Overview

This article delves into the various types of filtration tubes and their wide-ranging applications across multiple scientific disciplines, underscoring their essential role in maintaining sample purity and adhering to regulatory standards. It examines how distinct types of filtration tubes—such as glass, plastic, fritted glass, membrane separation, and capillary devices—are meticulously designed to meet specific laboratory requirements. This tailored approach not only enhances the reliability of analytical results but also safeguards sensitive equipment from potential damage. By understanding these diverse filtration options, laboratories can make informed choices that elevate their operational standards and ensure compliance with industry regulations.

Introduction

In the realm of scientific research and industrial applications, filtration tubes stand as essential instruments that guarantee the purity and integrity of samples. These specialized tools are meticulously engineered to separate solids from liquids or gases with high efficiency, playing a pivotal role across various fields, including:

- Pharmaceuticals

- Environmental testing

- Biotechnology

As the demand for precise analytical results escalates, it becomes crucial to comprehend the diverse types of filtration tubes and their specific applications. Their importance spans from enhancing the accuracy of moisture content analysis in pharmaceuticals to protecting sensitive laboratory equipment. This exploration delves into the multifaceted functionalities and vital roles that filtration tubes serve across multiple industries, underscoring their impact on quality control and adherence to regulatory standards.

Define Filtration Tubes and Their Importance

Filtration devices, such as the filtration tube, are indispensable laboratory instruments engineered to efficiently separate solids from liquids or gases. Comprising a porous medium, these structures function as filtration tubes, permitting fluid flow while retaining solid particles. This process is pivotal in sample purification, which is essential across various scientific disciplines, including chemistry, biology, and pharmaceuticals, as it directly impacts the accuracy of analytical results. By employing a filtration tube to eliminate impurities, these devices bolster the reliability of experiments and protect sensitive equipment, such as high-performance liquid chromatography (HPLC) systems, from particulate damage.

The significance of filtration tubes extends beyond mere sample clarity; they are crucial for compliance with regulatory standards, particularly in pharmaceutical contexts where precision is paramount. The implementation of Karl Fischer titrators, including , exemplifies how separation solutions can enhance the accuracy of moisture content analysis in pharmaceuticals, ensuring compliance with the Japanese Pharmacopoeia. These titrators are meticulously designed to provide precise measurements, making them vital in pharmaceutical testing.

Practical applications underscore this influence, as demonstrated in case studies where the utilization of filtration tubes in chemical reactors improved overall analytical outcomes, highlighting their versatility and efficiency in diverse laboratory settings. For instance, a study on heat pipes using liquid sodium as the working fluid illustrated the critical nature of selecting appropriate materials and techniques in laboratory processes, underscoring the role of purification solutions in enhancing analytical precision. Expert opinions reinforce the significance of filtration tubes in analytical chemistry, asserting that their application is essential for achieving high levels of accuracy in pharmaceutical assessments. As noted by Japanese researchers, the durability of materials such as Inconel 600 can profoundly affect the efficacy of filtration systems, ensuring that only uncontaminated samples are analyzed. This commitment to purity significantly contributes to the integrity of research findings and the progression of scientific knowledge.

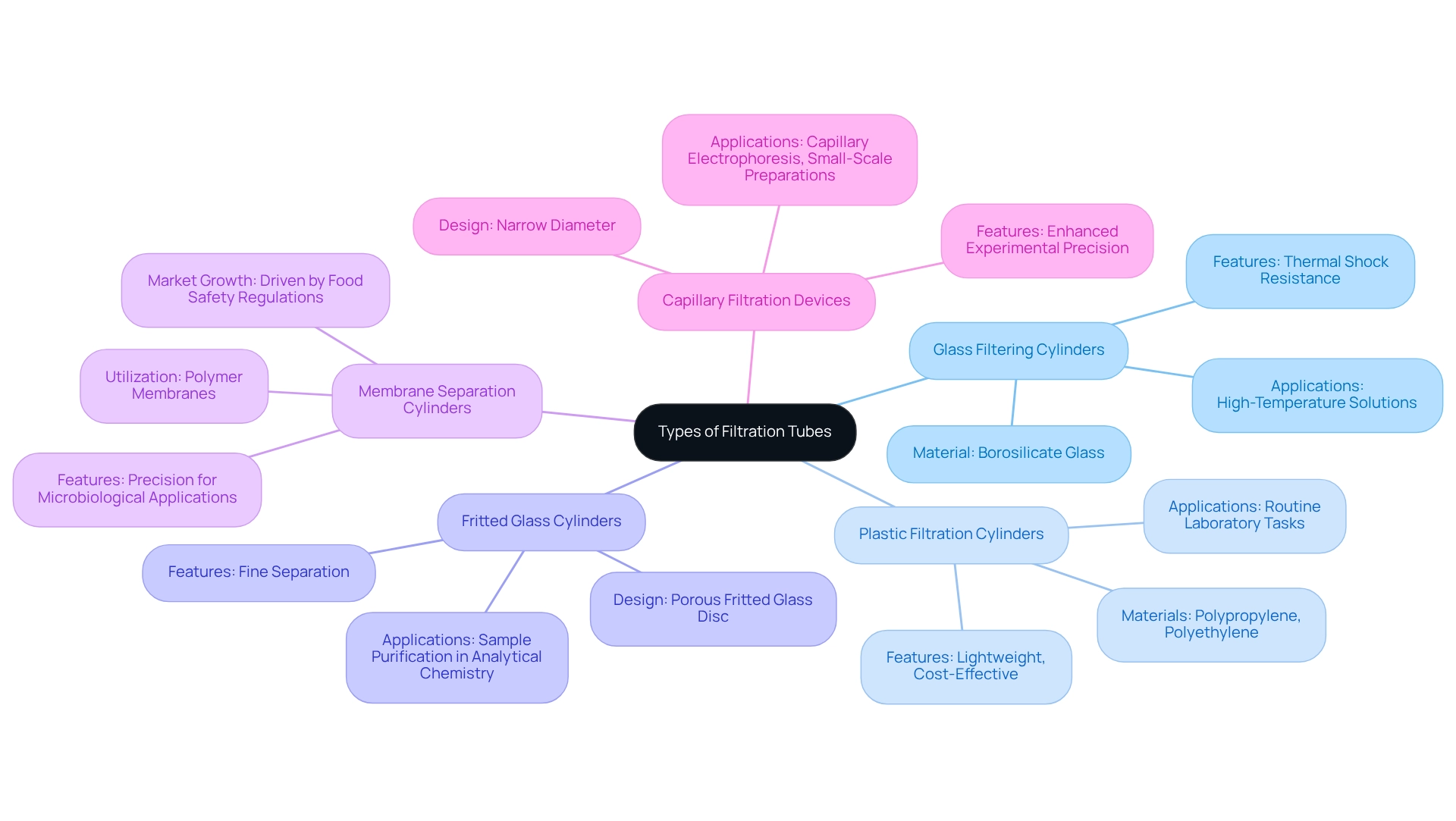

Explore Types of Filtration Tubes

Filtering devices are indispensable instruments in laboratory environments, each specifically designed for distinct applications. Grasping the differences among these devices can profoundly influence experimental outcomes.

Glass Filtering Cylinders: Composed of borosilicate glass, these cylinders are adept at withstanding thermal shock and chemical corrosion, rendering them ideal for high-temperature and reactive solutions. Their robust construction guarantees dependable performance in demanding settings.

Plastic Filtration Cylinders: Fabricated from materials such as polypropylene or polyethylene, plastic cylinders are lightweight and cost-effective, making them suitable for routine laboratory tasks. Their adaptability allows for extensive use across various applications without sacrificing quality.

Fritted Glass Cylinders: Featuring a porous fritted glass disc, these cylinders enable fine separation, establishing their importance in analytical chemistry for sample purification. Their design promotes efficient separation of particulates from liquids, ensuring optimal results.

: Utilizing polymer membranes tailored for specific particle sizes, these cylinders are commonly employed in microbiological applications to filter bacteria and other microorganisms. Their precision is vital for preserving sample integrity in sensitive experiments. With the market for membrane separation technology expected to expand significantly, driven by increasing regulations on food safety, the importance of these components in laboratory applications cannot be overstated.

Capillary Filtration Devices: With a narrower diameter, capillary instruments are crafted for precise applications, such as capillary electrophoresis or small-scale sample preparations. Their specialized design facilitates accurate handling of minute volumes, thereby enhancing experimental precision.

Recent market analysis indicates that the tubular systems segment captured the largest market share in 2023, reflecting a growing consumer preference for high-quality purification solutions. Selecting the appropriate filtration tube is critical for achieving optimal outcomes in laboratory procedures. Each type of filtration tube presents unique benefits tailored to specific needs, ensuring researchers can effectively fulfill their analytical requirements. Expert insights suggest that the choice between glass and plastic filtration devices should consider both performance and usage context, further underscoring the necessity for informed decision-making in laboratory environments.

Examine Applications of Filtration Tubes

Filtration tubes are integral to numerous applications across various industries, capturing attention with their essential role in ensuring quality and compliance. In pharmaceutical production, these tubes are crucial for clarifying solutions and removing impurities, ensuring that final products meet rigorous quality standards and are devoid of contaminants. is expected to expand at a CAGR of about 8.5% from 2023 to 2031, indicating a rising need for dependable purification solutions in this sector.

In the realm of environmental testing, filtration tubes play a vital role in filtering water samples to identify pollutants and microorganisms, thereby supporting environmental monitoring and protection efforts. Their effectiveness is underscored by the growing emphasis on technological innovations and regulatory changes shaping the environmental testing market. As Neel Daphtary, President of Chemtech International, states, 'The progress in purification technology is essential for satisfying the strict regulatory standards in environmental testing.'

In the Food and Beverage Industry, filtration tubes ensure product safety and quality by removing particulates and pathogens during processing, which is essential for compliance with health regulations. Additionally, in biotechnology, these containers, particularly filtration tubes, are utilized in critical processes such as cell harvesting and protein purification, where the removal of cellular debris is necessary to obtain pure samples for further analysis.

Furthermore, in research laboratories, filtration tubes are frequently utilized in sample preparation for numerous analytical methods, such as HPLC and mass spectrometry. They protect sensitive instruments from clogging and damage, thereby enhancing the reliability of analytical results.

Comprehending these applications underscores the vital role of filtering devices in upholding quality and compliance across scientific fields. This highlights their significance in both pharmaceutical production and environmental assessment. Moreover, case studies demonstrating the effectiveness of filtration tubes in pharmaceutical processes could provide practical insights for lab managers, further emphasizing their critical role in the industry.

Conclusion

The exploration of filtration tubes underscores their essential role in a multitude of scientific and industrial applications. These specialized instruments are crucial for the separation of solids from liquids or gases, ensuring sample purity and integrity across various sectors, including pharmaceuticals, environmental testing, and biotechnology. By employing diverse types of filtration tubes—ranging from glass and plastic to fritted and membrane options—researchers are empowered to enhance the accuracy of their experiments while upholding stringent quality standards.

The applications of filtration tubes extend well beyond simple sample clarification; they are vital for compliance with regulatory mandates, particularly in the pharmaceutical sector. Their effectiveness in filtering out contaminants not only safeguards sensitive laboratory equipment but also ensures that analytical results are both reliable and precise. As industries increasingly acknowledge the significance of high-quality filtration solutions, the market for these tools continues to expand, reflecting a shift towards prioritizing accuracy and safety in laboratory practices.

In conclusion, grasping the diverse functionalities and applications of filtration tubes is imperative for any laboratory or industry that prioritizes precision and quality control. As the demand for accurate analytical results intensifies, the role of filtration tubes will undoubtedly remain central to advancements in scientific research and industrial processes. Embracing these tools transcends merely enhancing experimental outcomes; it is about safeguarding the integrity of scientific inquiry and fostering innovation across various fields.