Overview

This article delves into the setup and troubleshooting of UV detectors in pharmaceutical labs, highlighting their vital role in ensuring accurate analyses and compliance with regulatory standards. It presents essential best practices for calibration, maintenance, and optimization of UV detectors.

Moreover, it addresses common challenges such as baseline noise and signal spiking, providing a comprehensive guide for laboratory professionals. By implementing these strategies, professionals can significantly enhance analytical reliability, ultimately leading to improved outcomes in their laboratory settings.

Introduction

Understanding the intricate world of UV detection is essential for pharmaceutical laboratories aiming for precision and compliance. UV detectors, capable of quantifying analytes and assessing product purity, are indispensable tools that significantly enhance analytical capabilities.

However, as technology evolves, so too do the challenges associated with their setup and maintenance. What best practices can ensure optimal performance? How can laboratories effectively troubleshoot common issues to uphold the integrity of their results?

This article explores the principles of UV detection, the various types of detectors available, and essential strategies for setup and troubleshooting, equipping professionals with the knowledge required to master this critical analytical technique.

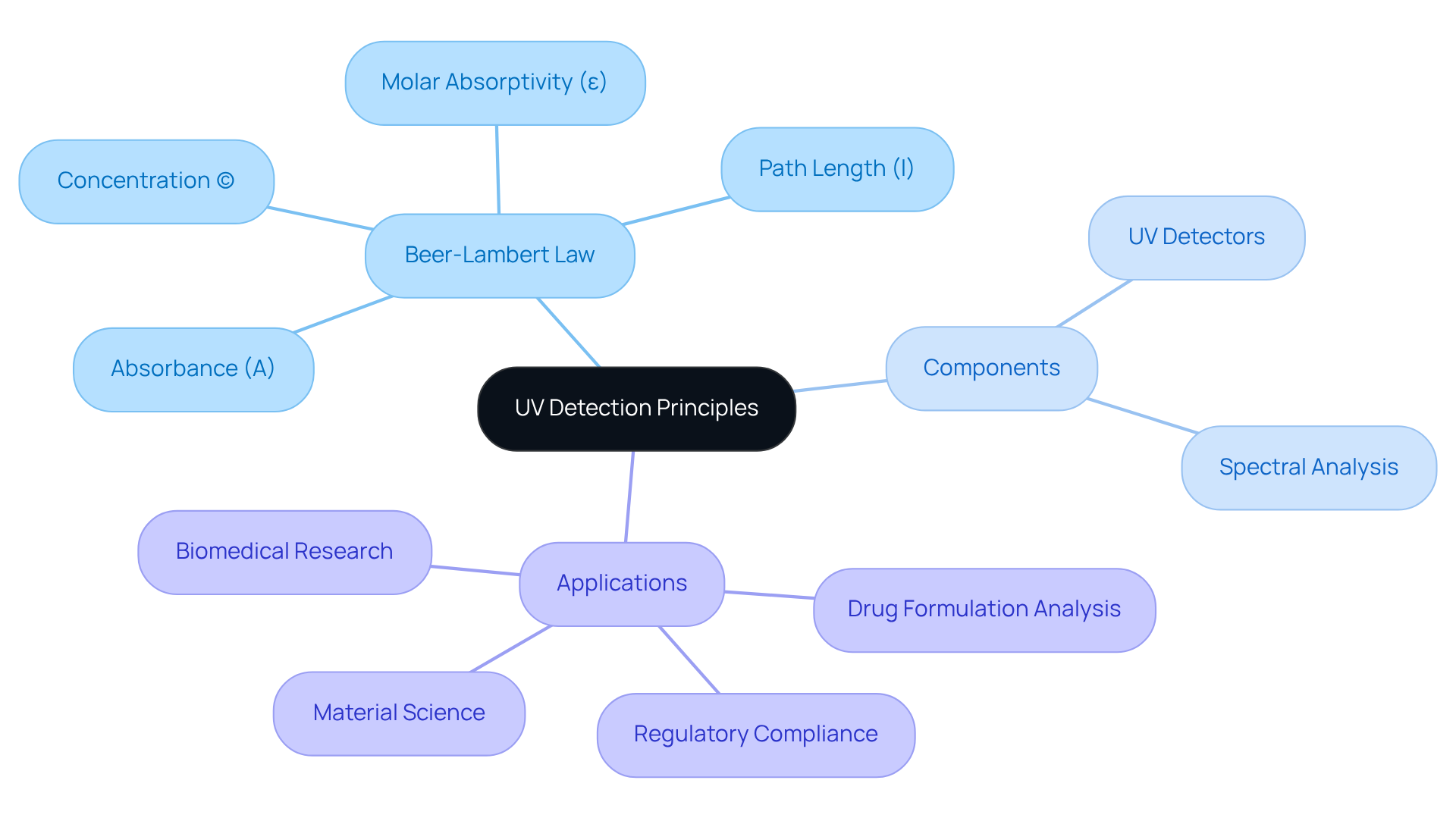

Explore the Principles of UV Detection in Pharmaceutical Applications

UV sensing operates on the principle that certain molecules absorb ultraviolet light at specific wavelengths, which facilitates the quantification of analytes in a sample. The Beer-Lambert law articulates this relationship, stating that absorbance (A) is directly proportional to the concentration (c) of the absorbing species and the path length (l) of the light through the sample:

A = ε * c * l

Here, ε represents the molar absorptivity coefficient. In drug-related environments, a UV detector is pivotal for measuring active components, assessing purity, and conducting stability studies. For example, applying the Beer-Lambert law in drug formulation analysis enables precise determination of concentration levels, essential for ensuring product efficacy and safety.

The significance of the Beer-Lambert law transcends mere measurement; it is vital for enhancing identification techniques and ensuring compliance with regulatory standards. Its impact is evident in various studies, particularly those utilizing UV-Vis spectroscopy to assess the quality of nanoparticles, which promote greener synthesis alternatives. Furthermore, advancements in UV detector methods have bolstered the ability to observe spectral variations linked to alterations and compound reactivity, making it indispensable for real-time evaluations across diverse medical applications.

As noted by industry experts, including Dr. Balamurugan Krishnamoorthy, "UV-Vis spectroscopy has long been a cornerstone analytical tool, especially valuable in material science, environmental monitoring, and biomedical research." This underscores the technique's —qualities that are crucial in drug analysis. Additionally, with over 25 million research publications utilizing UV-Vis spectroscopy, its widespread acceptance and significance in the field are undeniable.

Moreover, recent advancements in UV-Vis spectroscopy, particularly with the use of UV detectors, have broadened its capabilities and applications within the drug industry, aligning with regulatory requirements and enhancing analytical precision. For instance, the development of a copper-doped biochar nanozyme for uric acid identification exemplifies the practical application of the Beer-Lambert law in medical diagnostics. Such innovations not only affirm the law's relevance but also highlight the ongoing evolution of UV detector methods in drug laboratories.

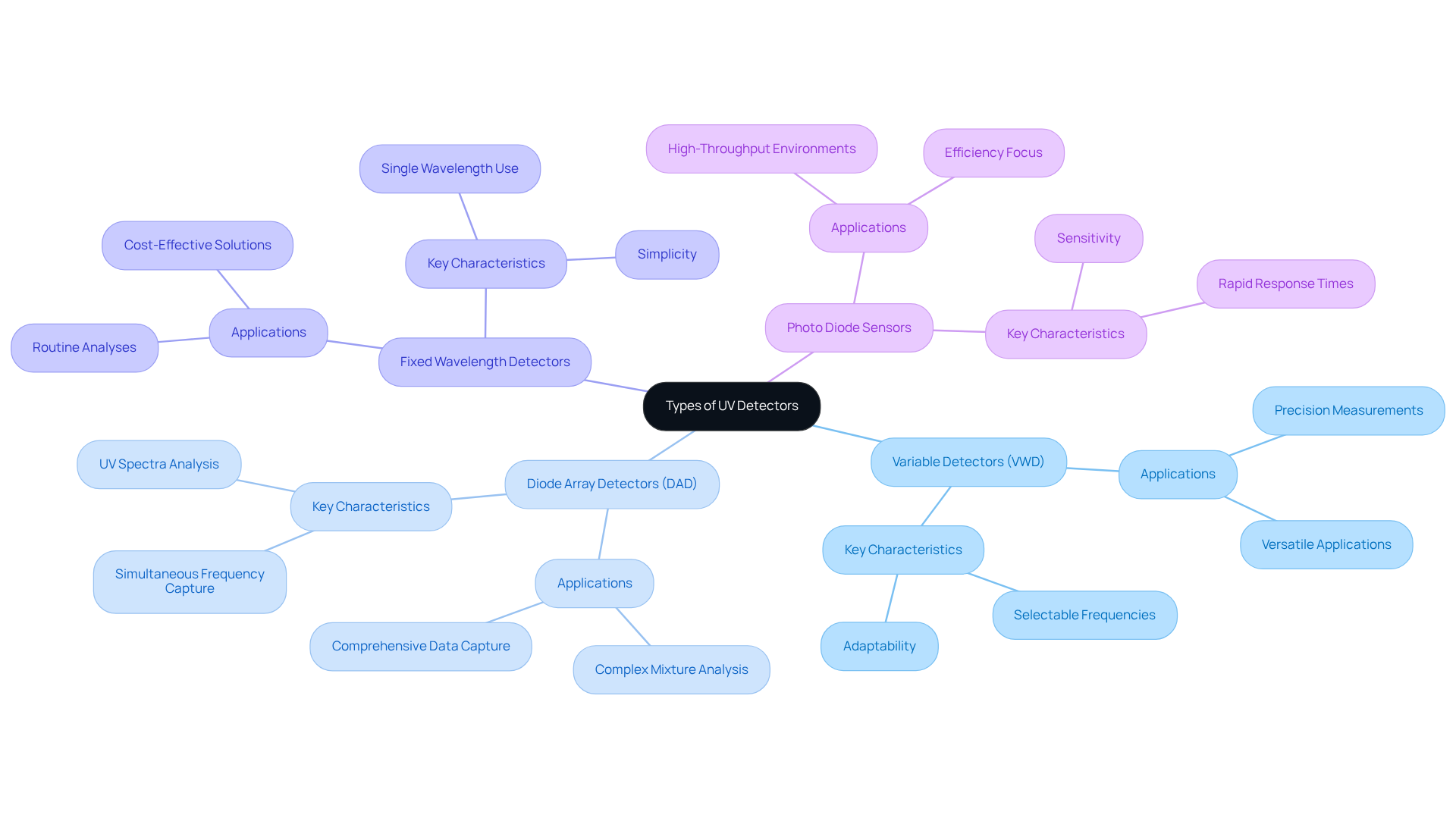

Examine Different Types of UV Detectors and Their Applications

In pharmaceutical laboratories, several types of UV detectors play a crucial role in ensuring accurate analyses:

- Variable Detectors (VWD) allow for the selection of specific frequencies, making them versatile for a variety of applications. This adaptability is essential for laboratories that require precision in their measurements.

- Diode Array Detectors (DAD) excel in capturing UV spectra across multiple frequencies simultaneously with the help of a UV detector. This capability is particularly advantageous for analyzing complex mixtures, providing comprehensive data on the analytes involved.

- The fixed wavelength UV detector is a more straightforward and cost-effective option, ideal for routine analyses where only a single wavelength is necessary. Their simplicity does not compromise their effectiveness, making them a staple in many laboratory settings.

- The UV detector, a type of photo diode sensor, is recognized for its sensitivity and rapid response times, often utilized in high-throughput environments where efficiency is paramount.

Each type of sensor possesses unique strengths, and the choice of which to use is determined by the specific requirements of the analysis, including sensitivity, speed, and the nature of the sample. Understanding these distinctions is vital for laboratory professionals aiming to optimize their analytical processes.

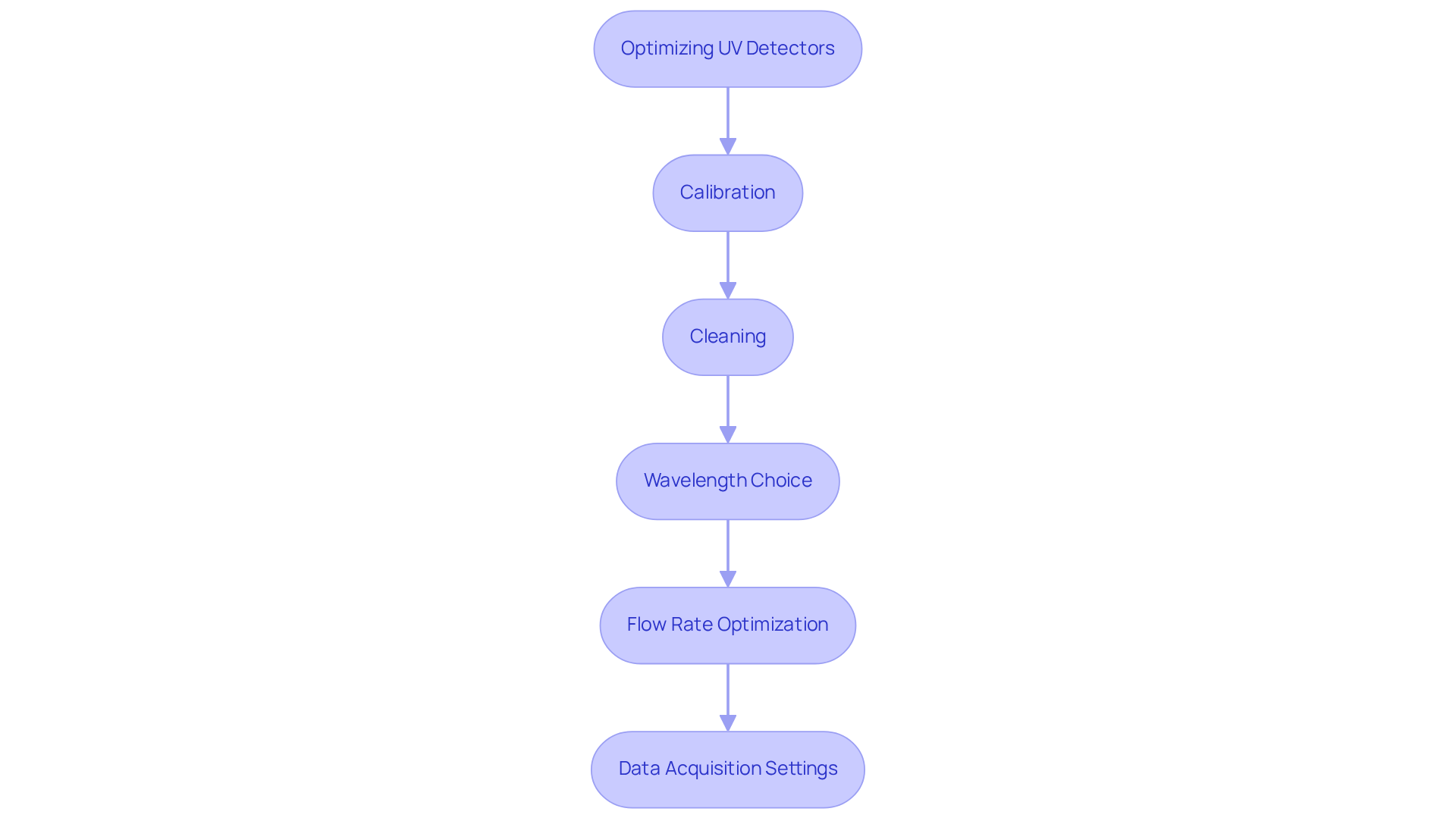

Implement Best Practices for Setting Up and Optimizing UV Detectors

To effectively set up and optimize the performance of UV detectors, it is imperative to adhere to that enhance reliability.

- Calibration is crucial; regular calibration using standard solutions is essential for maintaining accuracy. Employing NIST-traceable standards guarantees reliable results, ensuring that your measurements are both precise and trustworthy.

- Cleaning the optical components is vital to prevent contamination that can compromise readings. Utilize appropriate solvents and techniques for thorough cleaning. Regular maintenance, including the inspection and cleaning of windows and lenses, is crucial for optimal performance. Indicators such as low source energy and baseline wandering may signal the need for servicing. Periodic inspection and cleaning of the flow cell can help eliminate dirt and particles, ensuring stable detector performance.

- Wavelength choice plays a significant role in enhancing sensitivity. Selecting the optimal frequency for your analyte based on its absorbance traits will yield the best results. The maximum absorbance wavelength is often the most effective choice for monitoring in HPLC applications.

- Flow rate optimization is another key factor. Adjust the flow rate to ensure the sensor responds adequately to concentration changes without introducing baseline noise. Implementing a back-pressure device set between 50 to 300 psi can mitigate signal spiking, thus enhancing stability.

- Data acquisition settings must also be configured appropriately. Setting the right data acquisition rates and time constants balances sensitivity and response time, ensuring that the sensor captures all pertinent data without distortion. This contributes significantly to enhanced baseline stability.

By adopting these practices, laboratories can significantly improve the performance of UV detectors, resulting in more dependable analytical outcomes. Routine inspections and upkeep, including clearing the flow cell to remove trapped air bubbles, further stabilize sensor performance and avert erratic baseline fluctuations. As Michael W. Dong observed, the DAD aids in peak identification, making it a favored instrument in pharmaceutical laboratories.

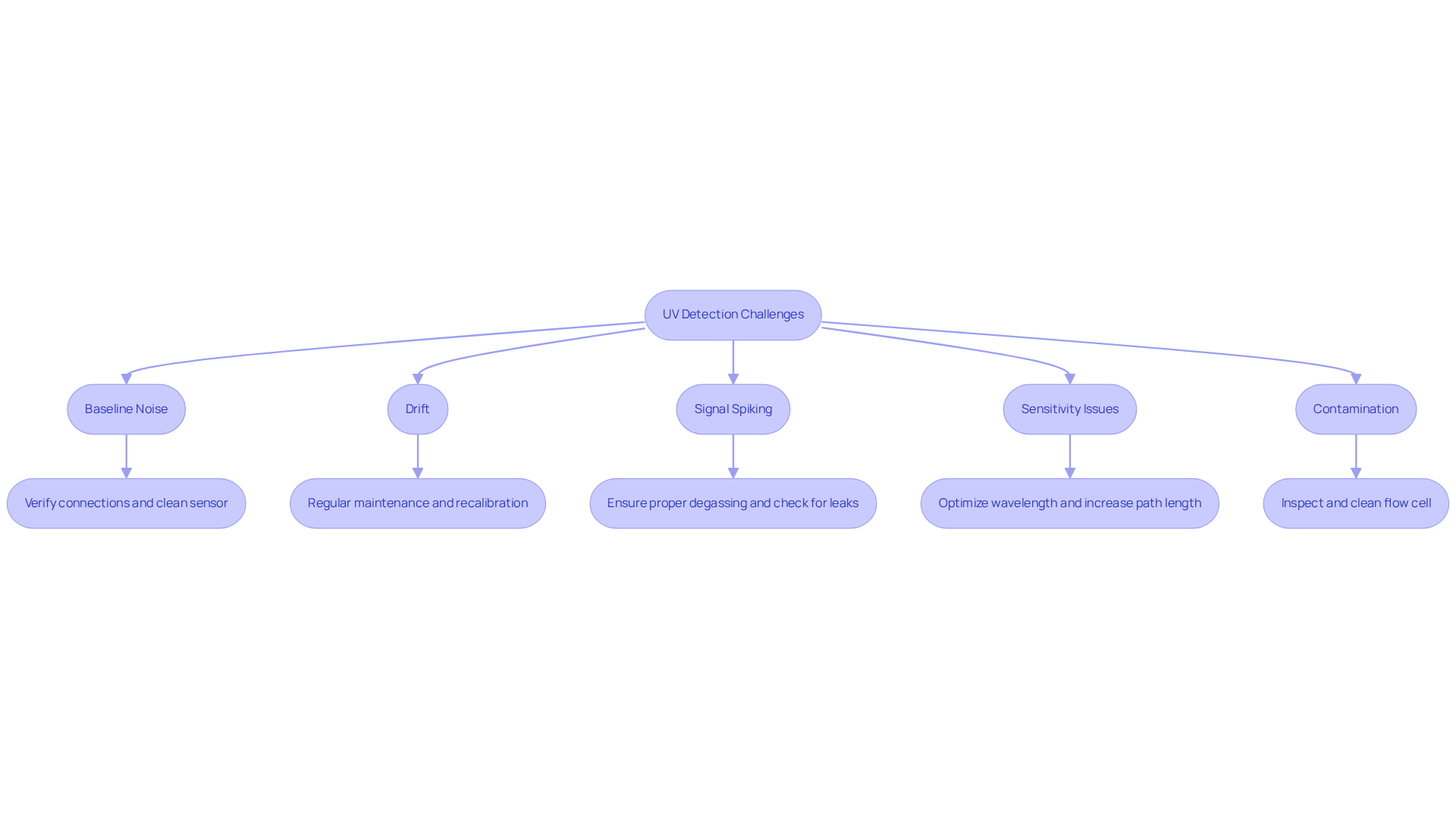

Identify Challenges and Troubleshoot UV Detection Issues

Common challenges in using a UV detector for UV detection are critical to address for maintaining the integrity of analytical outcomes.

- Baseline Noise is a prevalent issue, often stemming from electronic interference or inadequate cleaning of optical components. To combat this, it is essential to and ensure the sensor is meticulously cleaned.

- Drift represents a gradual change in the baseline, which may indicate underlying problems with the lamp or sensor alignment. Regular maintenance and recalibration are crucial strategies to mitigate this concern.

- Signal Spiking, frequently caused by bubbles in the flow path, can disrupt measurements. Ensuring proper degassing of solvents and checking for leaks within the system are effective resolutions.

- Sensitivity Issues may arise if the detector lacks adequate responsiveness. In such cases, optimizing the wavelength, increasing the path length, or selecting a more sensitive detector type can significantly enhance performance.

- Lastly, Contamination poses a risk that can skew results. It is vital to regularly inspect and clean the flow cell to prevent such occurrences.

By comprehensively understanding these challenges and implementing their respective solutions, laboratory personnel can uphold the integrity of their UV detector systems, ultimately ensuring reliable and accurate analytical outcomes.

Conclusion

Mastering the setup and troubleshooting of UV detectors is paramount for optimizing analytical processes in pharmaceutical laboratories. A comprehensive understanding of the principles behind UV detection, including the Beer-Lambert law, empowers professionals to measure and analyze compounds effectively, thereby ensuring product safety and compliance with regulatory standards. Furthermore, the ability to select the appropriate type of UV detector tailored to specific applications significantly enhances the accuracy and reliability of results.

Key insights encompass the various types of UV detectors, such as:

- Variable Detectors

- Diode Array Detectors

- Fixed wavelength detectors

Each presents unique advantages suited for diverse analytical needs. Adhering to best practices for calibration, cleaning, and optimizing operational parameters is crucial for maintaining detector performance. Additionally, recognizing common challenges, such as baseline noise and contamination, equips laboratory personnel with the skills to troubleshoot effectively, thereby safeguarding the integrity of their analyses.

In conclusion, the importance of UV detection in pharmaceutical applications is undeniable. As the industry progresses, embracing advancements in UV technology and adhering to best practices will be essential for achieving reliable outcomes. Laboratories are urged to implement these strategies and remain vigilant in addressing challenges, ultimately enhancing the overall quality of pharmaceutical testing and contributing to the advancement of drug development.