Overview

Ensuring oxidative stability in pharmaceuticals is paramount. Best practices in this domain encompass:

- The implementation of effective assessment techniques

- The selection of advanced testing instruments

- The establishment of continuous monitoring and quality control protocols

These practices are not merely recommendations; they are essential for maintaining drug integrity and ensuring patient safety. By detecting vulnerabilities early, they facilitate compliance with regulatory standards and mitigate the risks associated with oxidative degradation. In summary, the integration of these strategies is crucial for the advancement of pharmaceutical quality and reliability.

Introduction

Understanding oxidative stability is essential for the pharmaceutical industry, as it directly impacts the safety and efficacy of medications. Numerous active pharmaceutical ingredients are vulnerable to degradation, making the implementation of best practices for maintaining oxidative stability crucial for both researchers and quality assurance experts. Yet, how can pharmaceutical companies effectively navigate the complexities of oxidative stability testing and ensure their products remain safe and effective throughout their shelf life? This article explores four key practices that can enhance oxidative stability in pharmaceuticals, providing valuable insights for industry professionals.

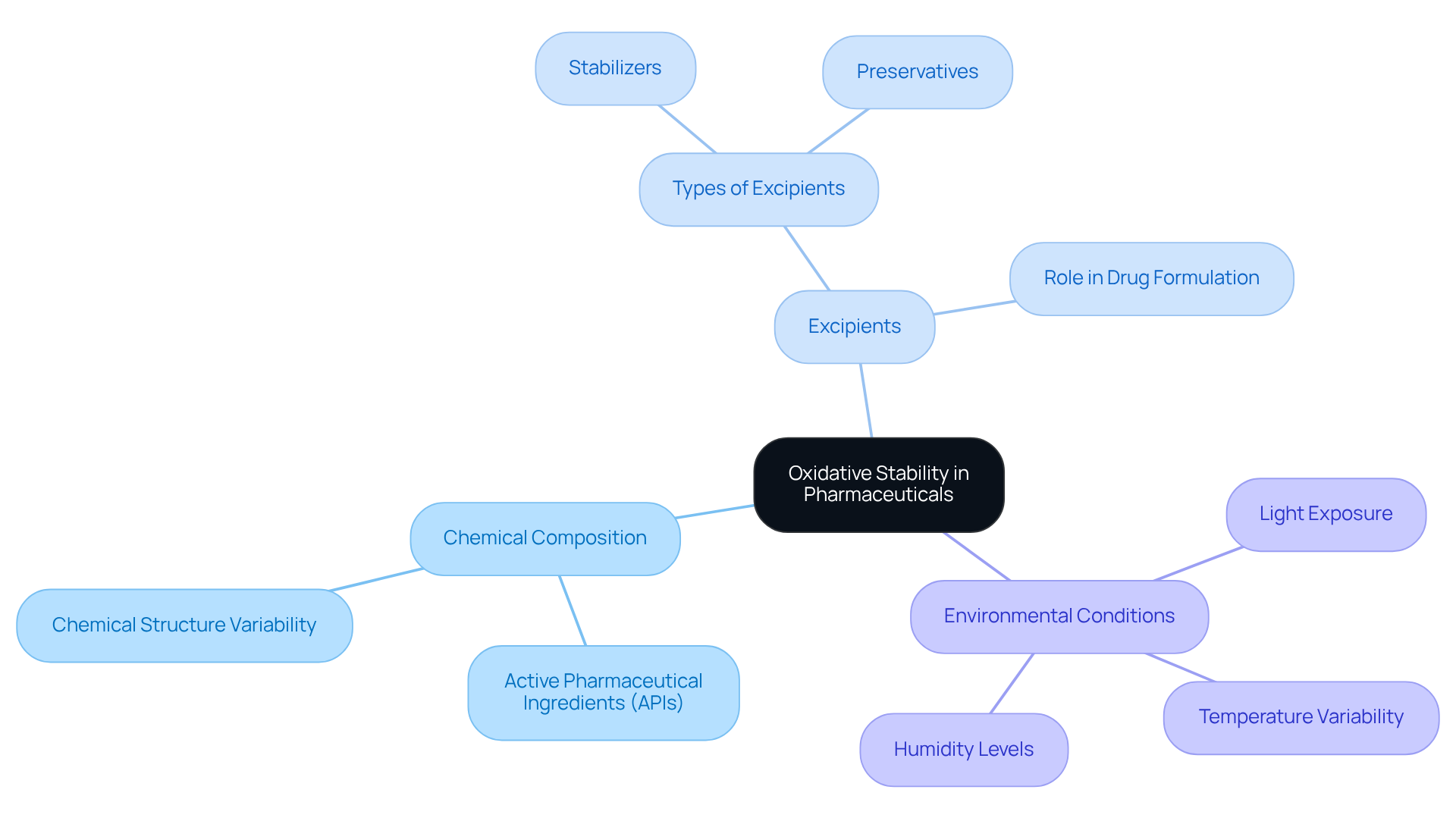

Understand Oxidative Stability in Pharmaceuticals

Oxidative stability is a critical characteristic of medical products, as it signifies their resistance to degradation and ability to withstand deterioration from reactive processes. This stability is influenced by several factors, including:

- The chemical composition of the drug

- The presence of excipients

- Environmental conditions such as light, temperature, and humidity

For drug researchers and quality assurance experts, understanding these elements is paramount; chemical degradation can significantly impact medication potency, alter pharmacokinetics, and heighten safety concerns. Notably, numerous active pharmaceutical ingredients (APIs) have low oxidative stability, which makes them particularly vulnerable to oxidation and results in the formation of harmful by-products that compromise quality.

For instance, research indicates that certain APIs exhibited a marked decrease in potency when exposed to stress conditions, underscoring the importance of rigorous durability assessments. As one scientist noted, "Ensuring chemical resilience is not solely about preserving effectiveness; it's about protecting patient safety throughout the item's shelf life."

Consequently, a comprehensive understanding of oxidative stability is vital for ensuring the safety and efficacy of medicinal products.

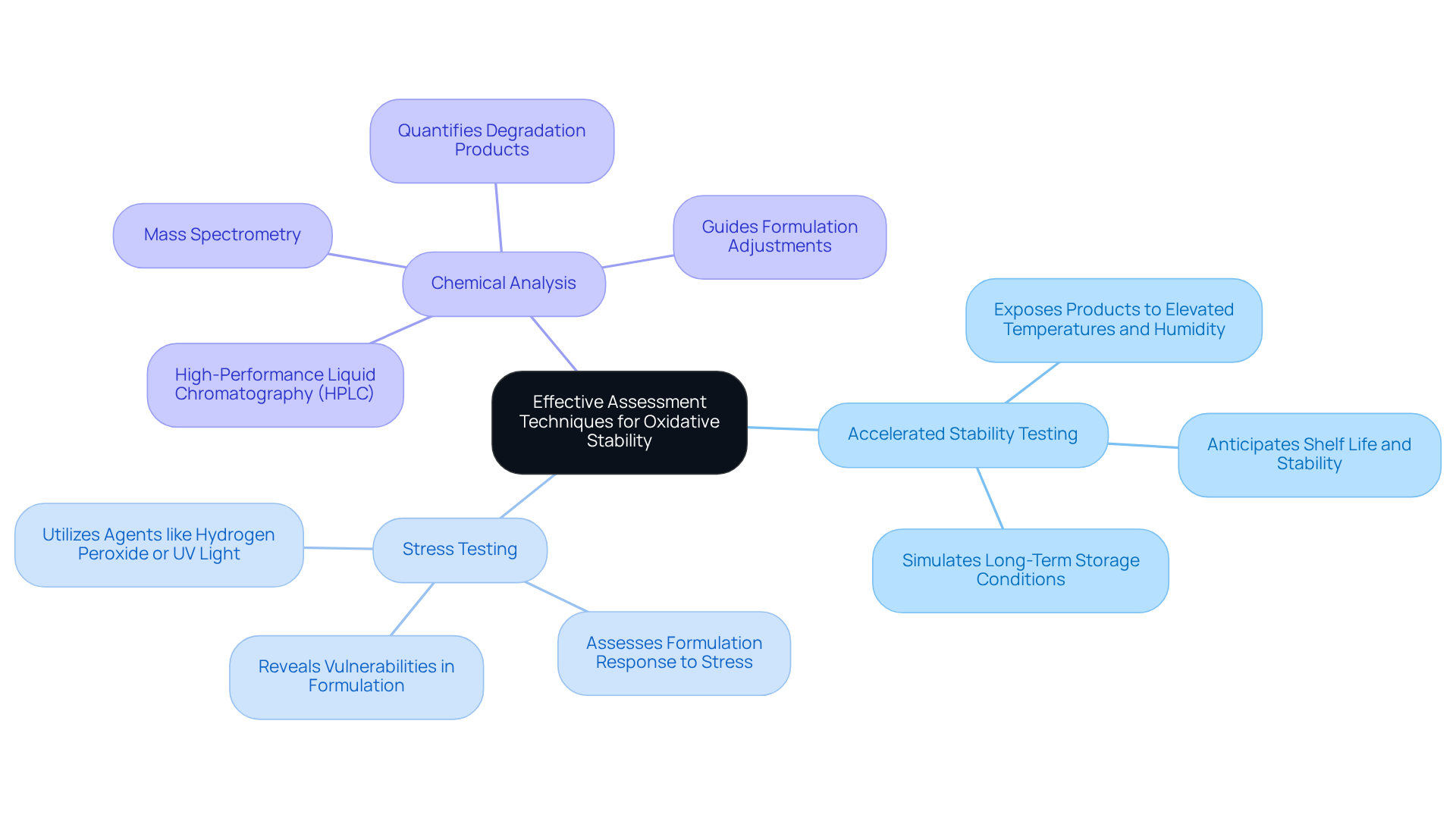

Implement Effective Assessment Techniques for Oxidative Stability

To effectively evaluate oxidative stability, pharmaceutical companies must implement a combination of analytical techniques. This strategy is crucial for ensuring oxidative stability and longevity of the product in the market. Common methods include:

- Accelerated Stability Testing: This method involves exposing products to elevated temperatures and humidity, simulating long-term storage conditions. By examining samples at various intervals, researchers can anticipate the shelf life and stability of the item.

- Stress Testing: By utilizing agents such as hydrogen peroxide or UV light, companies can assess how formulations respond to stress. This testing reveals vulnerabilities in the formulation that may not be apparent under normal conditions.

- Chemical Analysis: Techniques such as High-Performance Liquid Chromatography (HPLC) and mass spectrometry quantify degradation products and evaluate the degree of chemical degradation. These methods provide precise data that can guide formulation adjustments to enhance oxidative stability.

By employing these evaluation methods, laboratories can proactively detect consistency problems and implement necessary modifications to formulations before they reach the market.

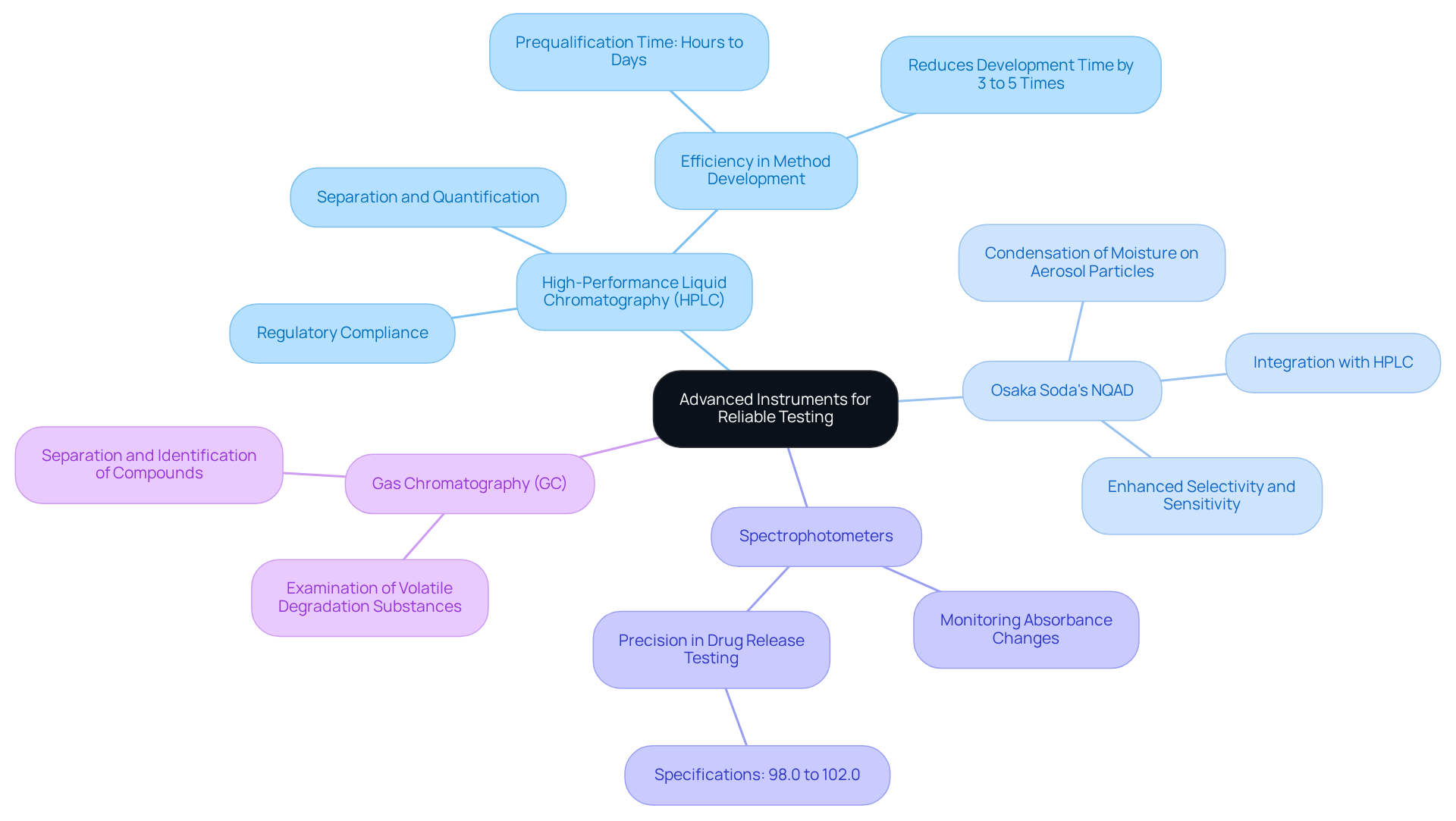

Choose Advanced Instruments for Reliable Testing

Choosing sophisticated tools is essential for attaining dependable evaluation of oxidative stability in drugs. Laboratories must prioritize the following technologies to ensure the highest standards in testing:

- High-Performance Liquid Chromatography (HPLC) is indispensable for the separation and quantification of pharmaceutical formulation components, including degradation products. Equipped with appropriate detectors and a variety of HPLC columns and accessories provided by JM Science, HPLC systems deliver thorough insights into product durability, making them crucial for analyses that indicate product integrity. Research indicates that HPLC method development can take from a few hours to a couple of days for prequalification, underscoring its efficiency in stability testing.

- Osaka Soda's NQAD represents a revolutionary aerosol-based detector that enhances selectivity and sensitivity in analytical applications. This technology is an excellent choice for laboratories focused on precise detection of components in pharmaceutical formulations. Its ability to condense moisture on aerosol particles allows for highly sensitive detection, surpassing traditional UV and MS detectors, thus capturing components that may have been overlooked in the past. The integration of NQAD with JM Science's HPLC solutions can significantly improve testing accuracy.

- Spectrophotometers are vital for monitoring changes in absorbance that signal oxidative degradation. By measuring absorbance at specific wavelengths, researchers can effectively track the consistency of formulations over time. Typical specifications for drug substance release testing range from 98.0% to 102.0%, highlighting the .

- Gas Chromatography (GC) serves as an effective analytical technique for examining volatile degradation substances and their oxidative stability. It aids in the separation and identification of compounds generated during oxidative processes, ensuring a thorough understanding of the oxidative stability of the results.

Investing in these advanced instruments not only enhances the reliability of testing but also simplifies laboratory operations, resulting in faster turnaround times for durability assessments. The combination of HPLC, Osaka Soda's NQAD, and spectrophotometric methods illustrates best practices in medication testing, ensuring adherence to regulatory standards and enhancing overall quality. Furthermore, considering regulatory aspects and life cycle management strategies is essential for developing stability-indicating HPLC methods.

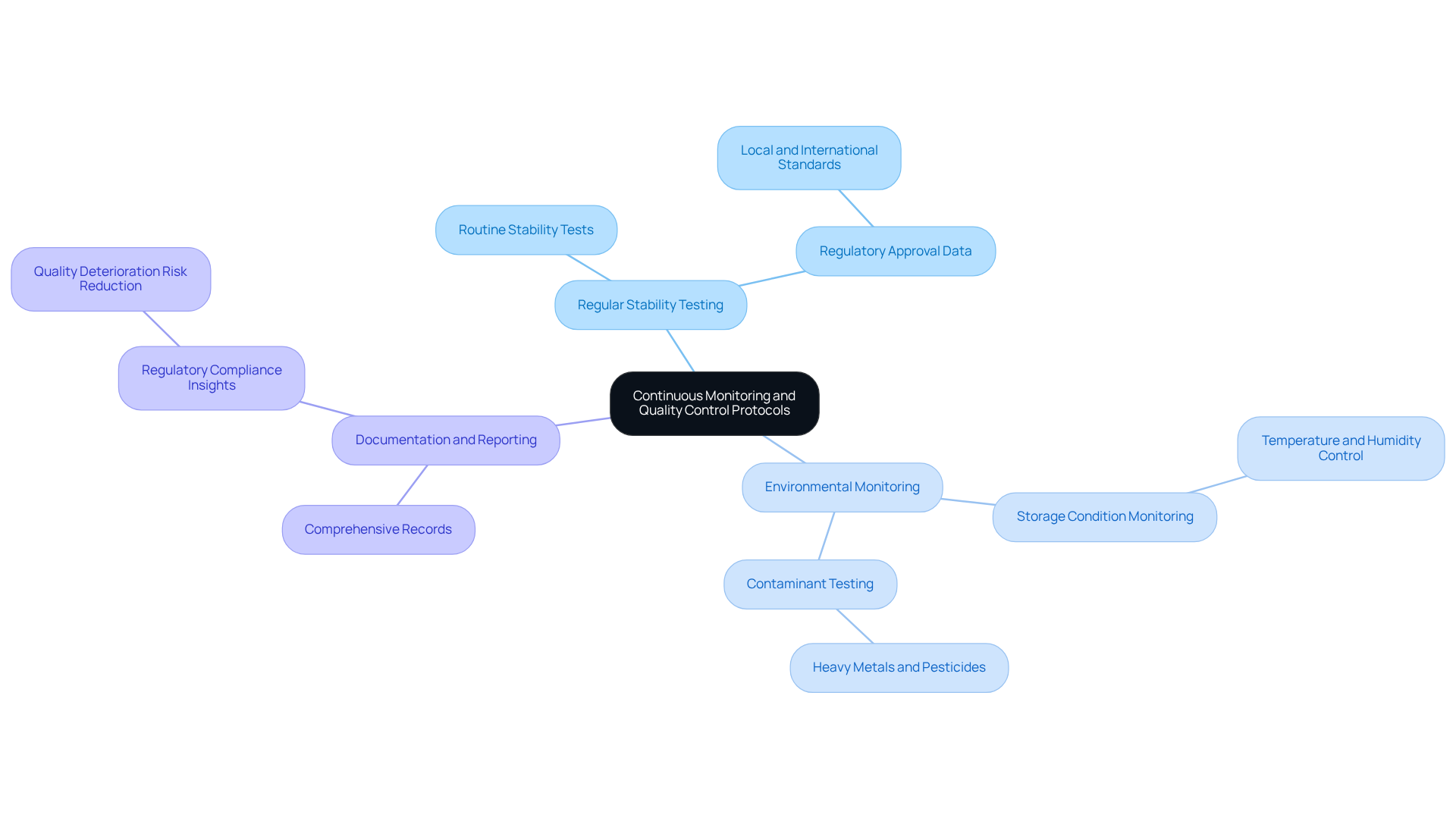

Establish Continuous Monitoring and Quality Control Protocols

Implementing ongoing surveillance and quality assurance procedures is essential for guaranteeing the oxidative stability of pharmaceuticals. Key practices include regular stability testing, environmental monitoring, and thorough documentation.

Regular Stability Testing: Schedule routine stability tests throughout the product lifecycle, particularly during storage and distribution. As highlighted by AyurStat, "The study provided valuable data for the item’s regulatory approval, ensuring that it met both local and international safety standards." This proactive approach aids in , thereby ensuring that items remain effective and safe for use.

Environmental Monitoring: Establish systems to monitor storage conditions, including temperature and humidity, to ensure they remain within specified limits. For example, a producer of Ayurvedic medicines conducted testing to ensure their herbal items were free from harmful contaminants, which included monitoring storage conditions to prevent deterioration. Such measures are vital for maintaining item integrity and averting circumstances that may lead to oxidative degradation.

Documentation and Reporting: Maintain comprehensive records of all testing and monitoring activities. This documentation is crucial for regulatory compliance and can provide valuable insights for the future development of offerings. Statistics indicate that effective environmental monitoring systems can decrease the risk of quality deterioration by up to 30%, underscoring the significance of these protocols.

By establishing these protocols, pharmaceutical companies can ensure the oxidative stability of their products, thereby safeguarding patient safety and product efficacy. However, it is crucial to avoid common pitfalls, such as inadequate training for staff on monitoring procedures or neglecting to update documentation regularly, as these can undermine the effectiveness of quality control measures.

Conclusion

Ensuring oxidative stability in pharmaceuticals is fundamental to maintaining the safety and efficacy of medical products. By understanding the various factors that influence oxidative stability—such as chemical composition, environmental conditions, and the role of excipients—pharmaceutical professionals can better safeguard against degradation that could compromise drug quality. These insights underscore the necessity of rigorous assessment techniques and advanced instruments to evaluate and enhance the oxidative stability of formulations.

Key practices include the implementation of effective assessment techniques such as:

- Accelerated stability testing

- Stress testing

- Chemical analysis

All essential for identifying vulnerabilities in drug formulations. Moreover, the adoption of sophisticated instruments like High-Performance Liquid Chromatography (HPLC), advanced detectors, and spectrophotometers is crucial for achieving reliable testing outcomes. Continuous monitoring and robust quality control protocols further ensure that products remain effective throughout their lifecycle, ultimately protecting patient safety.

The significance of oxidative stability extends beyond individual products; it is a cornerstone of pharmaceutical integrity and regulatory compliance. By prioritizing these best practices, pharmaceutical companies can not only enhance product quality but also foster trust in their medications. A proactive approach to oxidative stability is essential for the future of drug formulation, ensuring that patients receive safe and effective treatments.