Overview

The article defines process analyzers as essential tools for real-time measurement and analysis in industrial operations, particularly within the pharmaceuticals and petrochemicals sectors. Their importance cannot be overstated, as they play a crucial role in enhancing production efficiency, ensuring product quality, and complying with safety standards. Supported by the growing market demand and technological advancements, these instruments enable precise data collection and automated processes. As industries continue to evolve, the adoption of high-quality scientific instruments like process analyzers becomes increasingly vital for maintaining competitive advantage.

Introduction

The intricate world of industrial operations increasingly relies on sophisticated tools that ensure efficiency, quality, and safety. Among these, process analyzers emerge as essential instruments, delivering real-time insights into the physical and chemical properties of materials across various sectors, including pharmaceuticals and petrochemicals.

As industries strive to enhance productivity and meet stringent regulatory standards, a critical question arises: how do these advanced devices not only streamline operations but also tackle the challenges of compliance and quality assurance?

By exploring the definition, importance, and key features of process analyzers, we can uncover their pivotal role in shaping modern manufacturing and quality control processes.

Define Process Analyzer: Function and Purpose

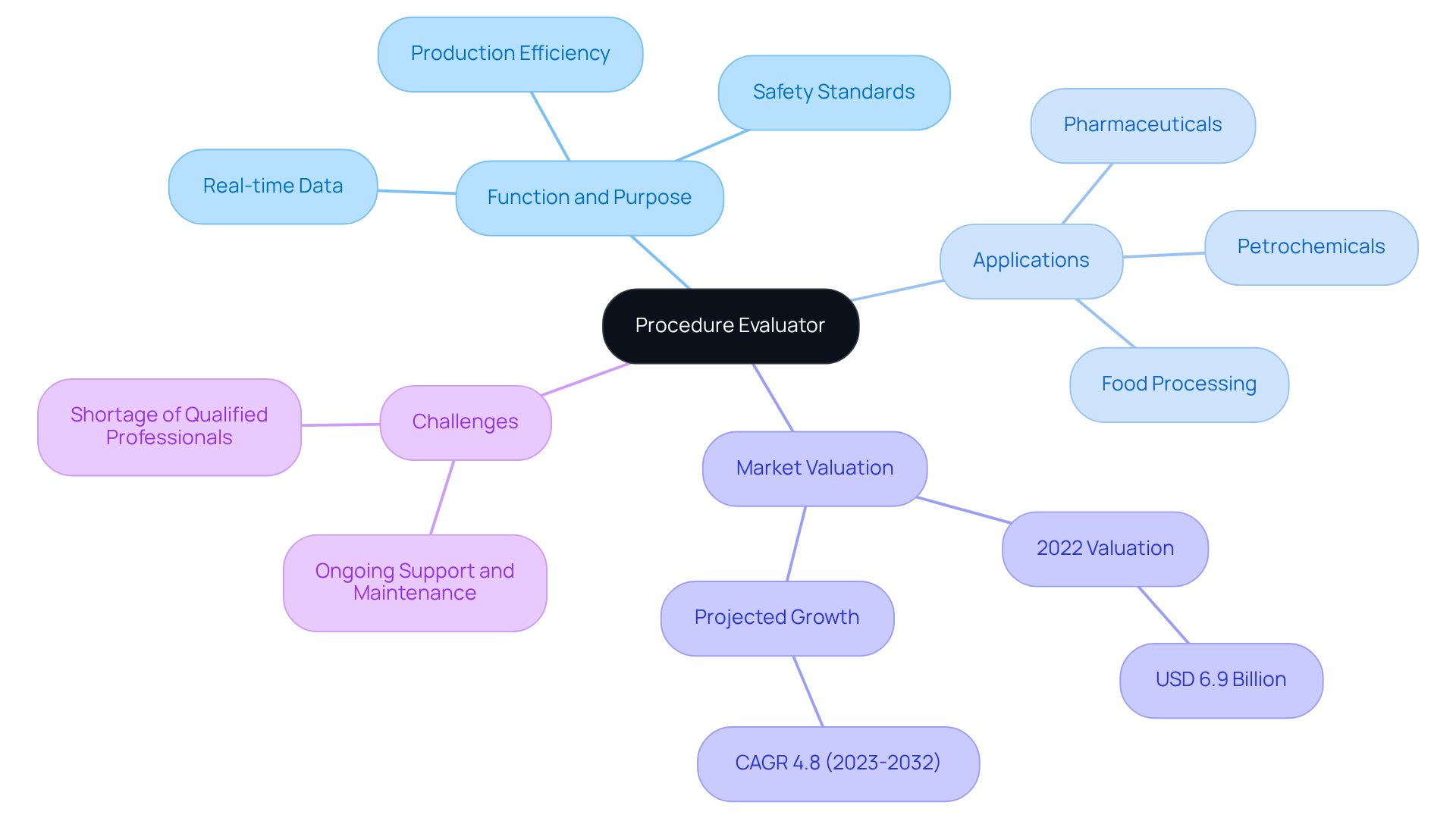

A procedure evaluator serves as a sophisticated instrument designed for the continuous measurement and analysis of the physical and chemical properties of materials in industrial operations. These devices operate in real-time, delivering critical information that , ensures product quality, and maintains safety standards. Their applications are widespread, encompassing sectors such as pharmaceuticals, petrochemicals, and food processing, where they monitor vital parameters like chemical composition, temperature, and pressure.

In the pharmaceutical industry, for instance, analytical tools are indispensable for maintaining stringent quality control, enabling manufacturers to meet regulatory standards while optimizing operational performance. The integration of real-time data collection empowers operators to make swift, informed decisions, significantly boosting production efficiency. Industry leaders underscore that the capacity to receive immediate feedback is crucial for refining operations and ensuring compliance with safety regulations.

The global system evaluation market was valued at over USD 6.9 billion in 2022 and is projected to grow at a CAGR of 4.8% from 2023 to 2032, reflecting the increasing demand for these advanced tools. However, the market faces challenges such as the need for ongoing support and maintenance of installed devices, as well as a shortage of qualified professionals—critical considerations for stakeholders in the industry.

Importance of Process Analyzers in Pharmaceutical Laboratories

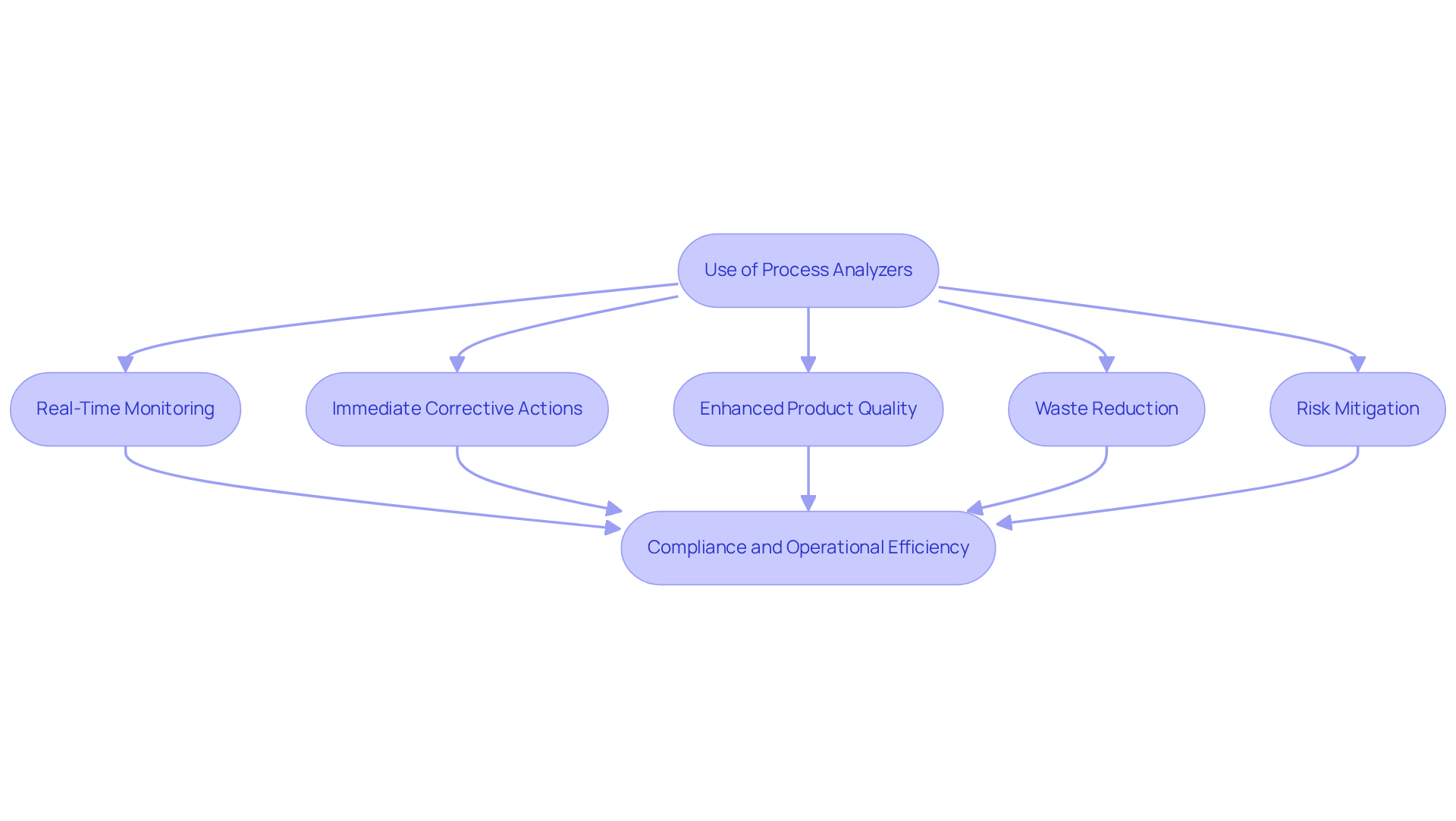

In pharmaceutical laboratories, measurement devices are indispensable for maintaining rigorous quality assurance and adhering to regulatory standards. They facilitate real-time monitoring of critical parameters, ensuring that products meet safety and efficacy benchmarks. As Suraj Gujar aptly states, "the measurement device is an automatic instrument which is utilized for the ongoing or regular evaluation of physical or chemical parameters in any industrial operation."

For instance, during drug production, these instruments can detect fluctuations in chemical composition or concentration, allowing for immediate corrective actions. This capability not only elevates product quality but also reduces waste and mitigates the risk of expensive recalls.

Furthermore, the integration of system evaluators into manufacturing processes supports the implementation of a process analyzer through Process Analytical Technology (PAT), which optimizes production and fosters innovation in drug development.

With the system evaluation sector valued at over USD 6.9 billion in 2022 and the pharmaceutical industry projected to grow at a CAGR of 5% through 2032, the adoption of is increasingly recognized as a strategic investment for ensuring compliance and enhancing operational efficiency.

Notably, the Asia Pacific region accounted for over 30% of the measurement technology market share in 2022, underscoring the global significance and acceptance of these advancements.

Evolution of Process Analyzers: Historical Context and Technological Advances

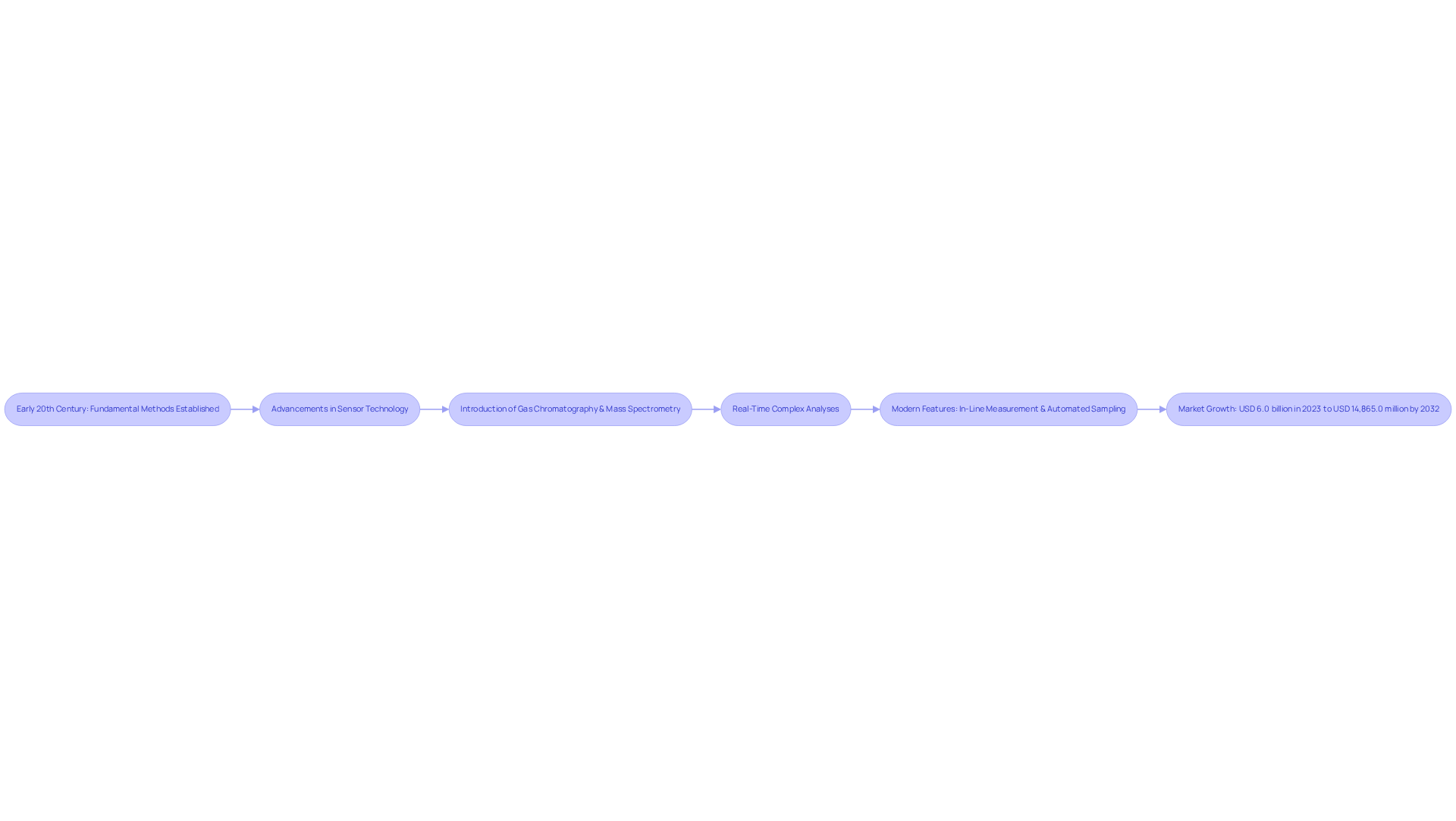

The evolution of measurement instruments can be traced back to the early 20th century, a period when fundamental analytical methods were first established. Over the decades, advancements in sensor technology, computing power, and analytics have transformed these instruments into sophisticated process analyzers capable of conducting complex analyses in real-time. Notably, the advent of gas chromatography and mass spectrometry has revolutionized the capacity to analyze chemical compounds with remarkable precision. Today, a process analyzer along with modern measurement instruments boasts features such as in-line measurement, automated sampling, and , enabling industries to achieve unparalleled levels of precision and productivity in their operations.

The global system evaluation industry, valued at USD 6.0 billion in 2023, is projected to reach USD 14,865.0 million by 2032, reflecting the growing demand for these technologies across various sectors. Key industries employing analytical tools, including pharmaceuticals, oil and gas, and water and wastewater, utilize a process analyzer to ensure compliance with stringent regulations, which is paramount. Innovations from leading companies like Siemens and ABB have significantly enhanced measurement accuracy and operational efficiency, illustrating the profound impact of technological advancements.

Moreover, case studies highlight the dominance of dissolved oxygen measurement devices in the market, underscoring their vital role in ensuring quality and safety. These developments not only showcase the capabilities of contemporary measurement instruments but also affirm their essential position in maintaining industry standards.

Key Features and Components of Process Analyzers

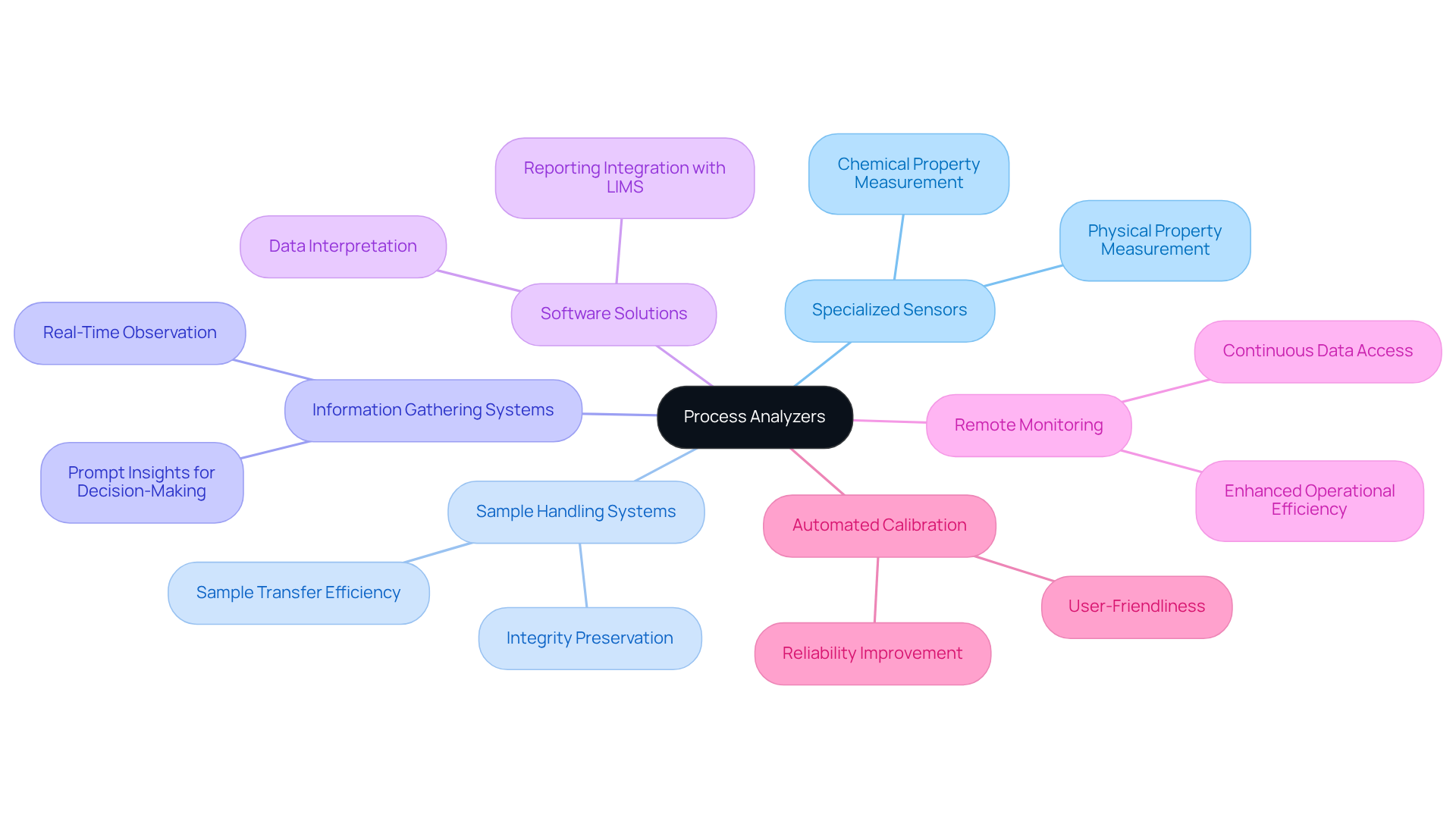

Process analyzers are equipped with essential components that greatly improve their functionality. Key features include specialized sensors designed to measure specific physical and chemical properties, which are crucial for accurate analysis across various industries, including pharmaceuticals, oil & gas, food & beverage, and water & wastewater. Effective sample handling systems enable smooth sample transfer, ensuring that the integrity of samples is preserved throughout the testing procedure. Moreover, information gathering systems allow real-time observation and evaluation, offering prompt insights that are crucial for decision-making.

Contemporary analysis tools frequently include sophisticated software solutions that simplify interpretation and reporting, enabling seamless integration with current laboratory information management systems (LIMS). This integration is crucial for preserving and information accuracy. Furthermore, features like remote monitoring abilities and automated calibration methods improve the reliability and user-friendliness of these instruments, rendering them essential tools in modern laboratory settings.

Real-world applications of these components can be seen in industries such as pharmaceuticals, where precise monitoring of chemical properties is critical for compliance with stringent regulations. For instance, the incorporation of advanced sensors and information acquisition systems in pharmaceutical manufacturing guarantees that product quality is consistently upheld, thus reinforcing the industry's dedication to safety and efficacy. As the demand for process analyzers continues to evolve, trends indicate a growing emphasis on automation and real-time data analytics, further solidifying the role of process analyzers in enhancing operational efficiency and regulatory compliance. According to recent market insights, the global process analyzer market is projected to grow from USD 7.8 billion in 2023 to USD 9.3 billion by 2028, highlighting the increasing demand for these process analyzer technologies.

Conclusion

Process analyzers are integral to modern industrial operations, functioning as vital instruments for the real-time measurement and analysis of the physical and chemical properties of materials. Their capacity to boost production efficiency, guarantee product quality, and uphold safety standards renders them essential across diverse sectors, particularly in pharmaceuticals, petrochemicals, and food processing.

The article has underscored the critical role of process analyzers in maintaining rigorous quality control and ensuring regulatory compliance, especially within pharmaceutical laboratories. The evolution of these instruments, propelled by technological advancements such as gas chromatography and mass spectrometry, has empowered industries to attain unprecedented levels of precision and productivity. Furthermore, the discussion highlighted the expanding market for process analyzers, which is projected to grow significantly in the coming years, reflecting their increasing adoption and vital importance across various sectors.

In conclusion, the insights presented assert that investing in process analyzers is not merely an option but a strategic necessity for industries striving to optimize their operations and adhere to stringent standards. As technology continues to evolve, the integration of process analyzers will be essential for fostering innovation and maintaining a competitive edge in a rapidly changing marketplace. Embracing these advancements can lead to enhanced efficiency, reduced waste, and improved product quality, ultimately benefiting both manufacturers and consumers alike.