Overview

Near Infrared Spectroscopy (NIRS) stands as a pivotal non-destructive analytical technique, harnessing near-infrared light to meticulously analyze the molecular composition of diverse materials, particularly within the realms of pharmaceuticals and medical diagnostics. This article illuminates the rapid and reliable capabilities of NIRS for quality control and real-time monitoring in drug development, showcasing its vital applications in food safety and agricultural practices. By underscoring its significant role, we see how NIRS enhances analytical processes across various industries, establishing itself as an indispensable tool in modern scientific endeavors.

Introduction

Near Infrared Spectroscopy (NIRS) is at the forefront of analytical technology, revolutionizing how industries assess and ensure the quality of their products. This innovative technique leverages near-infrared light to deliver rapid, non-destructive insights into the molecular composition of various materials. Its applications span critical fields such as pharmaceuticals, agriculture, and food safety, underscoring its invaluable role.

However, as the demand for efficient and reliable analytical methods escalates, what challenges emerge in the adoption and integration of NIRS technology? Examining these questions unveils the profound impact and potential of NIRS, shaping the future of scientific analysis and quality control.

Define Near Infrared Spectroscopy (NIRS)

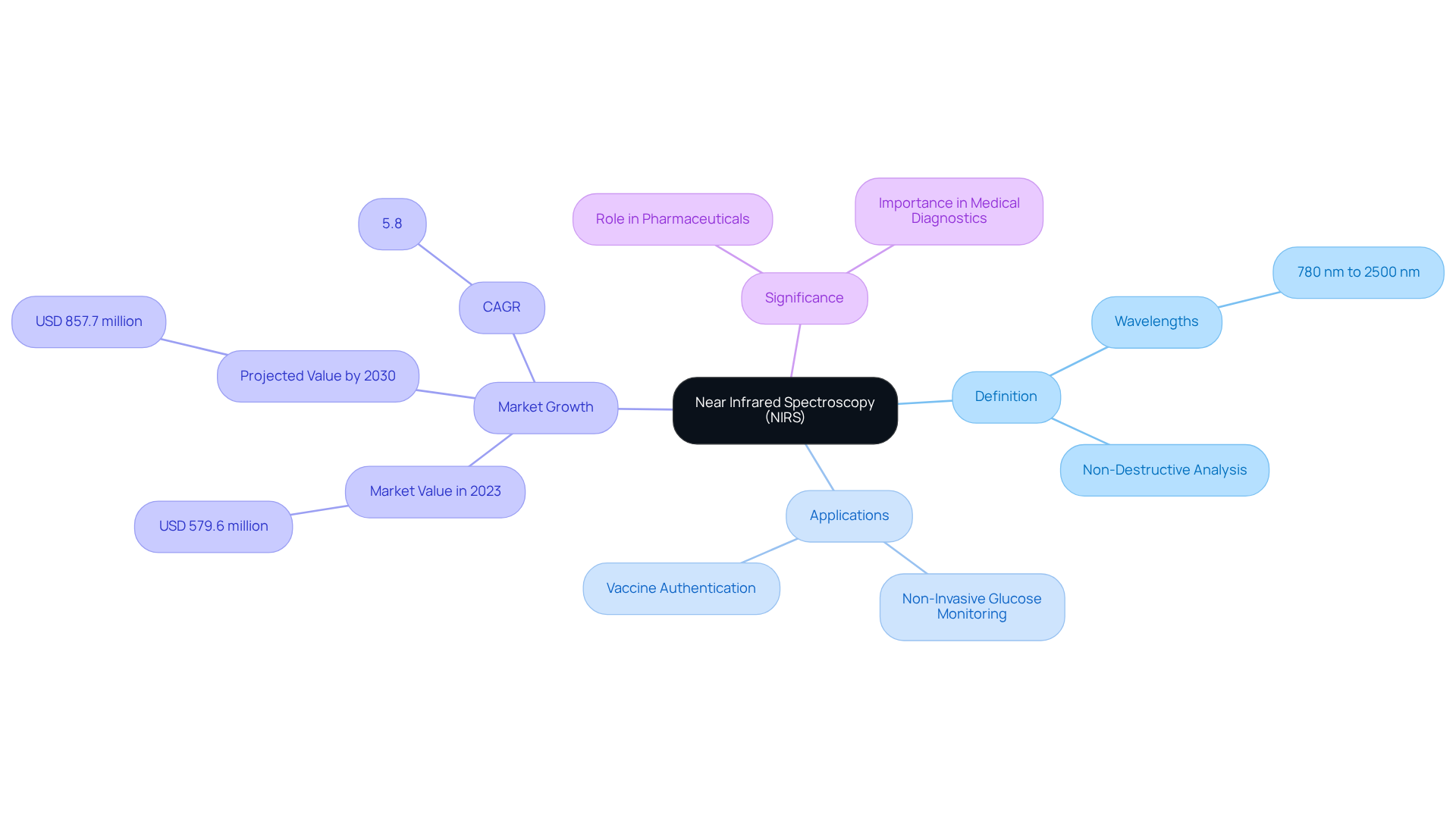

Near Infrared Spectroscopy (NIR) is a non-destructive analytical method, and if you're wondering what is NIRS, it utilizes the near-infrared region of the electromagnetic spectrum, specifically wavelengths from 780 nm to 2500 nm. This technique, which relates to what is NIRS, is instrumental in of diverse materials by measuring the absorption and reflectance of near-infrared light. Particularly in the fields of pharmaceuticals and medical diagnostics, understanding what is NIRS reveals that it provides rapid and reliable information without altering the sample being analyzed. Its significance in pharmaceuticals cannot be overstated; the method's swift and non-destructive sampling capabilities enhance process analytical technology (PAT), facilitating real-time monitoring of drug formulations and ensuring quality control.

The global near-infrared spectroscopy market was valued at USD 579.6 million in 2023 and is anticipated to reach USD 857.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.8% during this period. This growth is propelled by the increasing demand for efficient and non-invasive analytical methods in drug development and manufacturing. In 2022, the benchtop type segment represented over 76.9% of total revenue, indicating a robust preference for high-accuracy instruments. Meanwhile, the portable type segment is expected to achieve a growth rate of 6.1% in the forecast period, underscoring the rising demand for portable instruments, particularly in low- and middle-income regions.

The application of near-infrared spectroscopy in medical diagnostics includes non-invasive glucose monitoring and the assessment of blood components, both vital for managing chronic conditions. For example, recent studies have highlighted the method's efficacy in evaluating COVID-19 vaccines, illustrating its potential for rapid authentication of pharmaceutical products. Researchers have characterized it as "an effective and rapid method for COVID-19 vaccine authentication," further affirming its importance. Additionally, the technique's capability to detect multiple compounds simultaneously enhances its utility in ensuring the quality and safety of medicines, especially in areas where stringent quality control is essential.

In summary, what is NIRS shows that near-infrared spectroscopy emerges as a crucial tool in scientific analysis, offering significant advantages such as speed, accuracy, and non-destructive testing capabilities. Its role is increasingly indispensable in the dynamic landscape of pharmaceuticals and medical diagnostics.

Trace the History and Development of NIRS

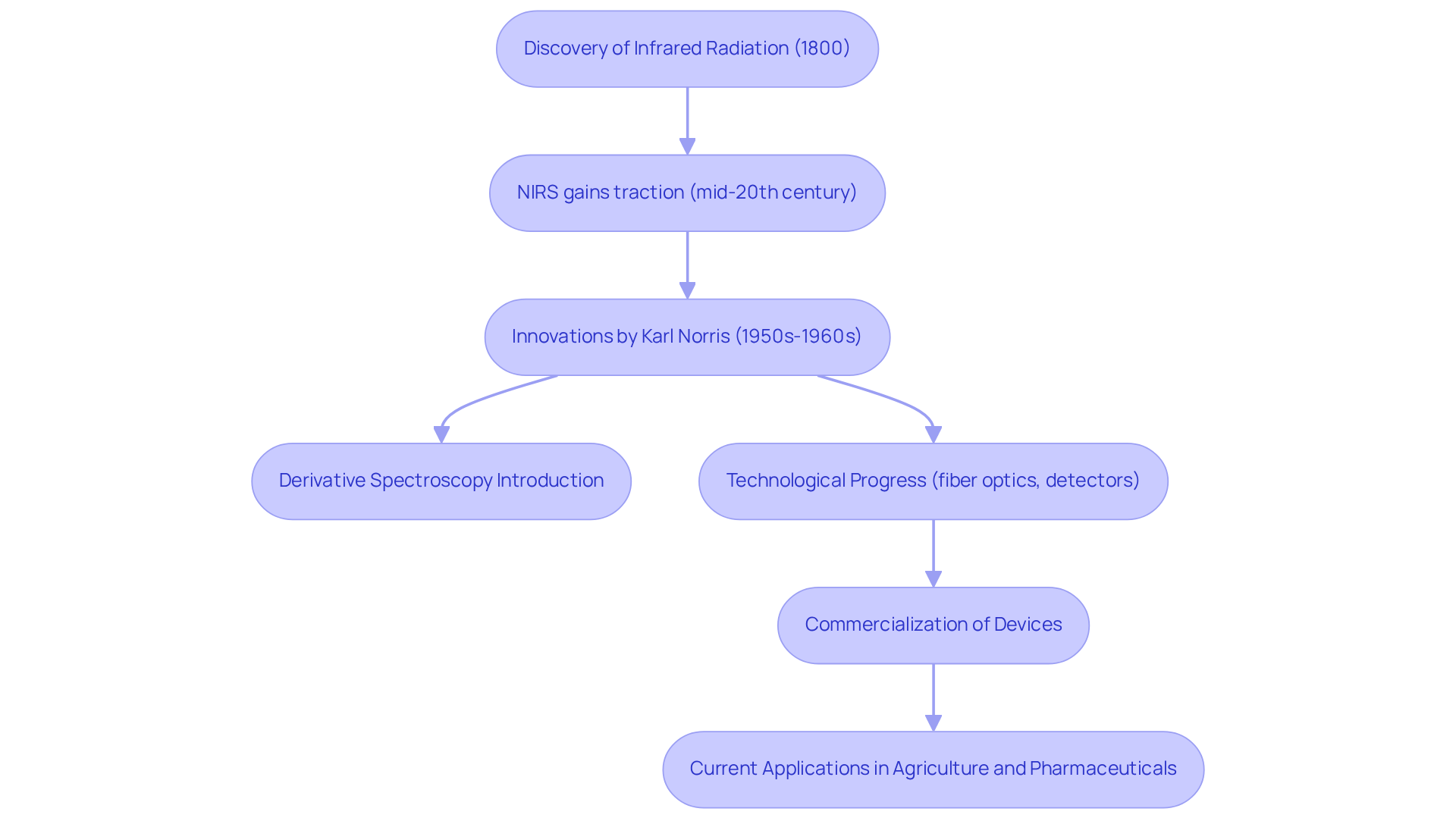

The origins of Near Infrared Spectroscopy can be traced back to the early 19th century, when Sir William Herschel discovered infrared radiation in 1800. However, it was not until the mid-20th century that near-infrared spectroscopy, known as what is NIRS, began to gain traction as a practical analytical tool. Innovative efforts by Karl Norris, who lived from 1921 to 2019, during the 1950s and 1960s helped to establish what is NIRS as a dependable technique for analyzing agricultural products, particularly in evaluating moisture levels in grains. His introduction of derivative spectroscopy and mathematical pre-treatments significantly enhanced the precision and reliability of NIR calibration models, laying the groundwork for widespread adoption across various industries. As Jerome Workman Jr. observed, Norris's innovations revolutionized the USDA’s analytical capabilities and established the foundation for advancements that would become essential across numerous sectors.

Over the years, technological progress, including the creation of fiber optics and improved detectors, has broadened the capabilities and applications of near-infrared spectroscopy, leading to the question of what is NIRS. For instance, the commercialization of ultracompact spectrometers and the launch of handheld devices have rendered near-infrared spectroscopy more accessible and versatile in laboratory environments. Recent case studies underscore the successful implementation of near-infrared spectroscopy in bioreactors and its integration with cloud computing for soil analysis, showcasing its adaptability in both agricultural and pharmaceutical contexts. Notably, there are over 25,000 citations in the NIR literature, underscoring the importance and influence of near-infrared spectroscopy within the scientific community.

The timeline of near-infrared spectroscopy technology advancements over the past 50 years reflects a continuous trend toward miniaturization and cost reduction, solidifying its status as a staple in modern laboratories. As regulatory frameworks evolve, the incorporation of near-infrared spectroscopy into manufacturing processes is anticipated to enhance its application in continuous manufacturing solutions. The contributions of pivotal figures such as Norris, coupled with ongoing innovations in the field, highlight the in improving analytical capabilities and fostering progress in both research and industry.

Examine Applications of NIRS in Various Fields

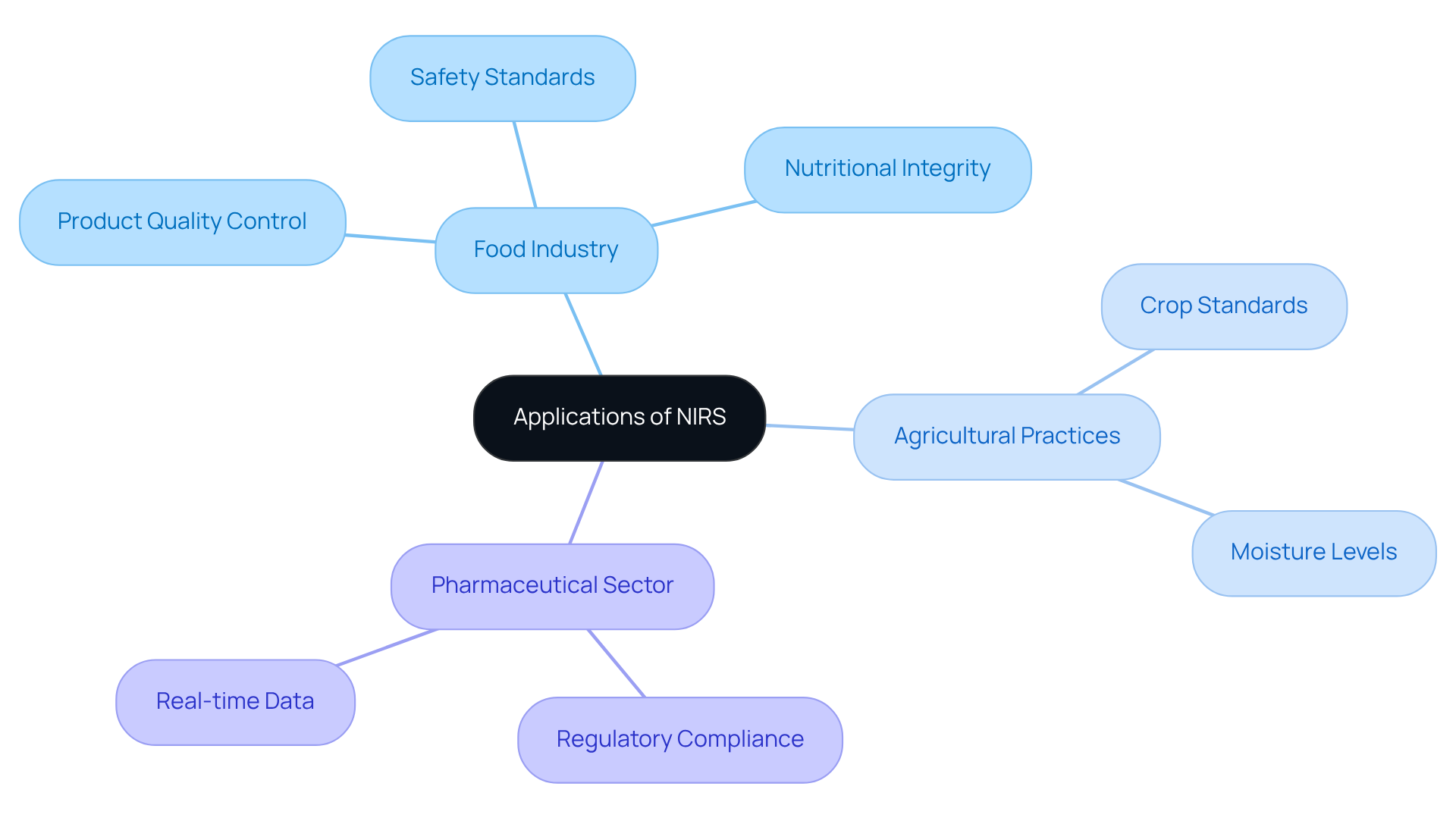

What is NIRS? It is increasingly recognized for its versatility across diverse industries, particularly in product quality control and pharmaceutical applications. In the culinary sector, this technology is vital for ensuring product safety and nutritional integrity. It effectively analyzes key components such as fat, protein, and moisture content, enabling manufacturers to adhere to stringent safety standards. For example, near-infrared spectroscopy has shown over 92% accuracy in detecting foreign contaminants in bread, while the moisture content in bread samples ranges from 49.05% to 53.85%, demonstrating its efficacy in food safety assessments.

Current trends highlight what is NIRS, emphasizing the growing adoption of near-infrared spectroscopy technology in agricultural practices, where it is employed to evaluate crop standards, moisture levels, and nutritional content. This allows for rapid assessments, which are crucial for maintaining the quality of perishable goods. Furthermore, near-infrared spectroscopy is being integrated into supply chains to enhance traceability and authenticity, addressing consumer demands for assurance of quality.

In the pharmaceutical sector, it is important to know what is NIRS, as it plays a crucial role in maintaining standards and facilitating drug development. It enables the swift analysis of raw materials and finished products, ensuring compliance with regulatory requirements. The system's capability to provide real-time data supports efficient production processes and enhances product reliability.

Experts underscore the transformative potential of near-infrared spectroscopy in product control. Dr. Mohammad Nadimi emphasizes the need for robust calibration models tailored to various types of produce, highlighting the system's capability to enhance safety and monitoring standards. Additionally, advancements in portable near-infrared spectroscopy devices are making this technology more accessible for field use, allowing for immediate assessments.

In summary, this technology is solidifying its position as an essential tool in the food and pharmaceutical industries, driving progress in quality assurance and safety oversight.

Understand NIRS Instrumentation and Technical Principles

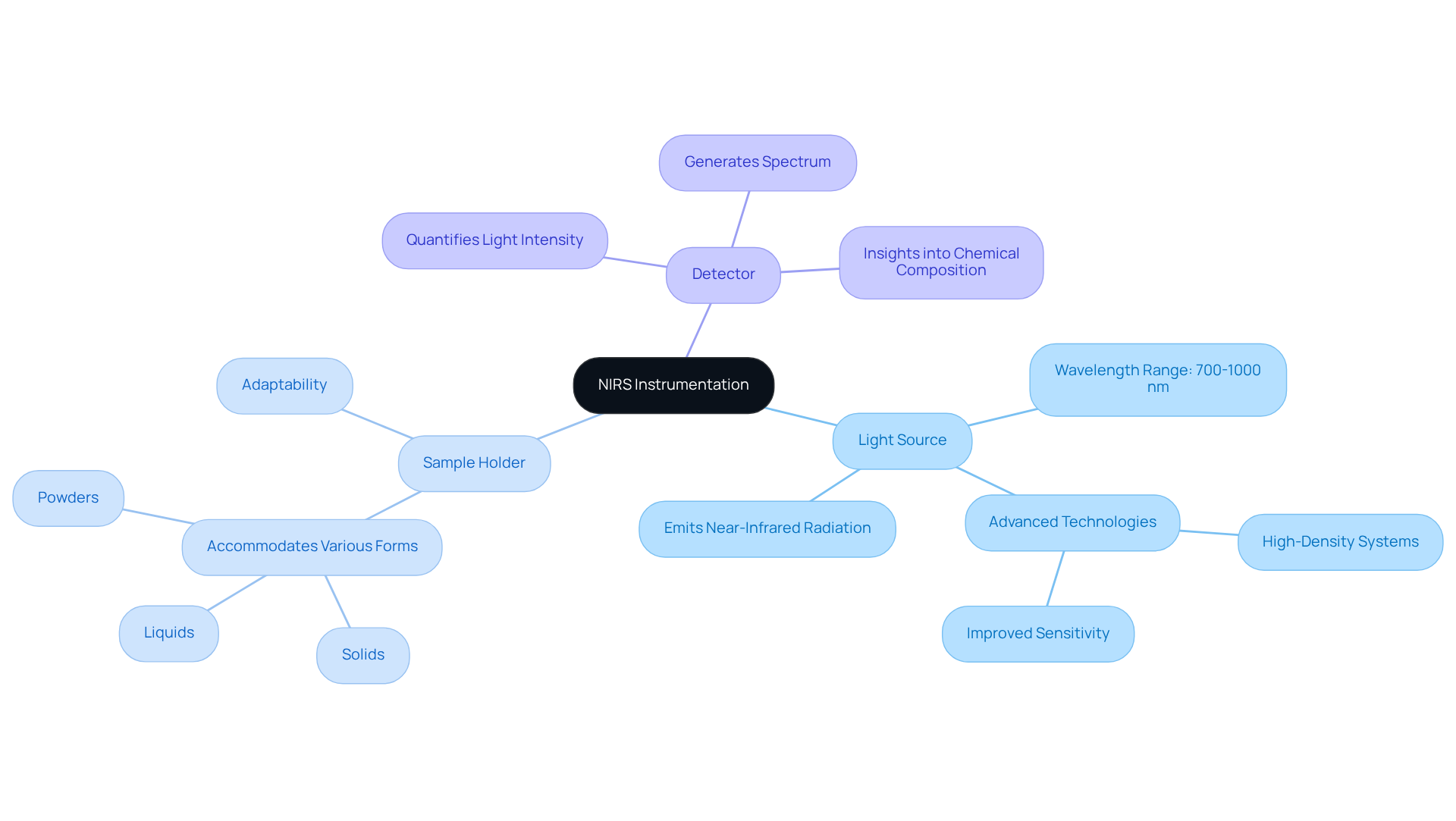

Near-infrared spectroscopy instrumentation comprises three essential components:

- A light source

- A sample holder

- A detector

The light source emits near-infrared radiation, typically within the 700 to 1000 nm range, which interacts with the sample. The sample holder is adaptable, accommodating various forms such as solids, liquids, or powders. As NIR light penetrates the sample, it is absorbed and scattered by the molecular bonds present in the material. This interaction is pivotal, as different molecular bonds absorb light at specific wavelengths, facilitating the of various components within the sample.

The detector quantifies the intensity of the transmitted or reflected light, generating a spectrum that unveils insights into the sample's chemical composition. Modern near-infrared spectroscopy systems leverage advanced light source and detector technologies, enhancing their sensitivity and precision. For instance, high-density near-infrared spectroscopy systems have improved spatial resolution, allowing for more accurate measurements. Additionally, the integration of machine learning methods into near-infrared spectroscopy analysis has significantly bolstered data processing capabilities, establishing it as a formidable tool in both laboratory and field settings.

The practical applications of near-infrared spectroscopy technology underscore its versatility. In the culinary sector, near-infrared spectroscopy is employed for rapid quality assessment, evaluating parameters such as moisture, protein, and fat levels across various products. Similarly, in agricultural contexts, near-infrared spectroscopy aids in analyzing the chemical composition of feed and manure, resulting in enhanced nutrient management and environmental sustainability. These advancements highlight what is NIRS and its increasing significance across diverse domains, ranging from food safety to precision agriculture.

Conclusion

Near Infrared Spectroscopy (NIRS) stands as a pivotal analytical tool, firmly entrenched in various fields, especially pharmaceuticals and medical diagnostics. By harnessing the near-infrared region of the electromagnetic spectrum, NIRS facilitates rapid, non-destructive analysis of materials, proving essential for quality control and process monitoring. The growing demand for efficient and reliable analytical methods underscores its significance, as reflected in the projected expansion of the NIRS market.

This article has delved into key insights regarding NIRS, encompassing its historical evolution, technical principles, and diverse applications. From its inception in the 19th century to its current impact on food safety and agricultural practices, NIRS has consistently advanced, propelled by technological innovations and the quest for analytical precision. Its capacity to deliver real-time data and adaptability across multiple sectors accentuates its transformative potential in enhancing quality assurance and safety standards.

As the analytical landscape evolves, the adoption of technologies like NIRS becomes imperative for industries striving to comply with stringent regulatory standards and meet consumer expectations. The continuous advancements in NIRS instrumentation, alongside its demonstrated efficacy in a variety of applications, herald a promising future for this analytical technique. By emphasizing the critical role of NIRS, stakeholders are encouraged to invest in and embrace this technology, thereby ensuring enhanced quality control and operational efficiency across sectors.