Overview

Column chromatography stands as a sophisticated separation technique, pivotal for isolating components of a mixture based on their interactions with stationary and mobile phases. This method is crucial for achieving optimal analytical outcomes. Understanding the principles of chromatography is essential, as is staying informed about advancements in packing techniques and the integration of automation. These innovations are designed to enhance efficiency, empowering lab managers with the knowledge necessary to tackle complex separation challenges effectively.

Introduction

In the realm of analytical chemistry, column chromatography emerges as a pivotal technique for the separation and analysis of complex mixtures. This method harnesses the interplay between stationary and mobile phases, enabling scientists to isolate components based on their unique affinities, which leads to precise and reliable results.

As technological advancements continue to reshape the landscape of chromatography, it becomes essential for laboratory managers to understand the fundamentals, explore various techniques, and master the intricacies of system components.

With a growing market projected to reach significant milestones in the coming years, it is crucial to stay informed about best practices and innovations in column chromatography. This knowledge is vital for enhancing laboratory performance and meeting the increasing demands of scientific research.

Understanding the Fundamentals of Column Chromatography

Column chromatography stands as a sophisticated separation technique that adeptly isolates components of a mixture through the interaction between a stationary medium and a mobile medium, leveraging their differing affinities. The stationary phase, typically composed of a solid substance packed within a tube, is pivotal in this process, while the mobile phase, a liquid solvent, traverses the tube, facilitating the movement of the sample.

A solid grasp of the principles of adsorption, partitioning, and polarity is crucial for attaining optimal separation outcomes. For example, polar compounds tend to engage more strongly with a polar stationary medium, resulting in a slower transit through the system compared to their non-polar counterparts. This principle underscores the importance of selecting the appropriate stationary and mobile phases to enhance separation efficiency.

Recent advancements in packing techniques have further refined these processes, yielding improved resolution and expedited analysis times. With the global market for electrokinetic separation columns projected to reach $747 million by 2025, propelled by increased adoption across diverse sectors, it is essential for laboratory managers to remain abreast of these developments. Erik Perison, US TPS Business Development Manager at Thermon, notes that this growth reflects the escalating reliance on advanced separation techniques.

Understanding the dynamics of stationary and mobile phases is vital not only for efficient separation processes but also for optimizing workflows in research facilities. JM Science Inc. consistently updates its product offerings and fosters robust relationships with leading manufacturers, ensuring lab managers have access to the latest innovations in separation technology. Recent statistics indicate that approximately 95% of research facilities refresh their separation services, highlighting the reliance on these methods for accurate and reliable results.

By mastering the fundamentals of column chromatography techniques, lab managers can equip their teams to address complex separation challenges, ultimately elevating the quality of their analytical outcomes. Moreover, employing a comprehensive research methodology, as demonstrated by Data Insights Market, can yield valuable insights that inform laboratory practices and decision-making in the realm of separation science.

Exploring Different Types of Column Chromatography

Column separation techniques encompass several distinct types, each tailored to specific applications and compound characteristics.

Normal Phase Chromatography employs a polar stationary medium combined with a non-polar mobile medium, making it particularly effective for separating polar compounds. Recent advancements have significantly improved the techniques utilized in normal separation processes, enhancing efficiency and accuracy across various applications.

Reverse Phase Separation utilizes a non-polar stationary phase and a polar mobile phase, widely adopted for the separation of non-polar compounds. This method has undergone significant updates in 2025, with innovations aimed at improving resolution and throughput, solidifying its role as a staple in pharmaceutical and biochemical laboratories.

Ion Exchange Chromatography separates ions and polar molecules based on their charge, proving invaluable in biochemistry for protein purification. Ongoing development in ion exchange materials has led to enhanced selectivity and capacity, addressing the growing demands of complex biological samples.

Size Exclusion Chromatography separates molecules based on size and is frequently employed for purifying proteins and polymers. The latest trends indicate a shift towards more sophisticated size exclusion media that offer improved resolution and faster processing times.

Flash Separation is a swift version of vertical separation that employs pressure to hasten the elution process. This method has gained popularity due to its efficiency and effectiveness in quick separations, particularly in preparative applications.

Each separation technique, such as column chromatography, presents unique advantages, with the choice of method dictated by the specific characteristics of the compounds being separated. Case studies have demonstrated the effectiveness of vertical separation techniques in various areas, including the extraction of pesticides and the synthesis of medical compounds like pramlintide. Additionally, the market share of normal phase compared to reverse phase separation techniques continues to evolve, reflecting changing preferences and technological progress within the industry.

As the landscape of separation science advances, practical applications are increasingly shaped by ongoing multicolumn separation (CMS) methods. Ohnmar Khanal observes that CMCC methods are more intricate than their batch separation equivalents due to the presence of multiple devices and valves. Despite their complexity, these approaches promise enhanced efficiency in biopharmaceutical manufacturing.

The integration of real-time monitoring and control strategies is essential for overcoming challenges associated with these advanced methodologies, ensuring laboratories can meet the rigorous demands of modern scientific research.

Key Components of Column Chromatography Systems

A typical column chromatography system comprises several essential components that work in concert to achieve effective separation of compounds:

- Column: This core element is where the separation process occurs. Columns are typically constructed from glass or plastic and vary in size and shape based on the application. JM Science Inc. offers a variety of HPLC materials, including Shodex, CapcellPak, and Reprosil, tailored for diverse chromatography needs.

- Stationary Stage: In column chromatography, the stationary stage, packed within the tube, is crucial for the separation process. Common materials include silica gel and alumina. The selection of the stationary medium must align with the polarity of the compounds being separated to ensure optimal results. This alignment is vital, as it directly influences the efficiency and effectiveness of the separation process.

- Mobile Phase Delivery System: This system consists of a pump that accurately transmits the mobile phase through the tube at a controlled flow rate. The efficiency of this system directly impacts the resolution and speed of the separation. JM Science's high-performance liquid separation systems are designed to enhance this aspect significantly.

- Detector: The detector plays a vital role in monitoring the elution of compounds from the chromatographic medium. It offers real-time information for analysis, allowing lab managers to evaluate the efficiency of the system effectively. JM Science also provides advanced detectors, including Shodex Refractive Index and Conductivity detectors, to support accurate monitoring.

- Fraction Collector: This component gathers the separated fractions as they elute from the apparatus, facilitating further analysis and application of the separated compounds.

Understanding these elements is crucial for lab managers seeking to sustain and enhance their separation systems, particularly through the use of column chromatography. For instance, the average lifespan of separation columns in laboratory settings is typically around 100 to 200 runs, depending on the application and maintenance practices. Implementing best practices, such as regular calibration of the mobile phase delivery system and routine checks on the detector's performance, can significantly enhance the longevity and efficiency of these systems.

Recent advancements in separation technologies, including the development of high-performance liquid systems, have further improved separation processes. These innovations are backed by an expanding market, with North America anticipated to lead the prepacked separation columns market due to significant R&D investments and the presence of numerous pharmaceutical firms. Historical market sizes from 2019 to 2024 indicate a robust growth trajectory, with forecasts extending to 2030 suggesting continued expansion.

Strategic partnerships, such as those between Astrea Bioseparations and Thermo Fisher Scientific, are enhancing product offerings and competitiveness in this sector.

Incorporating insights from experts, such as Dr. Sujatha Mahadevarao Premnath, who emphasizes that 'this technique helps accurately separate, identify, and quantify compounds in patient samples, enabling diagnostic, therapeutic, and research applications in healthcare,' underscores the critical role of this method in modern laboratory practices. By staying informed about the latest technologies and best practices, lab managers can ensure their separation systems are optimized for peak performance, leveraging the premium scientific instruments offered by JM Science Inc. Additionally, JM Science provides HPLC fittings, manual injection valves, and other accessories at competitive prices, making it a comprehensive solution for all separation needs.

Preparing and Packing Columns for Optimal Performance

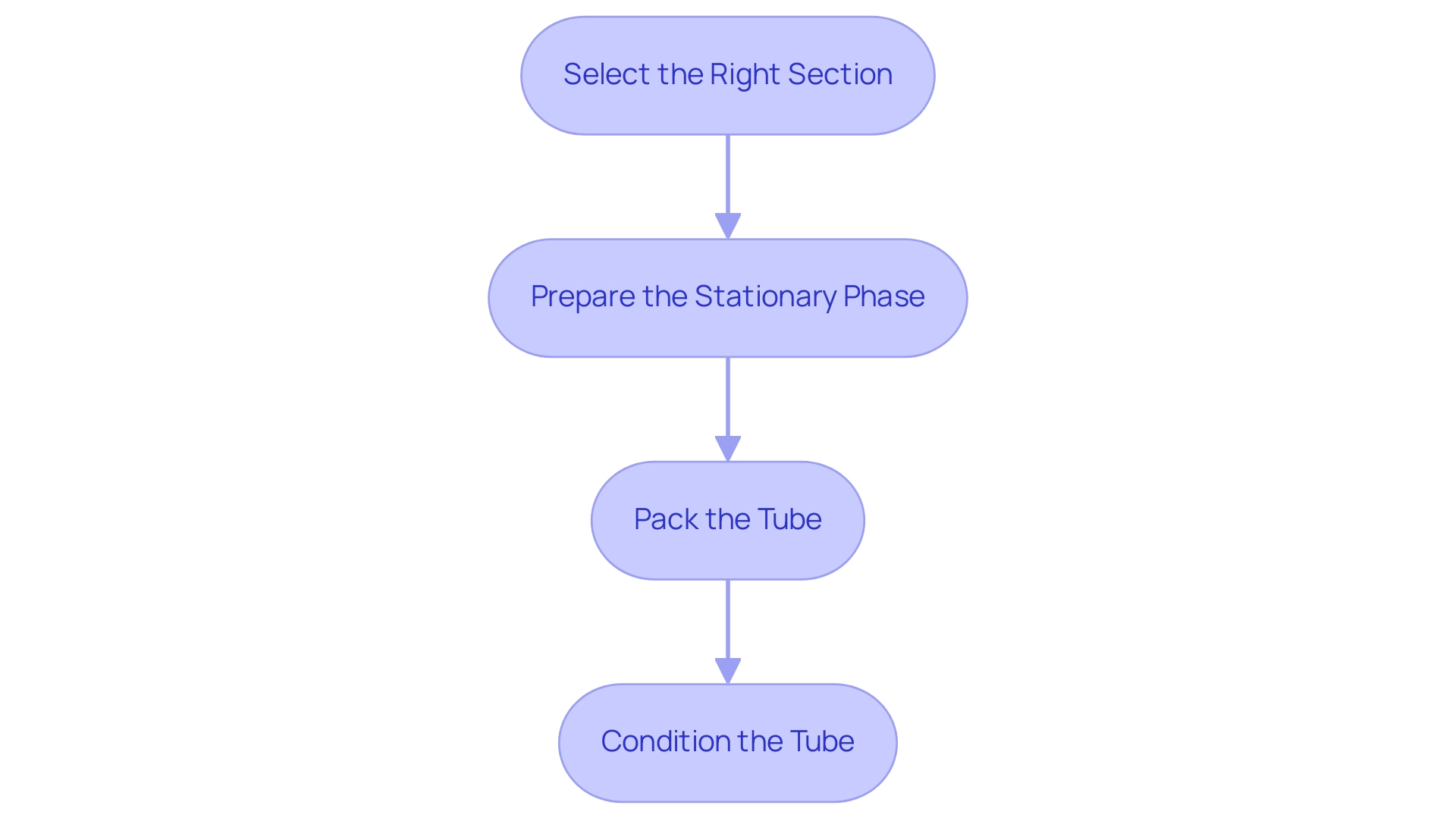

Adequate preparation and packing of separation tubes are crucial for attaining optimal performance in analytical applications. The following steps outline the best practices for preparing and packing chromatography columns in 2025:

- Select the Right Section: Begin by choosing a section that aligns with the specific type of chromatography being employed and the characteristics of the sample. This selection is critical as it directly influences the separation process.

- Prepare the Stationary Phase: For silica gel, ensure it is thoroughly dried and free from contaminants. In cases where wet packing is preferred, mix the silica gel with the mobile phase to create a uniform slurry. This preparation is vital for achieving consistent packing density and performance in column chromatography.

- Pack the Tube: Carefully pour the slurry into the tube, allowing it to settle evenly. It is crucial to avoid introducing air bubbles during this process, as they can disrupt the flow and lead to inconsistent results. Techniques such as tapping the support gently can help eliminate trapped air.

- Condition the Tube: Before loading the sample, run the mobile solvent through the tube to equilibrate it. This conditioning step is essential for stabilizing the stationary phase and ensuring reproducible retention times.

The effect of appropriate packing on chromatography performance cannot be overstated. Well-packed structures in column chromatography enhance separation efficiency, resulting in more accurate and reliable analytical results. Recent case studies have shown that laboratories employing optimal techniques in column chromatography preparation report significant improvements in their analytical outcomes, underscoring the importance of adhering to these best practices.

As James Waters aptly noted, "GPC took off like a rocket!" This reflects the rapid advancements in separation techniques that are reshaping the industry.

Furthermore, with the separation technology market projected to evolve significantly, as indicated by a forthcoming market report, it is crucial for lab managers to stay informed about current techniques and innovations. JM Science Inc. is dedicated to consistently refreshing its product range and fostering strong connections with leading manufacturers, guaranteeing that lab managers have access to the most recent developments in separation science. This commitment to innovation and adaptability positions JM Science Inc. favorably within the competitive landscape of the separation market, alongside key players like Thermo Fisher Scientific and Merck KGaA.

Troubleshooting Common Issues in Column Chromatography

Column chromatography stands as a fundamental technique in pharmaceutical laboratories, yet common challenges can significantly impede its effectiveness. To enhance separation processes, consider the following troubleshooting tips:

- Poor Separation: Often, this issue arises from improper packing or insufficient column conditioning. It is vital to confirm that the mobile medium is appropriately tailored for the specific compounds being separated. The diverse matrices utilized in the mobile context can greatly affect separation efficacy, particularly in applications such as antibody purification. Here, membrane chromatography has demonstrated promising results by overcoming mass transfer limitations. This innovative method facilitates the rapid purification of biomacromolecules, making it especially favored within the pharmaceutical sector.

- Low Flow Rate: A reduction in flow rate may signal blockages within the column or tubing. Regular inspections of these components are essential, alongside ensuring the pump is functioning correctly. Optimal flow rates are crucial for achieving the desired separation efficiency.

- Baseline Noise: An increase in baseline noise may point to issues with the detector or the mobile mixture itself. It is prudent to check for air bubbles or contaminants that may have infiltrated the mobile medium, as these can disrupt the detection process and yield inaccurate results.

- Retention Time Variability: Inconsistent retention times can result from variations in sample loading or fluctuations in the mobile mixture composition. To mitigate this, ensure uniform sample loading and maintain a consistent mobile phase throughout the analysis.

Addressing these common challenges not only bolsters the reliability of systems like column chromatography but also enhances the overall efficiency of laboratory operations. With the increasing frequency of troubleshooting needs in analytical labs, implementing these expert tips can lead to improved outcomes in drug development and purity testing. Ultimately, this contributes to advancements in healthcare diagnostics and therapeutics. As Sujatha Mahadevarao Premnath aptly states, "Chromatography helps accurately separate, identify, and quantify compounds in patient samples, enabling diagnostic, therapeutic, and research applications in healthcare."

This underscores the pivotal role of separation techniques in the pharmaceutical industry, where they are essential for drug development and purity testing. JM Science Inc. addresses these challenges by offering high-quality products such as premium HPLC tubes like Shodex and Capcell Pak, titrators, and innovative medical devices. Additionally, they provide extensive support resources, ensuring that lab managers are equipped with the necessary tools for success. Furthermore, JM Science offers competitive pricing on these products, making them accessible for pharmaceutical laboratories aiming to enhance their analytical capabilities.

Advanced Techniques and Innovations in Column Chromatography

Recent advancements in column chromatography are reshaping the landscape of analytical techniques, offering significant improvements in efficiency and effectiveness. Key innovations include:

- Gradient Elution: This technique enhances separation by systematically altering the mobile phase composition during the analysis. It is especially advantageous for resolving intricate mixtures, enabling enhanced resolution and peak separation.

- Flash Technique: Utilizing pressure to speed up the elution process, the flash technique is intended for high-throughput applications. This approach greatly decreases the time needed for separations, making it perfect for facilities that require quick results.

- Automated Systems: The incorporation of automation in separation systems reduces manual errors and improves reproducibility. These systems can operate unattended, freeing up valuable time for lab personnel and ensuring consistent results across multiple runs.

- Novel Stationary Phases: Recent innovations in stationary phase materials have led to enhanced selectivity and efficiency. These advancements allow laboratories to attain improved separation of difficult compounds, which is essential for intricate analytical tasks.

The compound annual growth rate (CAGR) for the separation equipment market is anticipated at 6.30% from 2025 to 2032, highlighting the increasing significance of these technologies in laboratory environments. Key players in this market include Bio-Rad Laboratories, Agilent Technologies, and Thermo Fisher Scientific, which are instrumental in driving innovation and quality in separation solutions.

As lab managers evaluate their separation processes, the adoption of these advanced techniques will be essential for maintaining a competitive edge and meeting the evolving demands of the scientific community. Continuous advancements in column chromatography technology and automation are transforming the sector towards high-throughput analysis, further enhancing the capabilities of modern laboratories. Real-world applications of gradient elution in column chromatography have demonstrated its effectiveness in separating complex mixtures, showcasing its benefits in practical scenarios. Moreover, the rising adoption rates of automated separation systems in research facilities indicate a wider trend towards efficiency and accuracy in analytical processes.

JM Science Inc. differentiates itself in this competitive landscape through exceptional customer support and a strategic focus on innovation, providing extensive resources such as how-to videos and application libraries to enhance its value proposition. By staying informed about these advancements, lab managers can optimize their separation processes and enhance overall laboratory performance.

Ensuring Quality Control and Compliance in Chromatography

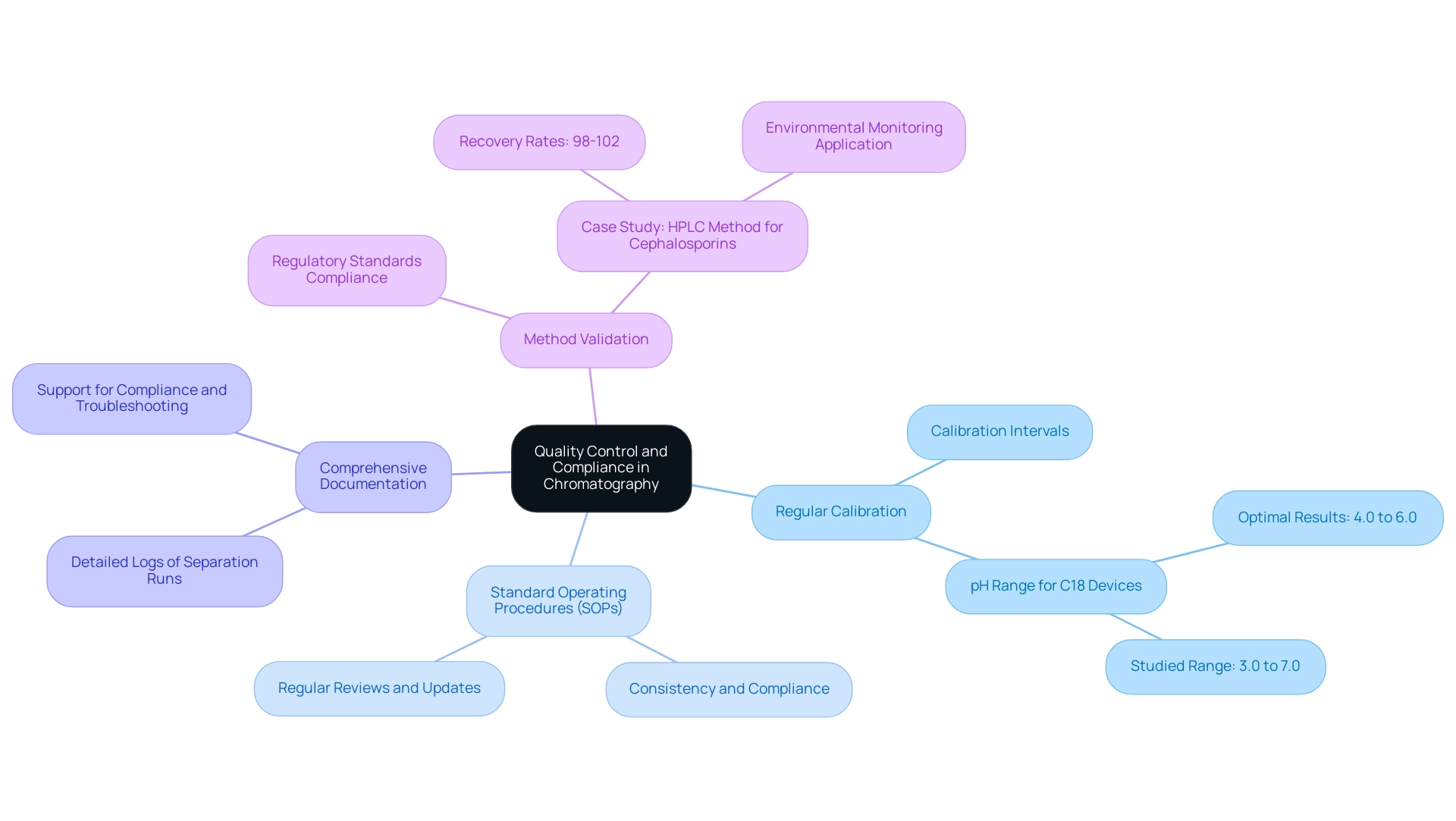

Quality control in column chromatography is critical for ensuring the reliability and accuracy of analytical results. Key practices include:

- Regular calibration

- Standard operating procedures (SOPs)

- Comprehensive documentation

- Method validation

Regular calibration of instruments is essential to uphold precision. Calibration should occur at defined intervals, emphasizing the preservation of accuracy within the specified pH range for C18 devices. The pH range studied for the C18 column was from 3.0 to 7.0, with optimal results observed between 4.0 and 6.0.

Establishing and adhering to SOPs is vital for consistency and compliance in separation processes. These procedures should be regularly reviewed and updated to reflect current best practices and regulatory requirements, ensuring that all laboratory personnel are aligned in their methodologies.

Comprehensive records of separation runs are essential, including detailed logs of conditions, results, and any deviations from established protocols. Such documentation not only supports compliance but also facilitates troubleshooting and method validation.

Regular method validation is necessary to confirm that analytical techniques meet regulatory standards and produce dependable results. For instance, a recent case study demonstrated the effectiveness of an HPLC method for quantifying cephalosporins in tap water, achieving recovery rates between 98-102%. This underscores the importance of validated methods in environmental monitoring.

Dr. Sujatha Mahadevarao Premnath noted, "This technique helps accurately separate, identify, and quantify compounds in patient samples, enabling diagnostic, therapeutic, and research applications in healthcare," highlighting the critical role of this process in medical applications.

Implementing these practices is crucial for lab managers aiming to maintain high standards of quality and compliance in analytical operations, particularly in the context of column chromatography. As the landscape of scientific practices evolves, staying informed about the latest developments, such as the Labmate Awards for Excellence 2025, can inspire facilities to adopt innovative quality control practices that enhance performance.

The Role of Automation in Column Chromatography

Automation in column chromatography offers a multitude of advantages that significantly enhance laboratory operations in 2025.

- Increased Throughput: Automated systems can process multiple samples concurrently, leading to a remarkable boost in productivity. This capability is crucial as research facilities face growing demands for faster results without compromising quality.

- Reduced Human Error: By minimizing manual handling, automation decreases the likelihood of errors, resulting in more reliable and accurate outcomes. This is especially important in high-stakes environments, such as pharmaceutical labs, where precision is paramount.

- Consistent Results: Automated systems maintain uniform conditions across all runs, enhancing reproducibility. This consistency is vital for validating results and ensuring compliance with regulatory standards.

- Time Savings: Automation facilitates unattended operation, allowing laboratory personnel to allocate their time to other essential tasks. This efficiency not only optimizes workflow but also contributes to overall operational effectiveness.

Current trends indicate that the adoption of automated separation systems is on the rise, driven by the increasing demand for advanced analytical techniques and government funding for research and development. For instance, the worldwide electrokinetic separation systems market is anticipated to reach a worth of $747 million by 2025, with a compound annual growth rate (CAGR) of 8.7% from 2019 to 2024. This growth is fueled by advancements in biomedicine, food safety, and agricultural science, highlighting the critical role of sophisticated analytical methods in these sectors.

As Erik Perison, US TPS Business Development Manager at Thermon, states, "The global electrokinetic separation systems market, valued at $747 million in 2025, is expected to see strong growth, fueled by the rising use of these systems across different sectors."

Real-world examples illustrate the impact of automation on laboratory throughput. Many labs have reported significant increases in sample processing capabilities, allowing them to meet the demands of high-volume testing environments. Experts in the field acknowledge that while automation has made substantial progress, achieving a level of intelligence comparable to experienced chromatographers remains a work in progress.

Nonetheless, the benefits of automation in column chromatography are evident, making it an essential consideration for lab managers seeking to enhance efficiency and accuracy in their operations.

Conclusion

Column chromatography stands as a cornerstone of analytical chemistry, offering sophisticated methods for the separation and analysis of complex mixtures. The exploration of its fundamentals, including the interaction between stationary and mobile phases, highlights the significance of choosing the right components to achieve optimal separation outcomes. By mastering various types of column chromatography—such as normal phase, reverse phase, and ion exchange—laboratories can fine-tune their approaches to meet specific analytical needs.

In addition to understanding the core components of chromatography systems, such as columns, stationary phases, and mobile phase delivery systems, the importance of proper preparation and packing techniques cannot be overstated. These practices directly influence the efficiency and accuracy of the separation process. Moreover, troubleshooting common issues, such as poor separation or low flow rates, is essential for maintaining high standards in laboratory operations.

The continuous evolution of chromatography technologies, including advancements in automation and innovative techniques like gradient elution, positions laboratories to enhance their throughput and precision. As the market for chromatography solutions expands, staying informed about best practices and emerging trends is vital for laboratory managers seeking to optimize performance and ensure compliance with quality standards.

Ultimately, the advancements in column chromatography not only promise improved analytical capabilities but also underscore the technique's critical role in various fields, including pharmaceuticals, environmental monitoring, and healthcare diagnostics. By embracing these innovations and maintaining a commitment to quality control, laboratories can ensure they remain at the forefront of scientific research and development, meeting the growing demands of the industry with confidence and expertise.