Overview

The article titled "10 Essential Tips for Your HPLC Analytical Column Success" presents vital strategies aimed at optimizing the performance and extending the lifespan of HPLC analytical columns. It underscores the critical nature of:

- Routine maintenance

- Effective cleaning techniques

- The careful selection of materials

Expert recommendations and empirical data bolster these strategies, ensuring that users achieve reliable and accurate analytical results across a range of applications. By emphasizing these practices, the article not only captures attention but also builds interest in the importance of high-quality scientific instruments in laboratory settings.

Introduction

Navigating the complexities of high-performance liquid chromatography (HPLC) can be daunting. In analytical chemistry, where precision and reliability are paramount, the right techniques and practices are essential. These elements can significantly enhance the performance of HPLC analytical columns, rendering them indispensable tools across various fields, from pharmaceuticals to environmental testing. However, many laboratories encounter common pitfalls and maintenance challenges that can compromise their results.

What essential strategies can ensure optimal performance and longevity of HPLC columns while maximizing analytical precision?

JM Science HPLC Columns: Enhance Your Analytical Precision

JM Science presents a diverse array of high-performance [HPLC analytical columns](https://jmscience.com/products/test-capcell-pak-c-18-mg-ii-hplc-column-35x1-5mm-pore-size-100a-particle-size-3um?srsltid=AfmBOopFF9q1JI0nzl4p0Hwo6jPtl8hczf4WFToIvrd0NJI8Bm3sODP8), meticulously engineered to meet the demanding standards of analytical chemistry. These structures excel in providing exceptional , enabling precise analysis of even the most intricate mixtures. By leveraging cutting-edge materials and technologies, they significantly enhance resolution and reproducibility, making them essential for applications in pharmaceuticals, environmental testing, and beyond.

Choosing the appropriate option from JM Science empowers laboratories to elevate their analytical capabilities, ensuring reliable and accurate results in their research endeavors. The increasing demand for tools like the HPLC analytical column is further underscored by their pivotal role in drug development and quality assurance, where precision is paramount.

Master HPLC Column Washing: Techniques for Optimal Performance

To ensure the optimal operation of chromatography systems, the application of efficient cleaning methods is essential. Regular flushing with suitable solvents, such as a gradient wash of water and organic solvents, effectively removes residual samples and contaminants. A widely adopted practice commences with a 50% water and 50% methanol solution, gradually increasing the methanol concentration to 90%. This method not only cleans the area but also prepares it for subsequent analyses, thereby .

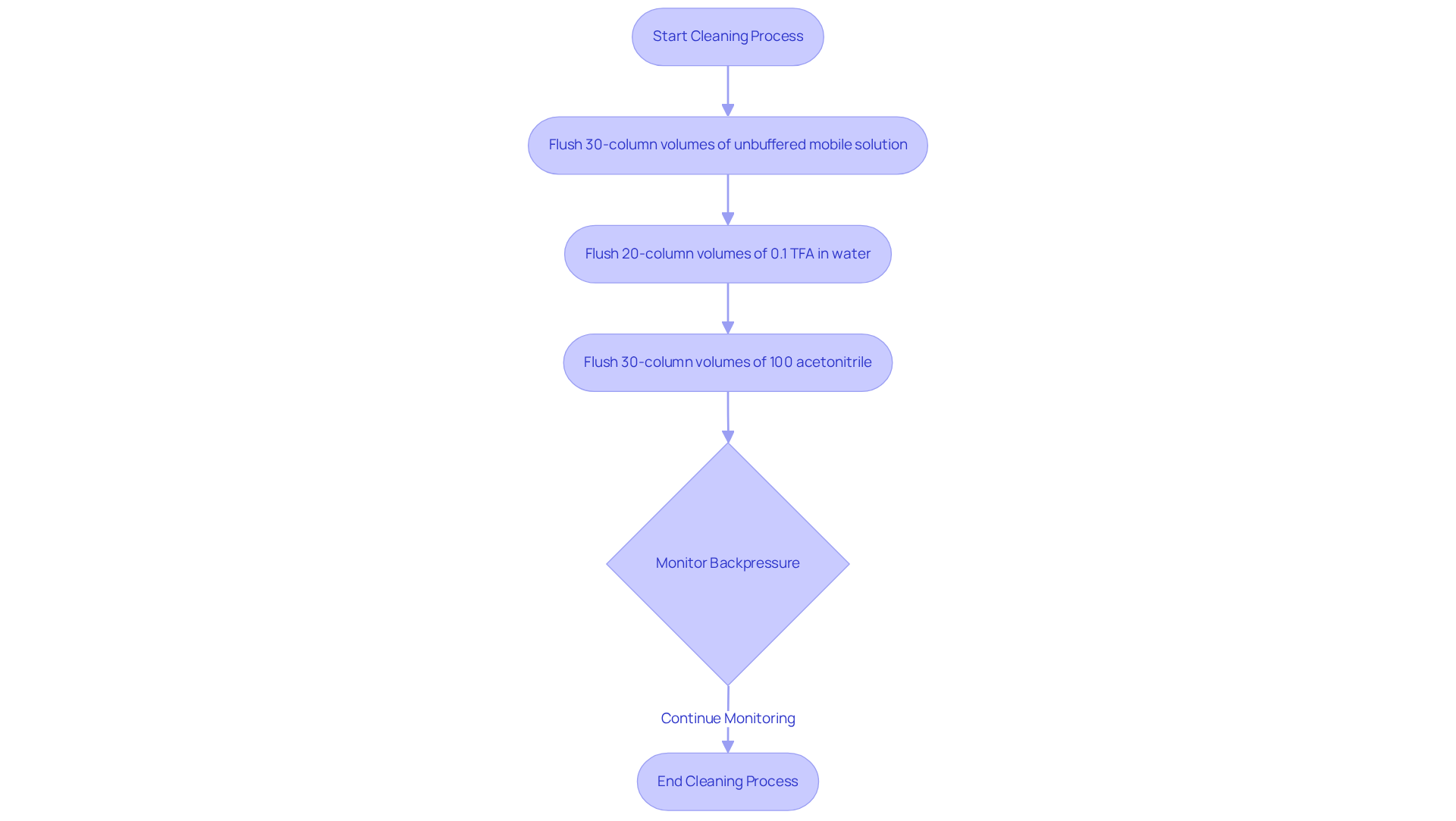

Routine cleaning is crucial; studies indicate that regular maintenance of the HPLC analytical column can significantly extend its lifespan, thereby reducing replacement frequency and costs. For instance, a thorough cleaning cycle involves a sequence of solvents—starting with:

- Flushing 30-column volumes of the unbuffered mobile solution

- Following with 20-column volumes of 0.1% TFA in water

- Concluding with 30-column volumes of 100% acetonitrile

This ensures contaminants are effectively flushed out.

Expert opinions underscore the importance of monitoring backpressure during cleaning, as a 5% increase can signal clogging due to impurities. Furthermore, using a stronger solvent than the mobile phase employed in prior analyses can enhance cleaning efficiency.

Best practices recommend that sections should be cleaned prior to storage, particularly after extended use, to prevent deterioration. Marking the section with the last-use date aids in tracking maintenance, especially in shared lab environments. By adhering to these techniques, laboratories can sustain high performance and reliability in their chromatographic analyses with an HPLC analytical column.

Achieve Proper HPLC Column Equilibration: Best Practices

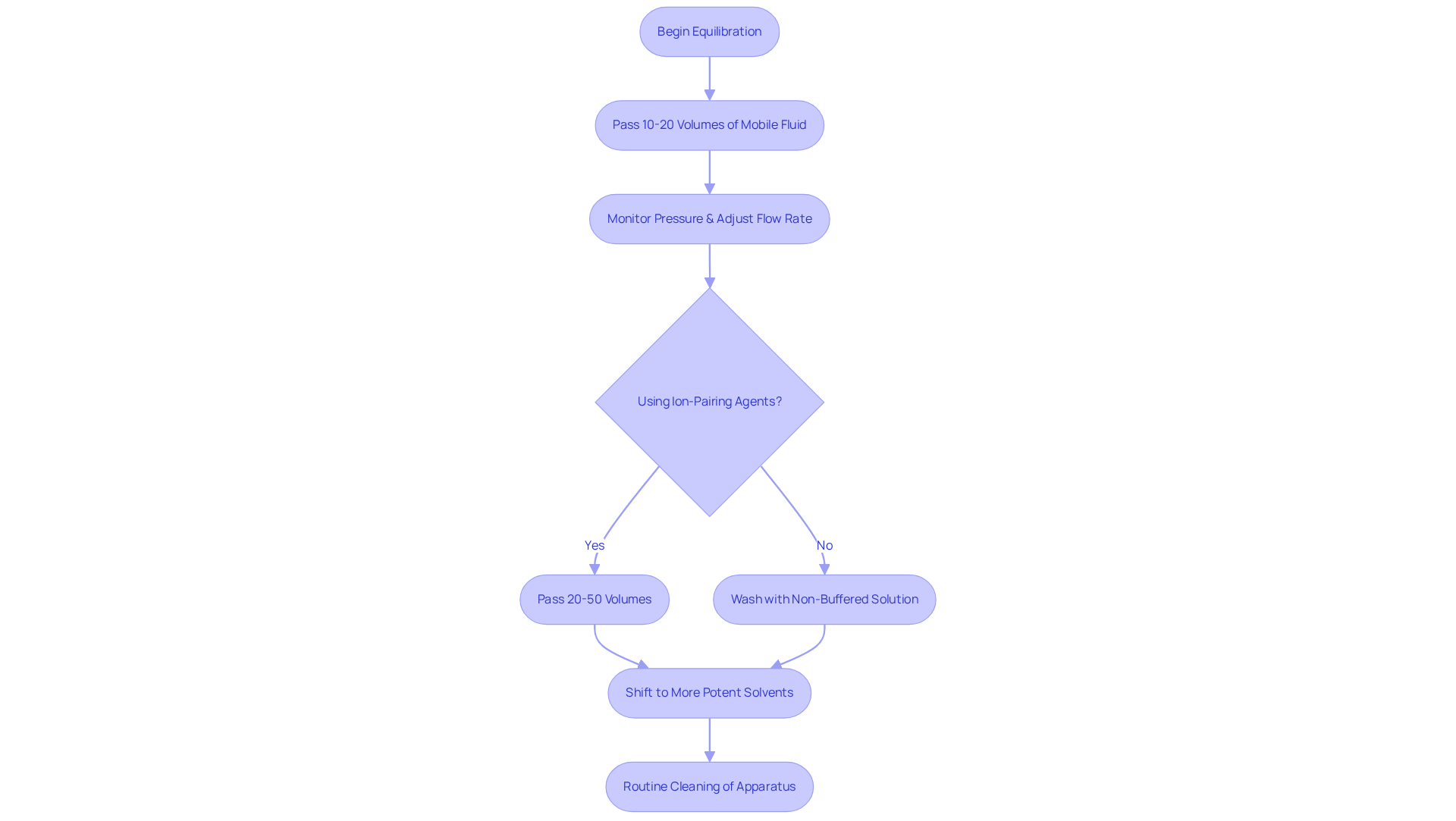

Proper equilibration of the HPLC analytical column is essential for obtaining consistent results. To establish a stable baseline and ensure that the stationary phase is fully saturated with the mobile phase, it is suggested to pass roughly 10-20 volumes of the mobile fluid through the setup before commencing the analysis. Additionally, overseeing the pressure and steadily modifying the flow rate can avert shock to the structure, further improving its performance.

It is crucial to note that when utilizing ion-pairing agents, equilibration can be particularly challenging, often necessitating 20-50 volumes of the medium to achieve stability. To prevent the accumulation of salts, prior to transitioning to more potent solvents is recommended for optimal use of the HPLC analytical column.

As John W. Dolan emphasizes, "Theory guides, experiment decides," highlighting the necessity of empirical data in chromatography. Many chromatographers have observed that adhering to these guidelines leads to significant improvements in data quality and reproducibility. Furthermore, routine cleaning of the apparatus after use or a shift in mobile conditions is vital for sustaining optimal functionality.

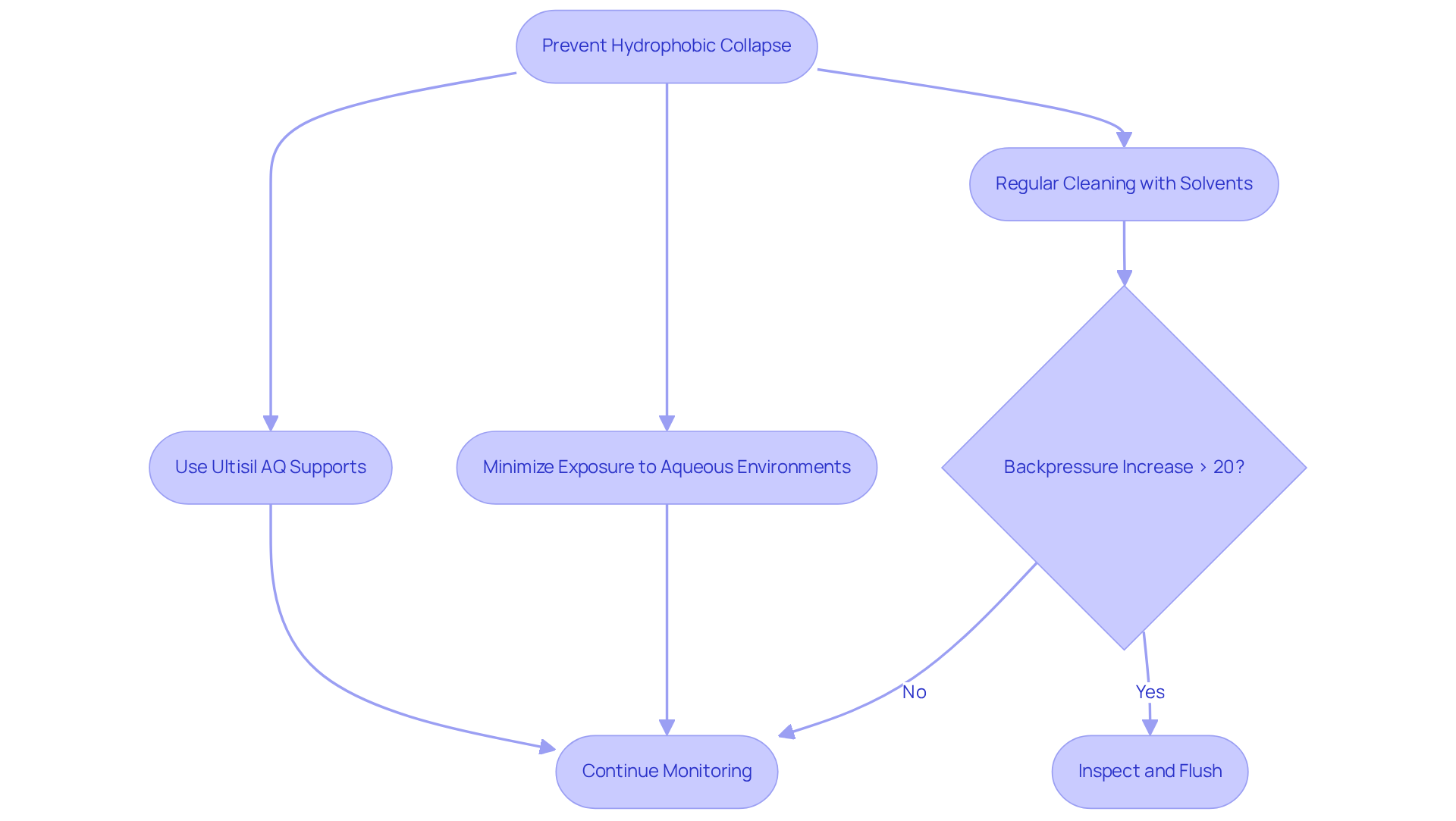

Prevent Hydrophobic Collapse: Strategies for HPLC Columns

To effectively in HPLC systems, particularly in reversed-phase chromatography, it is crucial to minimize prolonged exposure to highly aqueous mobile environments. Instead, opt for supports specifically engineered to withstand 100% aqueous mobile conditions, such as Ultisil AQ supports, designed to maintain performance even in challenging scenarios. Regular cleaning with potent natural solvents, including acetonitrile or methanol, is vital for preserving the hydrophobic properties of the support and preventing phase collapse. For example, flushing the tube with 95-100% organic solvent for several volumes can efficiently re-wet the stationary phase after contact with aqueous solutions.

Implementing these strategies not only protects the integrity of the HPLC analytical column but also enhances its analytical reliability. Real-world applications illustrate that consistent monitoring of key performance indicators, such as backpressure and retention time shifts, can alert analysts to potential issues before they escalate. A 20% increase in backpressure should trigger an inspection and flushing. By maintaining a minimum of 5-10% organic solvent in the mobile phase or storage solution, laboratories can further reduce the risk of de-wetting. These optimal methods bolster the durability of the HPLC analytical column components, ensuring they deliver precise and consistent results over time.

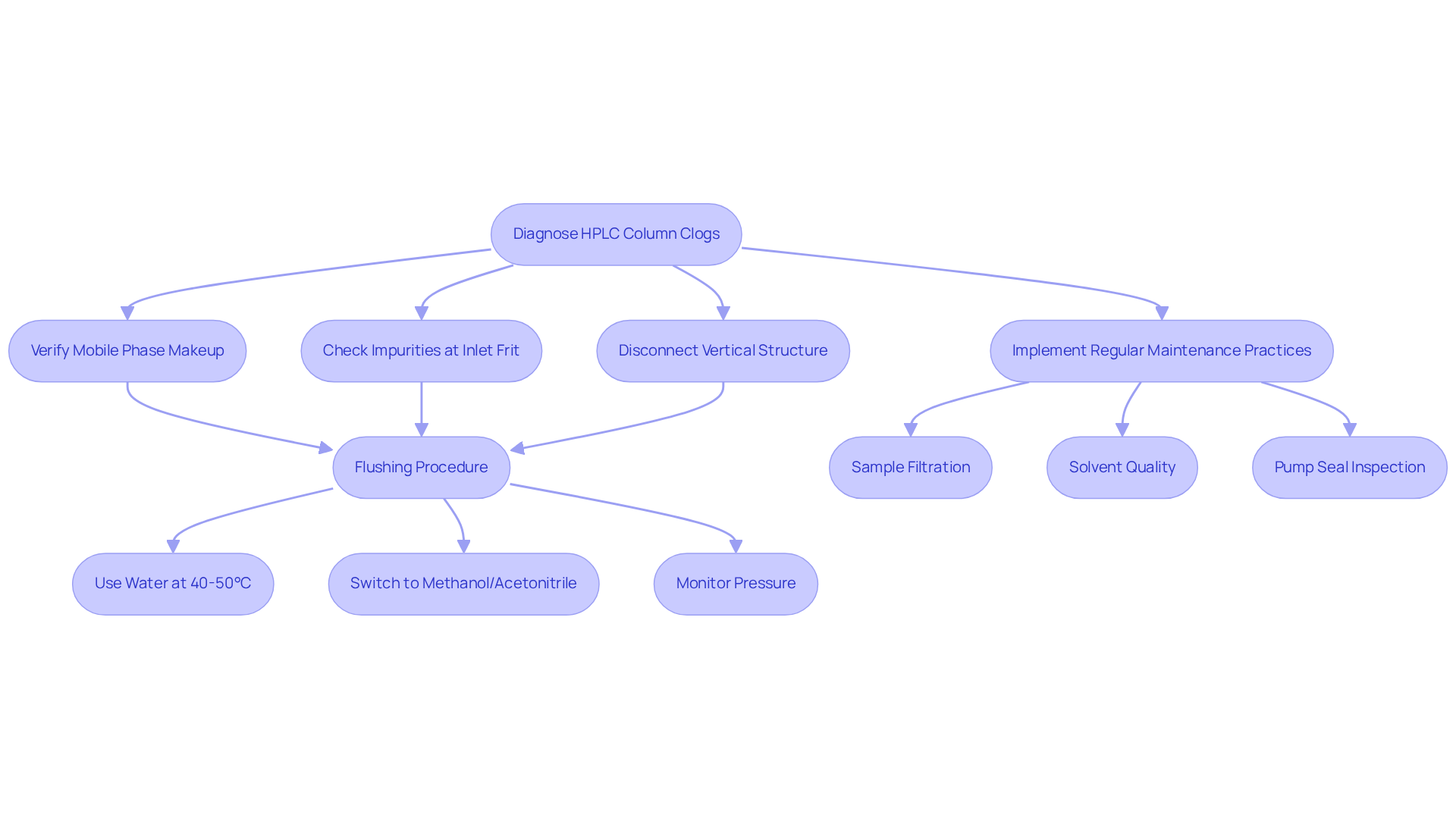

Diagnose and Resolve HPLC Column Clogs: Essential Steps

Diagnosing and resolving blockages in an HPLC analytical column system requires a methodical approach. Begin by verifying the mobile phase makeup to ensure compatibility with the system's structure. Impurities at the inlet frit can lead to increased backpressure, which is crucial for understanding the causes of clogs.

If a blockage is suspected, disconnect the vertical structure and initiate a flushing procedure using a series of solvents. Start with (40-50°C) and progress to organic solvents such as methanol or acetonitrile. Monitoring pressure throughout this process is essential, as it can help pinpoint the blockage's location.

Regular maintenance practices, including:

- Thorough sample filtration

- Consistent solvent quality

- Routine inspection and replacement of pump seals

are vital to maintain optimal system performance and prevent future clogs in the HPLC analytical column. As John Dolan aptly notes, "A clogged system doesn’t just cost time—it can also increase operating expenses and reduce confidence in your data."

Implementing these strategies not only enhances the reliability of analyses but also extends the lifespan of chromatography columns, ultimately leading to more precise and consistent results.

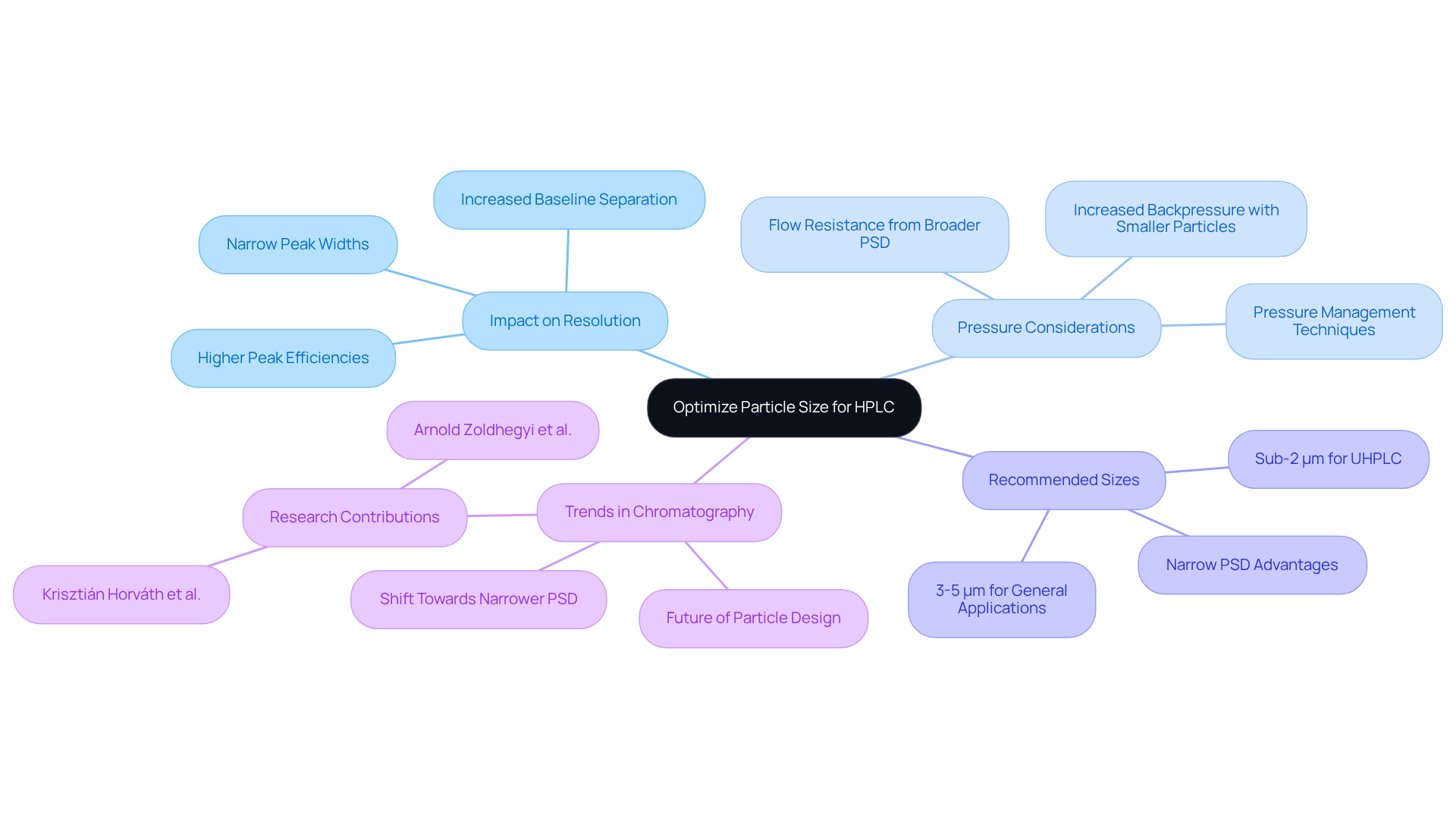

Optimize Particle Size: Key to Effective HPLC Separation

Optimizing particle size is essential for achieving effective separation with an HPLC analytical column. Smaller particle sizes typically and efficiency by minimizing mass transfer resistance. However, it is crucial to consider the system's pressure capabilities, as smaller particles can lead to increased backpressure.

For most applications, a recommended particle size range of 3-5 µm is advisable. In the realm of ultra-high efficiency liquid chromatography (UHPLC), utilizing sub-2 µm particles can significantly elevate efficiency and resolution. Recent studies, including research conducted by Arnold Zoldhegyi, Róbert Kormány, Szabolcs Fekete, Krisztián Horváth, and Imre Molnar, indicate that narrower particle size distributions (PSD) can further enhance the system's effectiveness, as they tend to produce lower pressure and improve peak efficiencies.

It has been observed that broader particle distributions generate more flow resistance due to smaller particles filling gaps between larger ones. For instance, smaller particle sizes in an HPLC analytical column correlate with narrower peak widths, which, in turn, increases resolution by extending the baseline between adjacent peaks.

As Richard A. Henry pointed out, managing particle size distribution is a viable method to enhance the effectiveness of HPLC analytical columns. As the sector progresses, the trend is moving towards the use of narrower PSD particles, anticipated to prevail in future chromatography applications because of their enhanced attributes. Furthermore, it is essential to recognize that efficiency is inversely related to particle size, underscoring the critical connection between particle size and chromatography performance.

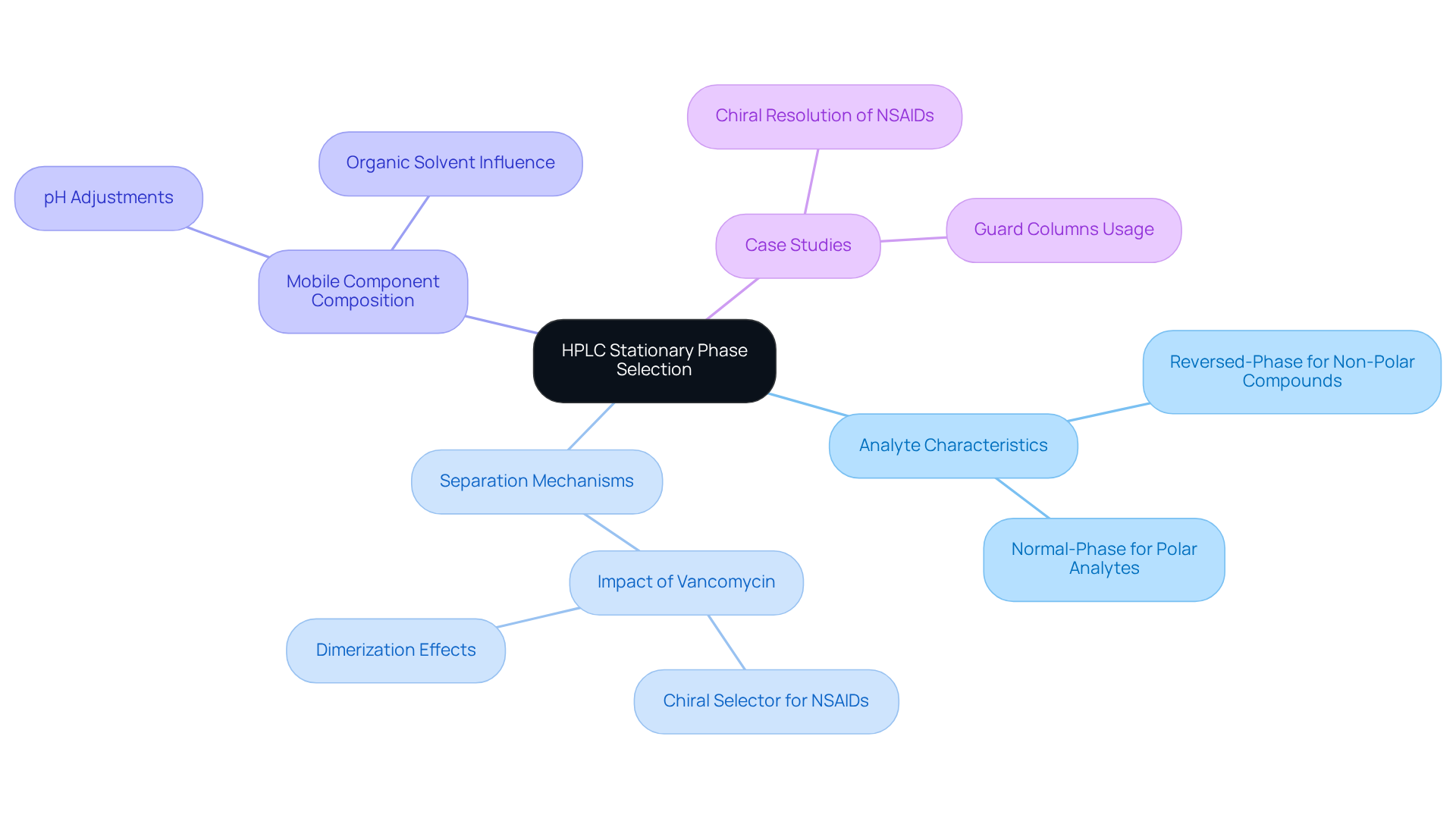

Select the Right Stationary Phase: Enhance HPLC Selectivity

Selecting the suitable stationary medium is crucial for enhancing HPLC selectivity. Key elements to evaluate include the chemical characteristics of the analytes, the intended separation mechanism, and the composition of the mobile component. For example, reversed-phase systems excel in separating non-polar compounds, while normal-phase setups are more effective for polar analytes. A notable study demonstrated that the selectivity for S-naproxen enantiomers reached 2.15, with a resolution of 2.5 when using vancomycin as a chiral selector. This showcases the significant impact that stationary material choice has on separation outcomes.

Moreover, the dimerization of vancomycin enhances its interaction with analytes, further improving enantiomeric resolution. Understanding the is essential for selecting the most effective column for specific applications, ultimately leading to improved separation efficiency.

As emphasized by industry specialists, the appropriate HPLC analytical column can considerably affect retention and selectivity, making it a critical factor in method development for high-performance liquid chromatography. Furthermore, the increasing importance of various stationary materials is underscored by the fact that HILIC usage has doubled since 2007. Financial considerations also play a role, with the average annual purchase budget for prepacked analytical HPLC columns being approximately $2890.

Additionally, managing vancomycin retention duration through mobile environment pH adjustments is essential, as highlighted by Dehbiya Gherdaoui. The practical application of stationary phase selection is further illustrated in the case study on the chiral resolution of NSAIDs using vancomycin, emphasizing its significance in achieving successful enantioseparation.

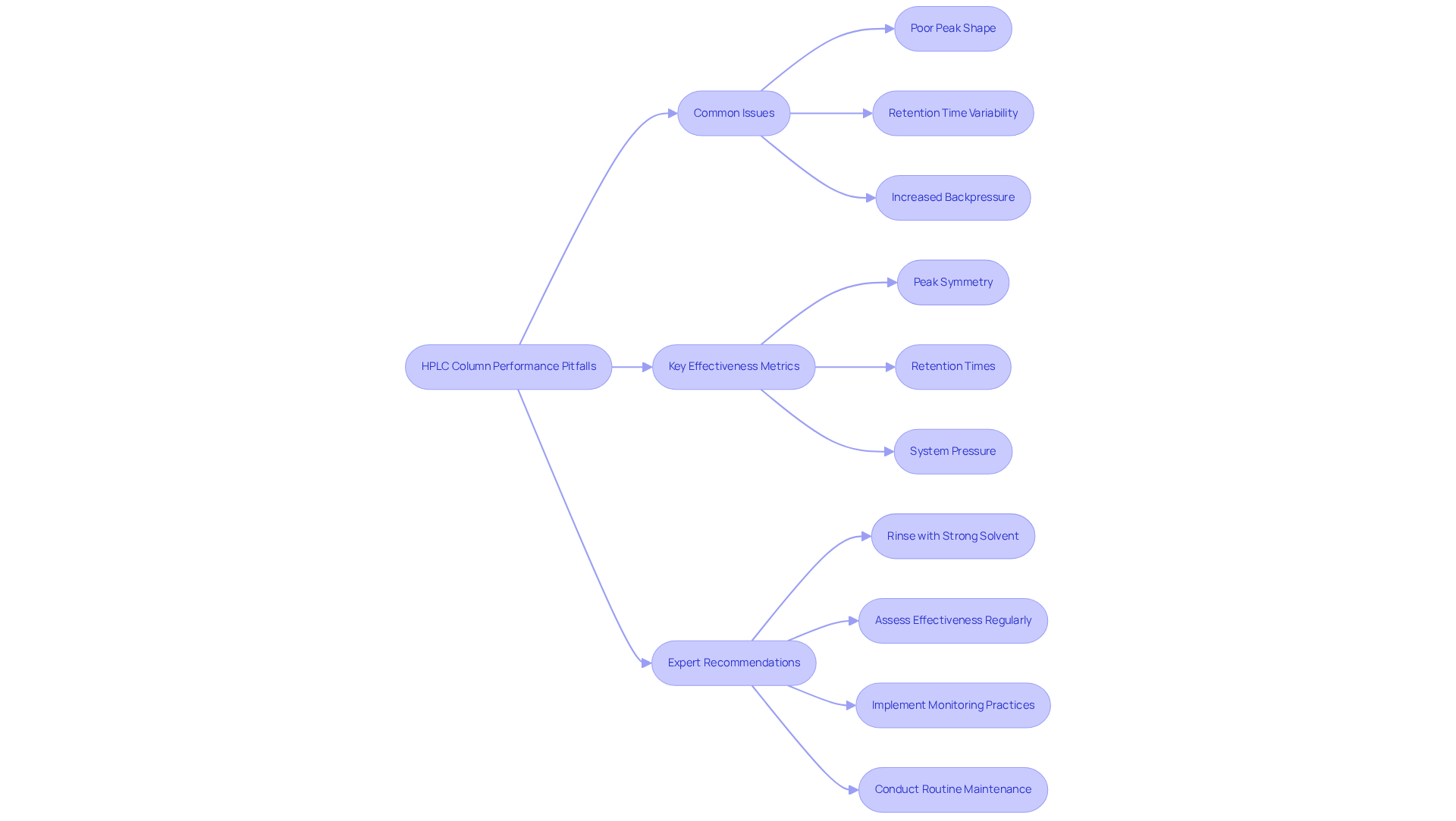

Understand Common HPLC Column Performance Pitfalls: Avoid Mistakes

Identifying frequent shortcomings in the HPLC analytical column setup is essential for obtaining dependable analytical outcomes. Issues such as poor peak shape, retention time variability, and increased backpressure often arise from improper handling or method development. For instance, using incompatible solvents can lead to significant efficiency degradation, while inadequate column equilibration may result in erratic retention durations. Moreover, maintaining proper solvent ratios in mobile phases is crucial to prevent problems related to hydrophobic collapse. Regular monitoring of —such as peak symmetry, retention times, and system pressure—enables early detection of potential issues, allowing for timely corrective actions.

Experts recommend:

- Rinsing the apparatus with a powerful solvent to eliminate impurities.

- Assessing its effectiveness every 20-50 runs or monthly, depending on sample complexity, to ensure data quality and avoid unforeseen analytical variations.

- Implementing strict monitoring and record-keeping methods.

- Conducting routine maintenance activities like replacing inlet solvent filters and pump seals.

By adopting these proactive measures, laboratories can significantly reduce the occurrence of performance pitfalls and improve the reliability of analyses conducted with their HPLC analytical column.

Optimize HPLC Column Lifespan: Maintenance Tips

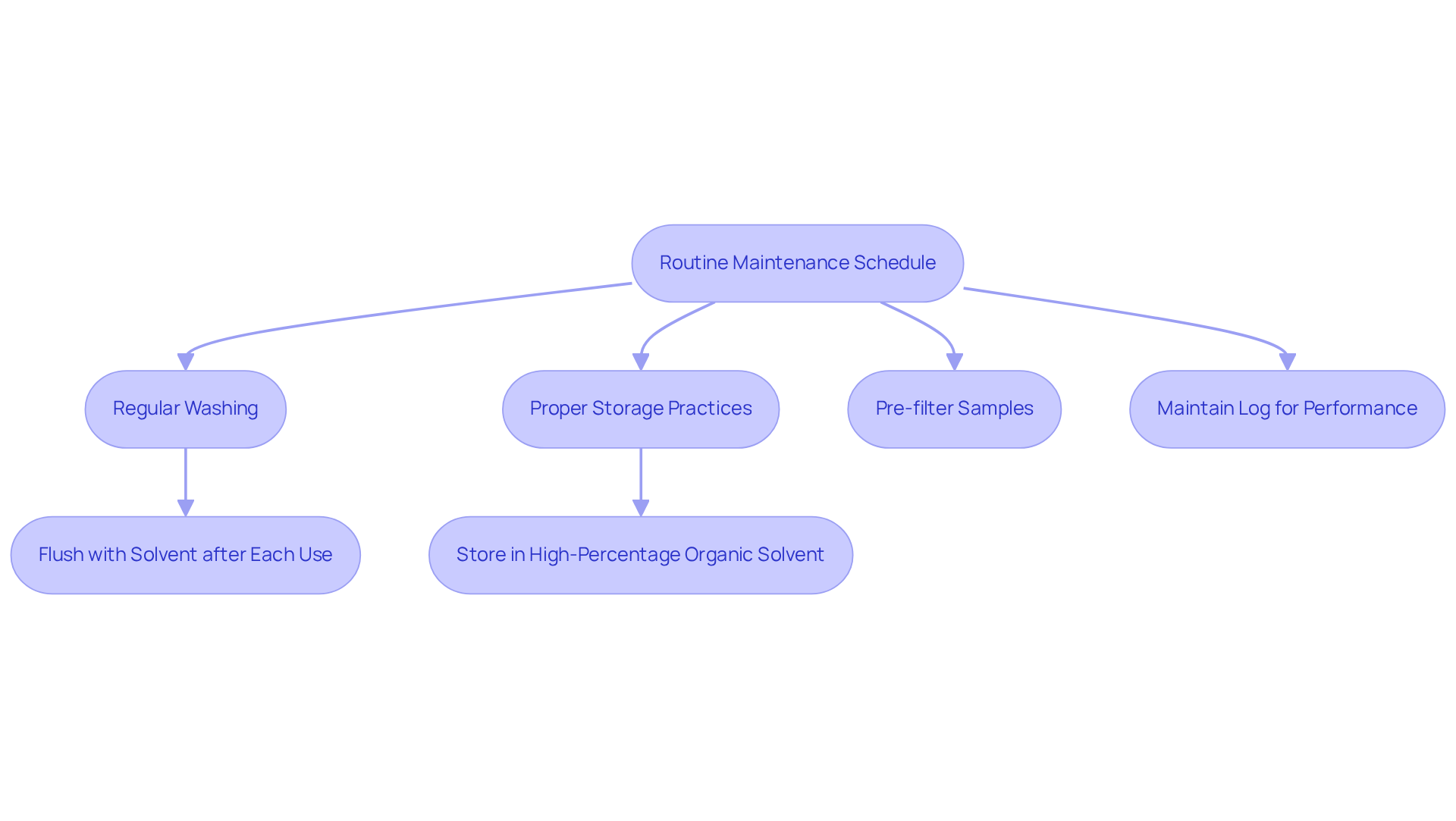

To maximize the lifespan of HPLC units, establishing a for the HPLC analytical column is essential. This schedule should encompass:

After each use, it is crucial to flush the apparatus with a suitable solvent, such as acetonitrile, to eliminate any residual samples that could lead to contamination or degradation. For optimal storage, structures should be maintained in a high-percentage organic solvent to prevent phase degradation and microbial growth.

Statistics indicate that the average analytical device is utilized roughly 7.4 times per instrument each year, underscoring the necessity for careful upkeep to ensure steady operation. Consistent oversight of vertical structure functionality is essential; neglecting maintenance can result in heightened backpressure or diminished resolution, signaling the need for replacement.

Effective maintenance practices include:

- Pre-filtering all samples and mobile phases with 0.22 or 0.45 µm syringe filters to prevent long-term blockages

- Keeping a log to monitor injections and performance irregularities, facilitating improved maintenance planning

By adhering to these practices and following manufacturer guidelines for pressure and pH, laboratories can significantly extend the lifespan of their HPLC analytical columns, ensuring reliable and reproducible results in chromatography.

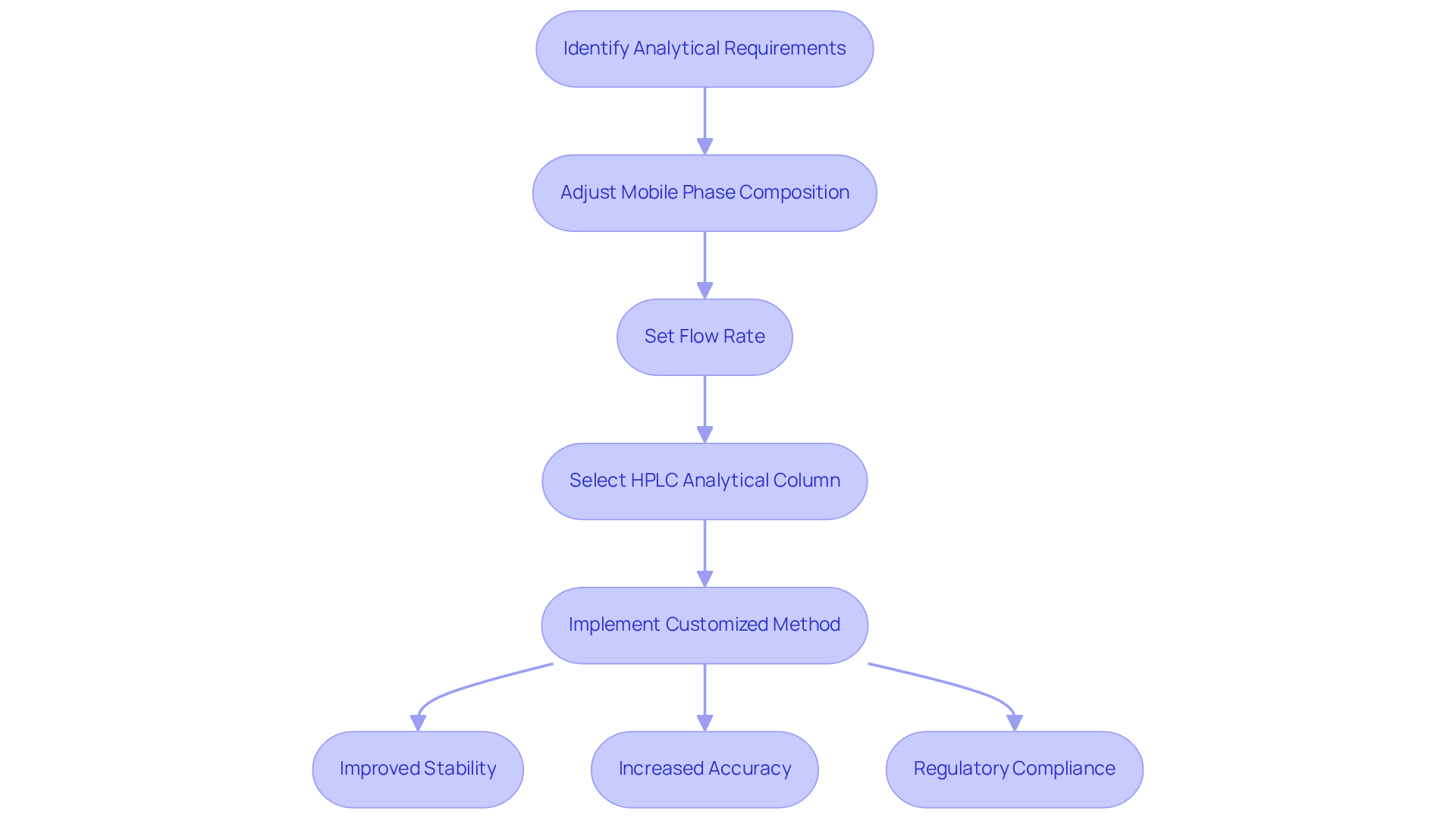

Implement Fit-for-Purpose Methods: Tailor HPLC to Your Needs

Tailoring chromatography techniques, particularly the HPLC analytical column, to meet specific analytical requirements is crucial for achieving optimal outcomes. This process necessitates the adjustment of parameters such as mobile phase composition, flow rate, and the HPLC analytical column selection, all based on the unique characteristics of the analytes being investigated. For instance, a study demonstrated that a reverse-phase chromatography method customized for tonabersat exhibited significant stability across various conditions, underscoring the necessity of method customization in ensuring reliable results.

By addressing the specific requirements of each project, laboratories can enhance both the efficiency and accuracy of their analyses. The implementation of a gradient RP-HPLC method for Ticagrelor (TCG) serves as a prime example, demonstrating linearity in the range of 5 - 200 µg/mL with a correlation coefficient of 0.99994. This showcases how tailored methods can significantly improve analytical performance.

Moreover, the impact of customized HPLC analytical column methods extends beyond mere efficiency; it profoundly influences the reliability of the generated data. Various case studies have noted that the often results in lower relative standard deviations (RSD), typically less than 2.5%. This ensures that analytical outcomes are both accurate and reproducible. Such levels of customization not only meet regulatory standards but also align with the principles of green analytical chemistry, minimizing environmental impact while maximizing analytical effectiveness.

Conclusion

Achieving success with HPLC analytical columns is contingent upon a deep understanding and implementation of best practices specifically designed to enhance performance and reliability. This article has delved into essential tips that encompass various aspects, from selecting the appropriate columns and stationary phases to effective cleaning techniques and maintenance strategies. By concentrating on these elements, laboratories can markedly improve their analytical precision and ensure consistent results in their research.

Key insights discussed include:

- The critical importance of proper column washing to avert contamination.

- The necessity of equilibration for stable results.

- Strategies to circumvent common pitfalls such as hydrophobic collapse and clogs.

- The emphasis on particle size optimization and fit-for-purpose methods further highlights how tailored approaches can lead to improved efficiency and accuracy in chromatographic analyses.

Ultimately, the dedication to maintaining HPLC columns through routine care and customization not only prolongs the lifespan of these indispensable tools but also elevates the quality of analytical outcomes. By embracing these practices, laboratories can position themselves at the forefront of analytical chemistry, ensuring they meet the escalating demands for precision and reliability in their work. Adopting these strategies will not only reinforce analytical integrity but also stimulate innovation in the continually evolving landscape of chromatography.