Overview

Selecting the appropriate stirrer for your laboratory is a critical decision that requires a thorough assessment of specific operational needs. Key factors include:

- Sample volume

- Viscosity

- The type of mixing device required, whether magnetic or mechanical stirrers

Understanding these elements, alongside technical specifications, safety compliance, and maintenance requirements, is essential. This knowledge not only enhances experimental efficiency but also ensures reliability. Ultimately, a well-chosen mixer can significantly impact your laboratory's performance.

Introduction

In the intricate world of laboratory research, the choice of equipment can significantly influence experimental outcomes. Among the essential tools, stirrers emerge as vital instruments that ensure the uniform mixing of solutions, a crucial factor for achieving reliable results.

With various types of stirrers available—magnetic, mechanical, and hotplate models—each designed for specific applications, selecting the right one can indeed be a daunting task.

This article delves into the multifaceted role of stirrers in laboratory settings, exploring their functionalities, the latest technological advancements, and the critical considerations for choosing the ideal stirrer.

As laboratories strive for precision and productivity, understanding the nuances of stirrer selection becomes imperative for researchers and technicians alike, enhancing both efficiency and safety in scientific research.

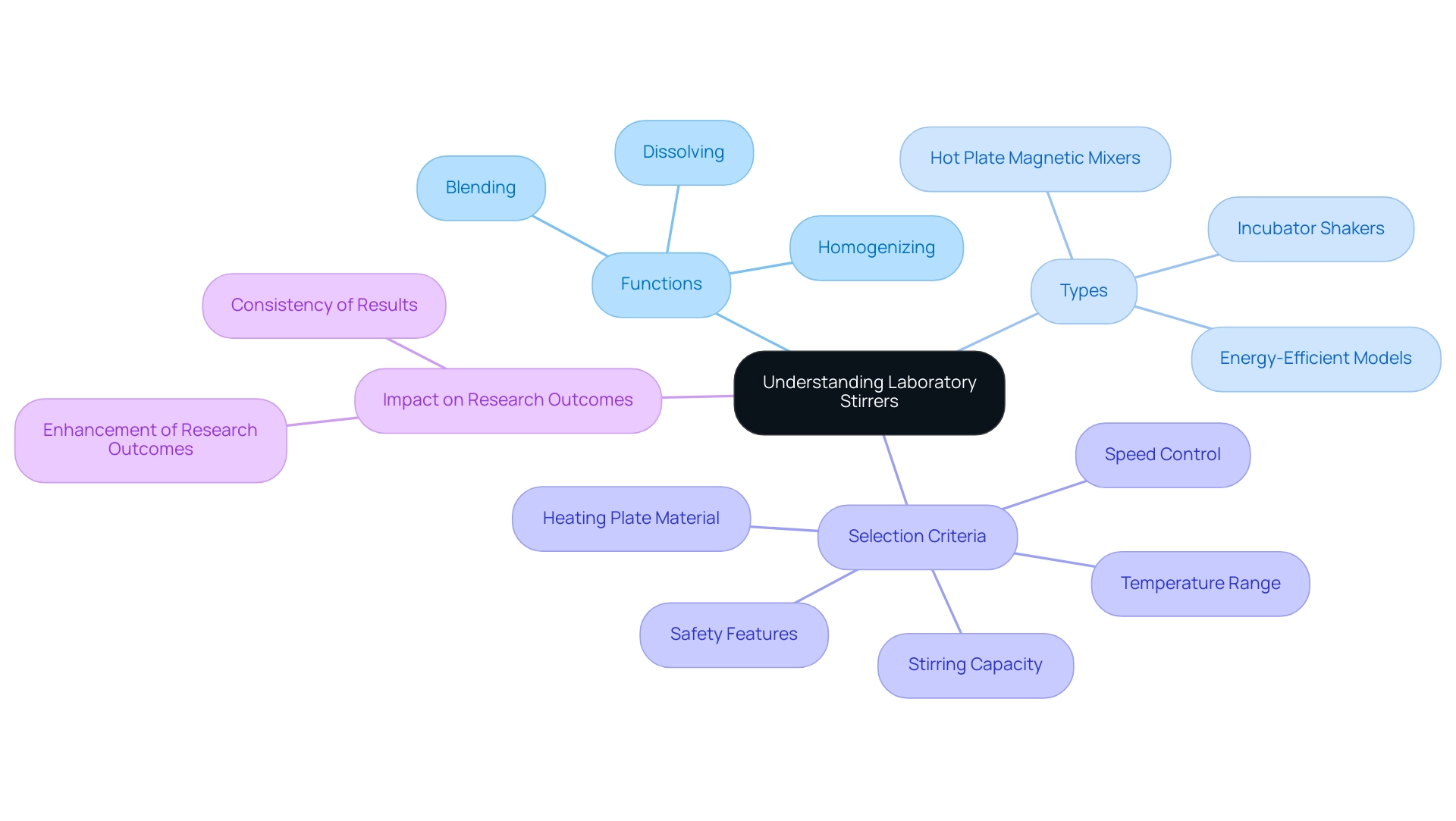

Understanding the Role of Stirrers in Laboratory Settings

Stirrers are essential tools in research settings, playing a crucial role in blending, dissolving, and homogenizing various solutions. Their ability to ensure uniformity in chemical reactions is vital for processes such as cell lysis, protein purification, and chemical synthesis. The choice of a suitable mixing tool can significantly affect the effectiveness and precision of experiments conducted in research environments. This highlights the importance for facility managers and technicians to understand their functions and uses in depth.

In research settings, mixing devices can be categorized into various types, each designed for specific tasks depending on the thickness of the substances being combined and the size of the operation. For instance, energy-efficient models of hot plate magnetic mixers not only enhance mixing capabilities but also contribute to reduced operating costs over time. This makes them a cost-effective choice in budget-conscious environments.

Recent advancements in lab mixing technology have led to the development of compact hot plates designed for crowded research spaces. These small-footprint hot plates optimize benchtop usage without compromising performance, making them ideal for shared-use core facilities where multiple users operate in limited space. Such innovations underscore the significance of mixing devices in facilitating collaborative research efforts.

When selecting a mixing device, it is essential to consider various factors, including temperature range, stirring capacity, speed control, heating plate material, and safety features. Expert opinions emphasize the importance of understanding the features of incubator shakers and making informed purchasing decisions. As Chris Manoogian, a former associate director of internal QC at Verve Therapeutics, noted, identifying from each area can greatly enhance the selection process.

This method guarantees that facility managers possess the understanding required to select mixers that fulfill their particular requirements.

The influence of stirrers on the consistency of chemical reactions cannot be overstated. Statistics indicate that using the right stirrers can significantly improve the consistency of results in experiments, thereby enhancing overall research outcomes. By acknowledging the essential function of mixers in chemical reactions, professionals can make strategic choices that lead to more dependable and consistent outcomes.

Exploring Different Types of Stirrers: Magnetic, Mechanical, and More

Laboratory stirrers are essential tools in scientific research, available in several types, each tailored for specific applications.

- Magnetic Stirrers are particularly effective for low-viscosity liquids and are widely used in routine laboratory tasks. They function by producing a rotating magnetic field that spins a stir bar within the liquid, ensuring efficient blending without direct contact. For optimal performance, a 15 mm Rare Earth Elliptical Starring Bar is recommended for use with 25 ml and 50 ml flasks.

- Mechanical Mixers are designed for high-viscosity solutions, utilizing an impeller or paddle to mix substances. They are ideal for applications requiring more robust blending capabilities, making them a staple in .

- Overhead Mixers are specifically engineered for larger volumes and more viscous materials. Equipped with a motor that drives a stirring shaft, they provide effective agitation for thick solutions, which is crucial in pharmaceutical labs where consistency is key.

- Hotplate Mixers combine heating and mixing functions, making them invaluable for reactions that require precise temperature control alongside blending. This dual functionality enhances experimental efficiency and accuracy.

Choosing the suitable mixer often involves trial and error, and evaluation kits are available to test different types of stirrers. Comprehending the specific needs of stirrers in stirring applications—such as accuracy, stability, volume, viscosity, and drive type—can significantly enhance reproducibility and efficiency in experimental processes. For instance, basic analog units offer reliability for non-critical applications, while electronic feedback controls provide the precision needed for critical stirring tasks. A case study titled 'Choosing Plate Stirrers and Stir Mantles' emphasizes that factors such as accuracy, stability, volume, viscosity, and drive type must be considered when selecting stirrers, enhancing the relevance of this discussion.

The market for research mixers is diverse, with magnetic stirrers holding a significant share due to their versatility and ease of use. However, mechanical mixers are also essential for applications that require more intensive mixing. As facility managers weigh their options, expert opinions emphasize the importance of balancing performance with budget constraints when investing in high-quality equipment. Lauren Everett, Managing Editor for Lab Manager, observes, 'While investing in high-quality equipment is important, it is also essential to consider budget constraints and find a balance between performance and cost when selecting hot plate magnetic devices.' By remaining updated on the newest advancements in mixing technology, staff can make knowledgeable choices that correspond with their particular blending requirements.

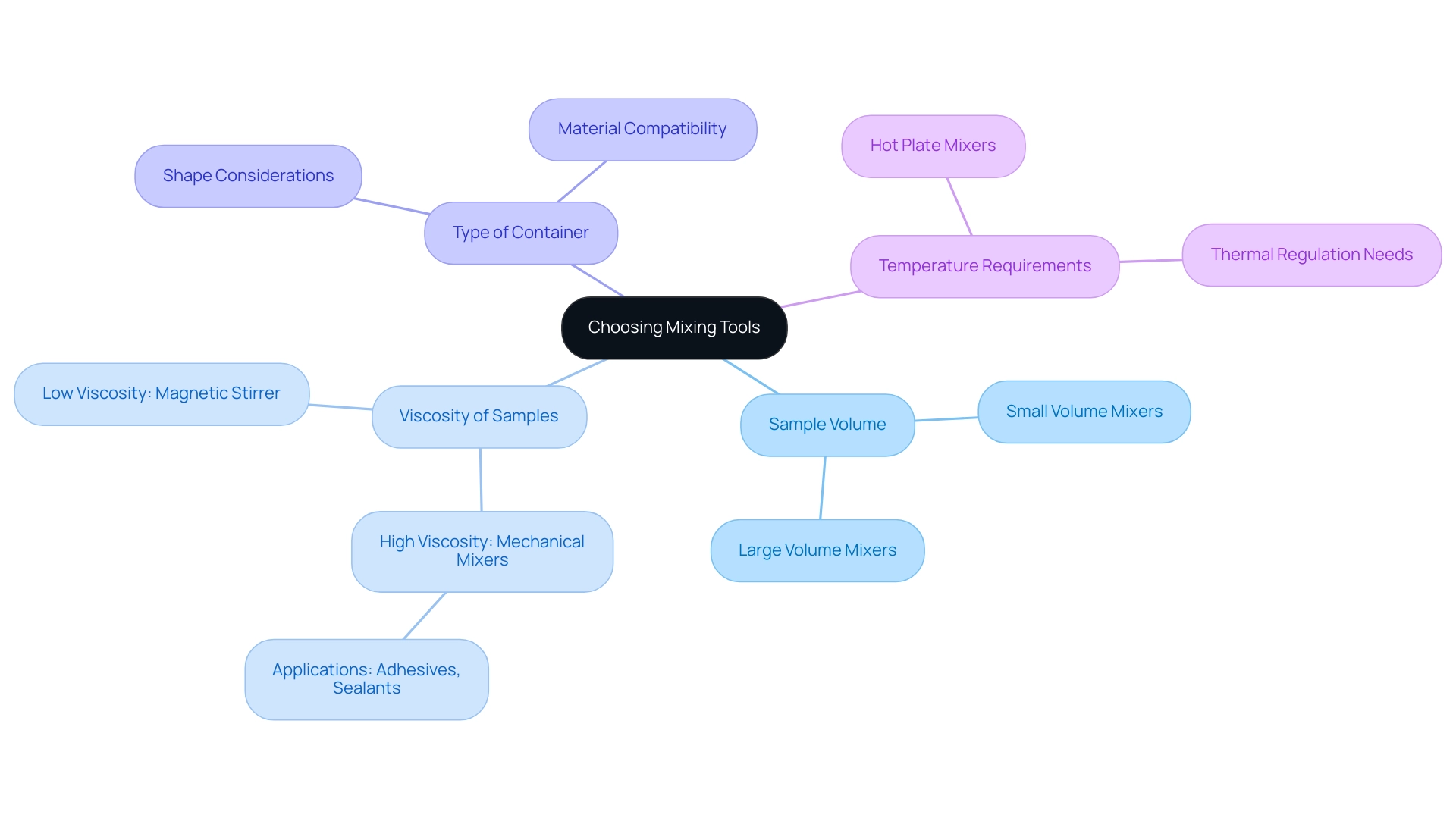

Assessing Your Laboratory's Needs: Compatibility and Application Considerations

Choosing the suitable mixing tool for your laboratory requires a thorough assessment of specific operational needs. Key factors to consider include:

- Sample Volume: Identify the maximum liquid volume you will be stirring. This is critical, as different mixing device models cater to varying capacities; some are optimized for small volumes, while others can accommodate larger quantities.

- Viscosity of Samples: The viscosity of the materials being mixed significantly affects the choice of mixing equipment. For instance, high-viscosity samples, which can reach up to 1,000,000 centipoise (cps), often require the use of mechanical or overhead mixing devices. In contrast, magnetic stirrers can efficiently mix low-viscosity solutions. Laboratory mixers can also simulate stirring patterns based on batch requirements, enhancing their adaptability to different laboratory needs.

- Type of Container: The shape and material of the container play a vital role in stirring efficiency. It is crucial to verify that the chosen device is suitable for the containers in use, as this can influence the blending process.

- Temperature Requirements: If your application involves heating, a hot plate mixer that can maintain the desired temperature during mixing is crucial. This feature is especially important for processes that necessitate accurate thermal regulation.

By carefully assessing these factors, technical staff can make informed choices when selecting stirrers that satisfy their specific operational needs. For instance, in a recent case study involving the processing of high-viscosity products for adhesives and coatings, specialized lab mixers demonstrated their capability to handle challenging substances effectively. This showcases the importance of matching equipment to the task at hand. This strategic approach not only enhances mixing efficiency but also contributes to improved productivity in research environments.

As Michael Dennis, PhD, indicated, bioelectronic materials are essential for developing devices that link electronics with the body’s natural systems, highlighting the importance of advanced materials in research environments. Furthermore, the versatility of mixers in handling , including adhesives and sealants, emphasizes their significance in contemporary applications. Lastly, employing statistical analysis, such as SPSS, to compare productivity between research sites can highlight the importance of data-driven decision-making in selecting equipment.

Key Technical Specifications to Consider When Choosing a Stirrer

When selecting stirrers for laboratory applications, it is essential to consider several key technical specifications that directly impact performance and efficiency.

- Speed Range: The stirring speed, measured in revolutions per minute (RPM), is crucial for achieving the desired blending intensity. For instance, the rotation speed of the outer cylinder in dynamically rotating axis micro reactors is restricted to 3600 RPM, illustrating the upper limits of velocity in advanced blending technologies. Different applications may necessitate varying speeds to optimize mixing outcomes.

- Torque: Torque is particularly vital for mechanical and overhead mixers, as it determines their capability to effectively mix viscous solutions. Understanding the torque requirements for various stirring applications ensures that the chosen device can handle the specific demands of the materials being mixed.

- Capacity: It is important to ensure that the mixing device can accommodate the maximum volume of liquid intended for use. Consulting the manufacturer's specifications for will help avoid operational limitations during experiments.

- Control Features: Modern mixing devices often come equipped with digital displays, programmable settings, and safety features such as automatic shut-off. These enhancements not only improve usability but also contribute to safer work environments, allowing for precise control over blending processes.

- Durability and Composition: The materials used in the device's construction are critical, especially when handling corrosive agents. A robust mixer crafted from high-quality materials will offer improved durability and reliability, minimizing the need for frequent replacements.

By focusing on these specifications, personnel can select a device that not only meets their technical needs but also enhances the overall effectiveness of their blending processes. For example, the development of stirrers like the curved-blade disc turbine and upward-pumping hydrofoils aims to minimize power draw while maximizing mixing efficiency, showcasing current trends in stirrer technology. Furthermore, the availability of ceramic membranes will facilitate the future development of rotating membrane reactors, which could significantly enhance productivity in experimental applications, as noted by Sen et al.

Understanding these specifications and trends empowers managers to make informed decisions that align with their operational needs. Moreover, real-world applications, such as those highlighted in the case study on ultrasound-enhanced plating rates, demonstrate the impact of advanced mixing technologies on experimental results, underscoring the importance of selecting the appropriate device based on technical specifications.

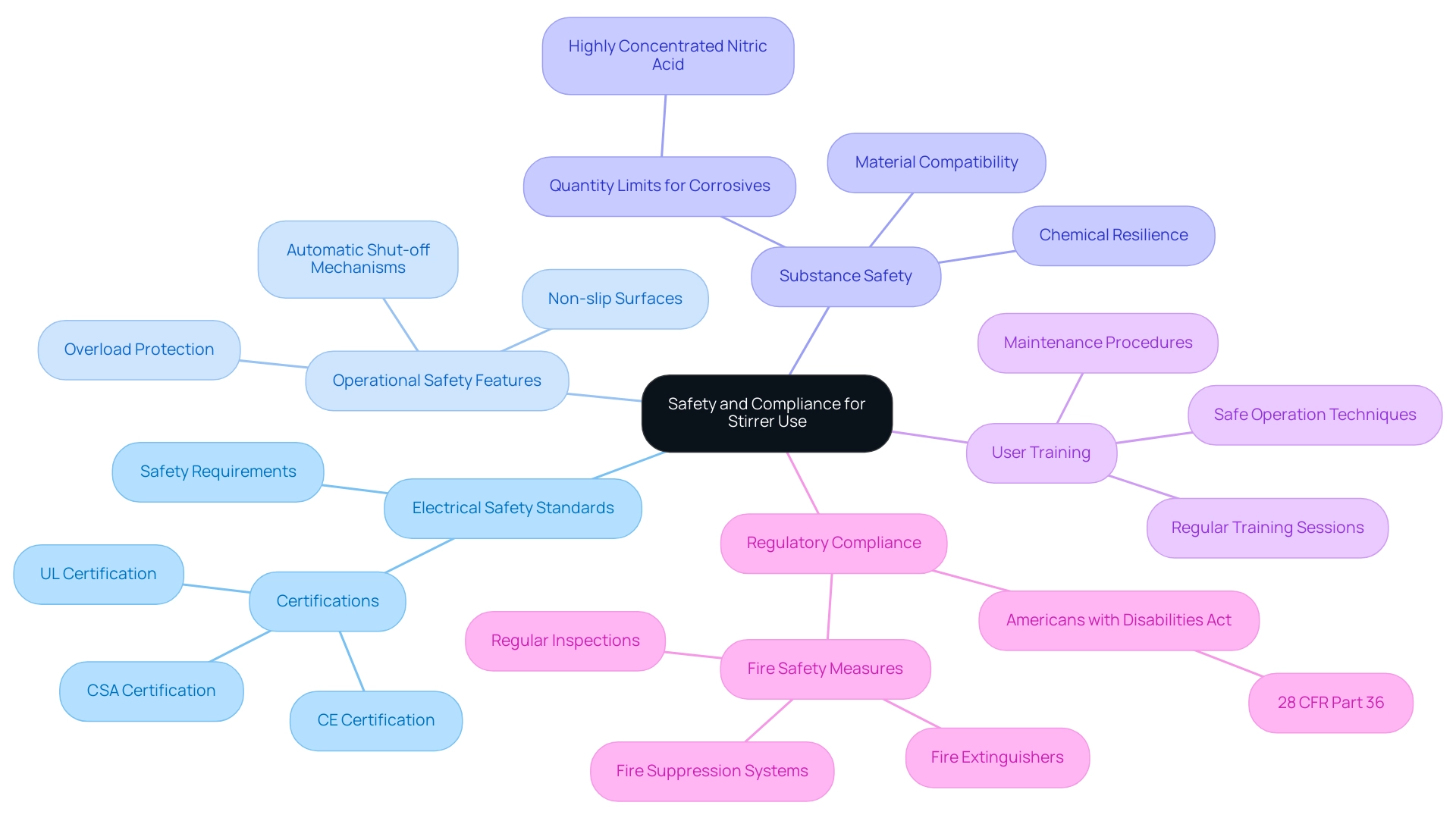

Safety and Compliance: Ensuring Your Stirrer Meets Regulatory Standards

Safety is paramount in experimental settings, particularly when selecting stirrers as mixing devices. Compliance with established safety standards is essential to mitigate risks associated with laboratory operations, especially when using stirrers. Key considerations include:

- Electrical Safety Standards: It is critical to ensure that stirrers and mixing devices are certified by recognized organizations such as UL, CE, or CSA. These certifications confirm that the equipment adheres to stringent safety requirements for electrical devices, significantly reducing the likelihood of electrical hazards.

- Operational Safety Features: Choose devices equipped with essential safety features. Look for stirrers that include overload protection, automatic shut-off mechanisms, and non-slip surfaces. These features minimize the risk of accidents during operation, thereby enhancing overall safety in the lab. For instance, tools with automatic shut-off can prevent overheating, which is crucial when working with volatile substances.

- Substance Safety: It is imperative to confirm that the components utilized in the mixer’s construction are compatible with the substances being combined. Incompatible substances can lead to hazardous chemical reactions, posing serious safety risks. Selecting stirrers made from chemically resilient materials is essential for secure experimental procedures. Additionally, be aware of quantity limits for corrosives, particularly for highly concentrated nitric acid, which can pose significant hazards if not handled properly.

- User Training: Comprehensive training for laboratory staff is vital. Ensure that personnel are well-versed in the safe operation of mixing devices, including proper handling techniques and maintenance procedures. Regular training sessions can reinforce safety protocols and promote a culture of safety within the workspace.

Moreover, it is important to stay informed about the current safety standards for stirrers in 2025. Regular inspections and adherence to safety codes, such as those outlined in the Americans with Disabilities Act (28 CFR Part 36), are critical for maintaining a safe working environment, especially when using equipment like stirrers. Case studies on fire safety measures highlight the necessity of having fire extinguishers and suppression systems readily available, underscoring the importance of preparedness in case of emergencies.

As noted in the case study titled "Fire Safety Measures in Laboratories," regular inspection and maintenance of are critical to ensure readiness in case of a fire emergency.

Furthermore, as Paracelsus famously stated, "What is it that is not poison? All things are poison, and nothing is without poison. It is the dose only that makes a thing not a poison." This quote underscores the significance of understanding the risks associated with testing equipment and the importance of proper dosing and handling.

By prioritizing safety and compliance, managers can foster a safer working environment, significantly reducing the risk of accidents and ensuring the well-being of all personnel.

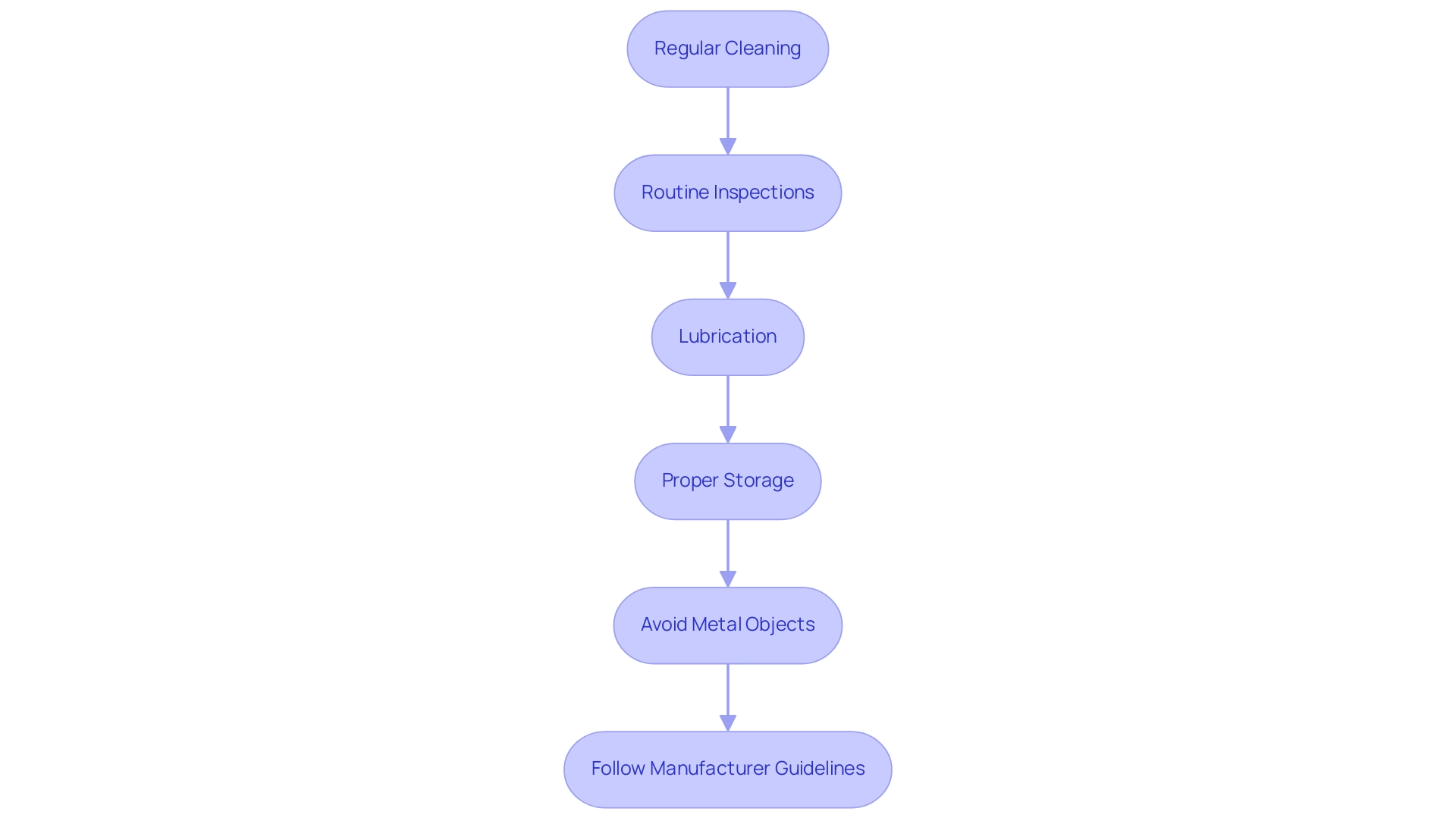

Maintenance Tips for Prolonging the Life of Your Laboratory Stirrer

To extend the lifespan of your laboratory stirrer and ensure optimal performance, it is essential to adhere to the following maintenance practices:

- Regular Cleaning: Thoroughly clean the after each use to eliminate residues that may compromise its functionality. Utilize a soft cloth and a mild detergent, avoiding abrasive materials that could scratch or damage surfaces.

- Routine Inspections: Conduct regular inspections to identify any signs of wear or damage. Pay close attention to the stirring bar, motor, and electrical components, ensuring they are in good working order.

- Lubrication: For mechanical and overhead mixers, adequately lubricate moving parts. This practice minimizes friction and wear, contributing to the longevity of the equipment.

- Proper Storage: When not in use, store mixing tools in a dry, dust-free environment. Avoid exposure to extreme temperatures or humidity, which can adversely affect their performance.

- Avoid Metal Objects: It is crucial to avoid using metal or magnetic items near magnetic devices to prevent interference with their operation.

- Follow Manufacturer Guidelines: Always consult the manufacturer's manual for specific maintenance recommendations and troubleshooting advice tailored to your mixing device model.

By implementing these maintenance strategies, staff can significantly enhance the durability and reliability of their stirring equipment. A case study highlighted that facilities adhering to regular maintenance protocols reported a 30% increase in the longevity of stirrers, showcasing the tangible benefits of proper care. Furthermore, managers have noted that consistent maintenance not only reduces downtime but also fosters a more efficient working environment, ultimately leading to improved research outcomes.

As Lauren Everett, Managing Editor for Lab Manager, emphasizes, "Regular maintenance is key to ensuring that laboratory equipment operates at peak performance, which is crucial for achieving reliable results in research.

Making the Final Decision: A Checklist for Choosing the Right Stirrer

To facilitate an informed decision on which mixer to purchase, consider the following comprehensive checklist:

- Identify Your Needs: Begin by assessing the volume, viscosity, and type of materials you will be mixing. Understanding these factors is crucial for selecting a mixing tool that can handle your specific applications effectively.

- Choose the Type of Mixing Device: Evaluate the options available—magnetic, mechanical, overhead, or hotplate mixers. Each type has distinct advantages depending on your mixing requirements, so choose one that aligns with your laboratory's objectives.

- Evaluate Technical Specifications: Scrutinize the technical specifications of potential mixers, including speed range, torque, capacity, and control features. These specifications will directly affect the mixer’s performance and suitability for your tasks.

- Ensure Safety Compliance: Confirm that the mixing device adheres to relevant safety standards and is equipped with necessary safety features. This is essential for maintaining a safe laboratory environment and protecting personnel.

- Consider Maintenance Requirements: Investigate the maintenance needs and durability of the mixing device. A dependable mixing device should require minimal maintenance while delivering consistent performance over time.

- Budget Considerations: Establish your budget and compare prices across various models and brands. In 2025, it’s essential to balance cost with quality, ensuring that you invest in a mixing device that meets your facility's demands without compromising on performance. provides competitive pricing on high-performance equipment, which can significantly impact your purchasing choices.

By following this checklist, personnel can confidently select the right stirrers that not only meet their operational requirements but also enhance the overall efficiency of their processes. This structured approach is particularly beneficial in today's fast-paced scientific environment, where the procurement cycle for biomedical equipment has significantly improved, reducing from an average of 154 days to just 92.5 days. Such efficiency underscores the importance of making well-informed purchasing decisions in a timely manner.

Furthermore, JM Science Inc. is dedicated to continually updating its product offerings and maintaining strong relationships with top manufacturers, ensuring that customers have access to the latest innovations in testing equipment. As mentioned by Farhad Shokraneh from King's College London, understanding the decision-making process for equipment selection is crucial for optimizing operations. Additionally, JM Science Inc. provides valuable support for sellers navigating complex purchasing processes, as demonstrated in their case study on seller support for MAS contractors, enhancing the overall context of the decision-making process for laboratory equipment.

Conclusion

The significance of stirrers in laboratory settings is paramount, as they are crucial for ensuring the uniform mixing of solutions—an essential factor for achieving reliable experimental outcomes. Various types, including magnetic, mechanical, and advanced hotplate models, cater to specific applications based on the viscosity of materials and operational requirements. Recent advancements in stirrer technology, such as compact designs for limited spaces and energy-efficient models, underscore the evolving landscape of laboratory equipment, aimed at enhancing efficiency and collaboration.

Selecting the right stirrer necessitates careful consideration of several factors, including:

- Sample volume

- Viscosity

- Container compatibility

- Temperature requirements

- Safety compliance

By understanding these elements, laboratory personnel can make informed decisions that align with their specific operational needs. Furthermore, maintaining stirrers through regular cleaning, inspections, and adherence to manufacturer guidelines is vital for ensuring longevity and optimal performance.

Ultimately, the choice of stirrer is instrumental in the consistency and reproducibility of laboratory results. By prioritizing the selection process and emphasizing safety standards, laboratory managers can cultivate a productive environment that fosters reliable research outcomes. As the scientific community progresses, the strategic selection and maintenance of stirring equipment will remain essential for driving innovation and efficiency in laboratory practices.