Overview

This article delves into the selection and troubleshooting of 0.45 um syringe filters, underscoring their essential role in the sterilization and clarification of liquid specimens across diverse laboratory environments. It delineates critical selection criteria, including:

- Membrane material

- Filter diameter

- Solvent compatibility

Furthermore, it addresses prevalent filtration challenges such as:

- Clogging

- Leakage

Thereby offering comprehensive guidance for optimizing filtration processes. Understanding these elements is vital for ensuring the efficacy and reliability of laboratory results.

Introduction

In the realm of laboratory science, precision and reliability are non-negotiable, particularly in sample preparation. Among the essential tools that enhance these qualities are 0.45 µm syringe filters, which play a pivotal role in the sterilization and clarification of liquid samples. These filters not only eliminate particulates and microorganisms but also serve a crucial function in pharmaceutical applications, such as high-performance liquid chromatography (HPLC).

As laboratories strive for accuracy and efficiency, it becomes essential to understand the specific functions and selection criteria of these filters. This article delves into the multifaceted world of 0.45 µm syringe filters, addressing common filtration issues and recognizing the latest technological advancements, ultimately equipping researchers with the knowledge needed to optimize their laboratory processes.

Understand the Purpose of 0.45 um Syringe Filters

The use of is pivotal in the sterilization and clarification of liquid specimens across various research environments. These devices are engineered to effectively eliminate particulates, including bacteria and other microorganisms, making them indispensable in microbiological applications.

In pharmaceutical laboratories, for example, they are crucial for preparing specimens for high-performance liquid chromatography (HPLC), safeguarding against contaminants that could compromise analytical results. Understanding the specific applications of these devices, such as the 0.45 um syringe filter, is essential for selecting the appropriate type for tasks like environmental testing, biological research, or chemical analysis.

Recent advancements in filtration technology, particularly the integration of parallel filtration techniques, have significantly enhanced the efficiency of these devices. This innovation addresses the increasing demand for high-throughput capabilities in modern research facilities, as highlighted by recent case studies demonstrating how such advancements facilitate faster processing of .

Furthermore, as the push for tailored medicine and biosimilar development continues to drive over 33% additional demand for these devices, their importance in pharmaceutical settings becomes increasingly evident. The advanced performance of contemporary filtration devices, now available in a more compact design, aligns with the evolving requirements of researchers, establishing them as essential instruments in today’s laboratory environments.

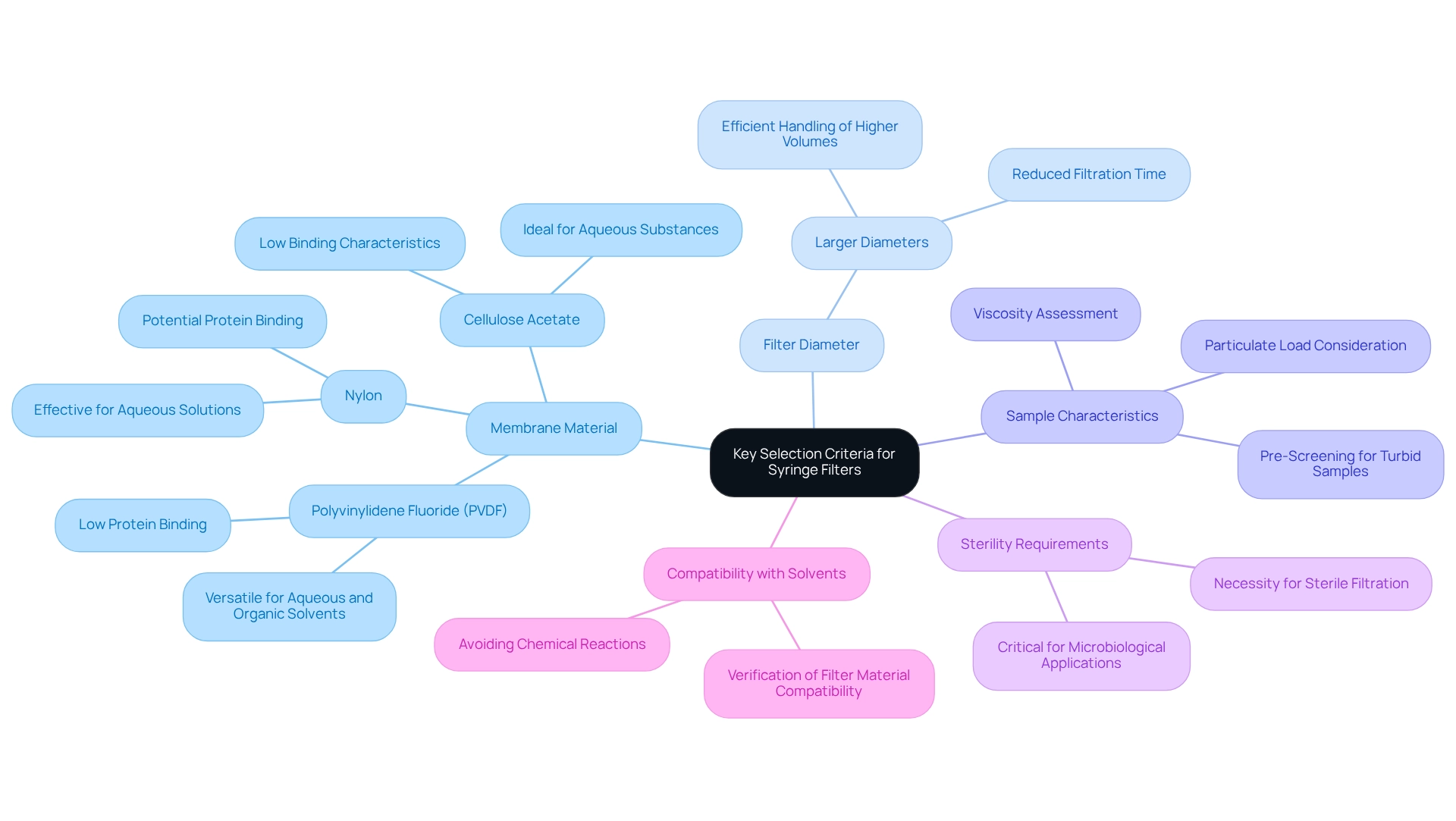

Identify Key Selection Criteria for Syringe Filters

Several key criteria must be considered when selecting a 0.45 um syringe filter to ensure optimal performance and reliability.

- Membrane Material: The choice of membrane material is crucial. Polyvinylidene Fluoride (PVDF) is recognized for its low protein binding properties, making it suitable for both aqueous and organic solvents, thus offering versatility for various applications. In contrast, Nylon is effective for filtering aqueous solutions, although it may exhibit protein binding that could compromise results in sensitive assays. Cellulose Acetate is ideal for aqueous substances, providing low binding characteristics that ensure minimal interference with sample integrity.

- Filter Diameter: The diameter of the filter should be selected based on the sample volume. Larger diameters facilitate the efficient handling of higher volumes, significantly reducing filtration time and enhancing throughput.

- Sample Characteristics: It is essential to assess the viscosity and particulate load of the sample. For turbid samples, pre-screening with a larger pore size can enhance the efficiency of the 0.45 μm sieve, leading to clearer results.

- Sterility Requirements: Determine whether the application necessitates sterile filtration. Numerous are available in sterile formats, which are critical for microbiological applications to prevent contamination.

- Compatibility with Solvents: Verifying that the filter material is compatible with the solvents being used is paramount. Incompatibility can lead to chemical reactions that compromise the specimen and adversely affect analytical outcomes.

According to market data, 0.45 um syringe filters account for approximately 38% of the market for these devices, primarily utilized in HPLC sample preparation. Furthermore, the anticipated growth of nanotechnology in filtration products is expected to exceed a yearly rate of 10% over the next five years, suggesting a changing environment that managers should consider when selecting filtration solutions. By thoroughly assessing these criteria, managers can select the most suitable device for their specific applications, thereby enhancing the dependability and precision of their results.

Troubleshoot Common Filtration Issues

Filtration problems frequently occur with the 0.45 um syringe filter, potentially hindering laboratory efficiency. Understanding these prevalent issues and their effective solutions is essential for maintaining optimal filtration processes.

- Clogging: Slow filtration rates or complete blockage of liquid flow are common symptoms. To mitigate clogging, consider utilizing a pre-filter with a larger pore size for turbid samples. Diluting viscous samples can also facilitate smoother filtration. Notably, studies demonstrate that capsule filters, , can manage several liters of river water without significant clogging, underscoring the importance of proper filter selection.

- Leakage: Symptoms include liquid escaping from the filter connection. To prevent leaks, ensure that the filter is securely seated within the syringe and confirm compatibility between the filter and syringe connection types.

- Bursting: This issue manifests as a rupture of the filter membrane due to excessive pressure. To avoid sudden bursts, apply steady, gentle pressure when operating the plunger. If necessary, opt for filters designed to withstand higher pressures.

- Sample Contamination: Anomalies in analytical results may indicate contamination. Always use new filters to avoid contamination from reused materials. It is also crucial to verify that the filter material is compatible with the sample to prevent leaching of filter components. Proper handling and disposal of filters, particularly those used with biohazardous materials, is vital for safety and compliance in laboratory environments. Wearing gloves during installation and disposal further ensures adherence to local regulations, maintaining a clean working environment.

By being aware of these common filtration challenges and their corresponding solutions, laboratory personnel are empowered to troubleshoot effectively, ensuring reliable and efficient filtration processes. Furthermore, as noted by Wenjing Dong, for accurate determination of macrolide antibiotics, it is advisable to utilize a 0.22 μm hydrophobic-PTFE or nylon filter, highlighting the significance of selecting the appropriate filter type based on specific applications.

Conclusion

The critical role of 0.45 µm syringe filters in laboratory settings is paramount. These filters are essential for the sterilization and clarification of liquid samples, effectively removing particulates and microorganisms to ensure the integrity of analytical results. Their application in high-performance liquid chromatography (HPLC) and various other laboratory processes underscores their importance in achieving reliable and reproducible outcomes.

Selecting the right syringe filter necessitates careful consideration of several factors, including membrane material, filter diameter, and compatibility with solvents. By understanding these key selection criteria, laboratory managers can enhance the efficiency of their filtration processes and maintain the quality of their samples. Furthermore, staying informed about advancements in filtration technology can bolster laboratory capabilities, enabling high-throughput processing that meets the demands of modern research.

Addressing common filtration issues such as clogging, leakage, and sample contamination is vital for maintaining laboratory efficiency. By implementing effective troubleshooting strategies, laboratory personnel can ensure smooth operations and safeguard the accuracy of their results. Ultimately, the informed use of 0.45 µm syringe filters is integral to advancing laboratory science, empowering researchers to achieve their objectives with confidence and precision.