Overview

To maximize efficiency with 0.45 micron syringe filters, it is crucial to adhere to best practices. Begin by inspecting filters prior to use. Apply gentle pressure during filtration and avoid overloading the device. Following these guidelines not only ensures optimal performance but also enhances the reliability of analytical results. Furthermore, it protects laboratory equipment from damage, ultimately leading to improved purification processes. These practices are essential for maintaining high-quality standards in laboratory settings.

Introduction

In the realm of laboratory research, precision is paramount. 0.45 micron syringe filters serve as a critical tool in achieving that precision. These filters play a vital role in sample preparation by effectively removing contaminants and particulates, ensuring that analyses yield reliable results. As laboratories increasingly adopt advanced filtration techniques, understanding the selection and best practices for these filters becomes essential. From chemical compatibility to appropriate handling, the nuances of using 0.45 micron syringe filters can significantly influence the integrity of scientific outcomes.

This article delves into the importance of these filters, guides on how to choose the right one for specific applications, and outlines best practices to maximize their efficiency in laboratory settings.

Understand the Role of 0.45 Micron Syringe Filters in Laboratories

Syringe filter 0.45 micron membranes are essential in laboratory environments, especially for sample preparation, as they effectively remove particulates and contaminants before analysis. Their pore size is meticulously engineered to exclude larger bacteria and particles, rendering them suitable for a diverse range of applications, including HPLC sample preparation and microbial analysis. By ensuring that samples are devoid of unwanted substances, these devices significantly enhance the precision and reliability of analytical results, which is crucial for both research and quality assurance processes. Furthermore, they play a vital role in protecting sensitive equipment from particulate damage, thereby extending the lifespan of instruments and boosting overall efficiency.

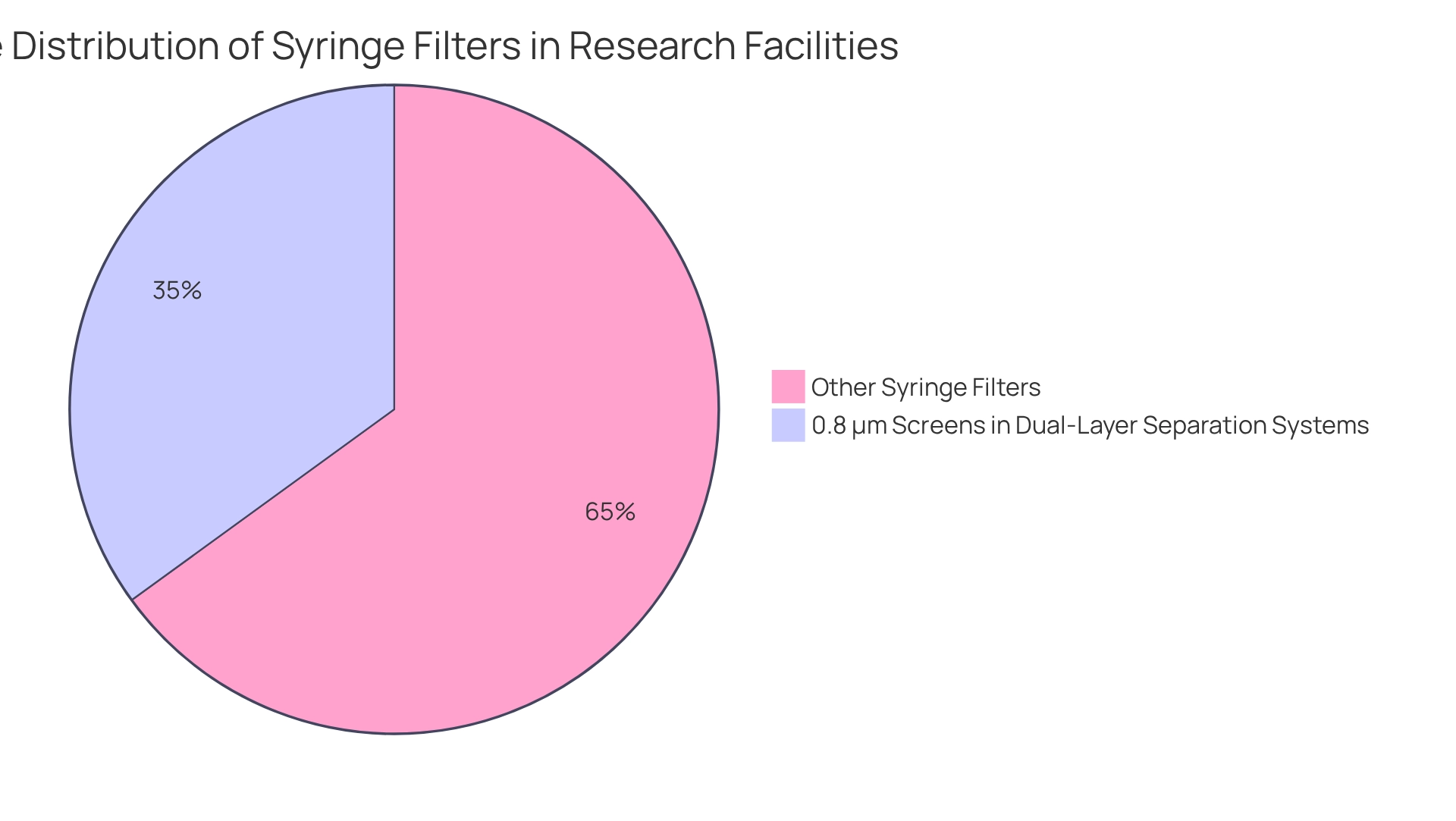

Recent data indicates that over 35% of research facilities utilize 0.8 μm screens in dual-layer separation systems, underscoring the growing reliance on accurate separation methods in modern research settings. The injection device market was valued at USD 0.34 Billion in 2024, reflecting the economic impact and importance of these tools in laboratory contexts. Additionally, a case study focused on chemical and industrial filtration illustrates how injection devices, such as 0.45 micron, are routinely employed to remove particulates from chemical solutions, thereby preserving the integrity of high-precision machinery and ensuring accurate outcomes in chemical analyses. The importance of the syringe filter 0.45 micron injection device membranes cannot be overstated; they are essential for maintaining the integrity of analytical processes and ensuring optimal performance in high-precision applications. As Ursula Koslik, Director of Marketing & PR, aptly noted, 'It is good that OpenPR exists!'—a statement that emphasizes the value of reliable information within the scientific community.

Select the Appropriate 0.45 Micron Syringe Filter for Your Application

Selecting the appropriate syringe filter 0.45 micron is crucial for optimizing laboratory processes. Consider the following factors:

- Sample Type: The chemical compatibility of the sample dictates the material choice for the sieve. Options such as nylon, PTFE, and PVDF are available, each tailored for specific chemical interactions.

- Volume and Viscosity: Assess the sample's volume and viscosity to ensure that the strainer can accommodate them effectively. For more viscous samples, opting for a larger mesh diameter can help prevent clogging and maintain optimal flow rates. Furthermore, the syringe size should correspond to the sample volume to achieve efficient separation without overloading.

- Application Requirements: Evaluate whether the purification process necessitates sterility. If so, a 0.22 micron filter may be more appropriate for sterilization, while a syringe filter 0.45 micron is commonly used for routine applications.

- Manufacturer Specifications: Always refer to the manufacturer's guidelines to ensure optimal performance and compatibility with your laboratory equipment. Adhering to these specifications can significantly enhance separation efficiency.

- Industry Trends: The anticipated rise of nanotechnology in purification materials, expected to exceed an annual growth rate of 10% over the next five years, indicates a shifting landscape that may influence the selection of purification devices.

By meticulously selecting the appropriate device based on these criteria, research facilities can significantly improve their purification processes and safeguard the integrity of their analytical results. This approach not only mitigates risks such as damage to screens or contamination but also aligns with best practices in laboratory operations. Moreover, the correct assembly and management of needle filters, as highlighted in various case studies, are vital to preventing issues like back pressure and plugging, thereby ensuring .

Implement Best Practices for Efficient Use of 0.45 Micron Syringe Filters

To maximize the efficiency of 0.45 micron syringe filters, it is crucial to adhere to the following best practices:

- Inspect Filters Before Use: Always examine the packaging for any signs of damage and confirm that the item is within its expiration date. This essential step ensures that inadequate screens do not compromise results.

- Use Gentle Pressure: Apply steady, moderate pressure when pushing the sample through the sieve. typically ranges between 0.5 to 2 bar. Excessive or rapid pressure can rupture the membrane, leading to system failure and potential contamination.

- Avoid Overloading: Adhere to the recommended volume limits for the device. Exceeding these limits can cause clogging, significantly reducing filtration efficiency and affecting the integrity of your results.

- Single Use Only: Most syringe membranes are designed for single use. Reusing screens can introduce contaminants and produce erroneous results, undermining the reliability of your experiments.

- Proper Storage: Keep the screens in a cool, dry environment to maintain their integrity until use. Proper storage conditions are essential for maintaining filter performance.

By adopting these methods, research facilities can significantly improve their purification processes by utilizing 0.45 micron, ensuring dependability and precision in study results. A recent study highlighted that understanding membrane compatibility and pore size can enhance lab efficiency and protect chromatography columns, leading to consistent results. Furthermore, it was noted that slow filtration could indicate underlying issues, as Dr. Susanne Huhmann stated, "Slow filtration isn’t just frustrating — it can indicate a problem." Adhering to these guidelines not only reduces failure rates but also enhances the overall effectiveness of laboratory analyses. Ultimately, by considering these factors, researchers can enhance the accuracy and reproducibility of experimental data through proper filter selection.

Conclusion

The significance of 0.45 micron syringe filters in laboratory settings is paramount. These filters are essential for ensuring that samples remain free from contaminants and particulates, thereby enhancing the accuracy and reliability of analytical results. By understanding their critical role in sample preparation and equipment protection, laboratories can effectively leverage these filters to improve both research outcomes and quality control processes.

Selecting the appropriate syringe filter represents a crucial step that can greatly influence experimental success. Factors such as sample type, volume, viscosity, and specific application requirements must be carefully considered to optimize filtration efficiency. Adhering to manufacturer specifications and remaining informed about industry trends further empowers laboratories to make informed decisions that align with best practices.

Implementing best practices for the use of 0.45 micron syringe filters is vital for maximizing their effectiveness. From inspecting filters prior to use to maintaining proper storage conditions, these practices are instrumental in ensuring reliable and reproducible results. By following the recommended guidelines, researchers can mitigate risks associated with filter failure and contamination, ultimately leading to enhanced laboratory performance.

In conclusion, the careful selection and use of 0.45 micron syringe filters are indispensable for achieving precision in laboratory research. By prioritizing filtration quality and adhering to best practices, laboratories can safeguard the integrity of their analyses, thus contributing to the advancement of scientific knowledge and innovation.