Overview

Accurate pipette calibration is crucial in pharmaceutical laboratories, as it ensures precise liquid measurements and prevents significant errors in drug formulation and testing. This necessity is underscored by the importance of:

- Regular calibration practices

- Adherence to ISO standards

- The implementation of advanced calibration technologies

These measures not only enhance reliability but also reduce costs, ultimately upholding research integrity and safeguarding patient safety. By prioritizing pipette calibration, laboratories can significantly improve their operational efficiency and the quality of their outcomes.

Introduction

In the realm of scientific research, precision is paramount, particularly in fields like pharmaceuticals where the stakes are incredibly high. Pipette calibration emerges as a critical practice, ensuring that these essential tools dispense accurate volumes consistently. With even minor discrepancies capable of skewing results and jeopardizing patient safety, the significance of regular calibration cannot be overstated.

This article delves into the importance of pipette calibration, highlighting its role in:

- Maintaining compliance with industry standards

- Enhancing data reliability

- Ultimately safeguarding the integrity of research outcomes

By exploring best practices, benefits, and key considerations for selecting calibration services, it provides a comprehensive guide for laboratories striving for excellence in their scientific endeavors.

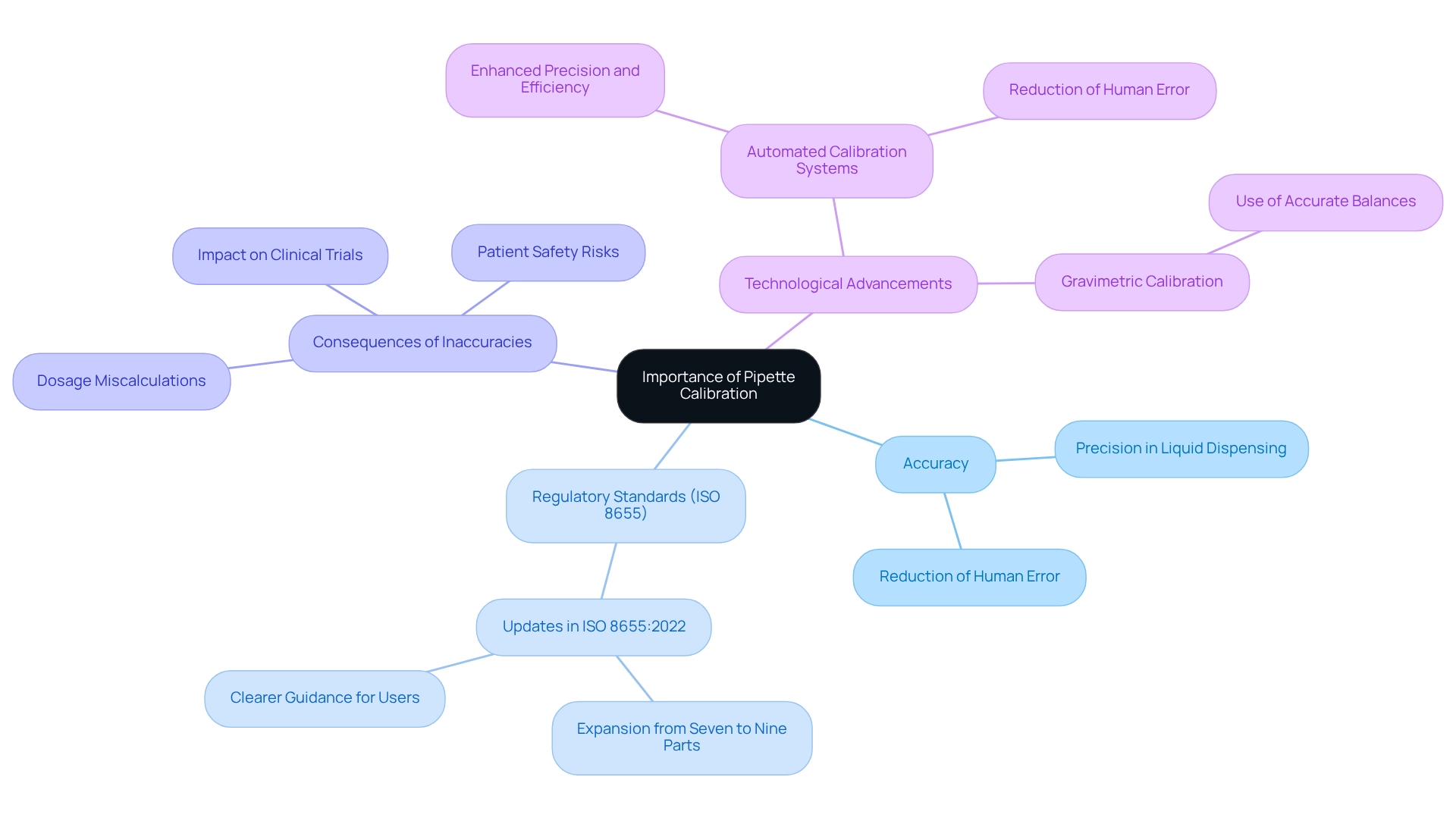

Understand the Importance of Pipette Calibration

The adjustment of liquid handling devices is essential for ensuring that the volumes dispensed by are both precise and uniform. In pharmaceutical facilities, where even slight variations can result in major mistakes in drug formulation and testing, regular adjustment is crucial. This process confirms that the accurate pipette devices deliver the correct volume, which is essential for reproducibility and compliance with industry standards like ISO 8655. Without accurate adjustment, facilities risk producing unreliable information, endangering research results and regulatory adherence. Acknowledging the significance of liquid transfer device adjustment is the initial step toward attaining high-quality laboratory outcomes.

Research underscores that inaccuracies in the use of an accurate pipette can introduce variability in experimental results, which is a particularly detrimental issue in pharmaceutical development where precision is paramount. Studies have indicated that incorrect adjustments can result in dosage miscalculations, distorting clinical trial results and potentially jeopardizing patient safety. The recent updates in ISO 8655:2022, which expanded from seven to nine parts, provide clearer guidance for manufacturers and users, ensuring better maintenance and the accuracy of an accurate pipette and other volumetric equipment. This emphasizes the continuous dedication to improving measurement practices in the industry, ultimately supporting the integrity of pharmaceutical research and development.

Furthermore, automated adjustment systems have been demonstrated to improve the performance of an accurate pipette, significantly decreasing human mistakes in the adjustment process. As Mariam Faizullabhoy observes, "Gravimetric adjustment depends on the exact measurement of the volume of liquid dispensed by a syringe, usually employing a highly accurate balance or scale." This highlights the essential importance of precise measurement in liquid measurement adjustment. Moreover, the significance of liquid handling device adjustment goes beyond pharmaceuticals, influencing diverse scientific disciplines, thus underscoring its importance throughout the larger scientific community.

Recognize the Benefits of Accurate Calibration

Precise liquid measurement adjustment is not merely a regulatory necessity in sectors such as pharmaceuticals, biotechnology, and medical device production; it also offers substantial benefits that extend beyond simple compliance. This practice enhances the reliability of experimental results, ensuring that the generated data is reproducible and valid—an essential factor in pharmaceutical laboratories, where the implications of errors can be significant.

Routine adjustment not only enhances precision but also leads to considerable cost reductions by minimizing the need for repeated experiments due to erroneous measurements. For instance, a properly calibrated tool significantly mitigates the risk of errors that could necessitate repeating experiments, thereby conserving both time and resources. Statistics indicate that can result in a decrease in operational expenses by as much as 30%, making it a financially prudent investment for research facilities. Expert citations, such as those from BioMedical Computing, emphasize that 'pipette adjustment is a regulatory requirement in various industries, including pharmaceuticals, biotechnology, and medical device manufacturing.'

Moreover, precise adjustment fosters a culture of quality within the testing environment. It promotes staff adherence to best practices and the maintenance of high work standards. This commitment to precision ultimately enhances laboratory performance and contributes to superior scientific outcomes. Case studies have demonstrated that applying gravimetric testing for adjustment not only verifies the accuracy of the instruments but also assists in identifying performance deviations, ensuring that devices consistently deliver the correct volumes.

To implement accurate pipette calibration effectively, consider the following key practices:

- Implement regular calibration schedules to meet regulatory requirements.

- Utilize modern technology and software solutions to simplify the adjustment process.

- Train staff on best practices for accurate pipette use and maintenance.

- Monitor and record adjustment results to ensure compliance and quality assurance.

By emphasizing precise adjustments, pharmaceutical facilities can achieve both operational efficiency and enhanced research quality, ultimately leading to improved patient outcomes.

Implement Effective Pipette Calibration Procedures

To execute efficient liquid handling measurement procedures, laboratories must utilize an accurate pipette and adopt a systematic approach.

- Establish a Verification Schedule: Determine the verification frequency based on usage and manufacturer guidelines. Frequently used droppers may require monthly adjustments, while others could need tuning every three to six months to ensure they function as an accurate pipette.

- Use Standardized Methods: Adhere to established protocols such as ISO 8655, which emphasizes the use of calibrated balances for gravimetric measurements. Notably, the new ISO requirements dictate that any pipette that is 20 μL or less necessitates a six-place balance. Managing environmental factors, such as temperature and humidity, during adjustments is essential for dependable outcomes.

- Document Adjustment Results: Maintain meticulous records of adjustment outcomes, including dates, technicians involved, and any modifications made. This documentation is vital for compliance with quality assurance standards and can be compared against performance specifications defined by users or manufacturers. Ensuring that measurement results meet or exceed these specifications enhances the reliability of across various applications.

- Train Staff: Ensure that all laboratory personnel are well-trained in proper pipetting methods and the importance of adjustments. Regular training sessions can reinforce best practices and enhance overall laboratory performance. Regular maintenance, which includes ensuring the accurate pipette is properly calibrated, is crucial for the instruments. This encompasses cleaning and examining for wear and tear, which can significantly affect performance.

By following these best practices, laboratories can ensure their devices remain precise and dependable, ultimately resulting in enhanced experimental outcomes. The SpeedCal Calibration System by Sartorius exemplifies an efficient solution, considerably minimizing setup time for multi-channel liquid handlers from nearly six hours to merely 15 minutes, thus improving productivity and adherence to ISO standards. Furthermore, it is feasible to assess dispensers against user-defined tolerances, provided they are stricter or equal to ISO specifications, allowing for flexibility in adjustment practices.

Select Reliable Pipette Calibration Services

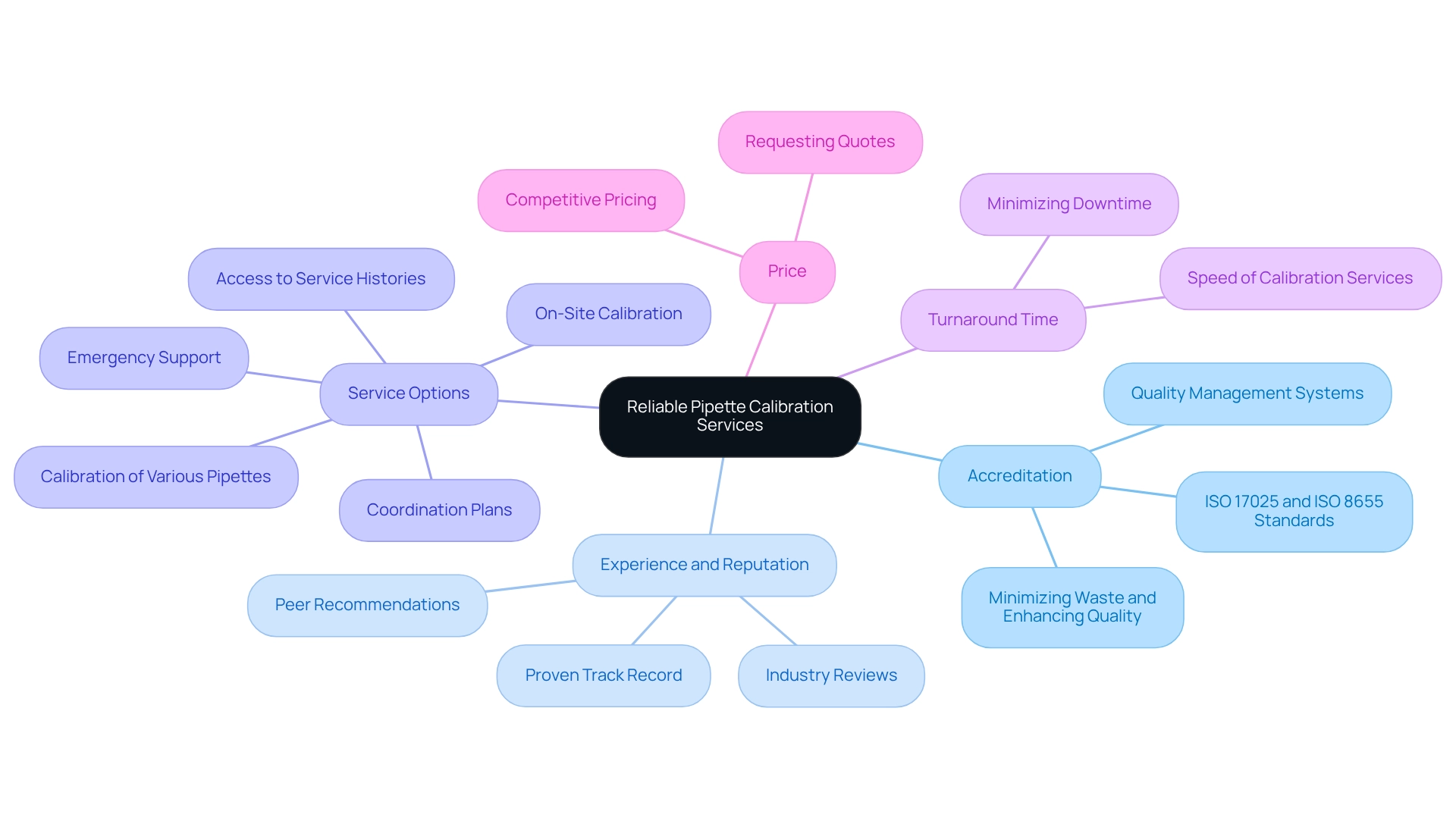

When selecting , laboratories must prioritize several key factors to ensure optimal performance and compliance.

- Accreditation is paramount; providers should be accredited to ISO 17025 and ISO 8655 standards. This accreditation guarantees adherence to established quality management systems, delivering reliable measurement results that meet rigorous quality standards. Specifically, ISO 17025 accreditation aids organizations in saving time and resources by minimizing manufacturing waste and enhancing product quality.

- Experience and Reputation play a crucial role in provider selection. Laboratories should seek providers with a proven track record in the industry. By examining reviews and obtaining recommendations from peer facilities, laboratories can identify trustworthy measurement providers that have consistently demonstrated their capabilities.

- Service Options are another critical consideration. Laboratories should evaluate the range of services available, such as on-site calibration, emergency support, and the capability to calibrate various types of pipettes. A comprehensive provider can effectively meet diverse laboratory needs. Additionally, inquire about complimentary access to service histories and coordination plans, which can further enhance reliability.

- Turnaround Time is essential; assessing the speed of calibration services is vital for minimizing downtime and maintaining productivity within the lab. Timely assistance is crucial for upholding quality standards in operations.

- Price should not be the sole determining factor, yet it is important to ensure that pricing is competitive and reflective of the quality provided. Requesting quotes from multiple providers facilitates effective comparison.

By meticulously selecting a reliable calibration provider, laboratories can maintain the accuracy of their accurate pipettes, thereby enhancing the quality of their research and ensuring compliance with regulatory standards. As Alvin Pastoral emphasizes, 'It’s essential to choose an ISO 17025 accredited testing laboratory if you’re pursuing measurement adjustments.' The impact of calibration quality on laboratory results is profound; precise measurements are fundamental to successful scientific endeavors. Furthermore, a case study titled "Choosing an ISO 17025 Accredited Calibration Lab" underscores the credibility and reliability that such accreditation offers, reinforcing the necessity of selecting accredited labs for accurate and dependable calibration services.

Conclusion

Pipette calibration stands as a cornerstone of scientific research, particularly within the pharmaceutical industry where precision is non-negotiable. This article has highlighted the critical importance of regular calibration in maintaining compliance with industry standards, enhancing data reliability, and safeguarding research integrity. Through the exploration of best practices, it is evident that accurate pipette calibration not only mitigates the risk of errors but also contributes significantly to operational efficiency and cost savings.

The adoption of systematic calibration procedures, including the establishment of a calibration schedule and the utilization of standardized methods, is essential for laboratories striving for excellence. Furthermore, selecting reliable calibration services that adhere to recognized standards can enhance the credibility of laboratory results. Emphasizing the training of personnel and maintaining meticulous documentation fosters a culture of quality, which is vital for achieving superior scientific outcomes.

Ultimately, the impact of proper pipette calibration extends beyond regulatory compliance; it is integral to the overall success of laboratory operations. By prioritizing accurate calibration practices, laboratories can ensure the reliability of their research, leading to improved patient outcomes and advancing the field of science as a whole. As the stakes in scientific research continue to rise, the commitment to precision through effective pipette calibration practices has never been more crucial.