Overview

Selecting the appropriate PTFE syringe filter for laboratory use necessitates a thorough evaluation of several critical factors:

- Pore size

- Filter size

- Chemical compatibility

- Sterility requirements

- Flow rate

Understanding these elements is crucial, as they directly influence filtration performance and reliability across various laboratory applications. This article presents a systematic approach to filter selection, highlighting that a meticulous assessment of these criteria is essential for achieving optimal results. By prioritizing these factors, laboratories can ensure they are equipped with high-quality instruments that meet their specific needs.

Introduction

In the realm of laboratory analysis, precision and reliability are paramount, particularly regarding sample preparation. PTFE syringe filters have emerged as indispensable tools, adept at removing particulates from a variety of liquid samples while showcasing remarkable chemical resistance. Their versatility extends across multiple applications, enhancing the accuracy of high-performance liquid chromatography and ensuring the integrity of biological samples and environmental testing.

As the demand for efficient and dependable filtration solutions grows, understanding the intricacies of selecting the right PTFE syringe filter becomes essential for laboratories aiming to uphold rigorous standards in their analytical processes.

This exploration delves into the key criteria for filter selection, practical steps for choosing the ideal filter, and troubleshooting common issues, equipping professionals with the knowledge needed to optimize their filtration workflows.

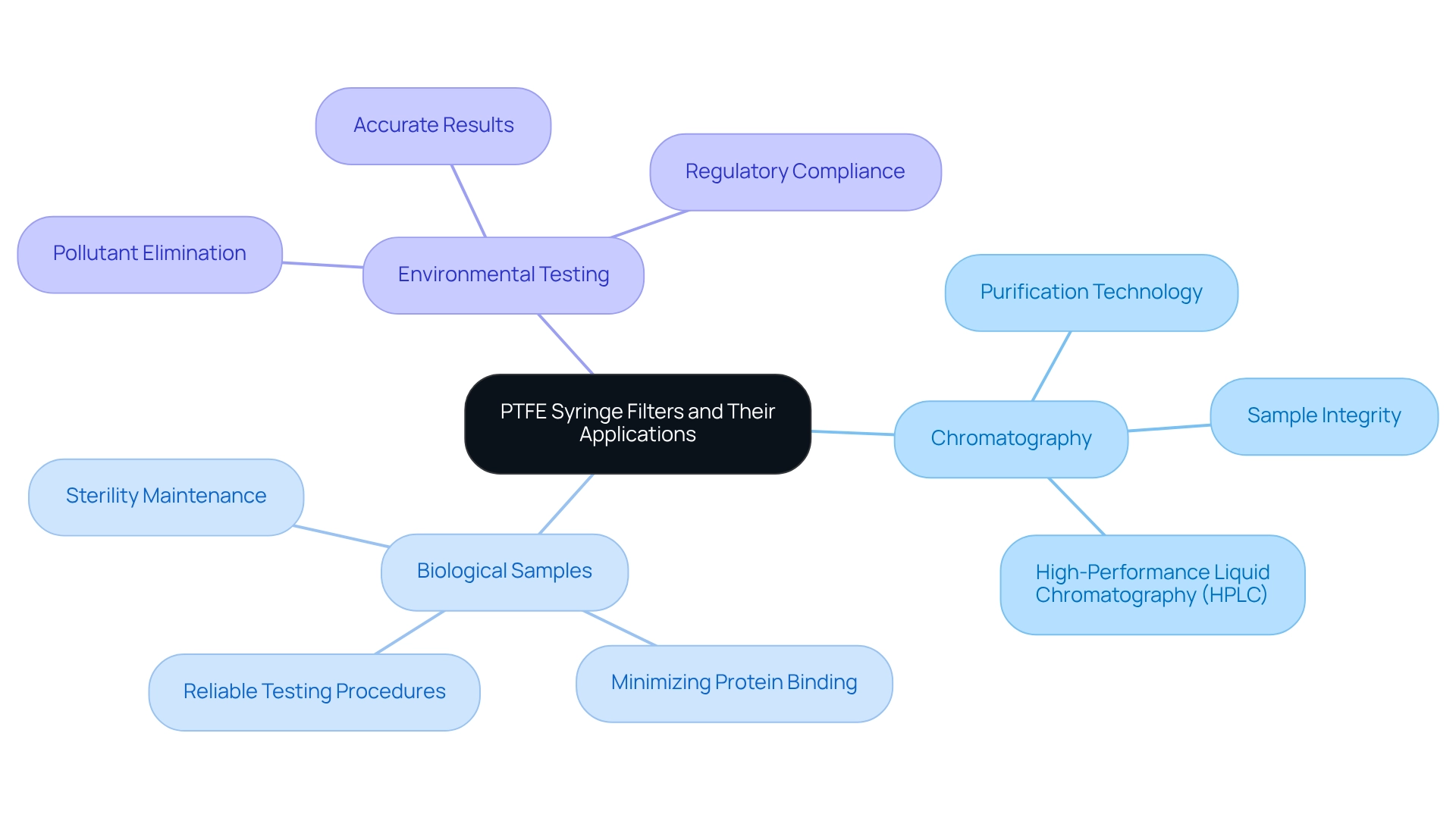

Understand PTFE Syringe Filters and Their Applications

PTFE (Polytetrafluoroethylene) filtration devices are essential tools engineered to eliminate particulates from liquid substances, particularly excelling in the processing of aggressive solvents, acids, and bases due to their exceptional chemical resistance. Their applications are critical across various domains:

- Chromatography: PTFE syringe filters are indispensable in preparing samples for (HPLC), effectively eradicating impurities that could jeopardize analytical outcomes. Recent advancements in purification technology have significantly enhanced their reliability, safeguarding sample integrity in high-throughput environments. Verified Market Reports highlights the increasing applications across diverse scientific fields, underscoring the vital role syringe devices play in ensuring precision and reliability in experimental protocols.

- Biological Samples: These devices are particularly adept at processing biological fluids, where maintaining sterility and minimizing protein binding is paramount. A growing body of evidence emphasizes their effectiveness in this area, demonstrating their crucial role in ensuring precise and reliable testing procedures.

- Environmental Testing: In environmental analysis, PTFE membrane devices are employed to assess water and soil samples, guaranteeing accurate results by eliminating pollutants. This application is increasingly vital as research facilities encounter intensified scrutiny concerning data accuracy and regulatory compliance.

The market for medical devices is currently experiencing rapid growth, driven by technological advancements and an expanding range of applications across various scientific disciplines. As facilities increasingly adopt automation trends, the demand for PTFE medical devices is expected to rise, signifying their essential role in enhancing efficiency, precision, and consistency within research environments. This trend is supported by case studies indicating that heightened automation correlates with greater adoption of filtration devices, particularly the PTFE syringe filter, in high-throughput applications, as highlighted in the case study titled 'Effects of Laboratory Automation Trends on PTFE Syringe Filter Adoption.'

Understanding these applications enables facilities to select the most suitable PTFE device for their specific needs, thereby ensuring optimal performance in their experiments. Additionally, the market dynamics are evolving due to a heightened focus on efficiency and health, which is influencing the accessibility of domestic versus international markets, shaped by regulatory frameworks tailored to regional requirements.

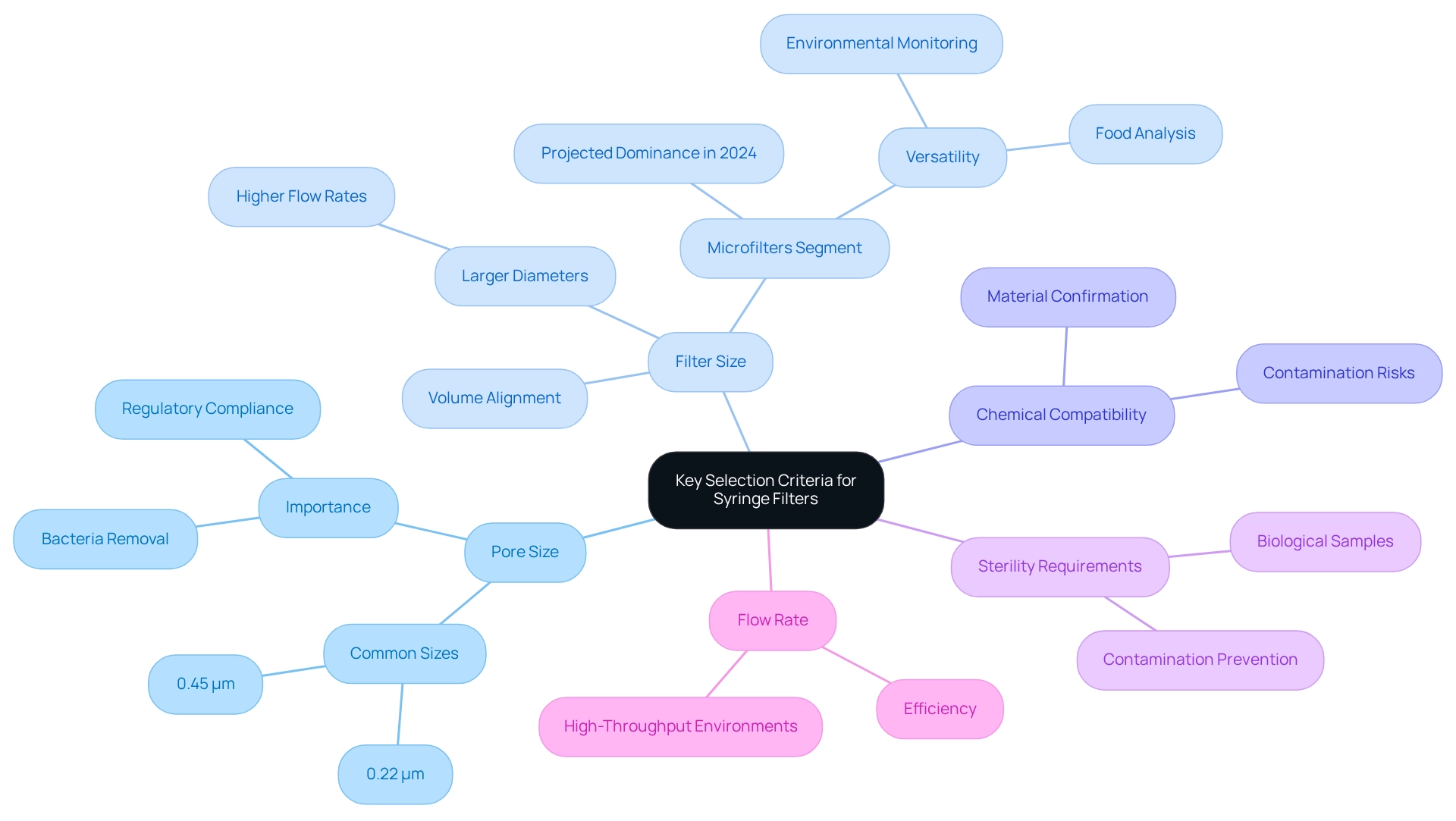

Identify Key Selection Criteria for Syringe Filters

When selecting a PTFE syringe filter, several critical criteria must be evaluated to ensure optimal performance and reliability in laboratory applications. First, consider Pore Size. This aspect is vital as it dictates the filtration capability. include 0.22 µm, effective for bacteria removal, and 0.45 µm, suitable for filtering larger particulates. Recent research highlights the importance of choosing the appropriate pore size to achieve reliable results and comply with regulatory standards in pharmaceuticals and environmental monitoring.

Next, examine the Filter Size. The size of the device should align with the volume of the specimen. Larger diameters facilitate higher flow rates, making them ideal for efficiently processing greater volumes. The microfilters segment is projected to dominate the syringe market in 2024, with sizes ranging from one to ten microns, showcasing their versatility across various applications, including environmental monitoring and food analysis.

Additionally, Chemical Compatibility is crucial. It is imperative to confirm that the strainer material is compatible with the solvents and substances in use. Incompatibility may lead to contamination or degradation of both the device and the specimen, ultimately compromising the integrity of analytical outcomes. Furthermore, Sterility Requirements must be addressed. For applications involving biological samples, selecting sterile membranes is essential to prevent contamination, thereby ensuring the accuracy of results and the safety of subsequent analyses.

Finally, the Flow Rate is another critical factor influencing the efficiency of the filtration process. A properly selected flow rate can enhance throughput and reduce processing time, which is vital in high-throughput laboratory environments. By meticulously evaluating these factors, laboratory supervisors can identify the most appropriate PTFE syringe filter devices, thereby optimizing their filtration methods and ensuring the reliability of their analytical outcomes.

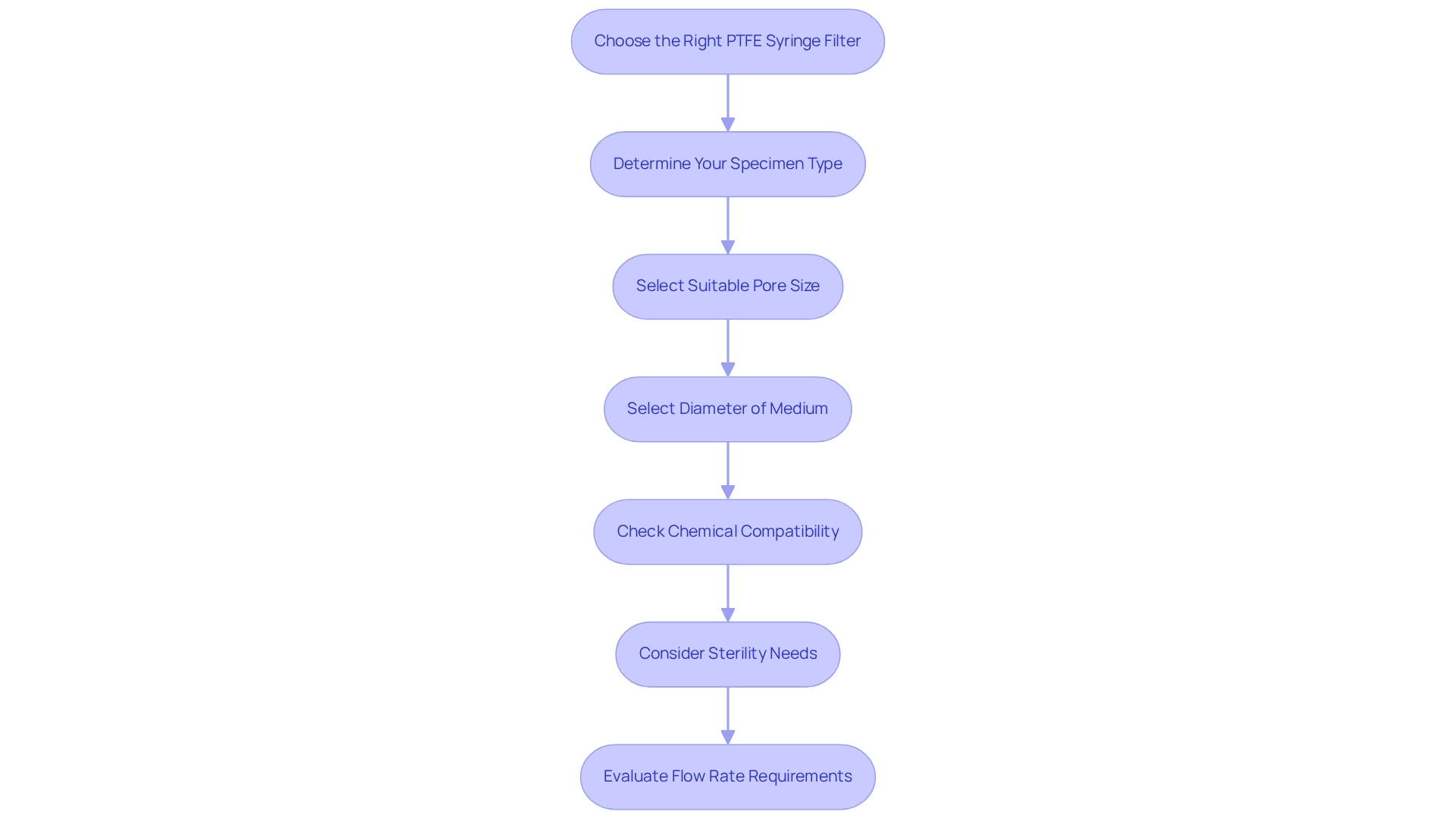

Follow Steps to Choose the Right PTFE Syringe Filter

To select the appropriate PTFE syringe filter, follow these steps:

- Determine Your Specimen Type: Identify the nature of the specimen you will be filtering, such as aqueous solutions, organic solvents, or biological fluids.

- Select the Suitable Pore Size: Choose a pore size that meets your requirements based on the particles you need to remove; for instance, a 0.22 µm pore size is ideal for bacteria filtration.

- Select the Diameter of the Medium: Ensure the diameter of the medium corresponds to your volume needs. For larger volumes, opt for a strainer with a larger diameter.

- Check Chemical Compatibility: Verify that the PTFE material is compatible with the solvents in use to avoid any adverse reactions.

- Consider Sterility Needs: When working with biological samples, select a sterile membrane to preserve sample integrity.

- Evaluate Flow Rate Requirements: Assess the necessary flow rate for your application and choose a device capable of accommodating it. It is important to note that the bubble point for hydrophobic 25 mm membrane devices typically ranges from 1 to 1.2 bar, which is crucial for understanding performance.

By adhering to these guidelines, research facilities can circumvent common selection errors that may compromise outcomes and extend downtime. For example, effectively utilizing filtration devices protects HPLC equipment from harmful particles, as highlighted in the case study 'Protecting HPLC Equipment with Filtration Devices.' This proactive strategy not only enhances the but also contributes to the overall efficiency of laboratory operations.

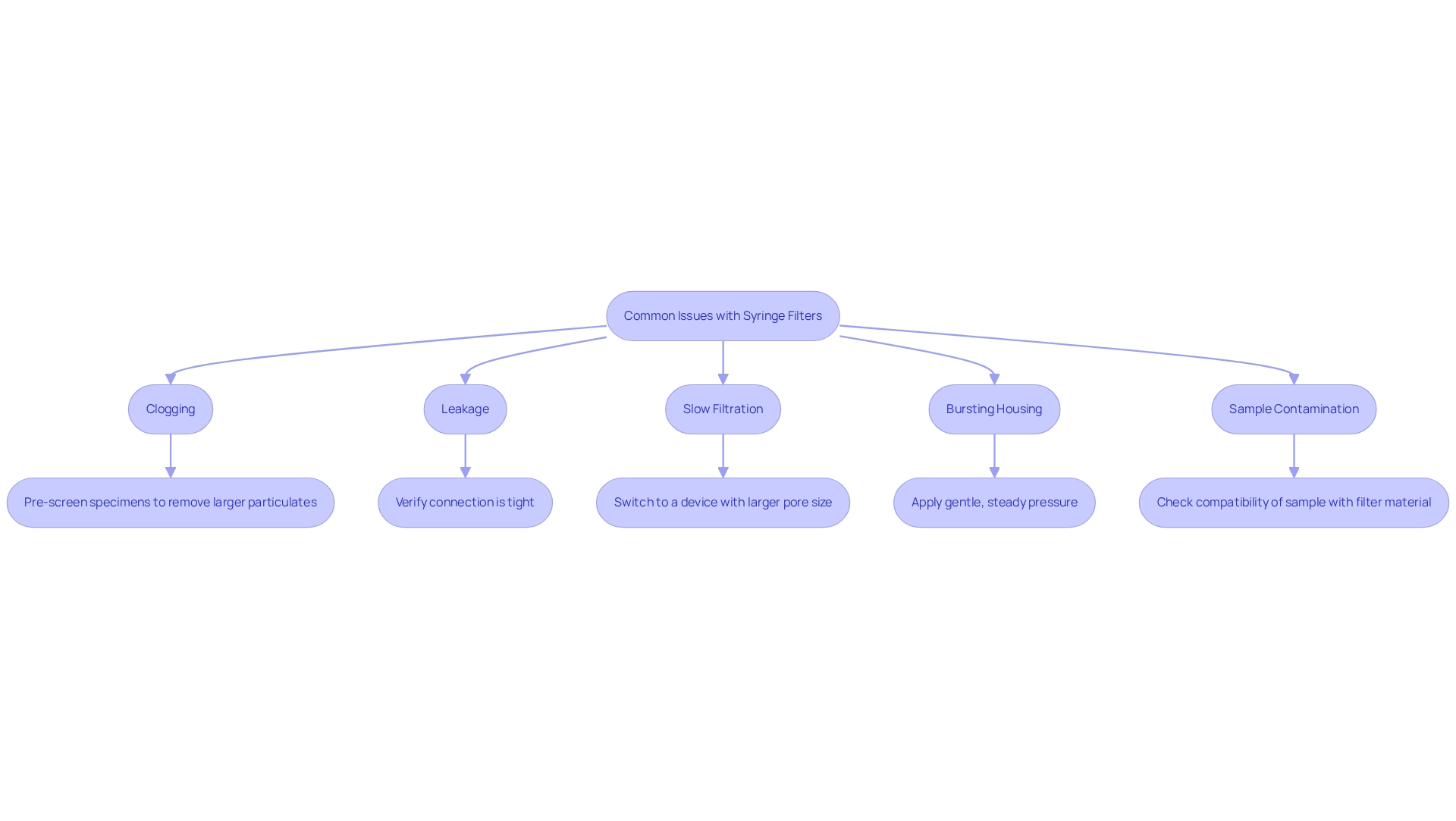

Troubleshoot Common Issues with Syringe Filters

Common issues with and their solutions are critical for maintaining effective filtration processes in laboratory settings.

- Clogging: Clogging can significantly impede the filtration process, often occurring after filtering approximately 100 mL of water through 0.45 µm membranes. This statistic underscores the importance of understanding clogging effects for reliable water quality assessments. To mitigate this issue, pre-screen specimens to remove larger particulates before utilizing the needle device. A relevant case study titled "Influence of Anthropogenic Factors on River Water Quality" illustrates how clogging can alter the chemical composition of water, emphasizing the necessity for effective management strategies in filtration applications.

- Leakage: Leakage may occur if the strainer is not securely attached to the syringe. Always verify that the connection is tight prior to use to prevent any loss of material.

- Slow Filtration: If is slower than expected, consider switching to a device with a larger pore size or diameter. Additionally, ensure that the viscosity of the specimen is compatible with the strainer being utilized.

- Bursting Housing: Excessive pressure can lead to bursting of the housing. It is crucial to apply gentle, steady pressure during the filtration process to avoid this issue.

- Sample Contamination: Contamination may occur if the membrane material is unsuitable for the specimen or if the strainer is outdated or compromised. As highlighted by Wondesen Workneh Ejerssa, "this study offers a systematic framework for comprehending the behavior of various MP classes and their potential losses on syringe membranes." Always check the compatibility of the sample with the ptfe syringe filter material to ensure reliable results.

Conclusion

PTFE syringe filters serve as indispensable components in laboratory analysis, guaranteeing the purity and reliability of liquid samples across a spectrum of applications, including chromatography, biological testing, and environmental analysis. Their remarkable chemical resistance and versatility are crucial for obtaining accurate results, especially in high-throughput environments. As laboratories adapt to the ever-evolving demands for efficiency and precision, grasping the essential selection criteria—such as pore size, filter diameter, chemical compatibility, sterility, and flow rate—becomes imperative.

Selecting the appropriate PTFE syringe filter necessitates a systematic approach that involves evaluating sample types, pore sizes, and solvent compatibility. By adhering to established guidelines, laboratories can sidestep common pitfalls that compromise results and operational efficiency. Furthermore, awareness of potential challenges like clogging, leakage, and sample contamination empowers professionals to troubleshoot effectively, ensuring consistent performance and reliability in their analytical procedures.

Ultimately, the judicious selection and application of PTFE syringe filters not only bolster the integrity of laboratory results but also align with the broader objectives of regulatory compliance and scientific advancement. As the market for these filters continues to expand, laboratories equipped with the requisite knowledge and tools will be better positioned to tackle the challenges posed by modern analytical demands, underscoring the significance of precision in every facet of their workflows.