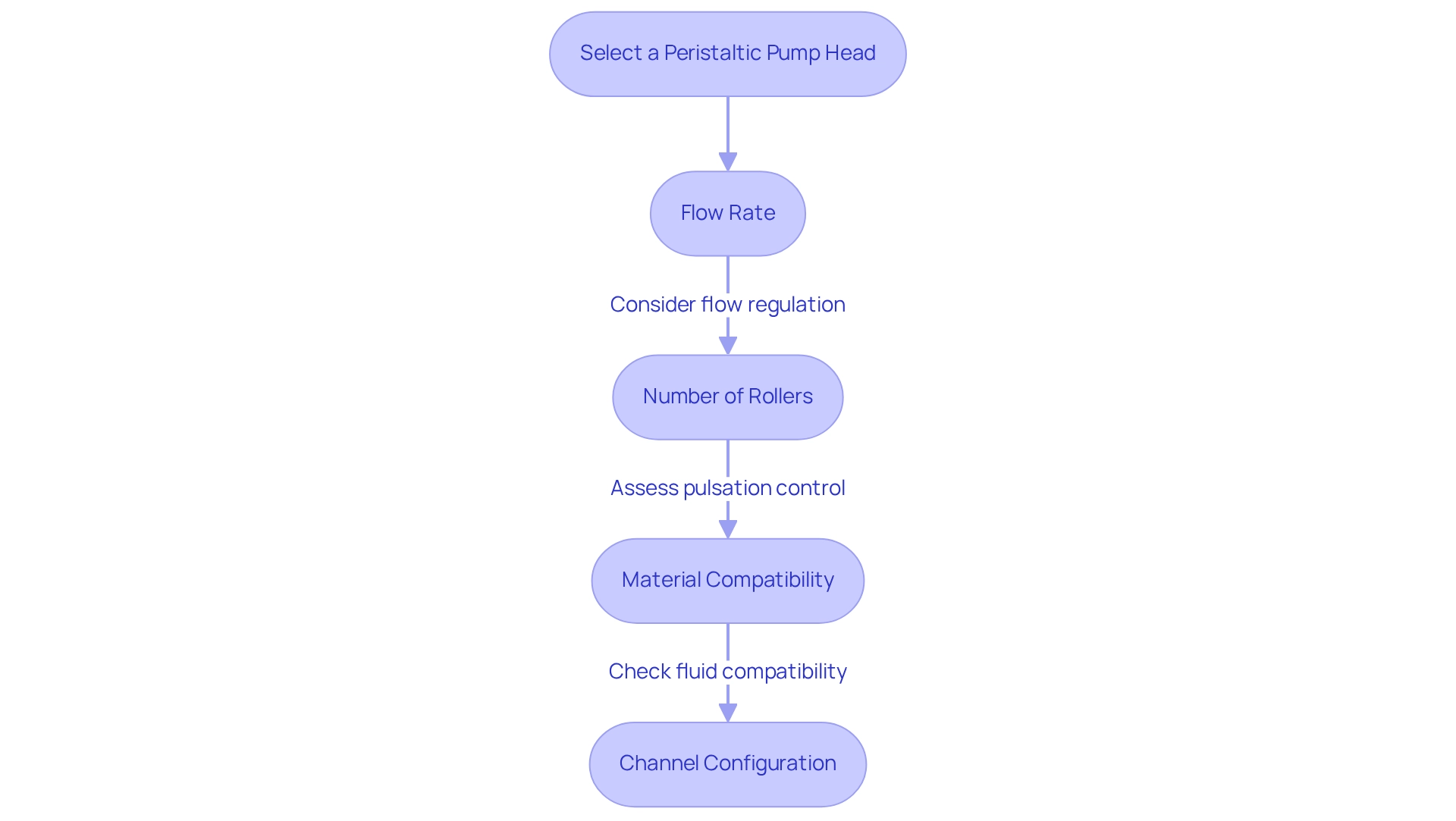

Select the Right Peristaltic Pump Head for Your Lab

Several key factors must be considered when selecting a peristaltic pump head to ensure optimal performance.

Flow Rate: Establish the required flow rate for your specific application. Various types of heads are designed to achieve differing flow rates, making it essential to select one that aligns with your operational needs. Multi-roller devices, which consist of two or more rollers, can significantly enhance flow regulation, rendering them suitable for applications requiring precise flow rates.

Number of Rollers: significantly impacts flow pulsation. Multi-roller peristaltic pump head can enhance flow control and reduce pulsation. According to the case study titled 'Impact of Roller Count on Pulsation in Peristaltic Pumps,' increasing the number of rollers results in reduced pulsation by creating smaller discrete volumes of liquid, which minimizes voids between pockets of liquid. While increasing the number of rollers may raise the frequency of pulsation, it simultaneously decreases the amplitude, resulting in a more stable and consistent liquid flow.

Material Compatibility: Ensure that the tubing material is compatible with the fluids being pumped. JM Science Inc. emphasizes that material compatibility is crucial to prevent degradation or contamination, which can compromise the integrity of your processes.

Channel Configuration: Determine whether a single-channel or multi-channel device head is necessary based on your application requirements. Multi-channel heads can significantly boost throughput by allowing simultaneous pumping, making them ideal for high-demand research environments. For example, multi-channel diaphragm devices are frequently utilized in areas like high-throughput screening and simultaneous sample processing.

By thoroughly evaluating these factors, you can select the most appropriate peristaltic pump head, tailored to your laboratory's specific needs, ultimately enhancing efficiency and reliability in your operations.

Conclusion

Peristaltic pumps play a crucial role in laboratory operations, providing a dependable solution for fluid management across diverse applications. Their innovative design significantly reduces contamination risks while ensuring efficient fluid transfer, rendering them essential for sensitive tasks such as chemical dosing and cell culture. Recent advancements in pump technology, including innovations like magnetic coupling, further bolster their safety and performance, reinforcing their indispensable status in contemporary laboratories.

Grasping the key components of peristaltic pumps, such as tubing materials and pump head configurations, is vital for optimizing their functionality. The selection of suitable materials and the maintenance of the pump head are critical steps that lead to consistent and reliable results. As laboratories continue to advance, the versatility of peristaltic pumps in handling various viscosities and flow rates guarantees their ongoing relevance in a multitude of scientific applications.

In summary, the increasing adoption of peristaltic pumps in laboratory environments underscores their effectiveness and reliability in managing fluid dynamics. By evaluating factors such as flow rate, roller count, and material compatibility, laboratories can identify the most appropriate pump heads tailored to their specific requirements. Embracing these sophisticated pumping solutions not only enhances operational efficiency but also preserves the integrity of essential scientific processes, paving the way for groundbreaking research and discoveries.