Overview

This article provides a comprehensive comparison of the 10 ml volumetric flask against other measuring tools, underscoring its superior accuracy and precision for specific applications within laboratory environments. It delves into the flask's design and calibration, essential elements for tasks such as drug formulation. Furthermore, it addresses the limitations of the volumetric flask in comparison to graduated cylinders and pipettes, particularly regarding flexibility and volume measurement. By understanding these distinctions, laboratory professionals can make informed choices about the instruments best suited to their specific needs.

Introduction

In the intricate realm of laboratory measurements, the 10 ml volumetric flask emerges as a quintessential tool, celebrated for its precision and reliability. Its unique design, characterized by a slender neck and a bulbous body, not only facilitates accurate liquid measurements but also enhances mixing efficiency while minimizing spillage.

Constructed from durable borosilicate glass, this volumetric flask is engineered to endure the rigors of laboratory environments, rendering it indispensable for critical applications such as titrations and dilutions. As the demand for accuracy in scientific research escalates, comprehending the features, advantages, and appropriate contexts for employing the 10 ml volumetric flask becomes essential for laboratory professionals.

This article explores the fundamental characteristics of this measuring instrument, compares it with alternative tools, and underscores considerations for selecting the appropriate equipment in pharmaceutical settings.

Understanding the 10 ml Volumetric Flask: Features and Applications

is an essential precision instrument, meticulously engineered to measure a specific volume of liquid with exceptional accuracy. Its distinctive design, characterized by a long neck and a bulbous body, facilitates thorough mixing while minimizing spillage risks. Typically crafted from borosilicate glass, the 10 ml volumetric flask exhibits notable resistance to thermal shock and chemical degradation, making it ideal for a range of scientific applications, including titrations and dilutions. Calibrated to hold precisely 10.00 ml of liquid at a specified temperature, the 10 ml volumetric flask ensures high accuracy with a tolerance of ±0.02 ml. This level of precision is critical in pharmaceutical and chemical facilities, where exact concentrations are paramount for experiments and formulations. Recent studies indicate that approximately 85% of laboratories utilize graduated containers for precise calculations, underscoring their significance in ensuring accuracy within laboratory environments. Furthermore, measuring containers are available in various capacities, including:

- 25 mL

- 50 mL

- 100 mL

- 250 mL

- 500 mL

- 1,000 mL

catering to diverse measurement requirements across multiple applications.

Case studies reveal that measuring vessels are optimized for accuracy and precision in assessing specific volumes, rendering them superior for applications where minor volume variations can significantly impact results. For instance, in pharmaceutical laboratories, the utilization of a 10 ml volumetric flask is vital in creating solutions for drug formulations, where even slight discrepancies can lead to substantial changes in effectiveness. The integration of measuring vessels with advanced titration techniques, such as the AQ-300 Coulometric and AQV-300 Karl Fischer titrators, enhances the reliability of moisture content analysis in pharmaceuticals, ensuring compliance with the Japanese Pharmacopoeia.

Moreover, innovations in measuring container design have enhanced their functionality, featuring improved calibration markings and user-friendly designs that promote ease of use. Authorities in the field, such as Dr. Nick Oswald, founder of Bitesize Bio Science Squared Ltd, emphasize the importance of accuracy in measurement containers, asserting, 'Do you concur that numerous biology researchers could/should perform tasks with greater precision?' This statement underscores the essential role of precise data in achieving dependable experimental results. As the landscape of experimental assessments evolves in 2025, the role of the 10 ml volumetric flask remains crucial for maintaining the integrity of scientific inquiry.

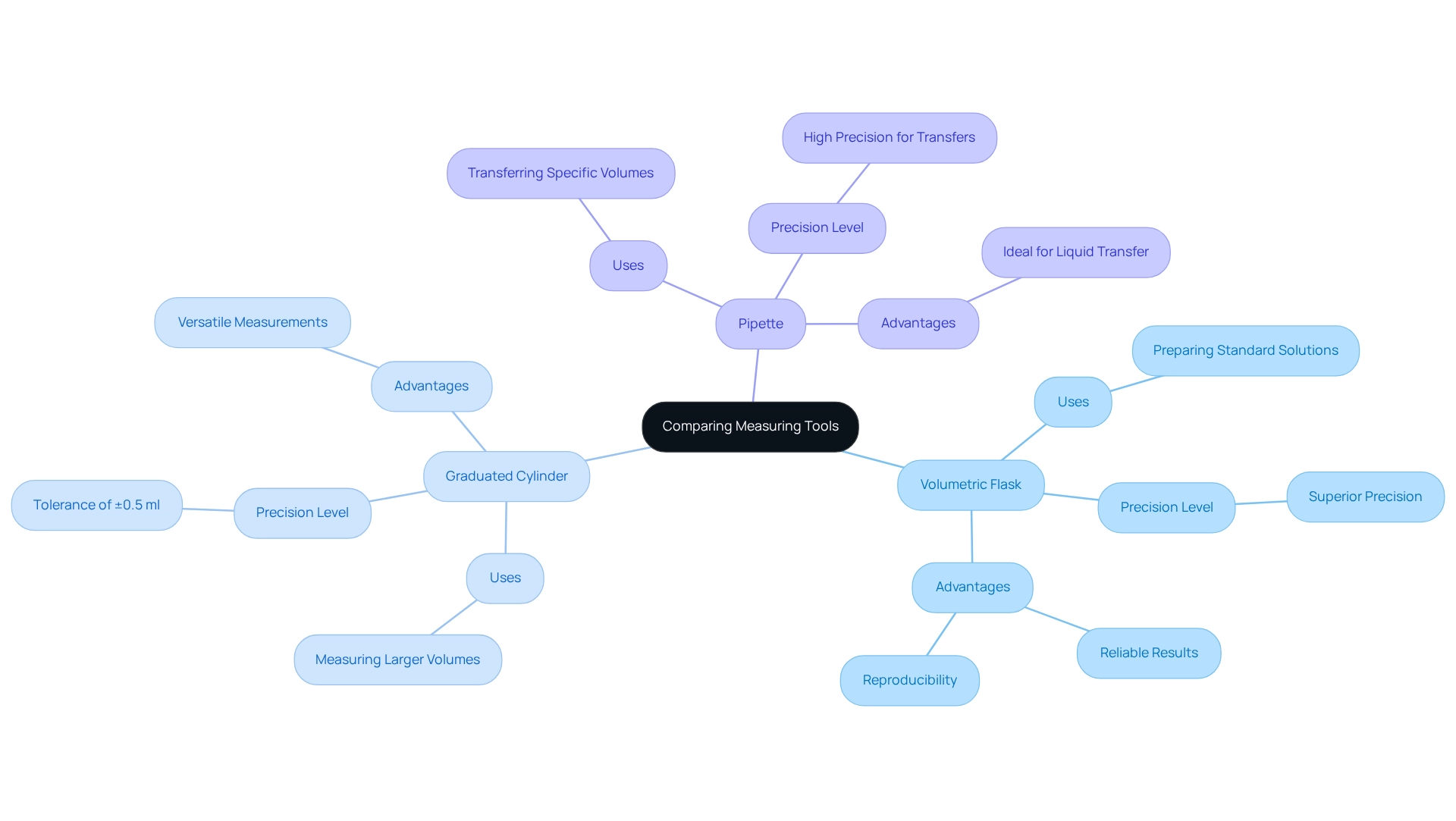

Comparing Measuring Tools: Volumetric Flask vs. Graduated Cylinder and Pipette

In the realm of lab assessments, understanding the distinctions between a 10 ml measuring container, graduated cylinders, and pipettes is crucial. The measuring container is engineered for high precision, designed to gauge a single volume with exceptional accuracy. Conversely, graduated cylinders, while versatile for various measurements, typically exhibit a tolerance of ±0.5 ml for , which can undermine their suitability for applications that require exact concentrations.

Pipettes fulfill a different role; they excel in transferring specific volumes of liquid but are not intended for mixing or containing solutions. Each instrument has its designated function:

- Measuring containers are optimal for preparing standard solutions.

- Graduated cylinders are beneficial for measuring larger volumes.

- Pipettes are essential for transferring precise amounts of liquid.

Statistics reveal that volumetric flasks generally offer superior precision compared to graduated cylinders, making them the preferred choice in scenarios where accuracy is paramount. With 17K facilities certified in material testing products, the importance of utilizing accurate instruments is underscored. Case studies, such as 'Ensuring Precision,' have demonstrated that the effectiveness of graduated cylinders can be influenced by pouring methods and the specific type of cylinder used, highlighting the critical nature of accuracy in experimental environments.

Laboratory managers often advocate for volumetric flasks over graduated cylinders, citing their advantages in achieving reliable and reproducible results in pharmaceutical applications. As Ryan, the writer of Certified Material Testing, aptly states, "Accuracy in measurement is essential for maintaining the integrity of experimental results." This nuanced understanding of each tool's capabilities, including their differences from beakers, is vital for optimizing practices in the lab.

Pros and Cons of the 10 ml Volumetric Flask in Laboratory Use

Advantages and Disadvantages of the 10 ml Volumetric Flask in Experimental Use

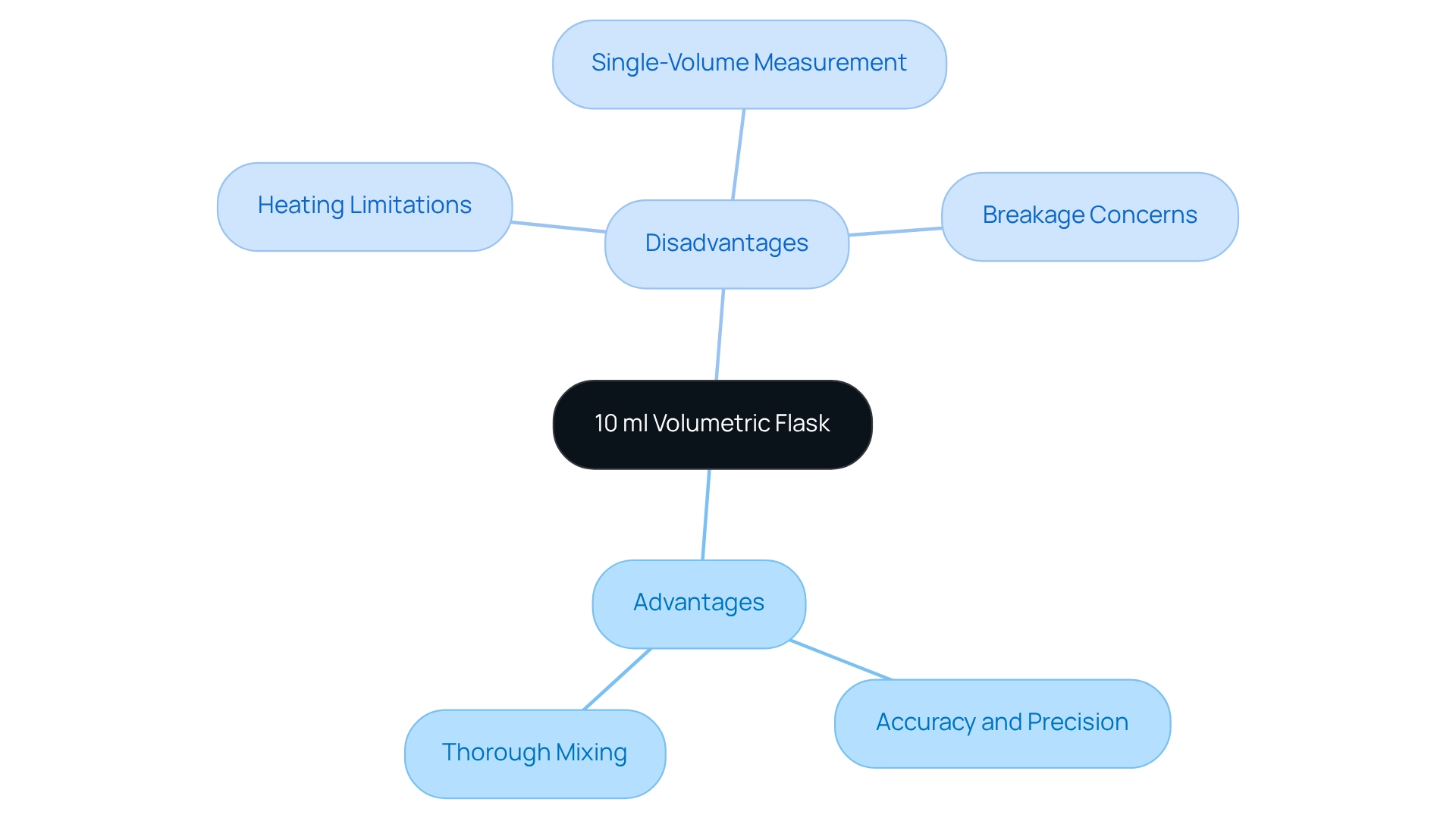

The 10 ml volumetric flask is renowned for its exceptional accuracy and precision, making it indispensable for quantitative assessment in experimental environments. Its design facilitates thorough blending of solutions, and the precise calibration ensures reliable readings, which are critical for maintaining experimental integrity. Nonetheless, several notable drawbacks warrant consideration regarding the 10 ml volumetric flask:

Advantages:

- Accuracy and Precision: The 10 ml volumetric flask is engineered for precise measurements, thereby ensuring the integrity of experimental outcomes.

- Thorough Mixing: The design of the 10 ml volumetric flask promotes effective mixing of solutions, which is essential in numerous scientific applications.

Disadvantages:

- Heating Limitations: The 10 ml volumetric flask is not intended for heating solutions, potentially limiting its application in specific experimental setups.

- Single-Volume Measurement: The 10 ml volumetric flask's capability for single-volume measurement can present challenges when multiple volumes are required across various experiments.

- Breakage Concerns: Glass 10 ml volumetric flasks are more prone to breakage compared to their plastic counterparts, raising safety and cost-effectiveness considerations. Statistics indicate that glass measuring containers are significantly more vulnerable to breaking under pressure.

Despite these challenges, the advantages of accuracy and reliability often outweigh the drawbacks, particularly in scenarios where precision is paramount. Case studies underscore the importance of measuring containers in educational contexts, where students investigate the design and purpose of various types of glassware, including measuring containers. This exploration enhances their understanding of and illustrates how design choices influence functionality and precision in experimental tasks. Laboratory technicians frequently express confidence in the reliability of measuring containers, emphasizing their critical role in pharmaceutical applications where accurate evaluations are vital. In summary, while the 10 ml volumetric flask presents certain challenges, its role in ensuring precise and dependable laboratory assessments remains unparalleled.

Choosing the Right Measuring Tool: Considerations for Pharmaceutical Lab Managers

Pharmaceutical lab managers must meticulously evaluate several critical factors when selecting measuring tools to ensure accuracy and reliability in their operations. Key considerations encompass the required precision, the volume of liquid to be measured, and the specific application at hand. For high-precision tasks, such as preparing standard solutions, the preferred choice is often because of its ability to consistently deliver precise results. Conversely, for applications requiring flexibility in measuring various volumes, graduated cylinders may be more suitable.

Simplicity is another vital aspect; instruments that are user-friendly and straightforward can significantly reduce the likelihood of user errors, which is crucial for maintaining accuracy. Additionally, the composition of the measuring instrument—whether glass or plastic—affects both durability and chemical compatibility, thereby influencing the overall decision-making process.

Statistics underscore the importance of precision in pharmaceutical assessments, with studies indicating that even minor variations can lead to substantial effects on research outcomes and product quality. For example, the SmartGene SaaS for HIV-1 is CE-IVD labeled and 21 CFR Part 11 compliant, underscoring the significance of regulatory compliance in ensuring measurement accuracy. Furthermore, a case study on chromatographic analysis revealed that incorrect peak identification could lead to erroneous conclusions regarding compound presence, highlighting the necessity for rigorous verification techniques.

Current trends among pharmaceutical lab managers reveal an increasing preference for tools that not only comply with regulatory standards but also enhance operational efficiency. Support for facilities seeking COFRAC accreditation ensures adherence to ISO 15189, which is progressively shaping tool selection. Expert recommendations advocate for structured training programs to address knowledge gaps in laboratory management, ensuring that staff are well-equipped to select and utilize measuring instruments effectively. By prioritizing these considerations, lab managers can significantly enhance the accuracy and reliability of their measurements, ultimately contributing to improved research and product development outcomes.

Conclusion

In summary, the 10 ml volumetric flask is a fundamental tool in laboratory environments, renowned for its exceptional accuracy and reliability in measuring liquids. Its unique design not only facilitates precise measurements but also enhances mixing efficiency, making it indispensable for critical applications such as titrations and dilutions. Constructed from durable borosilicate glass, it withstands the demands of various laboratory settings, ensuring that researchers can maintain the integrity of their results.

When comparing the volumetric flask to other measuring tools like graduated cylinders and pipettes, its superiority in accuracy and precision is evident. While graduated cylinders provide versatility in measuring larger volumes and pipettes excel in liquid transfer, the volumetric flask remains the preferred choice where exact concentrations are crucial, particularly in pharmaceutical applications. This distinction underscores the importance of selecting the appropriate measuring instrument based on the specific needs of the task at hand.

Despite some limitations, such as heating restrictions and fragility, the advantages of the 10 ml volumetric flask far outweigh its drawbacks. It plays a pivotal role in ensuring accurate and reliable measurements, foundational to successful laboratory outcomes. As pharmaceutical lab managers navigate the complexities of measurement tools, the emphasis on precision and regulatory compliance will continue to drive the preference for volumetric flasks in their operations. Ultimately, understanding the features and applications of the 10 ml volumetric flask is essential for laboratory professionals committed to maintaining high standards of accuracy and reliability in their work.