Overview

This article highlights best practices for utilizing debubblers in laboratory environments, underscoring their critical role in removing air pockets from liquid samples to guarantee precise analytical measurements. It offers essential guidance on:

- Selecting the appropriate debubbler

- Implementing effective operating procedures

- Maintaining equipment to optimize performance

Such practices not only enhance the reliability of results but also elevate the precision of pharmaceutical applications. By following these recommendations, laboratories can significantly improve their analytical accuracy and operational efficiency.

Introduction

The precision of pharmaceutical testing relies heavily on the seemingly simple yet crucial task of eliminating air pockets from liquid samples. Debubblers are essential devices in this process; they not only enhance the accuracy of analytical measurements but also play a vital role in ensuring the reliability of drug formulations. However, selecting the right type of debubbler and implementing effective operational procedures pose significant challenges that laboratories must navigate.

What best practices can laboratories adopt to optimize the use of debubblers and safeguard the integrity of their results?

Understand the Role of Debubblers in Pharmaceutical Applications

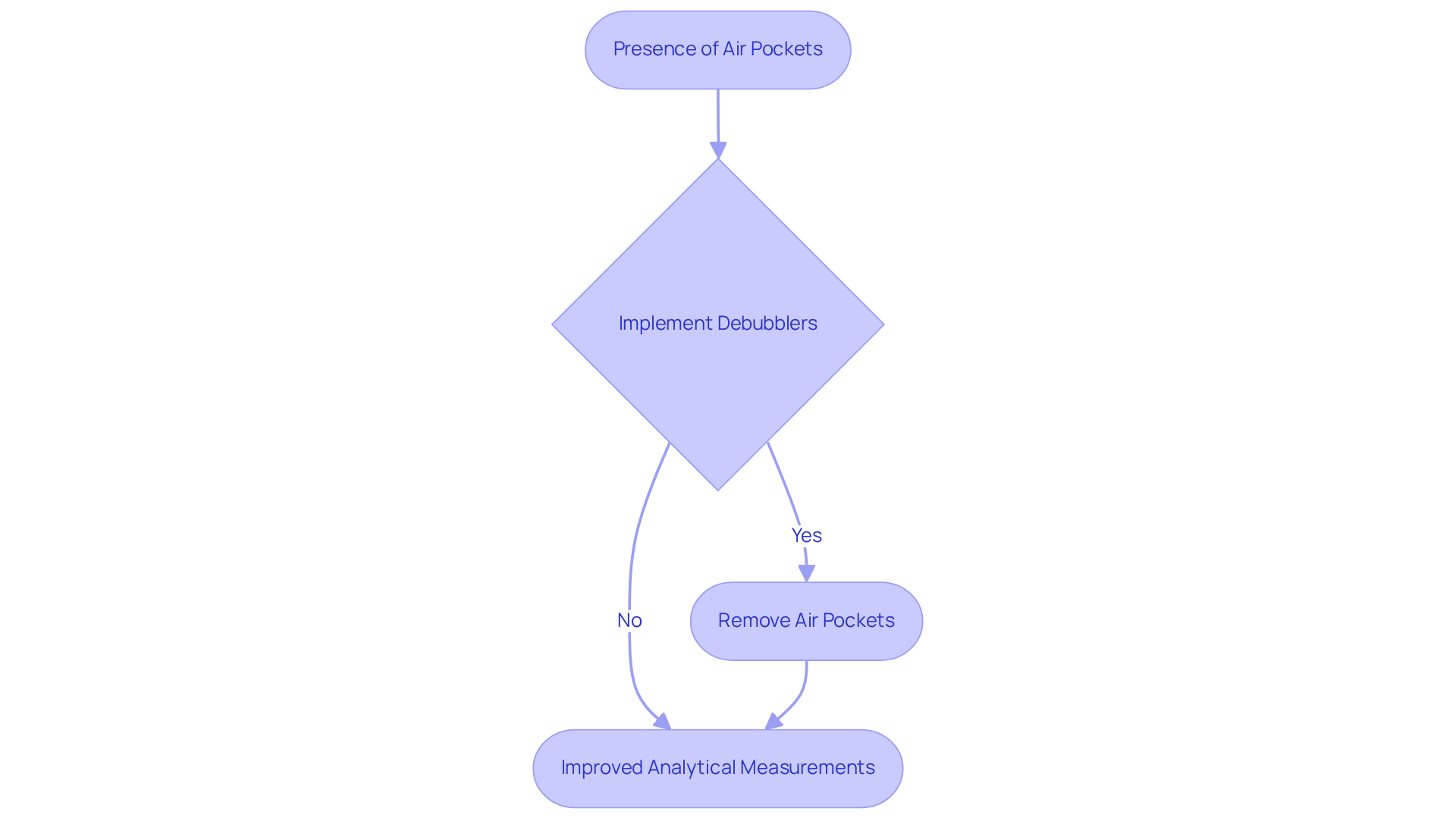

In pharmaceutical applications, debubblers play a pivotal role by effectively eliminating air pockets from liquid samples, which can disrupt analytical measurements and lead to inaccuracies. In high-performance liquid chromatography (HPLC) and other analytical methods, the presence of air pockets can cause fluctuations in flow rates and adversely affect detector responses, ultimately compromising data integrity. For example, gas pockets near the detector can result in spikes in the chromatogram, significantly impacting the precision of results. Implementing effective degassing techniques, particularly vacuum degassing, has been shown to reduce the occurrence of air pockets, thereby enhancing measurement accuracy.

The removal of bubbles is especially critical in drug formulation, where inconsistencies in dosage may arise from air contamination. By ensuring a bubble-free environment, air-removal devices, also known as debubblers, not only bolster the reliability of testing procedures but also enhance the stability of the final product. Industry leaders stress that minimizing air aspiration during sample preparation is essential to prevent undesirable variations in critical parameters. Understanding the importance of integrating into testing processes empowers staff to maintain high standards of precision and dependability in their analytical measurements.

Select the Appropriate Debubbler for Your Laboratory Needs

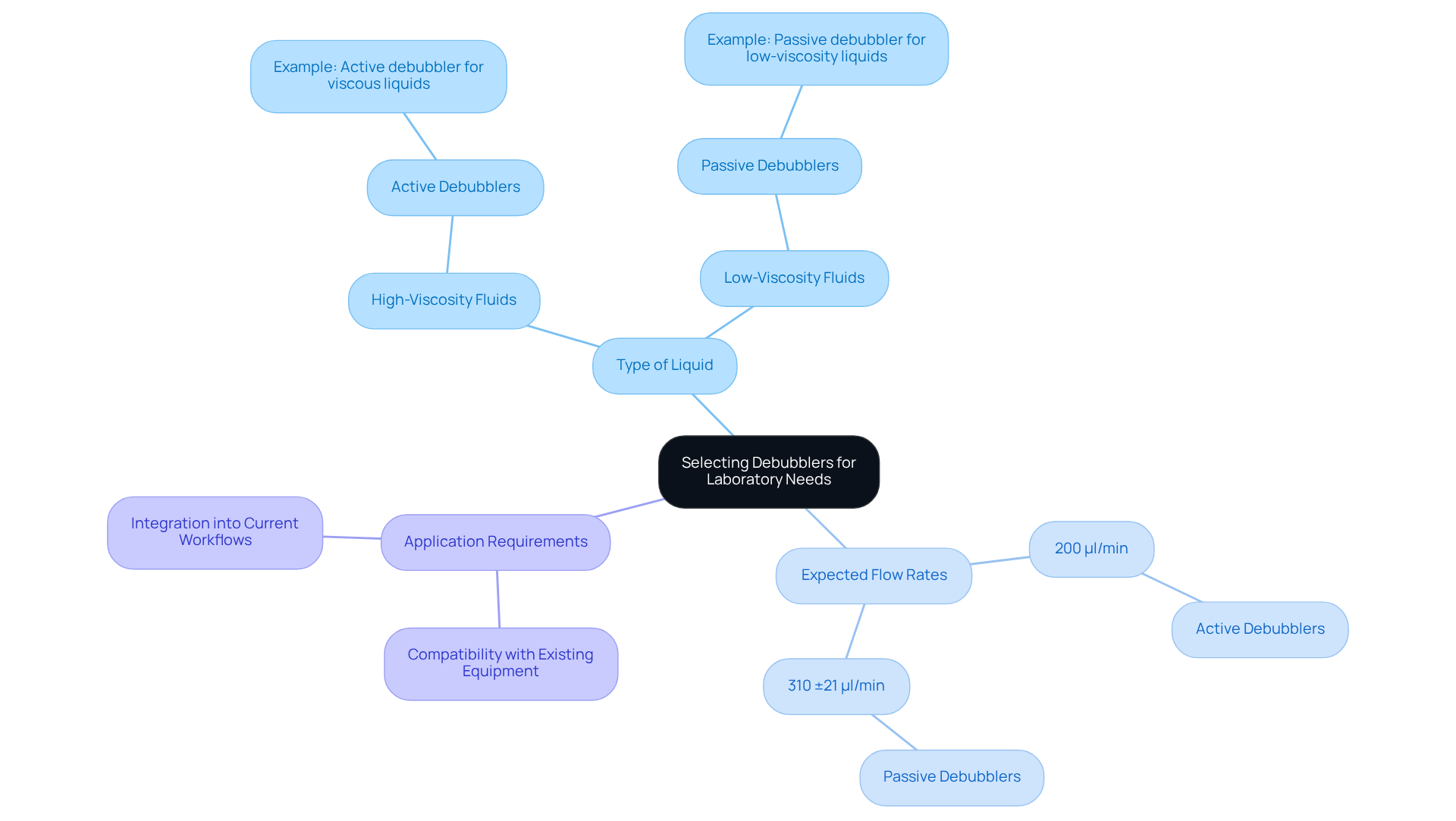

Selecting the is crucial for optimizing laboratory processes, involving careful consideration of several factors. Key elements include:

- The type of liquid being processed

- Expected flow rates

- Specific application requirements

Laboratories face a choice between:

- Active debubblers, which utilize external energy sources to eliminate bubbles

- Passive debubblers, which rely on natural forces such as buoyancy

For instance, an active debubbler is often more effective for high-viscosity fluids, whereas a passive option may suffice for low-viscosity liquids. Furthermore, evaluating compatibility with existing equipment and the simplicity of integration into current workflows is essential. By meticulously assessing these factors, managers can select debubblers that not only enhance operational efficiency but also preserve the integrity of their analytical processes.

Implement Effective Operating Procedures for Debubblers

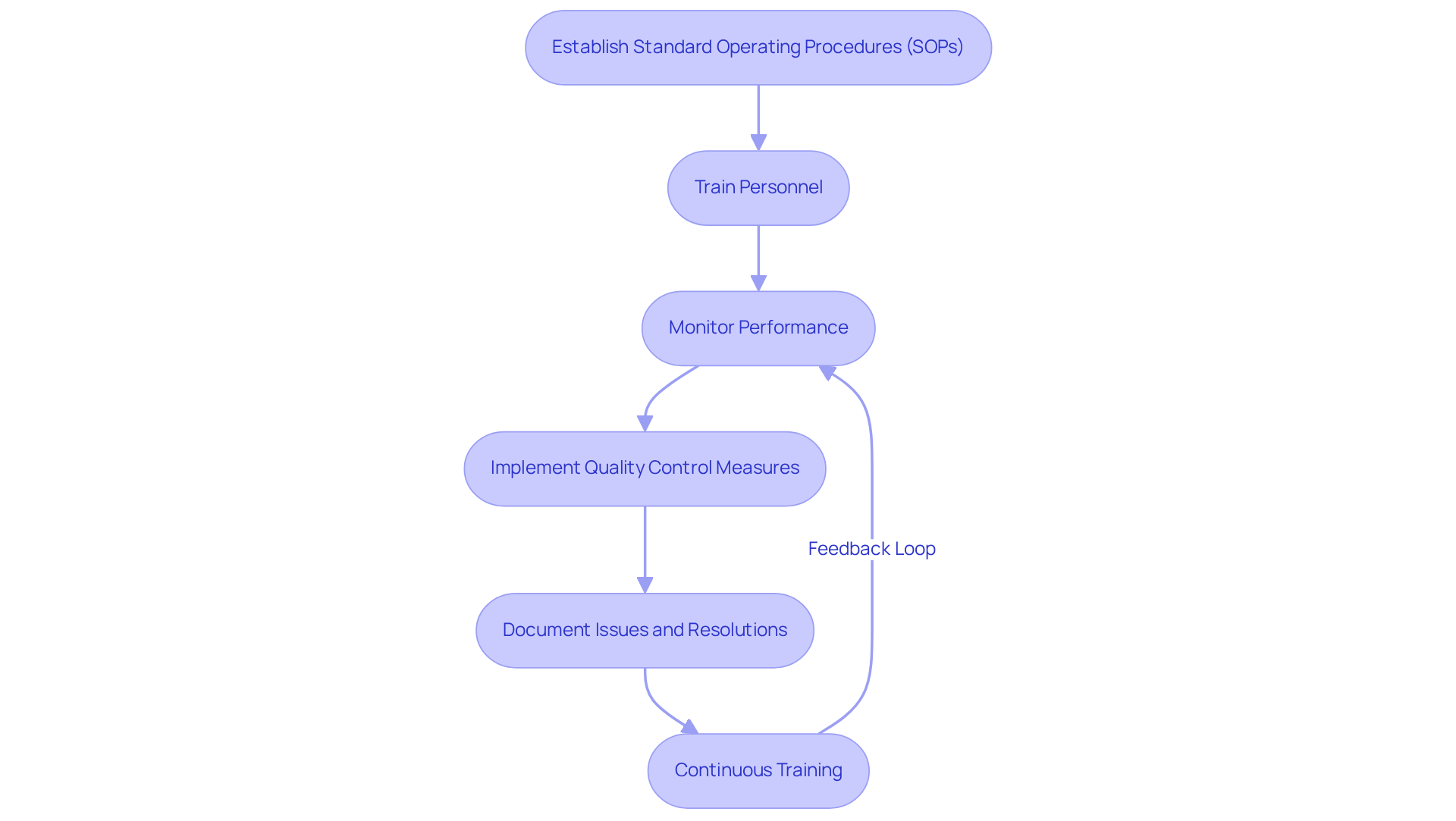

Establishing efficient operating procedures for bubble removers is essential for optimizing laboratory performance. Laboratories must develop comprehensive standard operating procedures (SOPs) that detail the proper setup, operation, and maintenance of the debubbler. As emphasized in external sources, SOPs guarantee consistent and accurate task execution in labs, which is fundamental for obtaining reliable results.

Training personnel on these SOPs is crucial to ensure consistent application and , significantly enhancing equipment reliability. For instance, a pharmaceutical facility that implemented a new SOP for the debubbler reported a 20% improvement in equipment performance metrics, echoing findings that another pharmaceutical establishment achieved a similar enhancement in testing accuracy after adopting a new SOP for quality control testing.

Regular monitoring of the debubbler's performance is also vital. Quality control measures, including frequent equipment calibration, are indispensable for ensuring reliable results. If a debubbler does not effectively eliminate bubbles, it may indicate a need for servicing or recalibration. Documenting any operational issues and their resolutions not only facilitates troubleshooting but also contributes to refining future training and procedures.

Continuous training fosters employee engagement and bolsters lab success, equipping personnel to adhere to SOPs effectively. By implementing and rigorously following these SOPs, facilities can enhance the reliability of their operations involving the debubbler, leading to more precise and consistent analytical outcomes.

Maintain and Troubleshoot Debubblers for Optimal Performance

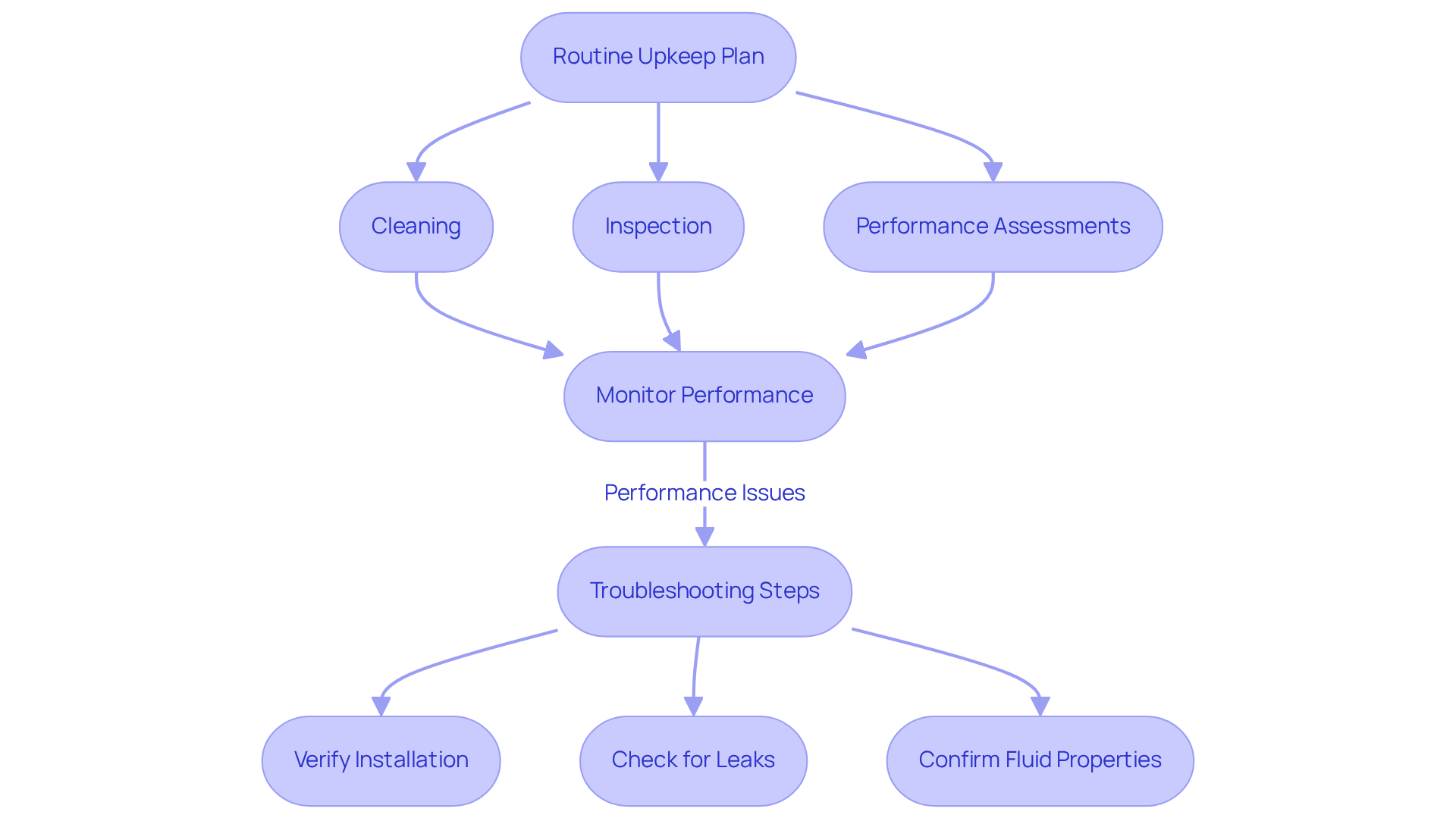

To ensure optimal functioning of devices, facilities must establish a comprehensive encompassing cleaning, inspection, and performance assessments. Regular cleaning of debubbler components is essential to prevent blockages and maintain efficient fluid flow. Equally important is the monitoring of performance; any signs of reduced efficiency, such as an increase in bubble presence in the output, should prompt immediate attention.

Troubleshooting steps include:

- Verifying correct installation

- Checking for leaks

- Confirming that fluid properties align with the debubbler's operational specifications

For example, issues like subpar performance may arise from incorrect fluid viscosity or temperature. By actively managing upkeep and troubleshooting, research facilities can significantly extend the lifespan of their debubblers, ultimately ensuring high-quality analytical outcomes.

Statistics indicate that preventive care reduces unforeseen downtime, which can disrupt research timelines, making it an essential practice in laboratory environments. As GenTech Scientific emphasizes, "Regular care of these instruments is not just a best practice suggestion, but a crucial necessity for obtaining precise and dependable results."

Furthermore, addressing minor issues through maintenance can avert major breakdowns, underscoring the cost-effectiveness of routine maintenance, as every $1 worth of deferred maintenance could escalate to $4 in capital renewal costs later on.

Conclusion

In the realm of pharmaceutical applications, the significance of debubblers cannot be overstated. These devices are essential for eliminating air pockets from liquid samples, which, if left unchecked, can lead to inaccuracies in analytical measurements and compromise data integrity. By integrating effective degassing techniques, laboratories can enhance the reliability of their testing processes and ensure the stability of their final products.

Throughout this article, we have highlighted key practices for optimizing the use of debubblers. From selecting the appropriate type based on liquid viscosity and application requirements to establishing comprehensive standard operating procedures that guarantee consistency and accuracy, each step is crucial for maximizing operational efficiency. Furthermore, ongoing maintenance and troubleshooting are emphasized as vital components in ensuring the longevity and effectiveness of debubblers, ultimately leading to more precise analytical outcomes.

The importance of these practices extends beyond mere operational efficiency; they represent a commitment to quality and reliability in laboratory settings. By prioritizing the proper use and maintenance of debubblers, laboratories can significantly improve their results, thereby enhancing the overall quality of pharmaceutical manufacturing. As such, adopting these best practices is not just beneficial but essential for any facility aiming to uphold high standards in analytical measurements and drug formulation.