Overview

The article "Master Gold Analyzer Integration for Pharmaceutical Labs" centers on providing expert guidance for the effective integration of gold analysis technologies into pharmaceutical laboratory workflows. It emphasizes essential considerations for selecting and incorporating gold analyzers, including:

- Evaluation of existing workflows

- Staff training

- Establishment of standard operating procedures

- Resolution of common troubleshooting issues

These factors collectively contribute to enhancing the accuracy and efficiency of gold testing processes within laboratories, underscoring the critical role that high-quality scientific instruments play in achieving reliable results.

Introduction

The precision of pharmaceutical testing is fundamentally reliant on the accurate analysis of gold, a critical element in numerous applications. As laboratories pursue excellence, it is essential to comprehend the diverse technologies at their disposal—such as:

- Atomic Absorption Spectroscopy

- Inductively Coupled Plasma Mass Spectrometry

- X-Ray Fluorescence

With a multitude of options available, how can laboratories ensure they select the appropriate gold analyzer and seamlessly integrate it into their workflows? This guide explores the essential features, integration strategies, and troubleshooting tips necessary for maximizing the potential of gold analyzers in pharmaceutical laboratories.

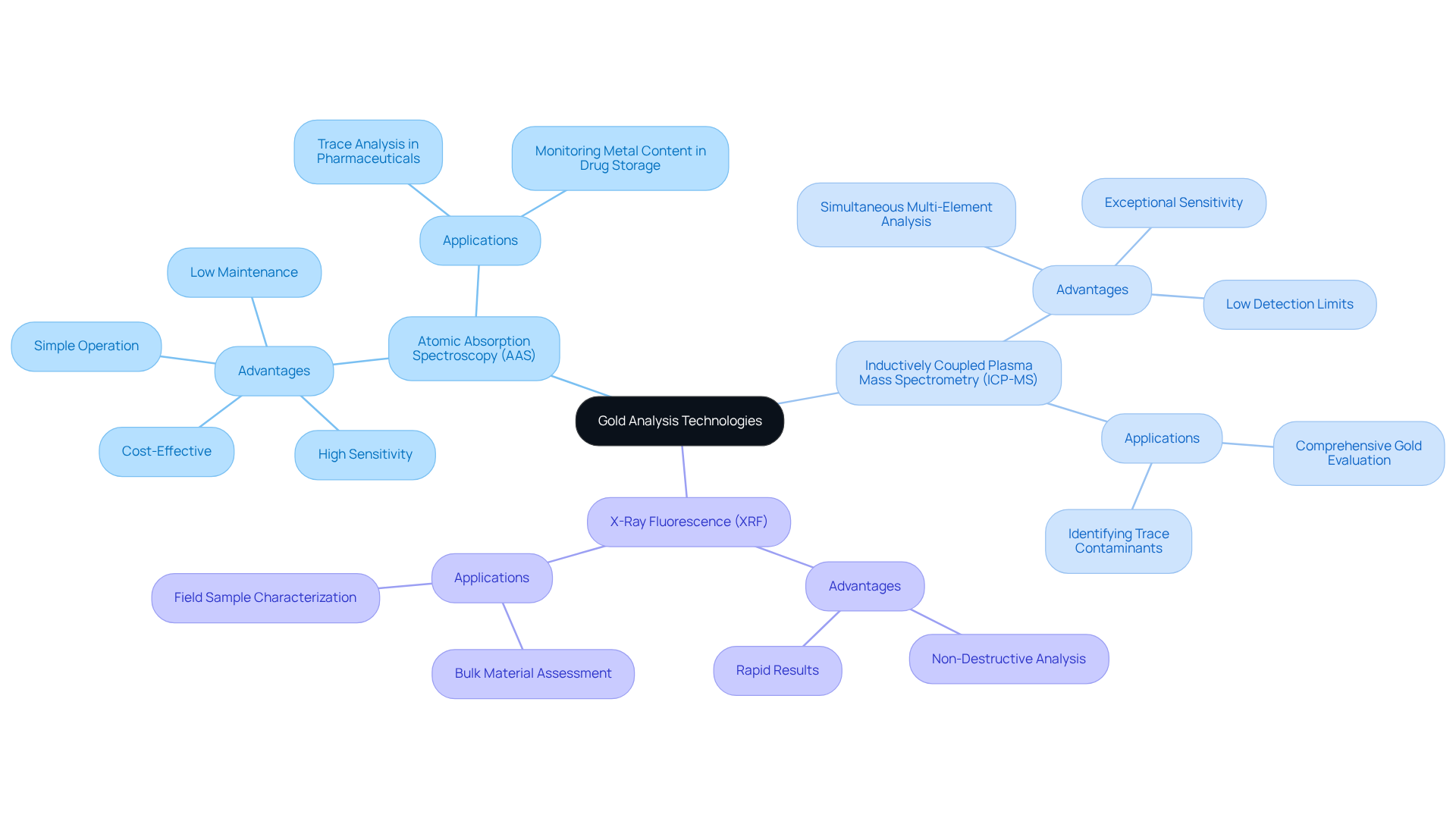

Understand Gold Analysis Technologies

Gold examination can be conducted using and several technologies, including:

- Atomic Absorption Spectroscopy (AAS)

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

- X-Ray Fluorescence (XRF)

Each method possesses distinct advantages that make it suitable for various applications in laboratory settings.

Atomic Absorption Spectroscopy (AAS) is a highly sensitive technique ideal for trace analysis, particularly in pharmaceutical applications where precision is paramount. Its cost-effectiveness, simplicity of operation, and low maintenance requirements make AAS accessible for many laboratories, especially those with lower throughput demands. This method ensures that even the smallest quantities of gold can be accurately measured, reinforcing its value in critical testing environments.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) stands out for its ability to analyze multiple elements simultaneously, making it an excellent choice for comprehensive gold evaluation in complex samples. With exceptional sensitivity and detection limits in the parts per trillion range, ICP-MS can identify trace contaminants that may affect product quality. Recent advancements in ionization techniques have further enhanced its efficiency and accuracy, solidifying its position as a powerful tool in pharmaceutical laboratories.

X-Ray Fluorescence (XRF) offers a non-destructive method for rapid analysis, particularly useful for bulk material assessment. Its capacity to provide immediate results facilitates quick decision-making in research environments, allowing scientists to act swiftly based on reliable data.

Understanding these technologies and their sensitivity evaluations is crucial for selecting the appropriate metal testing device, such as a gold analyzer, tailored to your laboratory's specific needs. This knowledge guarantees precise and dependable outcomes, ultimately enhancing the quality of your research and product development.

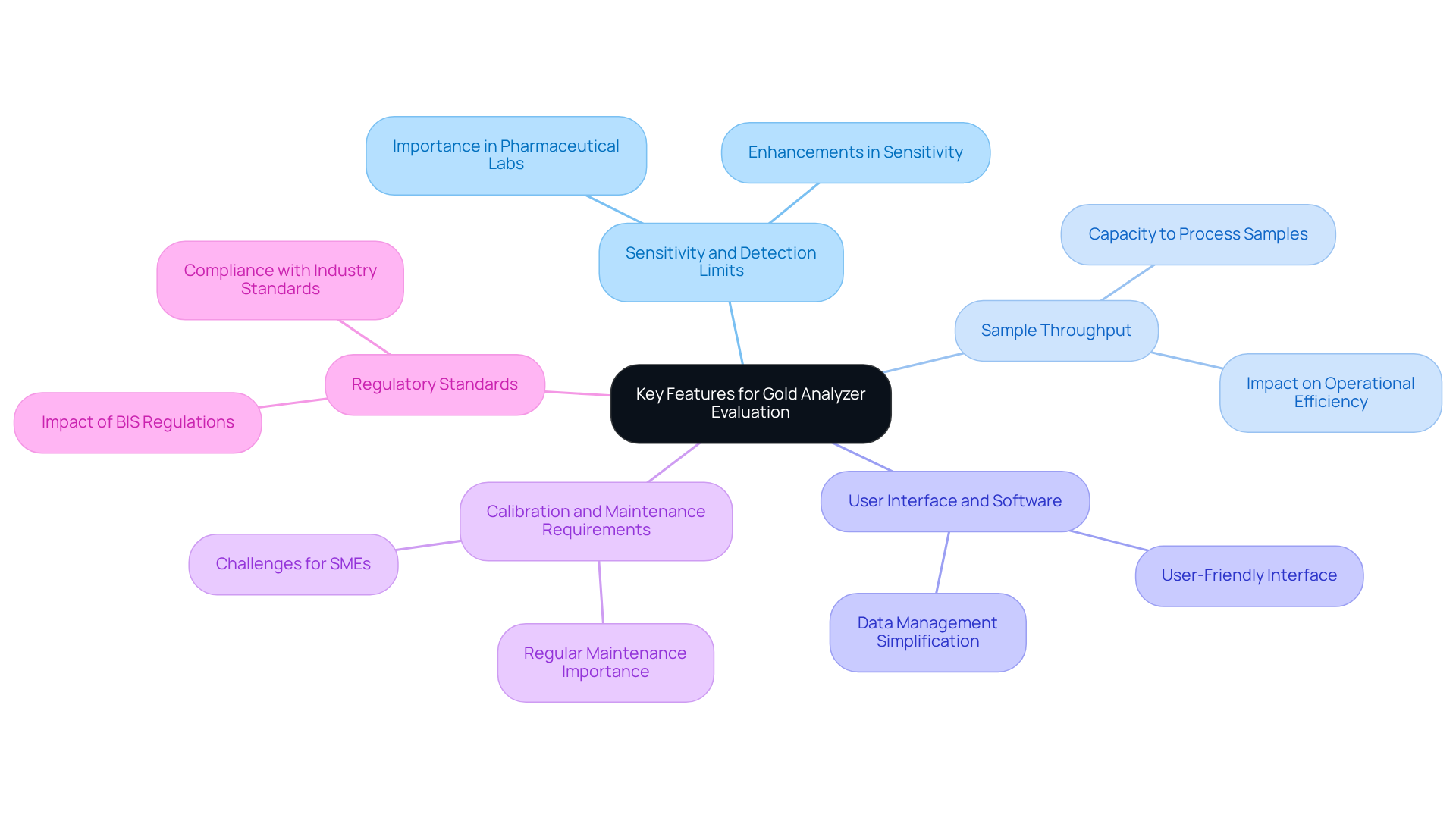

Evaluate Key Features and Specifications

When evaluating a gold analyzer, several key features and specifications must be prioritized to ensure optimal performance and reliability.

- are of utmost importance, as the analyzer must detect gold at the necessary concentrations for your specific applications. High sensitivity is particularly crucial in pharmaceutical labs, where precise measurements are vital. As James Tickner notes, efforts to enhance the sensitivity and accuracy of the gold analyzer methods are paramount for effective gold detection.

- Next, consider Sample Throughput. Assess the analyzer's capacity to process samples within a given timeframe, as high-throughput capabilities are essential for facilities managing large volumes of samples. This directly influences operational efficiency. The worldwide market for testing devices, including gold analyzers for precious metal purity, is projected to expand at a CAGR of 6.2%, underscoring the rising demand for effective testing solutions.

- The User Interface and Software also play a significant role. A user-friendly interface, combined with robust software, can greatly enhance operational efficiency and simplify data management, making it easier for staff to operate the equipment effectively.

- Furthermore, understanding the Calibration and Maintenance Requirements is vital for ensuring consistent performance over time. Regular maintenance is necessary to maintain accuracy and reliability in results. The challenges faced by small and medium-sized enterprises in adopting highlight the importance of manageable maintenance protocols.

- Lastly, ensure that the device adheres to Regulatory Standards. Compliance with industry standards and regulations relevant to pharmaceutical facilities is essential not only for quality assurance but also for maintaining credibility in testing results. Stringent regulations, such as those mandated by the Bureau of Indian Standards (BIS), are driving the adoption of advanced testing machines in the industry.

By thoroughly assessing these characteristics, you can select a testing device, specifically a gold analyzer, that aligns with your facility's operational objectives and enhances your analytical capabilities.

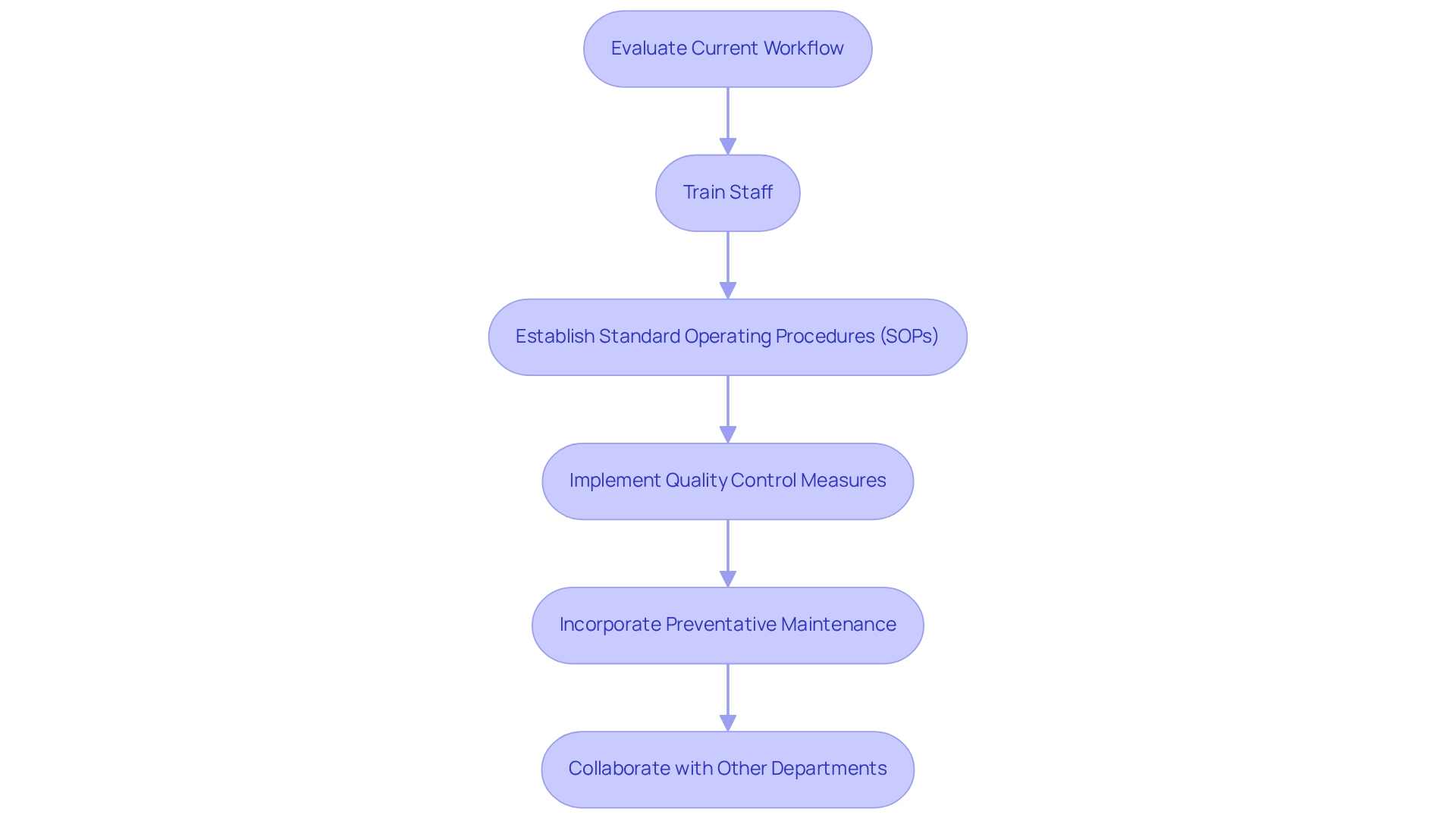

Integrate the Analyzer into Laboratory Workflow

To effectively integrate the gold analyzer into , it is essential to consider the following steps:

- Evaluate Current Workflow: Conduct a thorough examination of existing procedures to pinpoint the optimal placement of the gold testing device within your operations. This foundational step is critical for seamless integration.

- Train Staff: Implement for laboratory personnel, emphasizing both the operation and maintenance of the equipment. This ensures proficiency and instills confidence among staff members.

- Establish Standard Operating Procedures (SOPs): Develop detailed SOPs for sample preparation, analysis, and data interpretation. Such documentation promotes consistency and adherence to regulatory standards, which is vital for quality assurance.

- Implement Quality Control Measures: Establish robust quality control protocols to continuously monitor the performance of the device and validate results. This ongoing assessment guarantees reliability in your testing processes.

- Incorporate Preventative Maintenance: Schedule regular preventative maintenance for the precious metal testing device. This proactive approach ensures optimal performance and extends the equipment's longevity.

- Collaborate with Other Departments: Engage relevant departments, such as quality assurance and regulatory affairs, in the integration process. This collaboration aligns the integration with broader scientific objectives and enhances overall efficiency.

By adhering to these best practices, you can ensure a smooth incorporation of the precious metal testing device into your laboratory's operations. Ultimately, this will enhance your analytical capabilities and support your laboratory's objectives.

Troubleshoot Common Gold Analyzer Issues

Common issues encountered with gold analyzers warrant attention and action:

- Inconsistent results can undermine the reliability of analyses. To resolve this, ensure that calibration is accurate and that standard operating procedures are consistently followed. Regular maintenance and quality control checks are essential to mitigate discrepancies in results. Calibration curves must reflect elements of interest, such as gold in jewelry, to avoid matrix effects, which can significantly impact accuracy.

- Software glitches can disrupt operations. Ensure that the software is updated and compatible with your laboratory's operating system. A simple restart of the system or reinstalling the software can often rectify minor glitches.

- Sample contamination poses a significant risk to accuracy. Implement to prevent contamination. Training staff on proper techniques is crucial to maintaining the integrity of samples.

- Equipment malfunction can lead to unexpected downtime. Conduct regular inspections and maintenance of the device to identify mechanical issues early. Refer to the manufacturer's troubleshooting guide for specific problems and solutions.

- Statistical data indicates that the relative standard deviation for measurements can be less than 0.1%, underscoring the importance of proper calibration and maintenance in achieving reliable results. A study shows that EDXRF can obtain analytical outcomes similar to traditional methods when employing matrix-specific calibration materials, offering a practical illustration of how addressing calibration challenges can enhance precision in precious metal assessment.

By proactively addressing these common issues, laboratories can significantly enhance the efficiency and reliability of their gold analyzer, ensuring accurate and consistent results in their analyses.

Conclusion

The integration of gold analyzers into pharmaceutical labs marks a pivotal advancement in enhancing analytical precision and ensuring product quality. Understanding the various gold analysis technologies—such as Atomic Absorption Spectroscopy, Inductively Coupled Plasma Mass Spectrometry, and X-Ray Fluorescence—empowers laboratories to make informed decisions that align with their specific needs and operational goals.

Key considerations for selecting and integrating a gold analyzer encompass:

- Sensitivity and detection limits

- Sample throughput

- User interface

- Calibration requirements

- Adherence to regulatory standards

Each of these factors is crucial for ensuring the reliability and efficiency of testing processes. Moreover, implementing best practices in workflow integration, staff training, and quality control measures is essential for overcoming common challenges associated with analyzer usage, thereby guaranteeing consistent and accurate results.

Ultimately, the successful integration of gold analyzers not only optimizes laboratory operations but also reinforces a commitment to quality and compliance in pharmaceutical testing. Laboratories must prioritize these advancements and strategies to remain competitive and responsive to the evolving demands of the industry. By embracing these technologies and practices, they will pave the way for more reliable outcomes and enhanced research capabilities within the pharmaceutical sector.