Overview

This article serves as a comprehensive guide on selecting and utilizing 15 ml centrifuge tubes, underscoring essential features such as:

- Material durability

- Compatibility with various centrifuge models

- The critical importance of sterility

It elaborates on the advantages of polypropylene tubes, outlines best practices for their usage, and addresses common troubleshooting issues. Additionally, it highlights storage and disposal considerations, all aimed at enhancing laboratory efficiency and safety.

Introduction

In the intricate realm of laboratory research, 15 mL centrifuge tubes emerge as indispensable tools, seamlessly blending versatility with reliability. Crafted primarily from durable polypropylene, these tubes are engineered to endure the rigors of scientific experimentation while safeguarding sample integrity. With features such as clear graduations for precise measurements and secure sealing options to prevent contamination, they cater to a diverse array of laboratory needs.

As advancements in materials and design continue to evolve, comprehending the nuances of these essential instruments becomes critical for researchers striving to enhance their experimental outcomes. This article explores the key features, types, selection criteria, best practices, and troubleshooting tips associated with 15 mL centrifuge tubes, offering a comprehensive guide for laboratory professionals dedicated to achieving reliable and accurate results.

Understanding 15 mL Centrifuge Tubes: Key Features and Benefits

Centrifuge 15 ml tubes are essential instruments in research settings, celebrated for their adaptability and reliability. Key characteristics of these containers include:

- Material: Primarily constructed from polypropylene, these vessels demonstrate exceptional durability and breakage resistance, making them ideal for rigorous scientific environments.

- Graduations: Most containers feature clear graduations, facilitating precise measurement of liquid volumes, which is crucial for accurate experimental outcomes.

- Cap Types: Available with either screw caps or snap caps, these containers ensure secure sealing, effectively preventing leaks and contamination.

Benefits:

- Integrity of Contents: The design of polypropylene spinning containers significantly minimizes contamination risks, thereby preserving the purity of contents. Lab professionals emphasize that maintaining specimen integrity is crucial for reliable experimental outcomes.

- Compatibility: These containers are suitable for a wide range of spinning device models, reinforcing their role as a fundamental element in numerous laboratory environments.

- Cost-Effectiveness: Their resilience and potential for reuse (in specific applications) provide excellent value, making them a prudent choice for laboratory finances.

Recent trends in lab container materials indicate a growing preference for polypropylene due to its superior performance attributes. A study conducted by Gryphon Scientific and Ursinus College highlighted the reliability of conical containers, revealing insights into the occurrence of leaks, which is vital for upholding the integrity of scientific experiments. This research underscores the importance of selecting high-quality spinning containers to prevent compromising experimental outcomes and informs future biosafety guidelines and best practices regarding their use.

In 2025, advancements in centrifuge 15 ml tubes introduced features that enhance usability and safety, such as and enhanced clarity for better visibility of specimens. These innovations reflect a continuous commitment to quality and performance in scientific equipment, aligning with ISO 9001:2000 standards and FDA Quality System Regulation compliance. Notably, many items are produced in our advanced facility, adhering to ISO 13485 standards for quality you can trust.

Overall, the benefits of utilizing polypropylene containers are clear: they provide dependable performance, preserve specimen integrity, and are economical, making them indispensable in contemporary research practices.

Types of 15 mL Centrifuge Tubes: Material and Design Variations

15 mL centrifuge tubes are available in a variety of materials and designs, each tailored to specific laboratory needs.

- Polypropylene is widely favored for general applications due to its robust strength and excellent chemical resistance, making it suitable for a range of laboratory procedures. It remains the dominant choice for general use, optimizing recovery rates in many scenarios.

- Polycarbonate, renowned for its exceptional transparency, is perfect for uses where observation of the specimen is essential, facilitating straightforward monitoring of contents. Lab managers often prefer polycarbonate for its clarity in visual assessments, especially in specialized applications.

- Glass, although not as prevalent, is employed in specific scenarios where chemical reactivity presents a risk, offering an inert environment for delicate specimens.

- Conical Bottom tubes are particularly effective for pelleting cells and separating components based on density, facilitating efficient sample processing.

- Flat Bottom structures, created for stability, are beneficial in scenarios that necessitate a secure standing position, reducing the risk of spills.

- Additionally, Sterile vs. Non-Sterile containers are critical for microbiological applications, ensuring that contamination is prevented and the integrity of the samples is maintained.

Recent trends suggest an increasing preference for polypropylene and polycarbonate substances in the market for , fueled by their distinctive characteristics and uses. In 2022, North America possessed the largest portion of the worldwide standard spinning device market, indicating rising research efforts in healthcare and the need for dependable testing equipment.

HAWACH emphasizes that their produced containers are crafted to enhance protein and DNA analysis requirements, guaranteeing optimal protein/DNA retrieval. This insight underscores the significance of material selection in experimental environments.

The case study titled "Market Dynamics and Challenges" highlights key issues in the container market, including customer purchasing behavior and the influence of regulations and technological advancements. Understanding these dynamics is essential for lab managers when selecting materials for their specific applications.

As research facilities continue to develop, grasping the most recent materials and design variations of centrifuge 15 mL tubes will be crucial for improving research outcomes and ensuring accurate results. Moreover, the OHAUS multi-pro-rotors, costing CAD$7,212.00, illustrate the financial commitment needed for high-quality separation equipment, further highlighting the significance of selecting the appropriate containers for optimal performance.

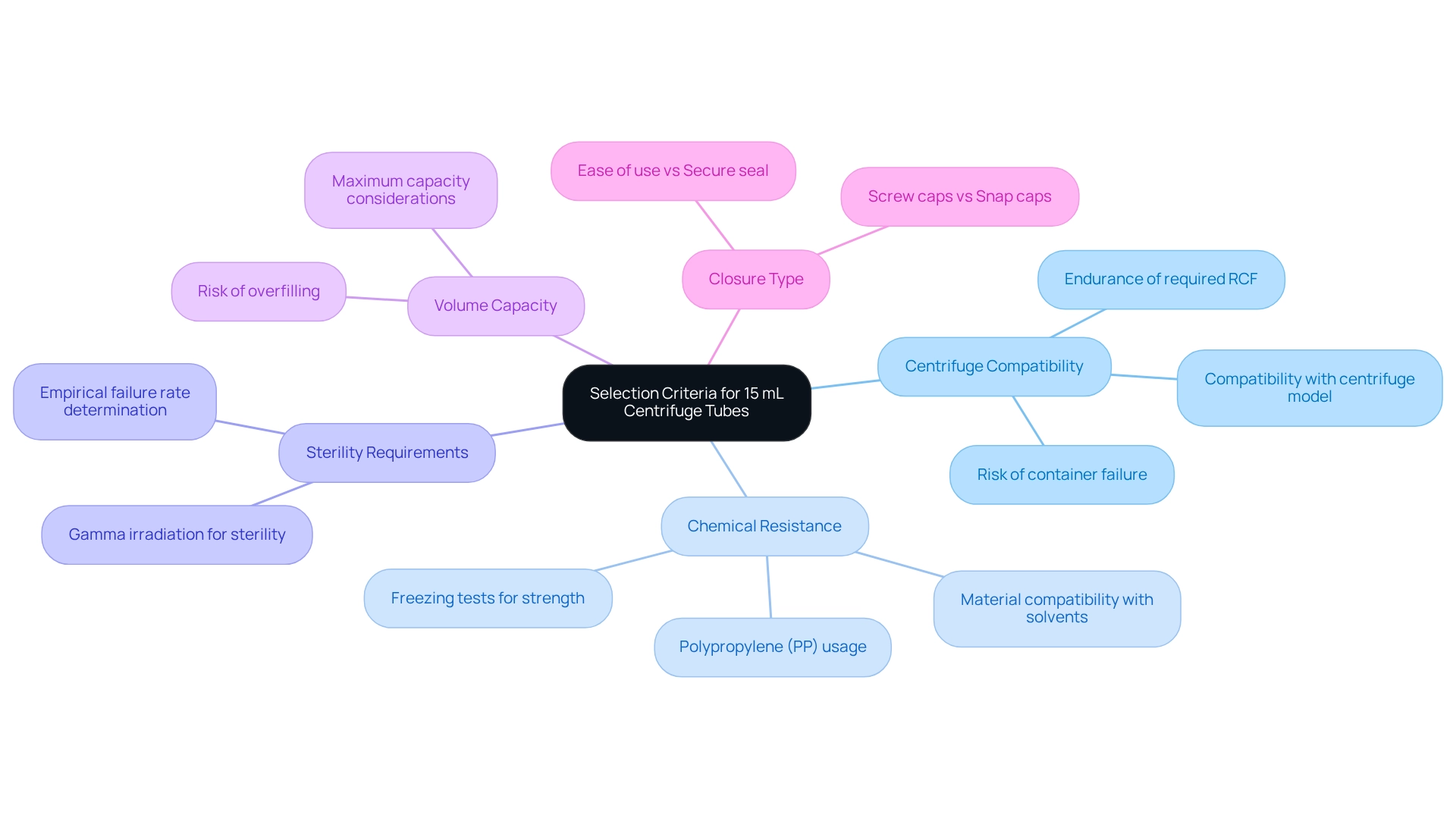

Choosing the Right 15 mL Centrifuge Tube: Essential Selection Criteria

When selecting a 15 mL centrifuge tube, several key criteria must be considered to ensure optimal performance and reliability in laboratory applications.

- Centrifuge Compatibility: Verifying that the tube is compatible with your specific centrifuge model and can endure the required Relative Centrifugal Force (RCF) is crucial. Incompatibility can lead to container failure, jeopardizing specimen integrity. The estimated marginal means (EMMs) for thread leaks in 15 mL containers indicate that some comparisons did not provide informative ranges of relative risk values, underscoring the need for careful selection.

- Chemical Resistance: The material of the centrifuge container must be compatible with the solvents and samples being processed. Polypropylene (PP) pipes are widely utilized due to their excellent chemical resistance; however, consulting chemical resistance ratings to avoid degradation under specific conditions is advisable. A case study on polypropylene pipes revealed a decrease in strength values under freezing conditions, emphasizing the necessity of conducting freezing tests to ensure they withstand mechanical loads without damage. This highlights the importance of testing containers under actual conditions, especially at temperatures below zero centigrade.

- Sterility Requirements: Choosing sterile containers is paramount for applications involving biological samples to prevent contamination. Gamma irradiation is a typical technique employed to guarantee sterility, and all containers should be confirmed for this characteristic. As Rocco Casagrande observed, "This paper shows that very simple methods could be utilized to empirically ascertain the rate of failure of common consumables."

- Volume Capacity: Ensure that the container can accommodate your sample volume without exceeding its maximum capacity. Overfilling can lead to spills and contamination, ultimately affecting experimental outcomes.

- Closure Type: The choice between screw caps, which provide a secure seal, and snap caps, which offer ease of use, may depend on the specific requirements of your laboratory procedures.

Real-world examples underscore the importance of these criteria. Research indicates , significantly impacting experimental outcomes.

In summary, selecting the appropriate centrifuge 15 mL tubes necessitates a thorough evaluation of compatibility, chemical resistance, sterility, volume capacity, and closure type. By adhering to these crucial standards, laboratory managers can enhance the reliability of their experiments and uphold the integrity of their specimens.

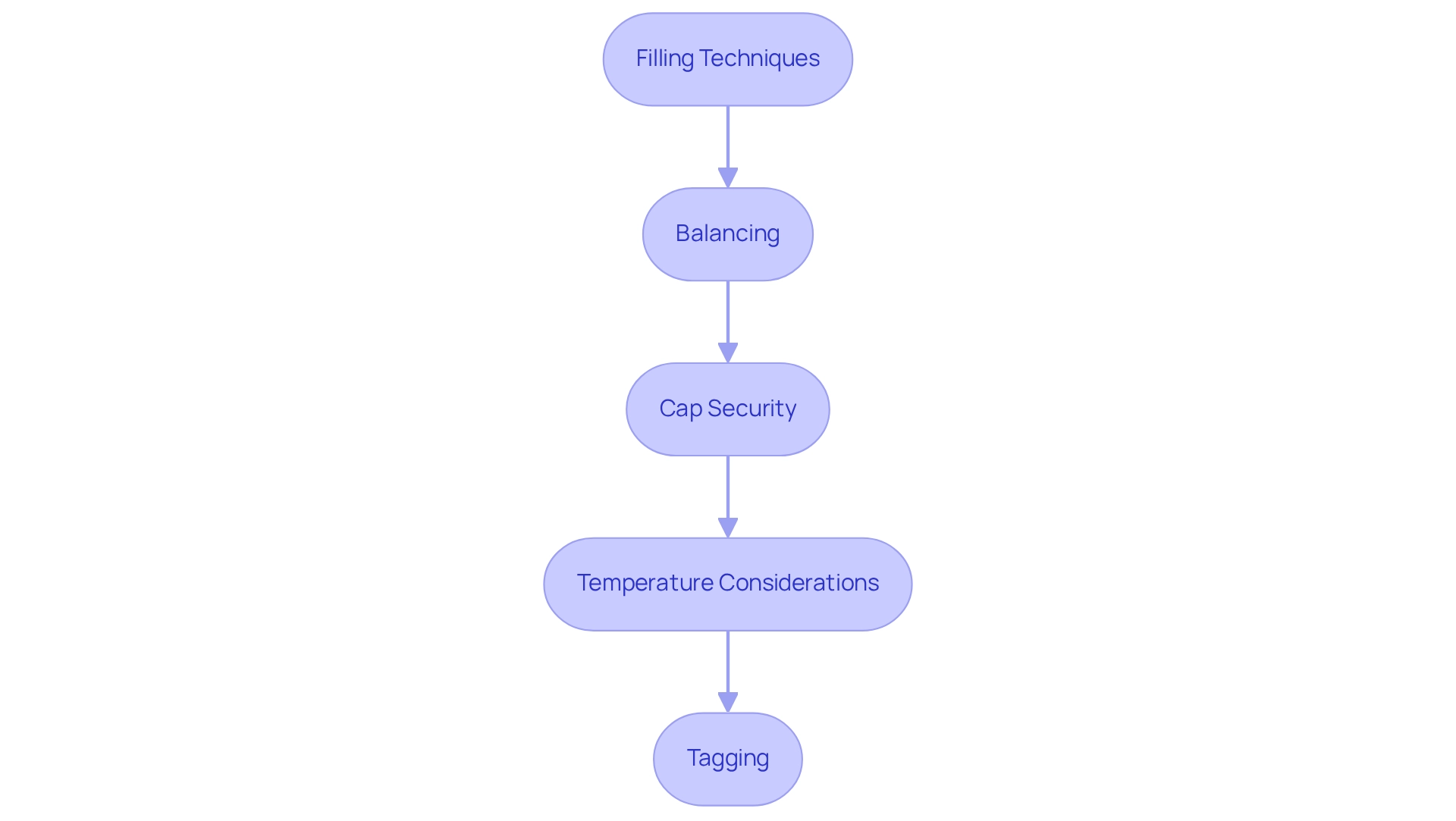

Best Practices for Using 15 mL Centrifuge Tubes: Tips and Techniques

To maximize the effectiveness of , it is imperative to adhere to the following best practices:

- Filling Techniques: Aim to fill tubes to at least 75% capacity. This practice significantly reduces unnecessary stress on the containers during centrifugation, which can lead to breakage or sample contamination.

- Balancing: Properly stabilize the device by placing containers of equal weight directly opposite one another. This is essential for preserving the integrity of the device and ensuring precise results. As noted by Anina Werner, Content Manager, "Balancing your device and using the correct tubes are the most crucial aspects of centrifugation safety (besides regular maintenance)."

- Cap Security: Always ensure that caps are tightly secured before starting the centrifuge. Loose caps can lead to leaks, compromising sample integrity and creating potential hazards in the laboratory.

- Temperature Considerations: Be mindful of the temperature limits specified for the containers. Surpassing these limits can jeopardize the structural integrity of the containers and influence the outcomes of your experiments.

- Tagging: Clearly mark each container with pertinent information about the specimen. Correct labeling is crucial to prevent mix-ups, which can result in significant mistakes in the management and analysis of specimens.

Centrifuge 15 mL tubes are essential in scientific investigation and experimental work, influencing specimen preparation, DNA extraction, and protein purification. Applying these best practices not only improves the reliability of your experimental findings but also enhances overall efficiency in the workspace. For instance, facilities that prioritize proper filling and balancing techniques have reported improved outcomes in sample preparation and analysis, underscoring the critical nature of these practices in scientific research.

Moreover, JM Science's commitment to consistently refreshing its product range and sustaining robust connections with leading manufacturers ensures that facilities have access to high-quality test vessels, which is crucial for attaining precise and dependable outcomes. Prompt access to testing supplies, such as those provided by Lab Pro Inc. with next-day service in California, further supports the need for efficient operations.

Troubleshooting Common Issues with 15 mL Centrifuge Tubes

Common problems faced with centrifuge 15 ml tubes can significantly affect laboratory results and efficiency. The primary concerns include leaking, breakage, sample contamination, and inconsistent results, each with effective solutions that are crucial for laboratory integrity.

- Leaking is a notable issue, occurring in 0.3–2% of cases with 50 mL tubes. This highlights the necessity of ensuring that caps are securely fastened and that the tubes are free from cracks before use. To mitigate risks, employing absorbent materials for storage and using parafilm around the cylinder's exterior can prevent contamination and leaks, safeguarding sample integrity.

- Breakage often arises from overfilling or using containers that do not align with the centrifuge's speed settings. It is essential to confirm that the centrifuge 15 ml tubes are rated for the relative centrifugal force (RCF) being utilized and to adhere to the recommended fill volume to avoid this issue.

- Sample contamination can compromise results, making it vital to use sterile containers for biological specimens and to avoid touching the inside of the caps. This practice is essential for maintaining the integrity of sensitive samples, ensuring reliable outcomes.

- Inconsistent results may stem from improper balancing and filling techniques. Ensuring that containers are filled uniformly and balanced properly in the rotor is crucial for achieving consistent centrifugation results.

Troubleshooting Tips: If leaks are detected, inspect both the integrity of the tube and the cap to identify any potential issues. For breakage, confirm that the container is suitable for the RCF being applied.

Real-world examples illustrate the importance of these practices. A study titled "" emphasizes the need for careful handling during filling and uncapping to reduce leak risks. Laurel Macmillan, an advisor on statistical methods, noted, "The authors thank Laurel Macmillan for advising on the statistical methods and supplement," underscoring the importance of rigorous methodology in addressing these issues.

By implementing these recommendations, facilities can enhance their operational efficiency and ensure reliable results. As the diagnostics sector continues to expand, propelled by the increasing need for early detection and testing, tackling these frequent problems with collection vessels becomes progressively vital for managers of testing facilities. Moreover, upcoming research is suggested to investigate the dangers linked to activities such as centrifugation and vortexing, which may result in leaks from conical containers.

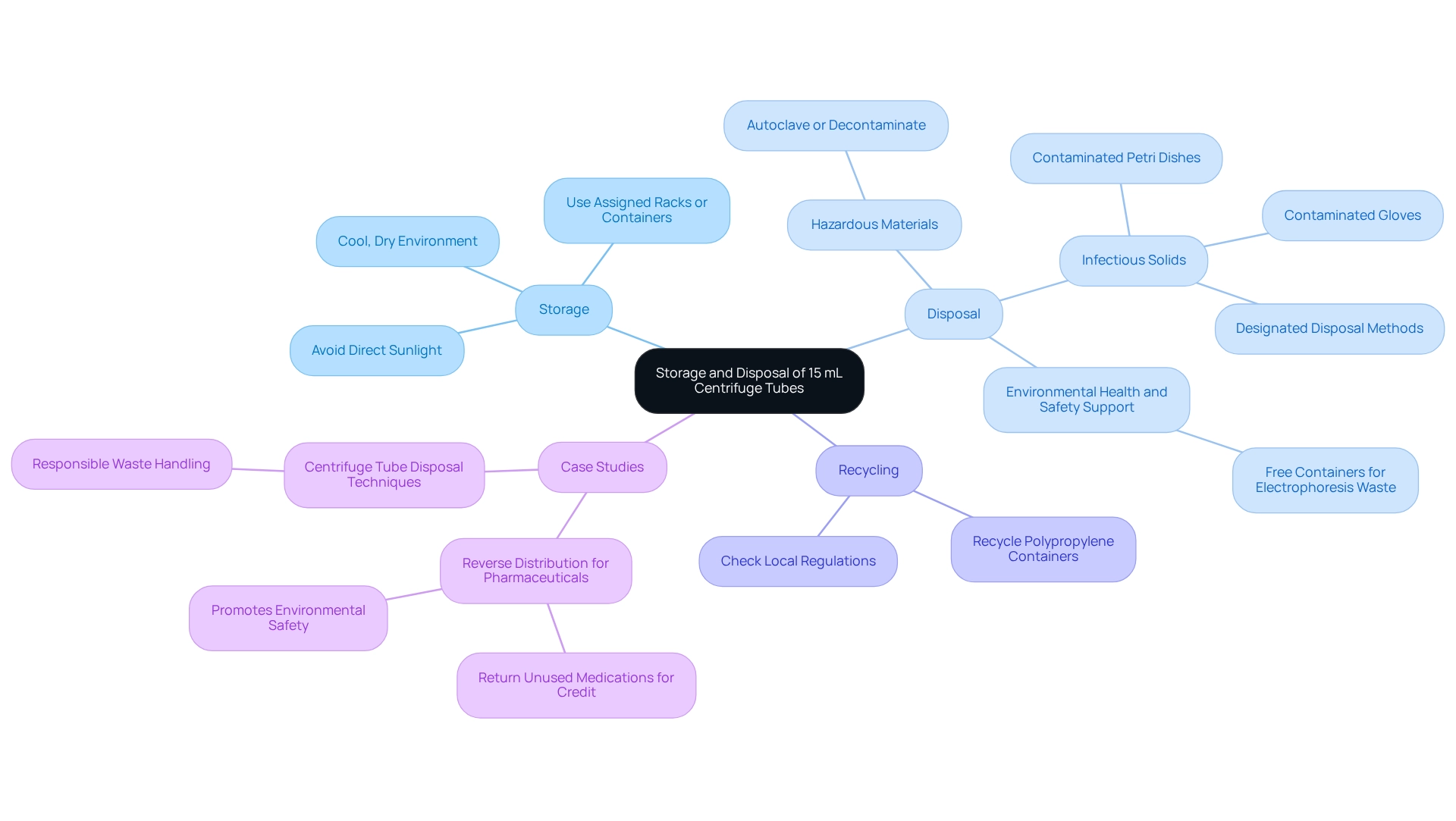

Storage and Disposal of 15 mL Centrifuge Tubes: Safety and Environmental Considerations

To ensure safety and compliance with the 2025 regulations concerning waste disposal, it is essential to adhere to the following guidelines for the storage and disposal of spinning containers:

Storage: Spinning containers must be kept in a cool, dry environment, away from direct sunlight to prevent material degradation. Utilizing assigned racks or containers is critical for maintaining organization and reducing the risk of harm or contamination.

Disposal: It is imperative to follow your facility's specific waste disposal guidelines for used test containers. Tubes that have come into contact with hazardous materials must be autoclaved or decontaminated prior to disposal to ensure safety and compliance with environmental regulations. For example, infectious solids, such as contaminated Petri dishes and gloves, have designated disposal methods that should be strictly adhered to. Furthermore, the Environmental Health and Safety’s Hazardous Waste Management offers containers for electrophoresis waste collection at no cost to UF labs, presenting a valuable asset for laboratories.

Recycling: Whenever feasible, recycle polypropylene containers to minimize environmental impact. Checking local regulations regarding recycling options is crucial to ensure compliance with waste management practices.

Case Studies: A notable example of effective waste management is the reverse distribution process for unused pharmaceuticals, which streamlines the disposal of excess materials while promoting environmental safety and regulatory compliance. This process involves sending back unused medications for credit via , emphasizing the significance of appropriate disposal techniques in clinical environments. Similar procedures can be utilized for the disposal of centrifuge 15 ml tubes, ensuring that all waste is handled responsibly. By adopting these guidelines, facilities can enhance their waste management practices, ensuring both safety and adherence to evolving regulations. Moreover, utilizing reliable products from JM Science, which continually updates its offerings and maintains strong relationships with top manufacturers, can further support compliance and safety in laboratory environments.

Conclusion

The exploration of 15 mL centrifuge tubes reveals their critical role in laboratory settings, underscoring their versatility, reliability, and essential features. These tubes, constructed from durable polypropylene, ensure sample integrity and come in various designs tailored to specific laboratory needs, making them indispensable tools for researchers. By understanding the types available—polypropylene, polycarbonate, and glass—laboratory professionals can make informed choices that align with their specific applications.

Selecting the right centrifuge tube necessitates careful consideration of several criteria, including:

- compatibility with centrifuge models

- chemical resistance

- sterility requirements

Adhering to best practices, such as proper filling techniques and balancing, enhances the reliability of experimental outcomes while minimizing common issues like leaks and breakage. Furthermore, effective storage and disposal practices ensure compliance with safety regulations and promote environmental sustainability.

In conclusion, mastering the use of 15 mL centrifuge tubes is paramount for achieving accurate and reliable results in laboratory research. By prioritizing quality materials, adhering to best practices, and understanding the nuances of these essential instruments, laboratory professionals can significantly enhance their experimental outcomes. As advancements in design and materials continue to shape the future of laboratory research, staying informed about these developments will empower researchers to navigate the complexities of their work with confidence and precision.