Overview

This article delves into the essential applications of T-flasks within pharmaceutical laboratories, emphasizing their pivotal role in cell culture for a variety of biological research. T-flasks are indispensable for maintaining sterility, optimizing cell growth, and enhancing the efficiency of drug development processes.

Recent advancements in technology and materials have significantly improved their reliability and performance in laboratory settings. Understanding these applications is crucial for any professional aiming to leverage high-quality scientific instruments effectively.

Introduction

In the realm of pharmaceutical research, the significance of T-flasks is paramount. These versatile vessels are engineered to create optimal conditions for cell growth, playing a crucial role in various laboratory applications, from drug development to metabolic assessments. As the demand for reliable cell culture solutions escalates, advancements in T-flask technology are paving the way for enhanced performance and efficiency.

With a focus on sterility, cost-effectiveness, and innovative designs, T-flasks are integral to current research practices and are shaping the future of cell culture methodologies. This article explores the multifaceted benefits of T-flasks, highlighting their essential role in advancing scientific discovery and ensuring the integrity of experimental outcomes.

JM Science T-Flasks: Reliable Solutions for Cell Culture

JM Science t-flasks are meticulously engineered to establish optimal conditions for cellular growth, ensuring consistent and reliable results across diverse laboratory environments. Constructed from premium materials, these flasks facilitate effective attachment and proliferation, making them suitable for both academic research and industrial applications. Their innovative design not only promotes easy handling but also significantly reduces contamination risks, which is vital for preserving the integrity of biological samples in pharmaceutical laboratories.

The significance of high-quality materials in the production of t-flasks is paramount. These materials directly influence cellular growth outcomes by providing a stable environment that supports cellular activities. Recent advancements in t-flask technology have resulted in the creation of single-use containers, which dominate the vessel market by reducing contamination risks and streamlining manufacturing processes. This trend is poised to continue, with single-use technology maintaining its market leadership while reusable containers experience moderate growth.

Key players in the vessel market for biological materials, such as Thermo Fisher Scientific, Merck KGaA, and Corning Incorporated, underscore the competitive landscape in which JM Science operates. Laboratory supervisors have expressed confidence in the reliability of JM Science vessels for pharmaceutical applications, with one supervisor stating, "The steady performance of JM Science containers has made them a crucial component of our biological processes." As the laboratory equipment market continues to expand, particularly in Europe—the fastest-growing market—the demand for high-quality flasks is on the rise. This growth is bolstered by strategic partnerships within the industry, exemplified by between Sartorius and BICO, aimed at enhancing product offerings and innovation, ultimately benefiting companies like JM Science.

In summary, JM Science vessels stand out for their exceptional characteristics and advantages, positioning them as a preferred choice for cellular studies in pharmaceutical laboratories. Their unwavering commitment to quality and innovation establishes JM Science as a leader in the field, ensuring that researchers have access to dependable tools that meet the evolving demands of the scientific community. Pharmaceutical laboratory supervisors are encouraged to consider JM Science vessels to enhance their cellular growth outcomes.

Suspension Cultures: Utilizing T-Flasks for Enhanced Cell Growth

These containers demonstrate exceptional efficiency for suspension systems, enabling organisms to thrive in a liquid environment without the need for adhering to the vessel's surface. This methodology is vital for producing substantial quantities of biological units, which is essential for applications such as vaccine development and biopharmaceutical production. The use of T-bottles empowers scientists to maintain optimal growth conditions, resulting in increased cellular densities and enhanced outputs.

Recent research indicates that transitioning to suspension systems can significantly boost growth rates. For instance, the overall cost to produce 100 × 10 iPSCs under 3D suspension conditions is merely 46.9% of what is required for 2D planar scenarios, underscoring the financial benefits of this approach. In the context of vaccine development, transitioning HEK293 organisms from adherent to suspension environments has been effectively achieved using t-flasks. Case studies reveal that, after adapting to serum-free conditions, these structures were cultured in non-treated flasks augmented with anti-clumping solutions, yielding primarily single entities without aggregation. This successful transition not only confirms the viability of but also enhances the applicability of biological stocks for future experiments. Importantly, the metabolic characteristics of HEK293 lines are closely regulated by external nutrients, emphasizing the critical role of nutrient control in suspension cultures.

The advantages of utilizing these containers extend beyond mere cost-effectiveness; they also facilitate the maintenance of ideal growth conditions, which is crucial for biopharmaceutical production. Expert perspectives highlight that optimizing growth in liquid environments can lead to significant improvements in yield and quality, further reinforcing the importance of culture vessels in modern laboratory techniques. As trends in vaccine development continue to evolve, the role of specific containers in supporting efficient and scalable cellular processes remains indispensable. The authors declare no conflict of interest.

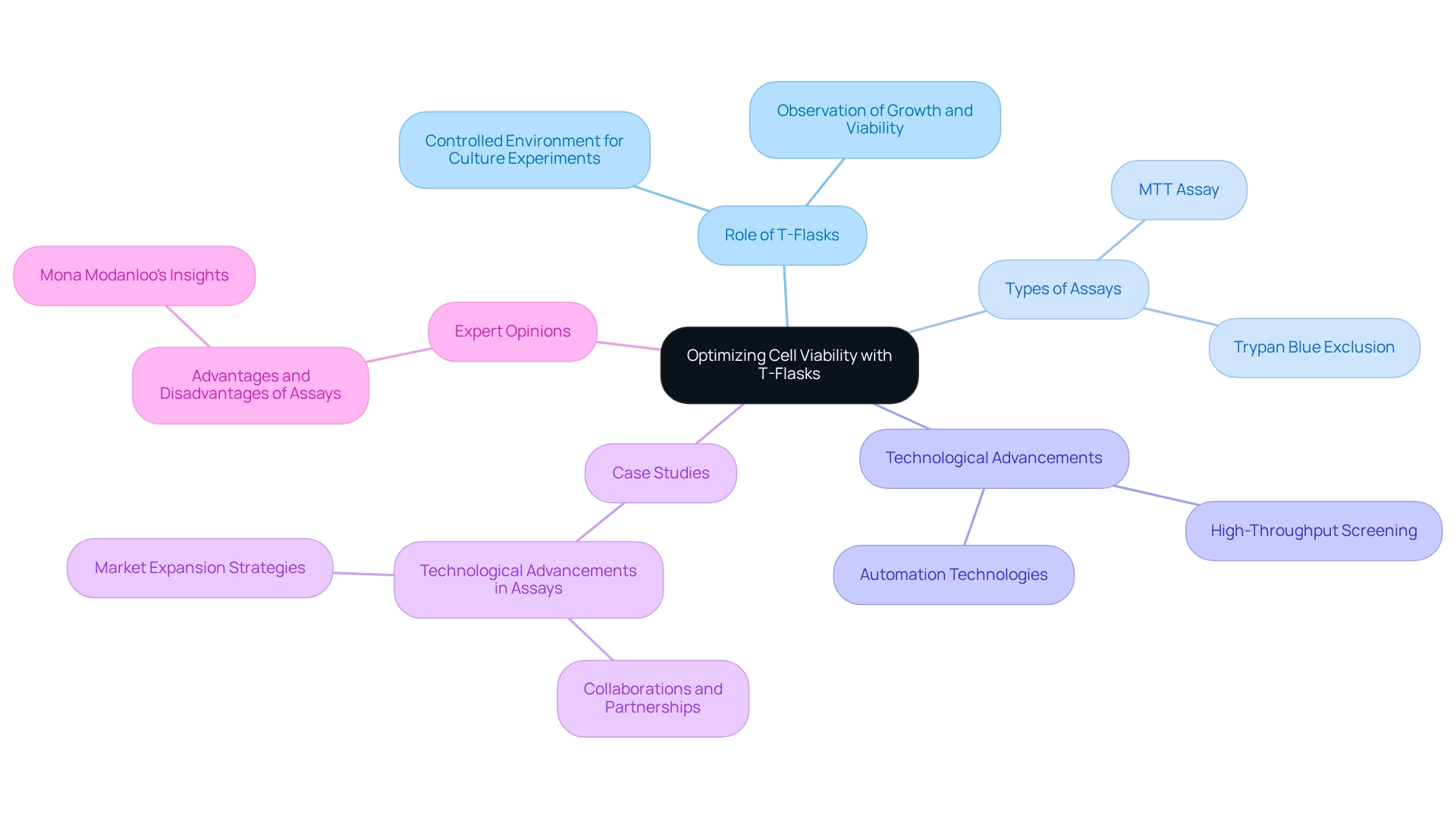

Optimizing Cell Viability: The Role of T-Flasks in Metabolic Assessments

T-flasks serve as essential instruments in metabolic evaluations, as they provide a controlled environment that is critical for culture experiments. Their design allows for straightforward observation of growth and viability through assays such as MTT and Trypan Blue exclusion, which are standard practices in pharmaceutical laboratories. These assays deliver reliable metrics for assessing cellular health, empowering researchers to make informed decisions crucial for effective drug development.

Recent advancements in the field underscore the importance of optimizing viability assays during preclinical drug discovery, as highlighted in a May 2023 study. This focus on assay accuracy is further supported by the competitive landscape of , where companies are integrating high-throughput screening and automation technologies to enhance efficiency and precision. Notably, the stem cell study segment was valued at USD 713.3 million in 2023, emphasizing the financial significance of effective cell viability assays within the broader investigative landscape.

A notable case study on technological advancements in assays illustrates how collaborations and partnerships are driving innovation in metabolic evaluations through specialized containers. These innovations not only enhance assay accuracy but also streamline the overall research process, yielding tangible outcomes that improve laboratory efficiency.

Expert opinions affirm the efficacy of MTT and Trypan Blue assays in culture vessels, with researchers acknowledging that each method presents unique advantages and disadvantages. As Mona Modanloo articulated, "Each of the aforementioned methods has its own advantages and disadvantages," underscoring the necessity of selecting the appropriate assay for specific experimental conditions.

In conclusion, t-flask containers play a pivotal role in metabolic assessments, equipping researchers with the essential tools to monitor cell viability effectively. By adhering to contemporary best practices and leveraging advanced technologies, pharmaceutical labs can enhance their research outcomes and contribute to the ongoing advancements in drug development.

High-Throughput Screening: Leveraging T-Flasks for Efficient Drug Development

Cell culture flasks are integral to high-throughput screening (HTS) processes, allowing researchers to evaluate multiple compounds simultaneously under controlled conditions. Their design fosters uniform cell growth, which is crucial for reliable screening assays. By employing specialized containers, pharmaceutical laboratories can significantly enhance their drug discovery processes, effectively reducing the time and resources needed to identify promising candidates.

As we look towards 2025, the necessity for specific containers in HTS has become increasingly pronounced. Nearly half of the 1,000 most active compounds evaluated in the 872 HTS studies were identified as suspect PAINS, underscoring the urgent need for . The strategic use of specialized containers facilitates a more comprehensive evaluation of chemical behavior, transitioning from basic single-screen tests to a more intricate understanding of compound interactions.

Expert insights reinforce the efficacy of these containers in screening assays, with pharmaceutical scientists noting their ability to enhance result consistency. Andrew L. Hopkins asserts that "it is prudent for a research organization to reduce risk by adopting a range of discovery strategies instead of relying on just one or two." This perspective aligns seamlessly with the strategic deployment of specialized containers in drug discovery processes, a factor that is particularly vital given the significant impact initial screening phases have on the timeline for bringing a drug to market.

Recent case studies, exemplified by the title "Future Directions for HTS," suggest that forthcoming HTS studies should focus on challenging compounds and employ multiple assays to better characterize their chemical behavior. This strategy not only amplifies the effectiveness of drug discovery initiatives but also resonates with contemporary trends aimed at shortening drug development timelines. By leveraging specialized containers, researchers can embrace a more strategic portfolio of discovery strategies, ultimately leading to more successful outcomes in pharmaceutical development.

Maintaining Sterility: T-Flasks as a Barrier Against Contamination

These vessels are meticulously designed with specific features that promote sterility, including secure caps and sterile surfaces, essential for preventing contamination from airborne particles and microorganisms. Such design elements are crucial in pharmaceutical studies, where the integrity of cell systems directly impacts the reliability and reproducibility of outcomes. By utilizing specialized containers, researchers can effectively safeguard their cultures against contamination, thereby enhancing the accuracy of their findings.

The importance of preserving sterility cannot be overstated; contamination can lead to inaccurate data and compromised findings. In laboratory settings, the risk of contamination is a serious concern, particularly given the potential for vectorborne transmission of infectious agents in healthcare environments. T-flasks serve as a critical barrier, allowing researchers to concentrate on their experiments without the incessant worry of microbial interference, which laboratory experts emphasize as significant, asserting that 'the integrity of our work depends on our ability to prevent contamination at every stage of the process.' This sentiment is echoed in case studies highlighting in t-flask cultures, demonstrating how the proper use of t-flasks can drive significant advancements in pharmaceutical development. Furthermore, the complexities associated with developing monoclonal antibodies in the biologics market underscore the high stakes involved in contamination prevention. By prioritizing cleanliness through the use of specialized containers and adhering to Standard Precautions and Transmission-based Precautions, laboratories can navigate the complexities of contemporary studies with confidence.

Versatile Applications: T-Flasks for Diverse Cell Types in Research

These containers serve as essential instruments in pharmaceutical research, adept at fostering the growth of diverse biological cultures, including both adherent and suspension types. Their innovative design allows for easy adjustments to various environmental conditions, making them ideal for a multitude of applications. Whether cultivating mammalian, insect, or stem cultures, these containers offer an optimal setting for growth and experimentation.

Recent studies underscore the critical role of culture banks in advancing therapeutic innovations, with one study receiving approval from the Boston University IRB for research involving human participants. This highlights the containers' significance in facilitating future discoveries. For instance, personalized culture lines developed in specialized containers have proven instrumental in enhancing the relevance of scientific studies, allowing researchers to tailor conditions to specific experimental needs.

In practical applications, t-flasks exhibit remarkable versatility across various pharmaceutical research scenarios. They are integral to drug development processes, where government regulations significantly impact the availability of new medications, thus shaping market dynamics for vessel systems. As evidenced in a recent case study, regulatory challenges in drug development subsequently influence the market landscape for vessel systems. This adaptability is vital as researchers navigate the complexities of drug formulation and testing.

Furthermore, the integration of , particularly through the use of the AQ-300 and AQV-300 titrators, is crucial for ensuring the accuracy of moisture content in pharmaceutical products. This precision is essential for maintaining the quality and efficacy of drugs. Statistics reveal a growing trend in the adoption of various biological types within pharmaceutical laboratories, with culture vessels effectively accommodating these variations. Expert insights highlight the importance of modifying conditions in the t-flask to enhance growth across different cellular environments. Dr. Ralf Weiskirchen, a full professor at RWTH University Aachen, asserts, "The flexibility of these containers is crucial for researchers seeking to enhance their biological conditions, ultimately resulting in ." Overall, t-flasks support a wide array of biological types and enhance the efficiency and effectiveness of pharmaceutical research, particularly when paired with precise titration techniques.

Innovative Technologies: Enhancing T-Flask Performance with Acoustic Flow

Recent advancements in acoustic flow technology have revolutionized the designs of t-flasks, significantly enhancing cellular growth performance. This innovative strategy facilitates improved nutrient distribution and oxygenation, both of which are crucial for the optimal growth and viability of organisms.

By employing t-flasks integrated with acoustic flow, researchers can achieve more uniform cell populations, which improves experimental outcomes, particularly in high-density cultures. Research has shown that this technology enhances nutrient distribution efficiency, resulting in increased proliferation rates.

For instance, in wound-healing assays, 80,000 units were introduced into each chamber, illustrating the effectiveness of acoustic flow in promoting robust growth. Furthermore, a study titled 'Vibration Enhanced Cell Growth Induced by Surface Acoustic Waves' highlights how surface acoustic waves can stimulate the migration and growth of biological units, providing a promising in vitro model for wound healing applications.

The findings from this study indicate that acoustic flow technology not only optimizes nutrient distribution but also significantly boosts growth rates, underscoring its importance in cellular methodologies. Additionally, the versatility of acoustofluidics for separating micro/nanoparticles at cellular levels further emphasizes the potential applications of this technology in refining laboratory practices.

Future studies should focus on improving the accuracy and effectiveness of particle manipulation in microfluidic applications, which could lead to even greater advancements in cellular techniques. These developments showcase the transformative impact of acoustic flow technology on t-flask performance, establishing it as a critical factor for pharmaceutical labs aiming to enhance .

For related research, refer to PubMed ID: 33257581.

Cost-Effectiveness: Economic Advantages of Using T-Flasks in Laboratories

T-containers present a highly economical solution for cellular growth, delivering dependable functionality at a fraction of the cost associated with more complex systems. Their simple design reduces the necessity for extensive training and maintenance, establishing them as a cost-effective choice for laboratories. By integrating specialized flasks into their workflows, laboratories can significantly enhance their budgets while ensuring high-quality results in cell culture. This economic benefit is particularly pertinent in the competitive arena of laboratory operations, where budget limitations are a continual concern.

Notably, leading companies in the flask market, such as Corning, Thermo Fisher Scientific, and Greiner Bio-One, continue to innovate, enhancing the appeal of these containers through advancements in design and functionality. Furthermore, the ability to produce growth factors at lower costs and concentrations not only boosts the attractiveness of the containers but also enables laboratories to achieve their goals without compromising quality or efficiency. As articulated, 'Utilizing T-bottles has enabled us to optimize our procedures and greatly lower expenses, enhancing our studies' sustainability.

Educational Tools: T-Flasks in Training Future Scientists in Cell Culture

These containers are indispensable tools in educational environments for teaching cell culture techniques, featuring a user-friendly design that enhances students' understanding of cell growth and maintenance. Their versatility empowers educators to develop engaging laboratory courses that prioritize hands-on experience, which is crucial for fostering the skills essential for careers in scientific research and biotechnology.

Recent studies reveal that students experience high levels of enjoyment and engagement while working with experimental setups. One mentor noted, "The students were eager to participate in the program," underscoring the critical role of practical experience in their learning journey. This hands-on approach not only deepens comprehension but also equips students for real-world applications in the laboratory.

Specialist opinions underscore the effectiveness of these containers as teaching tools, as they provide a clear illustration of culture principles. Furthermore, statistics indicate that North America accounted for 39.48% of the overall market for laboratory equipment in 2022, reflecting the widespread use of specialized flasks in educational contexts and their vital role in preparing future scientists.

It is essential to consider practical factors such as media evaporation in containers, which can alter osmolality, nutrient concentration, and pH, thereby impacting growth and viability. Educators must prioritize proper sealing and monitoring to ensure optimal conditions for biological development.

By integrating specialized containers into biological training, educators can foster a deeper understanding of laboratory methods, preparing students for future challenges in the pharmaceutical and biotechnology sectors. The positive feedback from both students and educators reinforces the value of t-flasks as a cornerstone of effective laboratory education, supported by findings from that indicated students valued the hands-on nature of their lab experiences while also recognizing the importance of maintaining a clean workspace and adhering to safety protocols.

Future Trends: Innovations in T-Flask Technology for Cell Culture Advancements

The future of t-flask technology is poised for significant innovation, with a focus on enhancing usability, sterility, and overall performance. Emerging trends prominently feature the integration of smart technologies that facilitate real-time monitoring of biological samples, enabling precise control over growth conditions. Additionally, the advancement of multi-layered flasks is gaining traction, as these designs optimize surface area for growth, thereby enhancing yield and efficiency in biological practices.

The market is experiencing a notable shift towards T-flasks, which are single-use and constituted 71.08% of the market share in 2024. This shift is driven by the imperative for sterility and reduced contamination risks. Factors such as the rising prevalence of chronic diseases and increased R&D investments are propelling this trend, underscoring the relevance of t-flask innovations in addressing current healthcare challenges. Innovations like custom multilayer vessel flasks, featuring enhancements such as built-in filters and specialized coatings, are tailored to meet the diverse needs of researchers and manufacturers. These advancements not only support pharmaceutical research and development but also align with the growing demand for effective and reliable tissue growth solutions.

As Aditi Shivarkar notes, " dominated the market with a share as they are generally used to produce biological products such as enzymes, synthetic hormones, monoclonal antibodies, leukocytes, lymphokines, vaccine immunity, and vaccines." This statement underscores the critical role of t-flask in the production of essential biological products.

Moreover, robust relationships with leading manufacturers drive advancements in t-flask technology, ensuring that innovations align with laboratory needs. As industry leaders continue to explore these innovations, the focus remains on developing T-flasks that not only satisfy current laboratory demands but also anticipate future challenges in cell culture technology.

Conclusion

T-flasks are indispensable in pharmaceutical research, providing essential conditions for cell growth and ensuring reliable results across diverse applications. Their design promotes effective cell attachment and proliferation, which are critical for drug development, metabolic assessments, and high-throughput screening.

The advantages of T-flasks in suspension cultures significantly enhance cell densities and yields, vital for vaccine development and biopharmaceutical production. Recent advancements, such as acoustic flow technology, further optimize nutrient distribution and oxygenation, ultimately improving cell viability.

From an economic perspective, T-flasks present a cost-effective solution, enabling laboratories to achieve high-quality outcomes while adhering to budget constraints. Moreover, they function as valuable educational tools, offering hands-on experiences that prepare students for careers in scientific research and biotechnology.

Looking ahead, T-flask technology is set for continued innovation, particularly with the increasing focus on single-use designs and smart technologies that enhance usability and sterility. These advancements reflect the evolving demands of the scientific community, ensuring researchers are equipped with reliable instruments.

In summary, T-flasks play a crucial role in advancing pharmaceutical research and refining cell culture methodologies. Their ongoing relevance and innovation will undoubtedly support the integrity of experimental outcomes and propel scientific discovery.