Overview

The article delineates seven compelling benefits of employing a near infrared spectrometer in food analysis. It underscores its:

- Precision

- Rapid analysis

- Non-destructive testing

- Real-time data acquisition

- Versatility

- Cost-effectiveness

- User-friendly operation

All while highlighting its significant contributions to food safety and sustainability. Each benefit is substantiated with examples illustrating how this technology enhances efficiency, ensures compliance with safety standards, and promotes eco-friendly practices in food laboratories. Consequently, it emerges as an indispensable tool for contemporary food analysis, reinforcing the necessity for high-quality scientific instruments in laboratory settings.

Introduction

The food industry is increasingly adopting advanced technologies to ensure quality and safety, with the near infrared spectrometer emerging as a pivotal innovation in this domain. This sophisticated instrument not only streamlines the analysis of critical food components but also enhances decision-making processes through real-time data acquisition. As the demand for efficiency and precision escalates, a pressing question arises: how can laboratories effectively leverage this technology to meet regulatory standards and consumer expectations? Delving into the multifaceted benefits of the near infrared spectrometer underscores its essential role in transforming food analysis and addressing the challenges faced by modern testing facilities.

JM Science Near Infrared Spectrometer: Precision in Food Analysis

The JM Science near infrared spectrometer represents a pinnacle of advanced technology in analytical measurement, showcasing exceptional precision in evaluating various components. This near infrared spectrometer is particularly noteworthy for its capacity to deliver with minimal sample preparation, making it indispensable for laboratories dedicated to safety and regulatory standards. It proficiently analyzes critical parameters such as moisture, fat, and protein levels, which are vital for maintaining product quality. Recent advancements in the near infrared spectrometer have significantly broadened its application, enabling rapid, high-throughput analysis that aligns with the increasing demands of the culinary sector.

As safety specialists emphasize, precise measurements are crucial for upholding product standards, and the JM Science spectrometer is instrumental in achieving this objective. Importantly, the near infrared spectrometer can process hundreds of samples in a single day at remarkably low operational costs, positioning it as a cost-effective solution for laboratories. Moreover, practical applications, such as Aotech's utilization of the near infrared spectrometer for product quality evaluation and research focused on enhancing flavor in plant-based meat alternatives, underscore the substantial influence of this technology on quality assessment. Industry leaders highlight that the continuous development of official methods based on NIR spectroscopy is vital for expanding its relevance within the food sector.

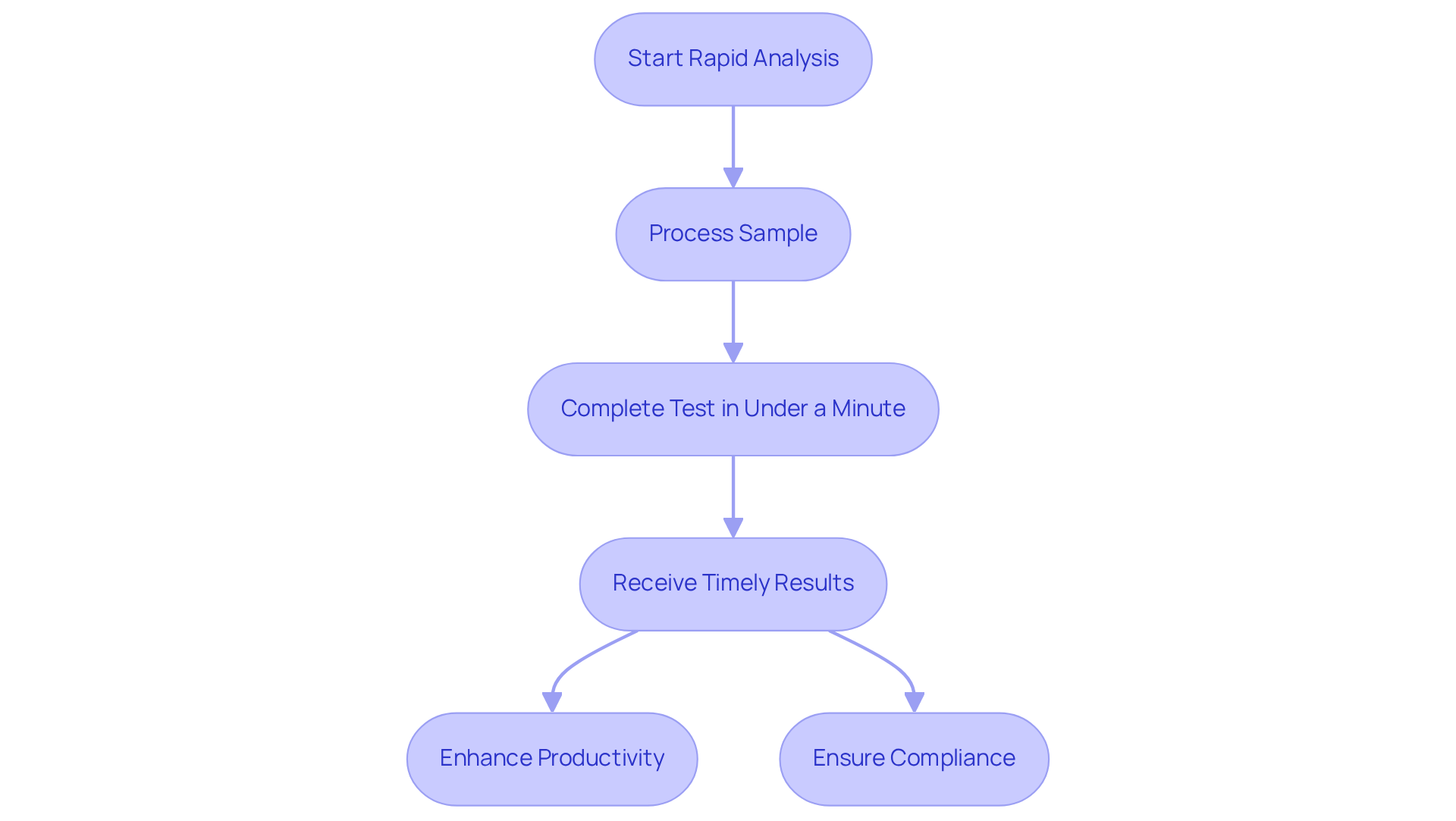

Rapid Analysis: Speeding Up Food Quality Testing

A prominent feature of the near infrared spectrometer from JM Science is its exceptional rapid analysis capability. Tests can be completed in under a minute, enabling laboratories to process samples with remarkable speed and efficiency. This rapid turnaround is particularly beneficial in high-throughput environments, where a near infrared spectrometer provides essential for maintaining standard control and ensuring compliance with safety regulations. The ability to achieve quick analysis not only enhances productivity but also supports laboratories in meeting stringent operational demands.

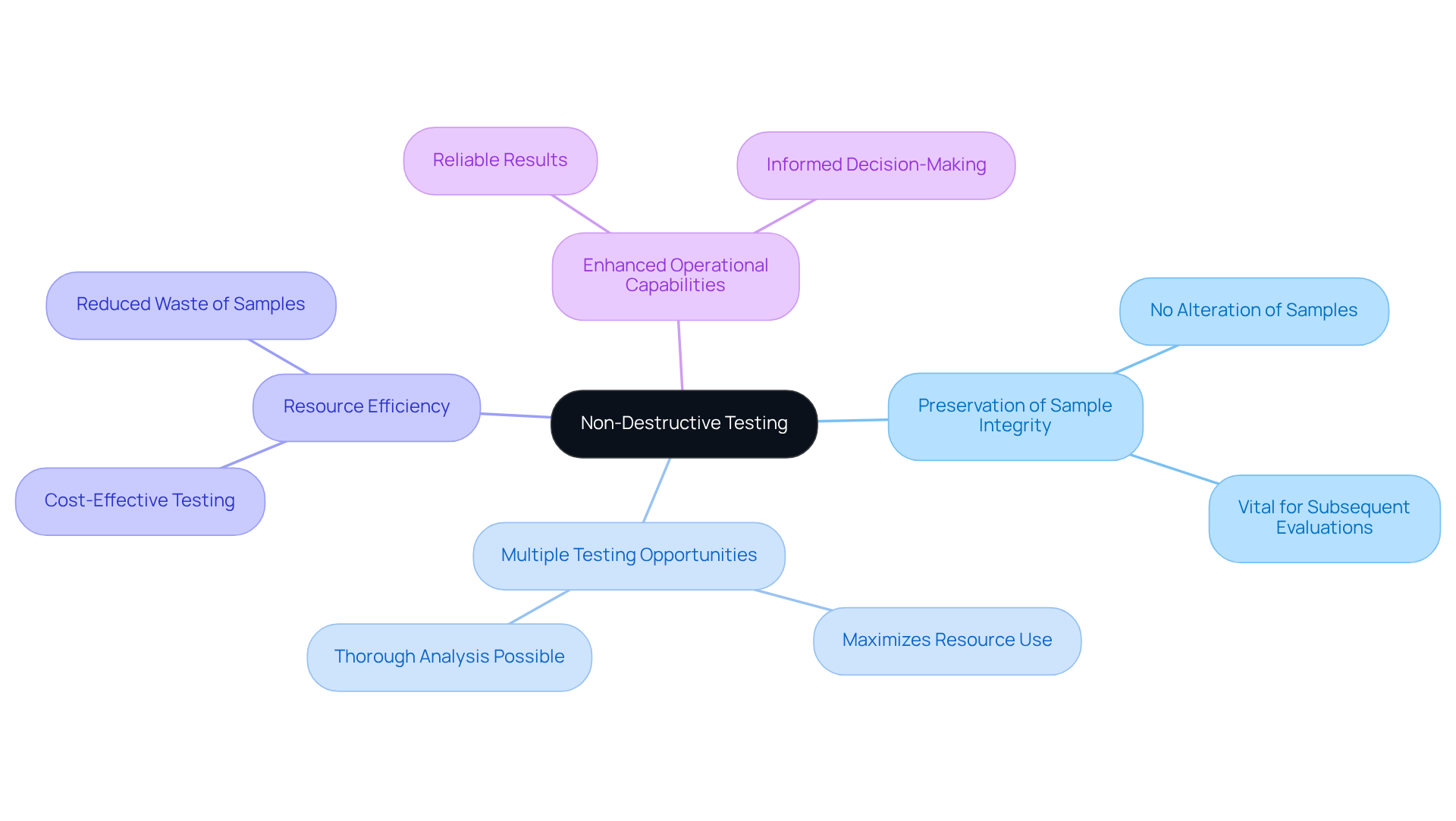

Non-Destructive Testing: Preserving Sample Integrity

The JM Science near infrared spectrometer features a non-destructive characteristic that enables the examination of sample materials without altering or damaging them. This feature is particularly advantageous in testing scenarios, where the preservation of the original sample is vital for subsequent evaluations or assurance checks. Laboratories can perform multiple tests on the same sample, thereby maximizing resource efficiency and ensuring thorough analysis. By employing the near infrared spectrometer, laboratories enhance their operational capabilities, leading to more reliable results and informed decision-making.

Real-Time Data Acquisition: Enhancing Decision-Making

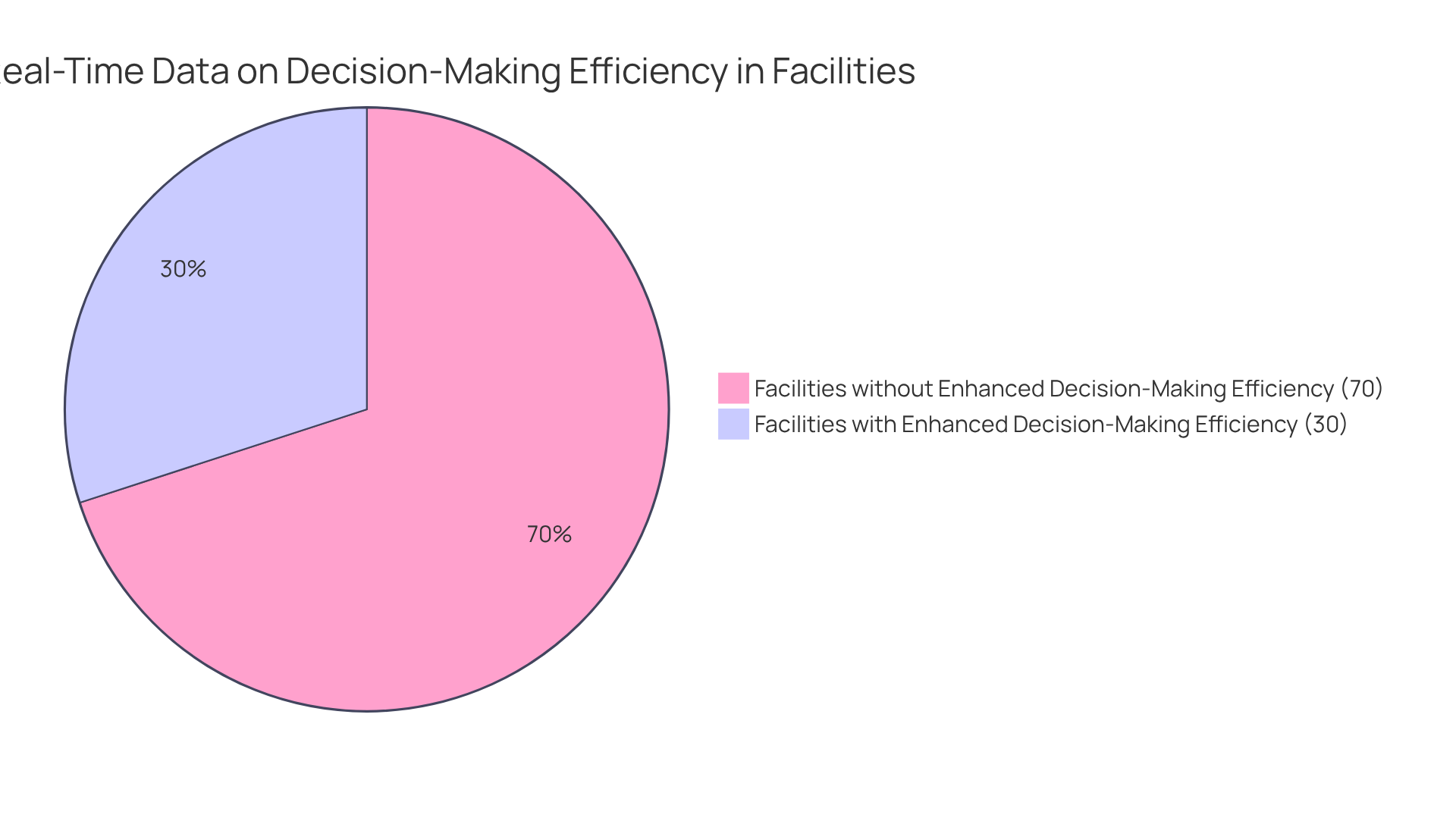

In the realm of food analysis, the near infrared spectrometer from JM Science stands out due to its exceptional real-time data collection capabilities. This feature empowers facilities to make immediately, a critical advantage for identifying potential quality issues before they escalate. Such immediate access to data facilitates swift corrective actions, ultimately preventing costly repercussions.

Industry studies reveal that facilities leveraging real-time data experience a 30% enhancement in decision-making efficiency, highlighting the transformative influence of this technology. Furthermore, real-time data collection is vital for maintaining rigorous safety standards, enabling facilities to adopt a proactive rather than reactive stance. By harnessing precise, real-time information, laboratories not only streamline their processes but also foster a management culture that is essential in today’s regulatory environment.

As industry leaders assert, 'Real-time data is not merely a benefit; it is essential for upholding high standards in safety and control.

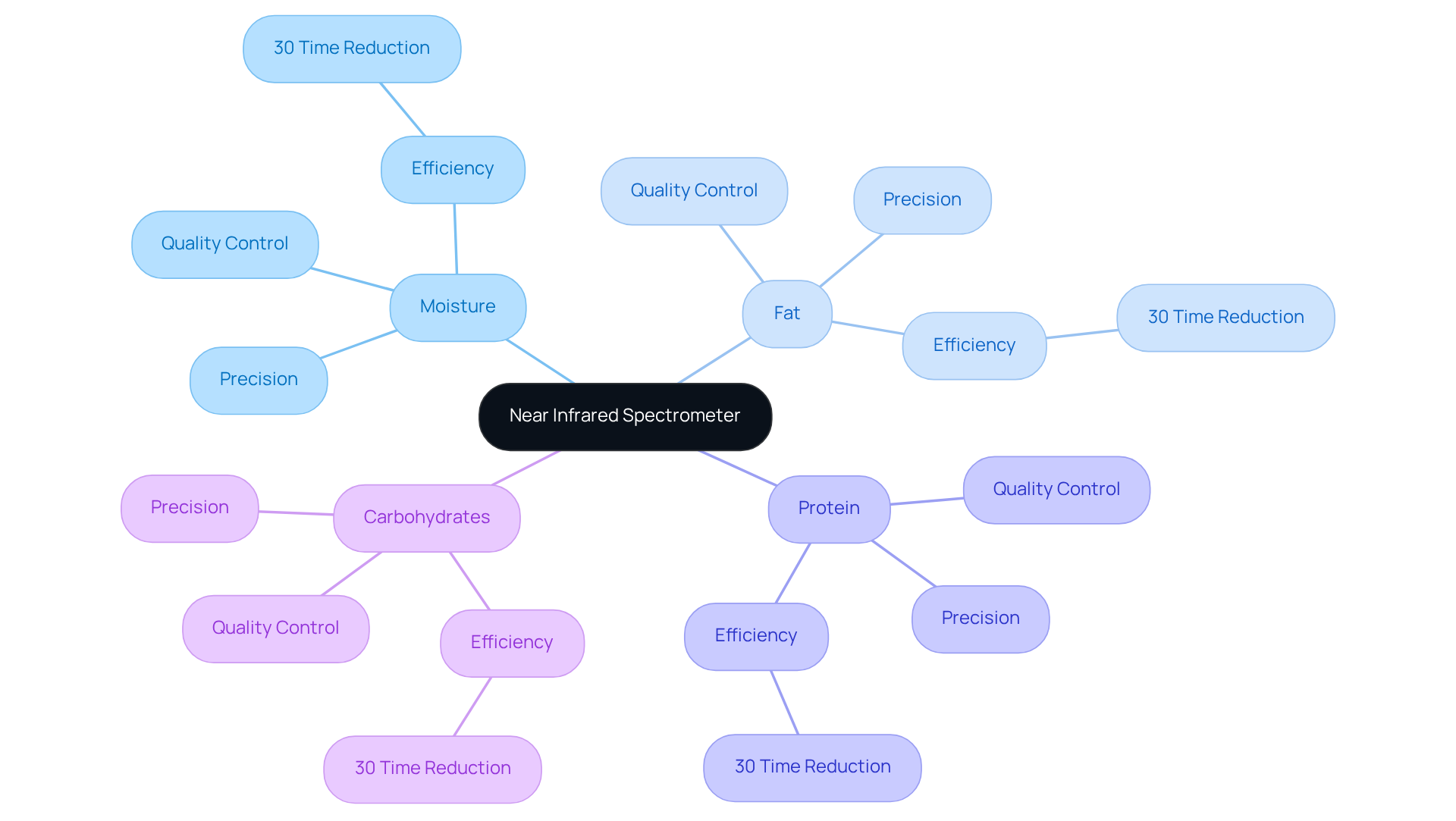

Versatility in Analysis: Assessing Multiple Food Components

The near infrared spectrometer from JM Science is distinguished by its remarkable versatility in analyzing critical nutritional components such as moisture, fat, protein, and carbohydrates. This is vital for producers and testing laboratories, facilitating comprehensive assessments within a single testing session.

A recent study highlights that the use of a near infrared spectrometer can reduce testing time by as much as 30%, thereby enabling quicker decision-making in production processes. Such efficiency not only streamlines the testing procedure but also enhances the precision of evaluations, making the near infrared spectrometer suitable for a wide array of applications—from raw material testing to final product assurance.

By enabling rapid and reliable evaluations, this instrument empowers producers to uphold rigorous standards of excellence and compliance. Moreover, insights from industry experts underscore the importance of real-time data in quality control, further accentuating the instrument's pivotal role in modern food evaluation.

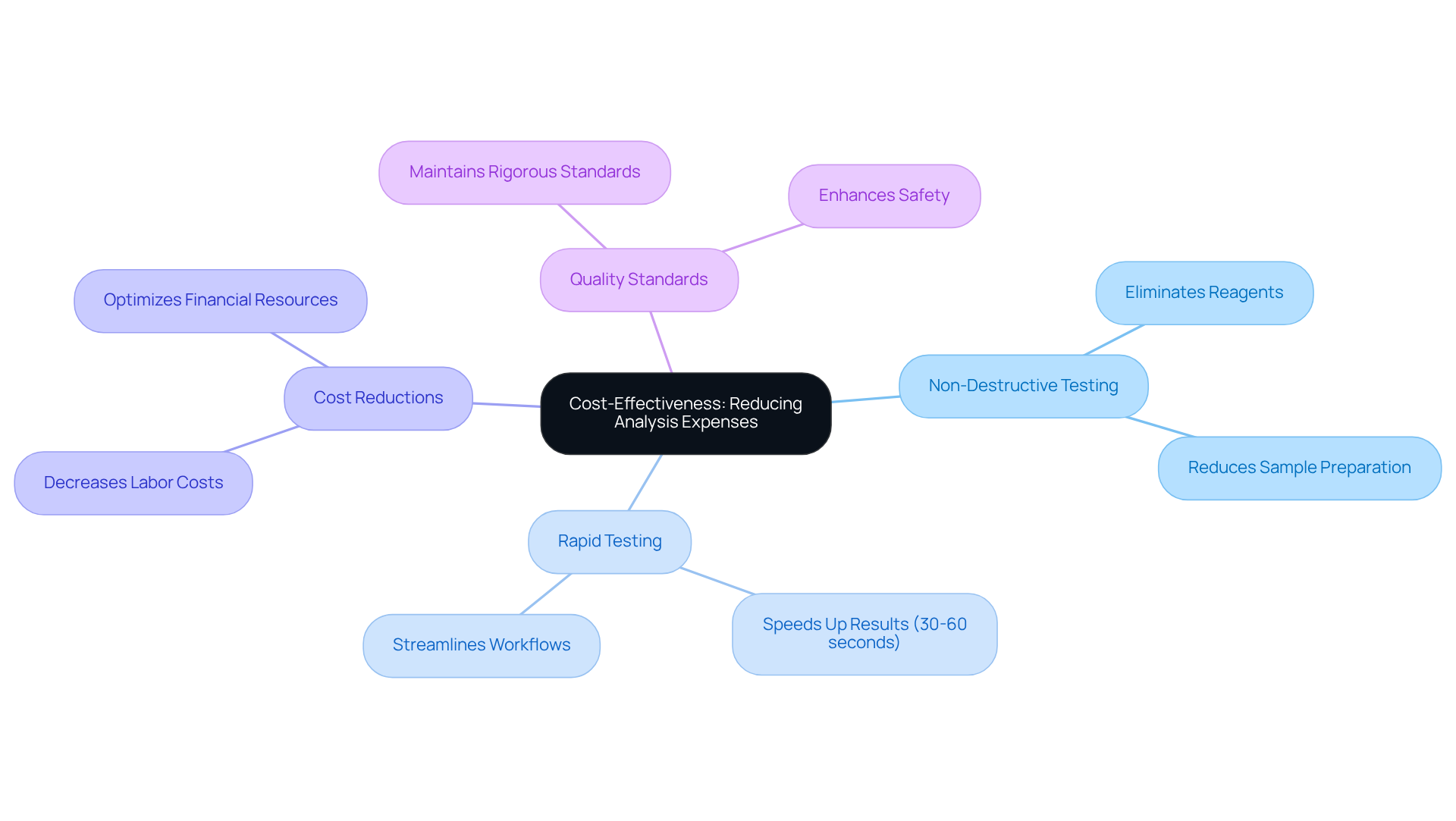

Cost-Effectiveness: Reducing Analysis Expenses

The near infrared spectrometer from JM Science presents an exceptional opportunity for research facilities to achieve substantial . Its non-destructive testing capabilities eliminate the need for costly reagents and significantly reduce extensive sample preparation, thereby lowering operational expenses.

Furthermore, the rapid testing capabilities of this spectrometer, delivering results in just 30-60 seconds, streamline workflows and decrease labor costs associated with extended evaluation periods. By integrating this advanced technology, facilities can maintain rigorous standards of quality and safety while optimizing their financial resources.

A recent study underscores that NIRS offers a cost-effective solution for predicting attributes such as sweetness and acidity in blueberries, further highlighting its importance in food evaluation.

Financial analysts emphasize that adopting technologies like the near infrared spectrometer can lead to significant reductions in analysis costs, establishing it as an indispensable instrument for modern research facilities.

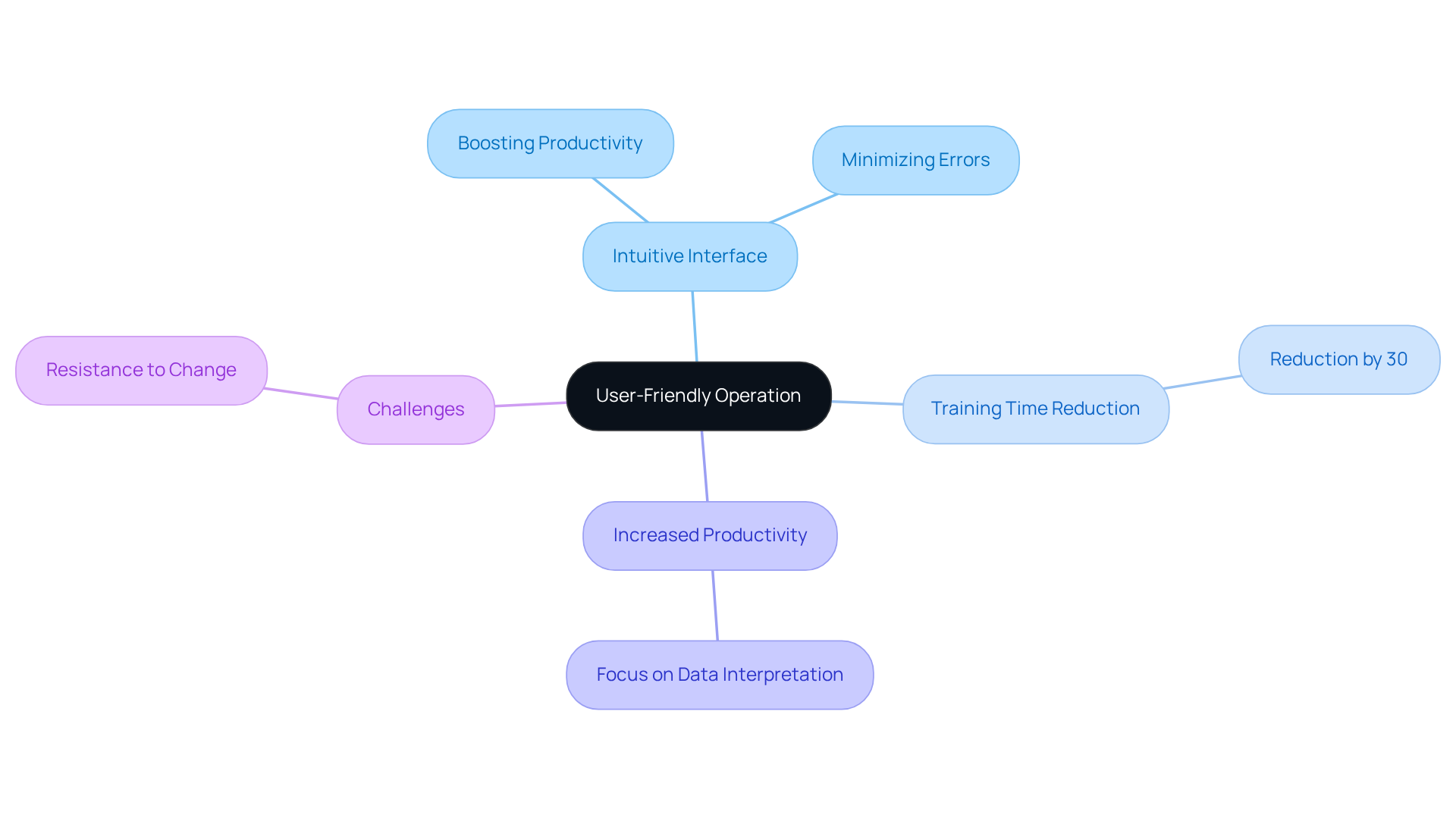

User-Friendly Operation: Simplifying Laboratory Workflows

The user-friendly features of the JM Science near infrared spectrometer significantly enhance laboratory workflows. With an , operators can quickly master the instrument, resulting in a notable reduction in training time—often by as much as 30%. This ease of use is particularly advantageous in high-demand environments, where maximizing efficiency is essential. Laboratory personnel have underscored the importance of such intuitive interfaces, highlighting their role in not only boosting productivity but also minimizing operational errors. For instance, integrating this spectrometer into routine evaluations has streamlined workflows, allowing technicians to focus more on data interpretation rather than instrument operation.

By adopting JM Science instruments, research facilities can achieve a more efficient and effective analytical process, ultimately enhancing outcomes in food analysis. However, it is crucial to recognize that resistance to change among staff can impede the transition to automation. As the demand for efficiency and accuracy in scientific processes escalates, the adoption of user-friendly instruments such as the near infrared spectrometer becomes increasingly vital. A facility manager remarked, 'The intuitive interface of the JM Science instruments has made a significant difference in our workflow, allowing us to adapt quickly and maintain high productivity levels.

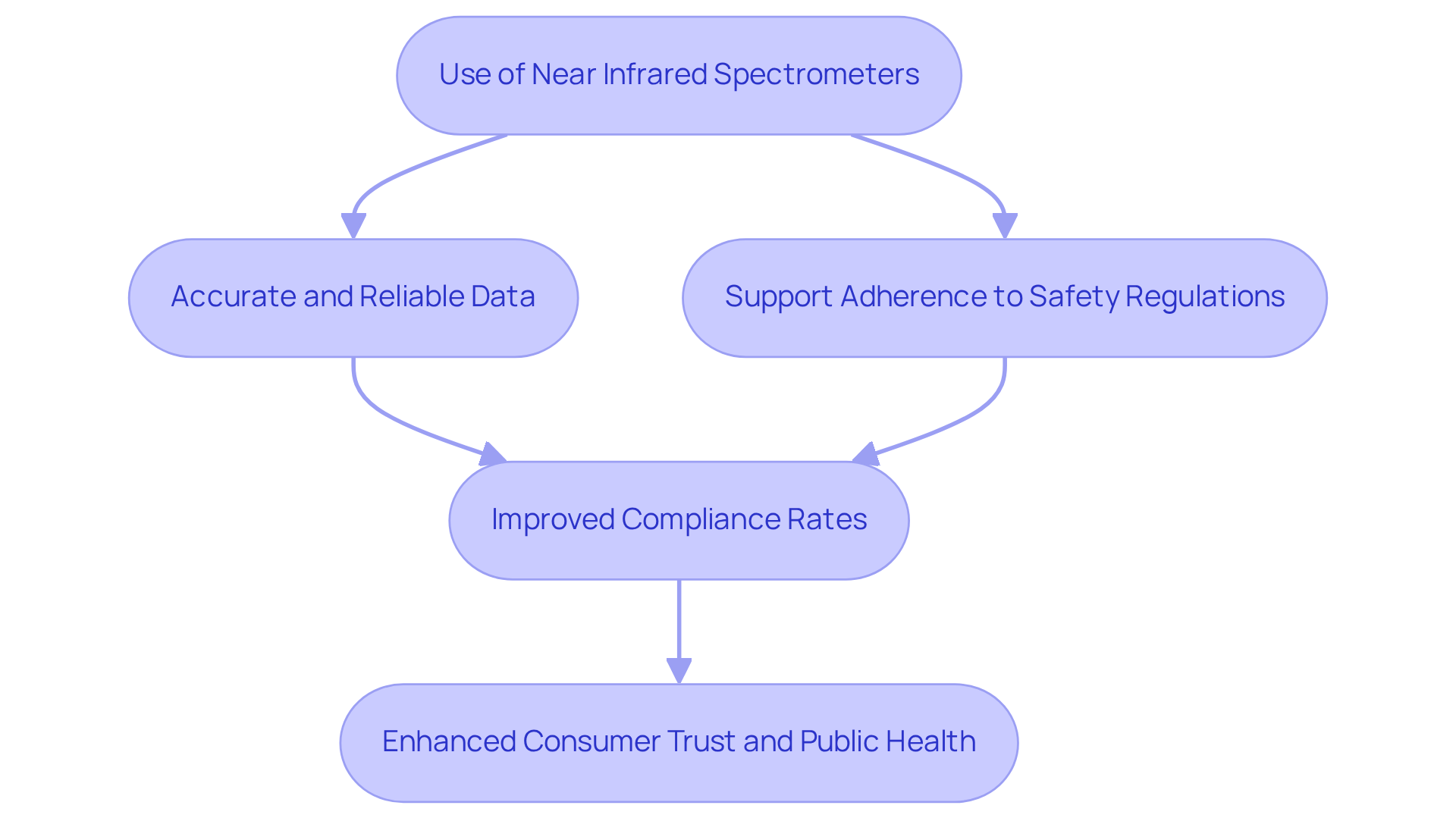

Food Safety Assurance: Meeting Regulatory Standards

The near infrared spectrometer from JM Science plays a pivotal role in safety assurance, enabling facilities to meet stringent regulatory standards. By delivering accurate and reliable data, it supports adherence to safety regulations, which is vital for ensuring that products are safe for consumer use. This capability not only cultivates consumer trust but also significantly contributes to the .

Notably, statistics reveal that facilities utilizing near infrared spectrometers have experienced substantial improvements in compliance rates with safety regulations, underscoring the effectiveness of this technology in fulfilling industry standards. Regulatory bodies, such as the Centers for Disease Control and Prevention (CDC), emphasize the importance of such advanced tools in enhancing safety protocols, highlighting the urgent need for laboratories to adopt innovative solutions to maintain high safety standards.

For example, the current action level for lead in processed items intended for infants and young children is established at 10 parts per billion (ppb), illustrating the critical function of technology in ensuring compliance with these rigorous regulations.

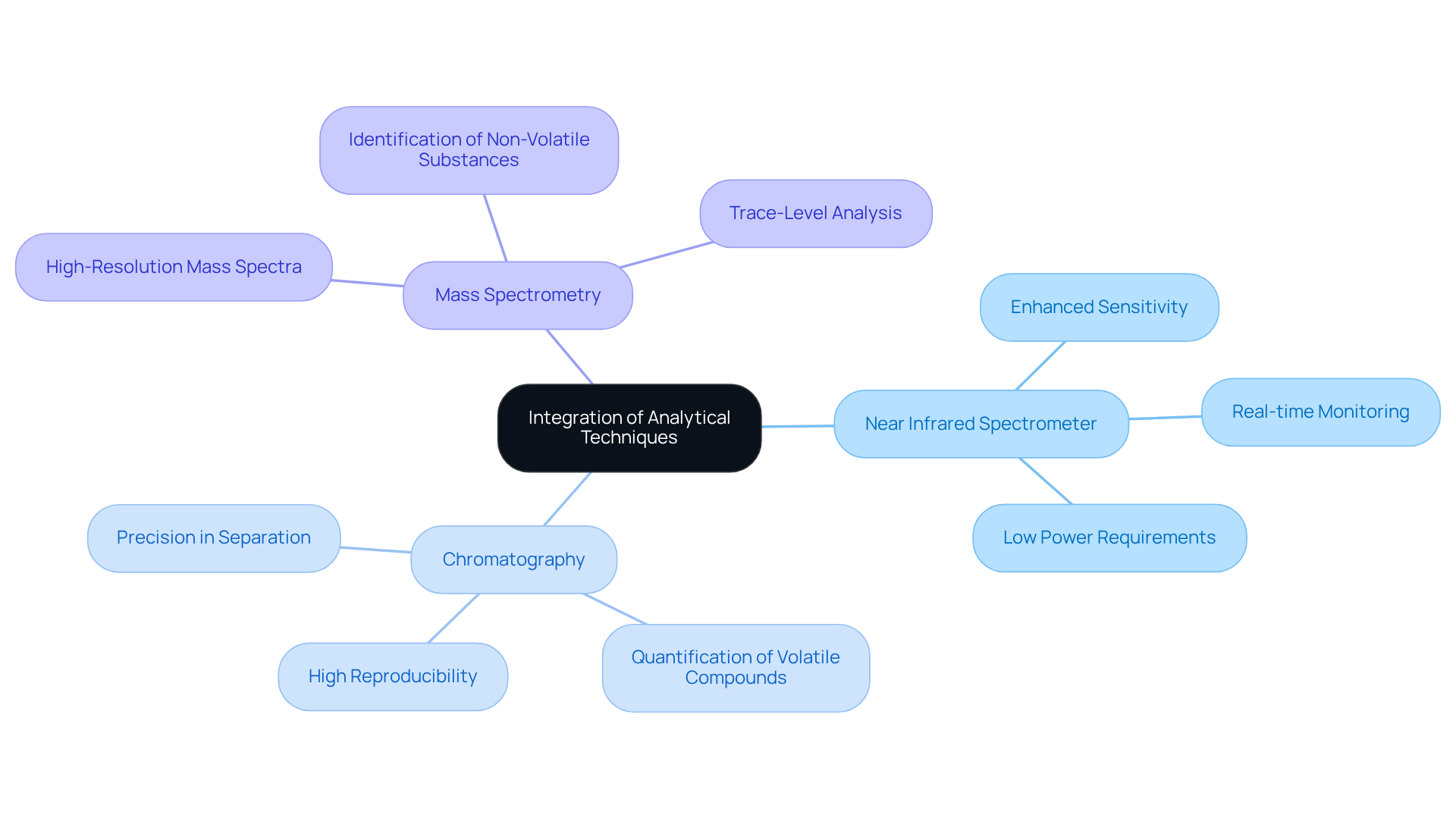

Integration with Other Techniques: Boosting Analytical Capabilities

The JM Science near infrared spectrometer is distinguished by its ability to seamlessly integrate with other analytical techniques, including chromatography and mass spectrometry, significantly enhancing its analytical capabilities. This integration facilitates thorough analyses, yielding deeper insights into and standards. For instance, the combination of a near infrared spectrometer with gas chromatography allows facilities to achieve remarkable precision in separating and quantifying volatile compounds, while mass spectrometry excels in identifying intricate non-volatile substances. Researchers have noted that this combination of techniques results in greater sensitivity and specificity, ultimately elevating the overall quality assurance in testing facilities.

Moreover, mass spectrometry typically provides superior resolution for separating closely related compounds compared to gas chromatography, further emphasizing its critical role in this integrated approach. Such synergistic methodologies not only enhance the reliability of testing processes but also facilitate the detection of contaminants at trace levels, addressing urgent safety concerns, particularly in light of the $30 billion global issue of fraud related to consumables. By employing these advanced methods, facilities can ensure more durable and dependable outcomes, which are essential for maintaining safety and compliance with industry standards.

Roland A. Levy highlighted the sensor design's numerous advantages, including real-time monitoring and low power requirements, which significantly enhance the effectiveness of these integrated analytical approaches.

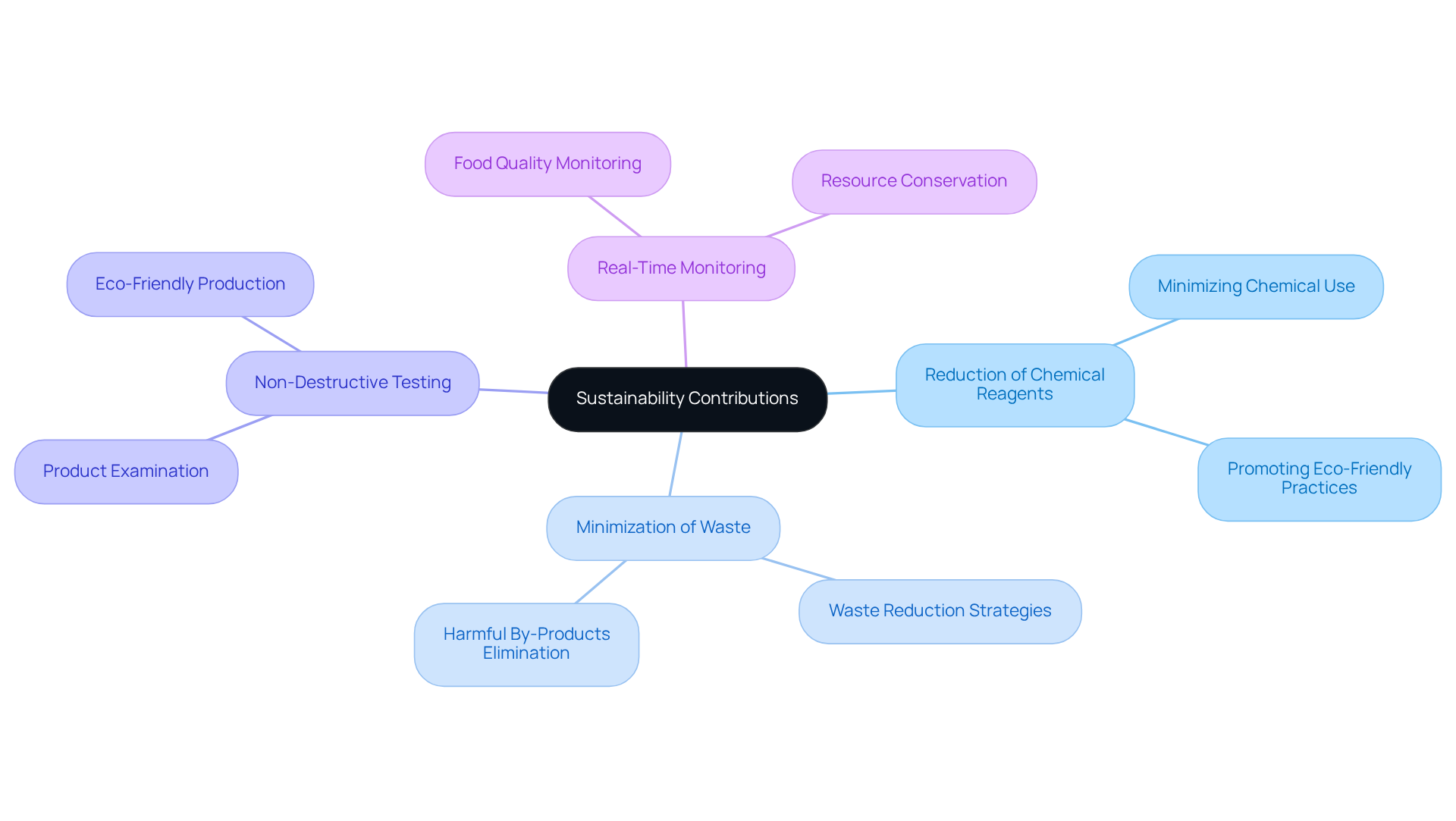

Sustainability Contributions: Supporting Eco-Friendly Practices

The near infrared spectrometer from JM Science is instrumental in advancing sustainability initiatives by significantly reducing reliance on chemical reagents and minimizing waste generation. The use of a near infrared spectrometer in its non-destructive testing capabilities enables the examination of products without generating harmful by-products, thereby promoting eco-friendly practices in production.

For example, laboratories employing this technology can implement real-time monitoring of food quality, conserving resources while aligning with the increasing consumer demand for sustainable practices within the food industry.

As environmental scientist Paul Polman articulates, "Looking at the world through a sustainability lens not only helps us ‘future proof’ our supply chain, it also fuels innovation and drives brand growth."

This alignment not only enhances operational efficiency but also contributes to a broader commitment to , underscoring the urgency of adopting such technologies in the face of sustainability challenges.

Conclusion

The JM Science near infrared spectrometer emerges as a pivotal instrument in food analysis, delivering unmatched precision and efficiency. By facilitating rapid testing and non-destructive evaluation, this technology not only improves the accuracy of nutritional assessments but also aids compliance with rigorous safety regulations. Its capability to provide real-time data empowers laboratories to make swift, informed decisions, ultimately cultivating a culture of quality and safety in food production.

Key advantages of the near infrared spectrometer are evident, including its cost-effectiveness, versatility in analyzing multiple components, and user-friendly operation. The integration of this technology with other analytical methods enhances its effectiveness, ensuring comprehensive evaluations that align with contemporary food safety standards. Furthermore, its role in promoting sustainability highlights the necessity of adopting eco-friendly practices in food analysis.

As the food industry evolves, the adoption of advanced tools like the JM Science near infrared spectrometer is crucial for maintaining product quality and safety. By harnessing this innovative technology, laboratories can not only boost their operational efficiency but also meet the increasing consumer demand for transparency and sustainability. The incorporation of such sophisticated analytical methods is essential in shaping a future where food safety and quality are paramount, driving both industry innovation and public health protection.