Overview

This article highlights ten significant benefits of FT-NIR (Fourier Transform Near-Infrared) spectroscopy for pharmaceutical laboratories. It emphasizes the technology's critical role in enhancing verification processes, improving accuracy, and ensuring regulatory compliance. The advantages of FT-NIR are underscored by its non-destructive testing capabilities, time efficiency, cost-effectiveness, and versatility. Collectively, these attributes streamline operations while upholding product quality and safety standards within the pharmaceutical industry. As laboratories seek to optimize their processes, the adoption of FT-NIR spectroscopy emerges as a strategic choice that aligns with industry demands.

Introduction

The pharmaceutical industry faces relentless pressure to guarantee product safety and adhere to stringent regulatory standards. As laboratories pursue innovative solutions to enhance their verification processes, the adoption of Fourier Transform Near-Infrared (FT-NIR) spectroscopy stands out as a transformative advancement. This article delves into ten key benefits of FT-NIR technology, illustrating its capacity to improve accuracy, efficiency, and cost-effectiveness in pharmaceutical testing. However, with such innovations at our disposal, one must consider: can these advancements genuinely address the growing demands of modern drug development, or do they merely skim the surface of potential?

JM Science FT-NIR Spectroscopy Solutions: Enhancing Pharmaceutical Verification

JM Science offers advanced ft-nir spectroscopy solutions that significantly enhance verification procedures in drug testing facilities. These sophisticated instruments are meticulously engineered to guarantee that both raw materials and finished products meet rigorous quality standards. By leveraging ft-nir technology, laboratories achieve swift and accurate validation, which is a critical factor for maintaining compliance with regulatory standards and ensuring product safety within the drug industry.

The current trend in near-infrared technology emphasizes its non-destructive sampling capabilities, allowing for rapid analysis without the need for sample preparation. This efficiency proves particularly advantageous in high-throughput environments where time is of the essence. Furthermore, recent advancements in near-infrared systems, coupled with the integration of chemometric methods, have bolstered their precision and reliability, establishing them as indispensable tools for drug verification. Notably, spectrometers constituted over 79.6% of total revenue in 2022, underscoring their market dominance and vital role in the drug industry.

As the drug industry continues to evolve, the adoption of ft-nir spectroscopy is expected to rise, driven by the increasing demand for faster, more reliable quality control methods. This technology not only streamlines verification processes but also supports adherence to (cGMP), ultimately enhancing the safety and efficacy of medical products.

Improved Accuracy: The Precision of FT-NIR Spectroscopy in Material Analysis

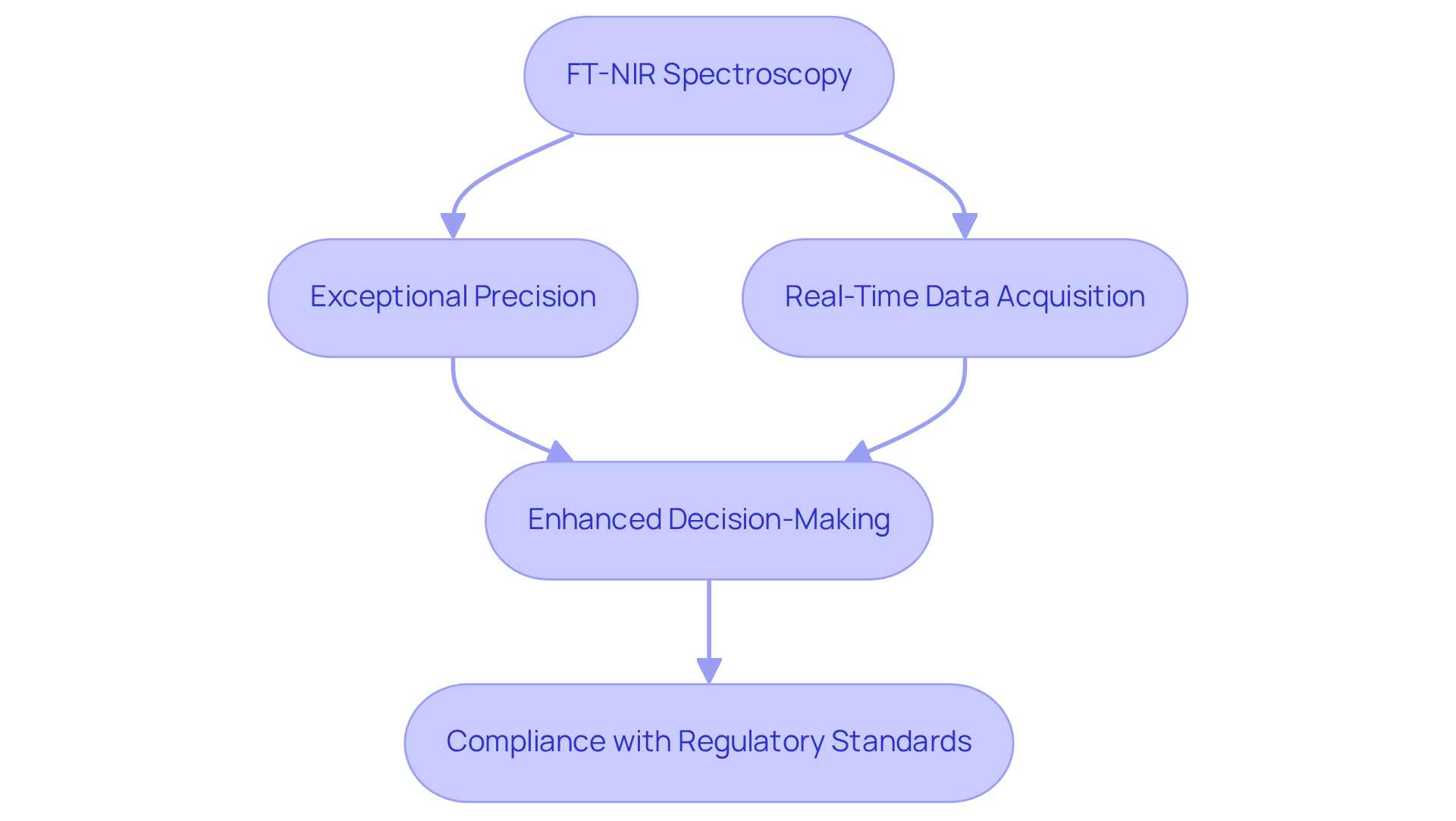

The use of ft-nir spectroscopy delivers exceptional precision in material analysis, enabling laboratories to detect even the most subtle differences in composition. This precision is vital for ensuring that active pharmaceutical ingredients (APIs) and excipients meet stringent specifications, ultimately contributing to the development of safer and more effective products.

Recent studies indicate that the root-mean-square error for in-line moisture monitoring has been minimized to a mere 0.1%, underscoring the technology's reliability in critical evaluation environments. The , further showcasing the accuracy of near-infrared spectroscopy across diverse scenarios.

Additionally, the capability to obtain real-time data significantly enhances the decision-making process, allowing for immediate adjustments and ensuring compliance with regulatory standards. For instance, a case study on the discrimination of different grades of Avicel demonstrated that advanced algorithms like SIMCA, specifically designed to differentiate materials with identical chemical compositions but varying physical properties, can effectively distinguish between these materials. This highlights the importance of accuracy in drug evaluation.

Overall, ft-nir spectroscopy not only enhances precision in identifying changes in drug components but also strengthens the industry's commitment to quality and safety.

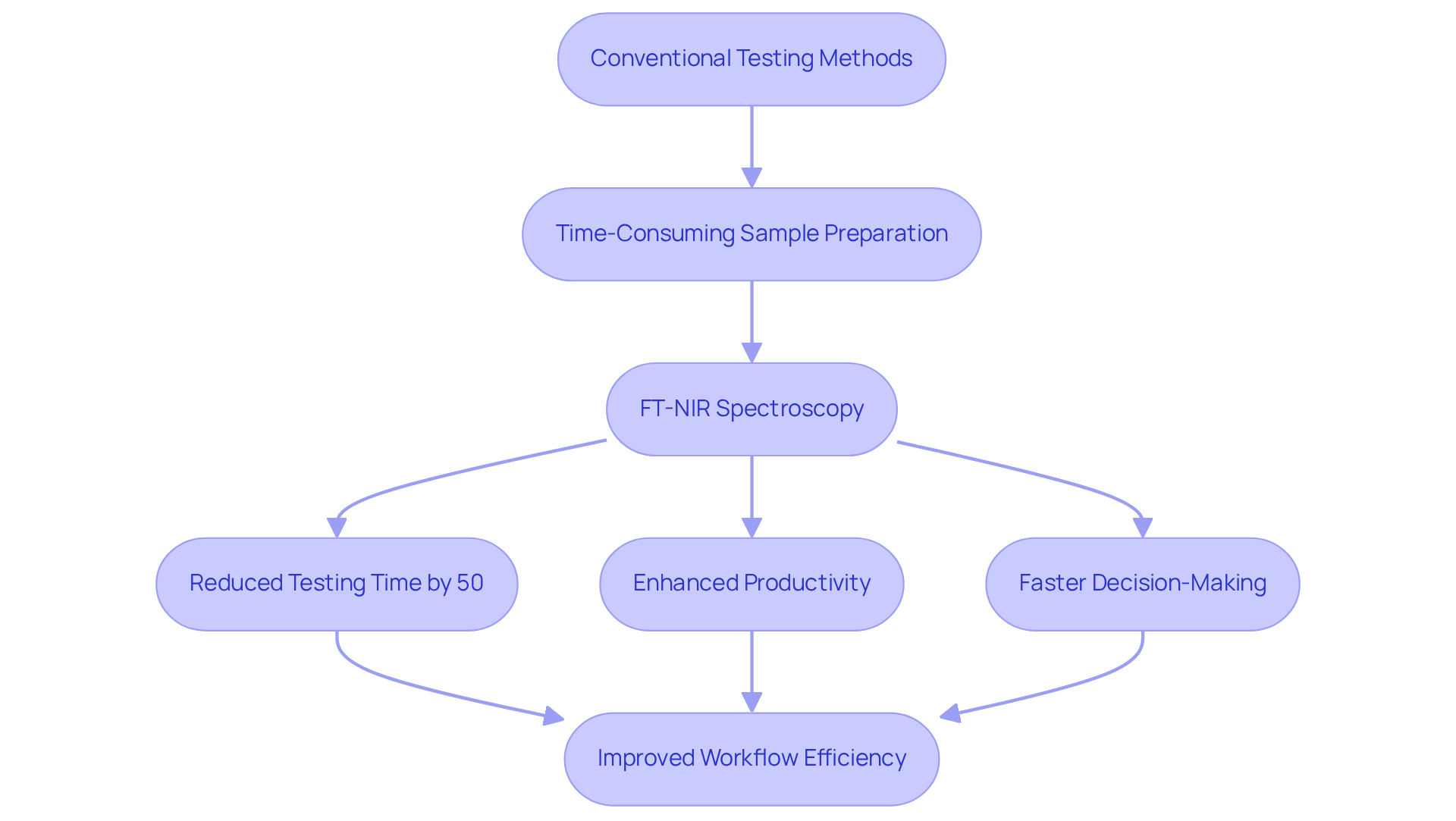

Time Efficiency: Accelerating Raw Material Testing with FT-NIR

The ft-nir spectroscopy stands out for its remarkable ability to significantly reduce the time needed for raw material evaluation in drug laboratories. In contrast to conventional techniques that often require extensive sample preparation and lengthy analysis, this method facilitates rapid, direct measurements. Such efficiency not only but also accelerates decision-making within the production process—a crucial element in the fast-paced pharmaceutical industry.

Research indicates that the adoption of ft-nir spectroscopy can reduce raw material assessment durations by up to 50%, allowing laboratories to optimize processes and respond swiftly to production demands. Furthermore, calibration models developed using partial least squares (PLS) regression have demonstrated the effectiveness of near-infrared spectroscopy in predicting water content and methanol concentration in industrial mixtures, achieving calibration errors of 2.56% and 0.42%, respectively.

Case studies highlight how pharmaceutical companies have successfully integrated ft-nir technology, leading to significant reductions in evaluation duration and enhanced overall workflow efficiency. By employing spectral analysis, laboratories can ensure the timely delivery of high-quality products while adhering to stringent evaluation standards.

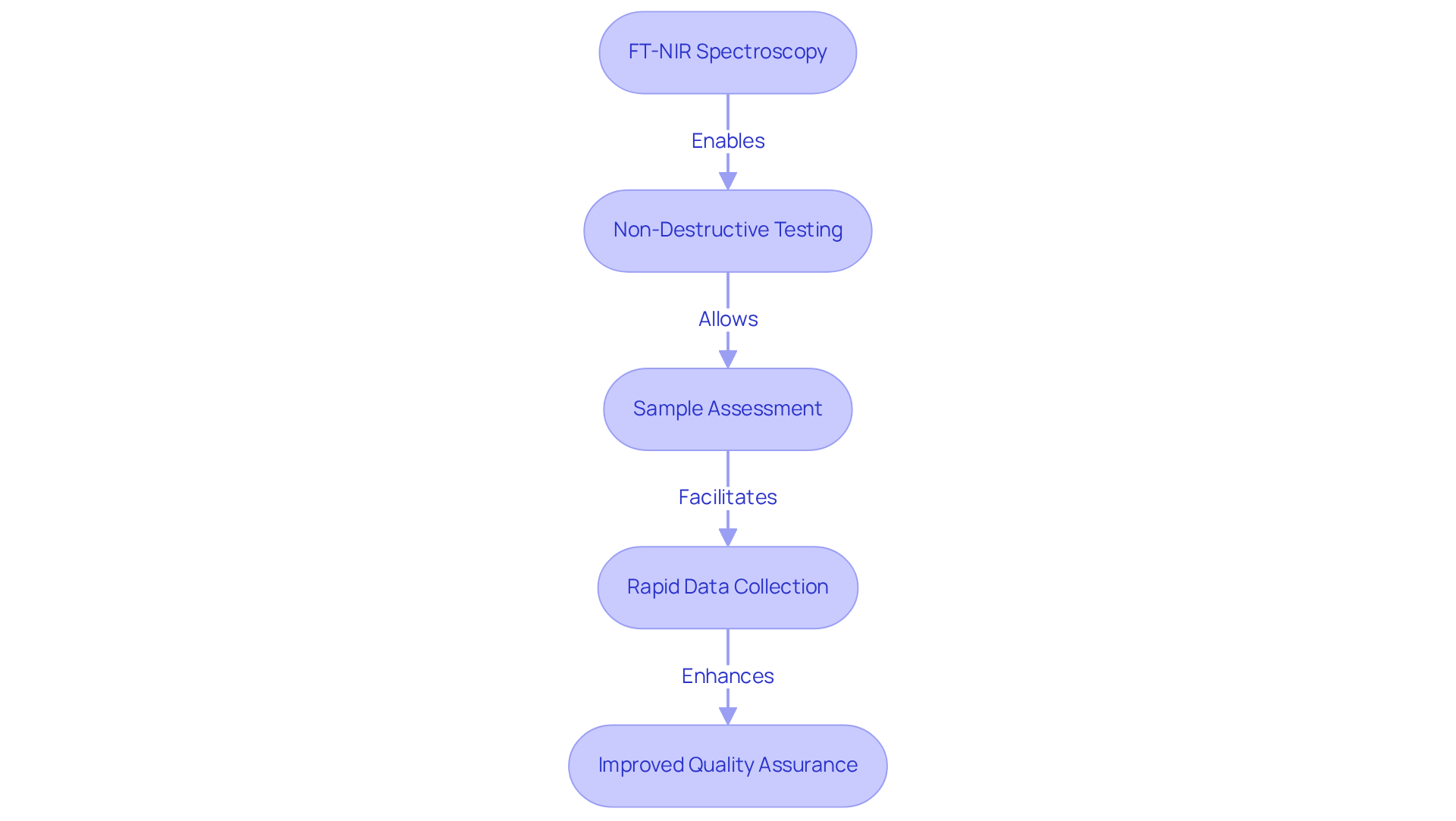

Non-Destructive Testing: Preserving Material Integrity with FT-NIR

NIR spectroscopy stands out as a non-invasive examination technique, allowing for the assessment of samples without altering or consuming them. This capability is particularly crucial in pharmaceutical laboratories, where preserving the integrity of raw materials and finished products is paramount.

By employing ft-nir spectroscopy, laboratories can perform comprehensive analyses while ensuring that samples remain intact for subsequent testing or production processes. Research indicates that this technique can achieve rapid data collection rates, obtaining spectra in as few as 10 seconds, thus facilitating effective workflows without compromising sample accessibility.

Furthermore, the application of near-infrared spectroscopy in healthcare environments has revealed significant advantages, such as enhancing quality assurance practices and ensuring compliance with stringent regulatory standards. This technology not only supports the maintenance of material integrity but also boosts the of medical operations.

Cost-Effectiveness: Reducing Testing Expenses with FT-NIR Technology

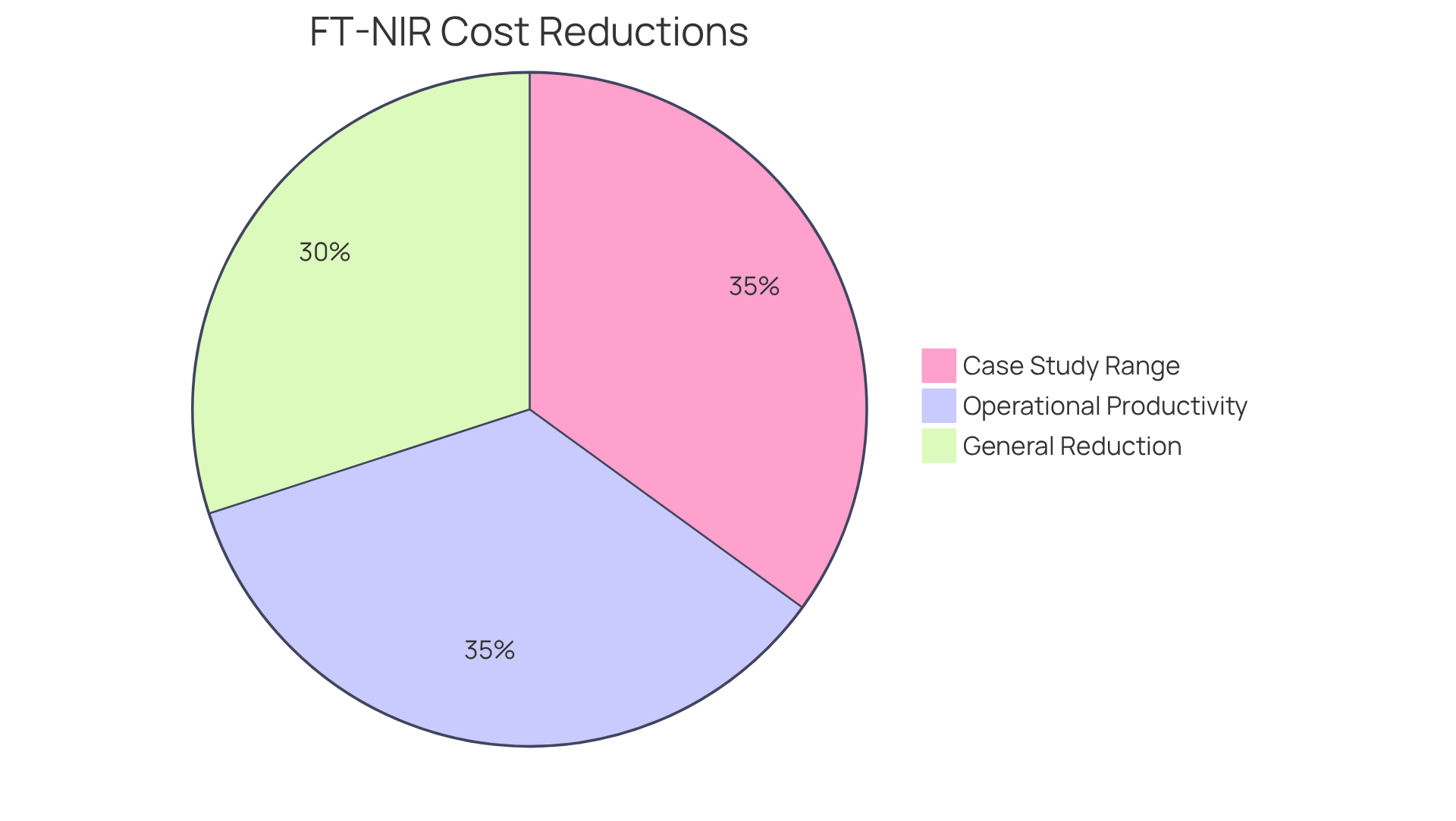

The adoption of ft-nir spectroscopy technology in pharmaceutical laboratories offers substantial cost reductions. By significantly decreasing reliance on costly reagents and optimizing sample preparation procedures, this method effectively lowers overall examination costs through the use of ft-nir. Research indicates that incorporating ft-nir spectroscopy can lead to a reduction in evaluation expenses by as much as 30%. This is primarily due to its , such as ft-nir, which eliminate the need for extensive sample management. Moreover, ft-nir analysis is associated with further cost reductions, reinforcing the financial advantages of this innovative technology.

The rapid results generated by ft-nir technology not only minimize downtime but also enhance throughput, enabling laboratories to conduct more tests in less time. This efficiency translates into improved operational productivity, positioning ft-nir technology as a financially advantageous choice for pharmaceutical analysis. Case studies reveal that laboratories employing ft-nir spectroscopy have experienced a decrease in evaluation costs ranging from 20% to 50%. These results particularly highlight its effectiveness in optimizing laboratory functions while maintaining high-quality standards.

Additionally, the capability of ft-nir technology to monitor fermentation kinetics facilitates timely interventions in stalled processes, preventing costly interruptions and further enhancing cost-efficiency. This comprehensive approach underscores the importance of integrating high-quality scientific instruments in laboratory settings, ultimately driving both financial and operational benefits.

Versatility: Adapting FT-NIR for Diverse Pharmaceutical Applications

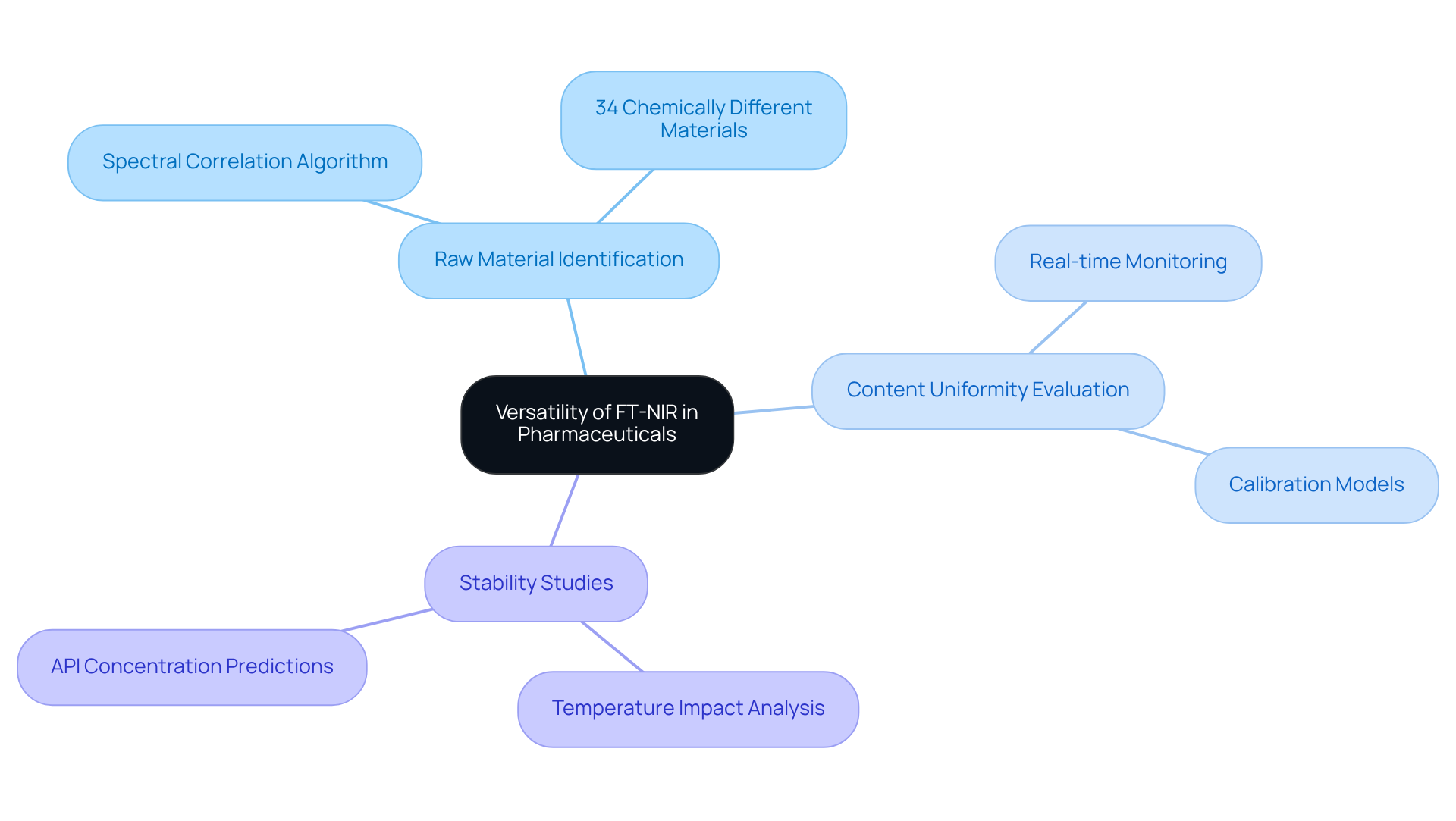

NIR spectroscopy stands out for its remarkable adaptability, making it suitable for a wide array of drug-related applications. These include:

This flexibility allows facilities to utilize a single technology to meet diverse assessment requirements, thereby and reducing the need for multiple specialized devices. The efficiency gained from this approach not only streamlines processes but also enhances overall productivity in laboratory settings.

Regulatory Compliance: Meeting Industry Standards with FT-NIR

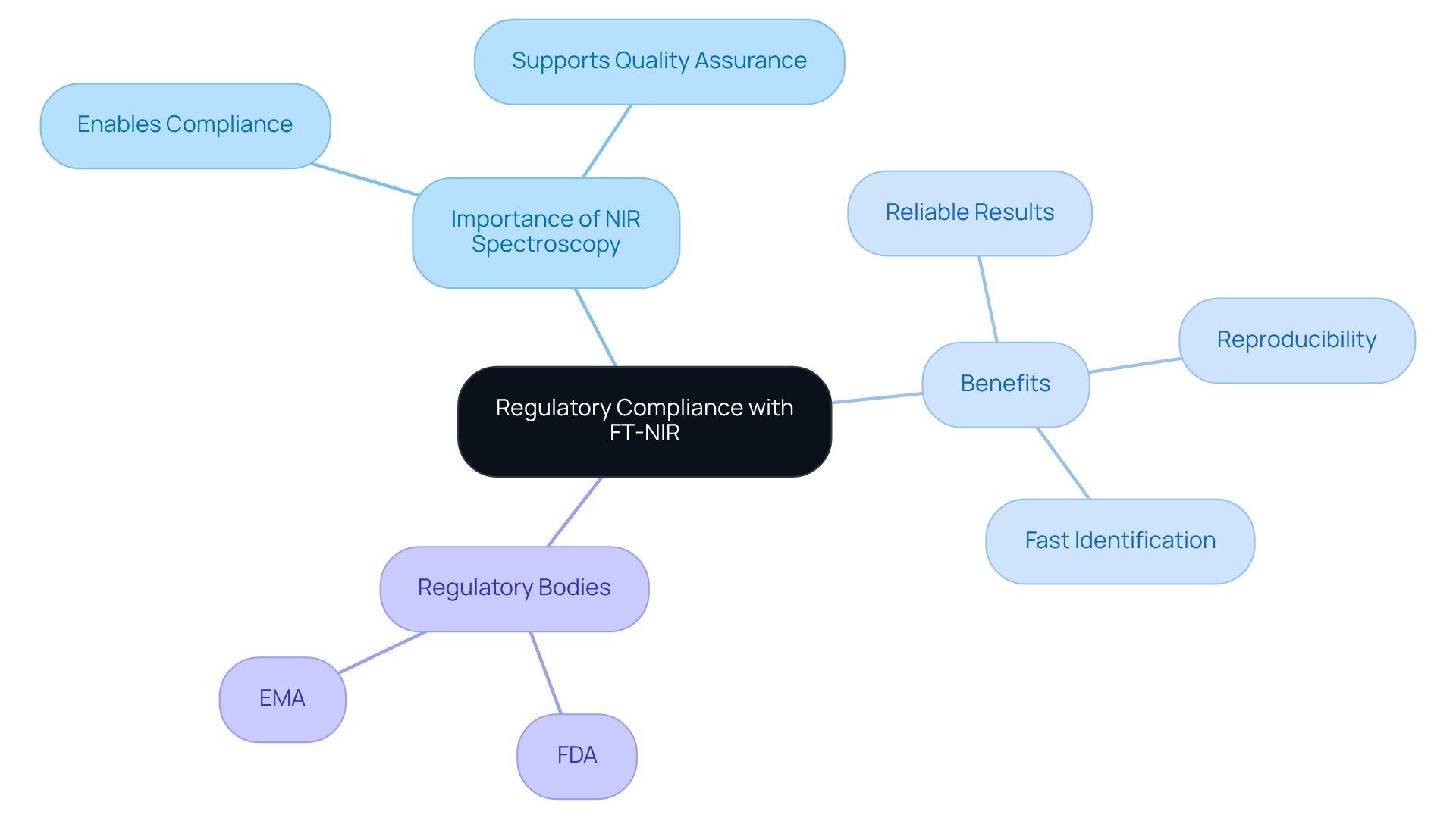

NIR spectroscopy plays a crucial role in enabling pharmaceutical facilities to meet stringent regulatory standards. This advanced technology delivers reliable and reproducible results, which are vital for adhering to guidelines established by regulatory bodies such as the FDA and EMA. By integrating ft-nir spectroscopy into their testing protocols, facilities not only ensure compliance with industry standards but also maintain the integrity of high-quality results. This commitment to excellence underscores the importance of utilizing in laboratory environments.

Seamless Integration: Incorporating FT-NIR into Laboratory Workflows

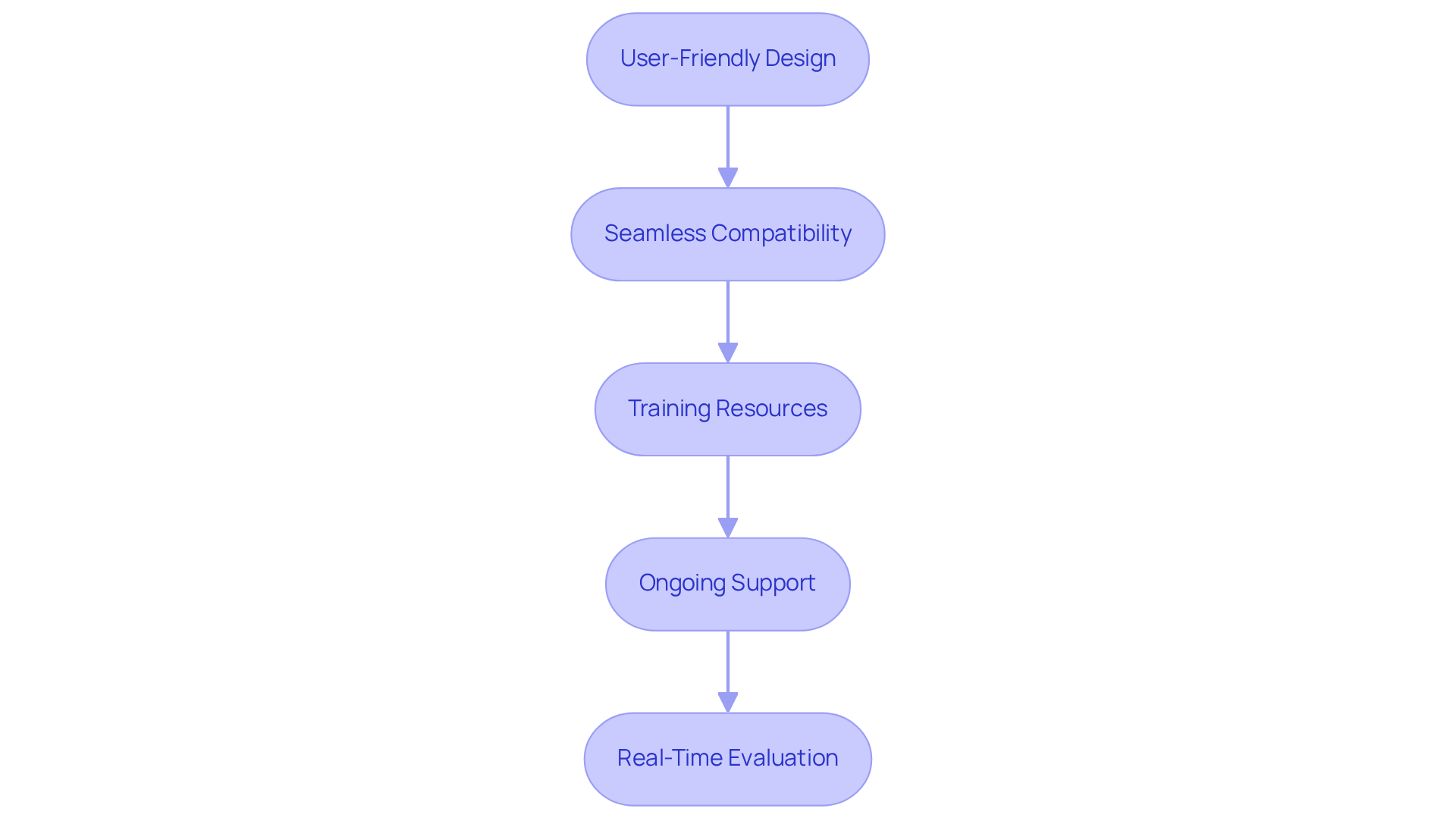

Incorporating ft-nir spectroscopy into work processes is remarkably straightforward due to its user-friendly design and seamless compatibility with various information management systems. This technology minimizes disruptions during implementation, allowing laboratories to swiftly harness the .

For instance, many pharmaceutical laboratories have successfully adopted near-infrared systems, significantly enhancing their analytical capabilities without substantial interruptions. Notably, ft-nir systems like the Phazir™ operate within a wavelength range of 1100-1700 nm, offering a resolution of 6 nm per pixel, which ensures precise measurements.

JM Science provides extensive training resources and ongoing support, facilitating a smooth transition for users. This commitment to customer support further simplifies the integration of near-infrared technology, empowering laboratories to refine their procedures and elevate productivity from day one.

Additionally, the non-invasive nature of ft-nir spectroscopy allows for real-time evaluation without compromising sample integrity, solidifying its role as an indispensable tool in laboratory environments.

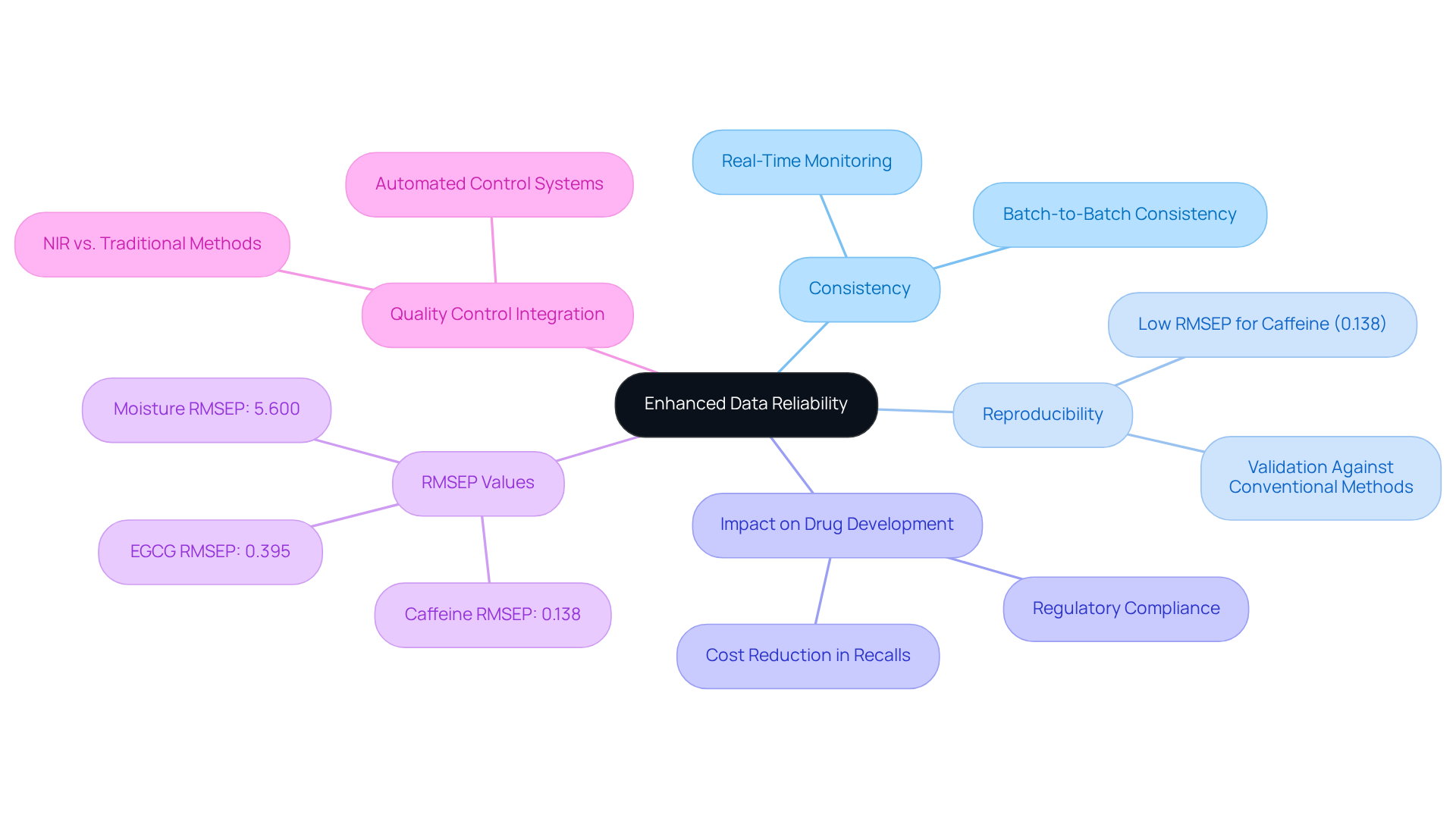

Enhanced Data Reliability: Trusting FT-NIR Results in Pharmaceutical Testing

The dependability of information acquired from near-infrared spectroscopy is a fundamental element for pharmaceutical laboratories, significantly enhancing trust in testing results. This technology excels in delivering , which are essential for informed decision-making regarding product quality and safety. Such reliability is particularly vital in drug development, where minor discrepancies can lead to costly recalls or regulatory issues.

Research has demonstrated that near-infrared spectroscopy techniques can achieve a root mean square error of prediction (RMSEP) as low as 0.138 for caffeine content, underscoring the accuracy of this analytical method. Furthermore, the incorporation of ft-nir spectroscopy into quality control processes has been validated against conventional methods, confirming its robustness and suitability for real-time monitoring. This capability not only streamlines workflows but also fosters trust among stakeholders in the pharmaceutical supply chain, ultimately supporting successful drug development initiatives.

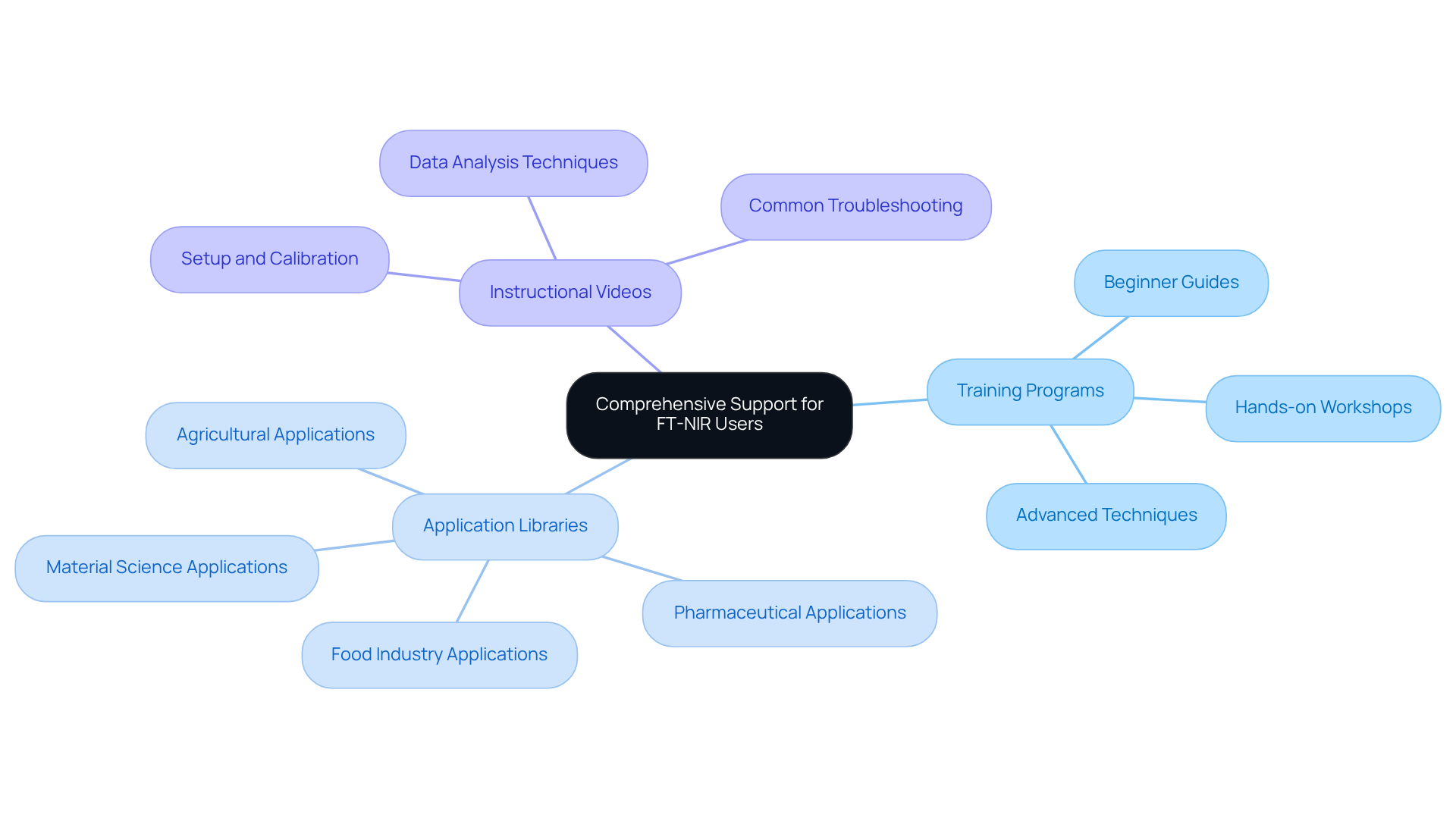

Comprehensive Support: Training and Resources for FT-NIR Users

JM Science offers comprehensive support for users of near-infrared technology, featuring training programs, application libraries, and instructional videos. These resources are meticulously designed to enable staff to utilize ft-nir technology effectively, ensuring they can maximize its capabilities. By providing continuous support, JM Science empowers laboratories to refine their testing processes, ultimately achieving superior results. This commitment to excellence not only enhances but also establishes a foundation for ongoing success in scientific endeavors.

Conclusion

The integration of FT-NIR spectroscopy into pharmaceutical laboratories signifies a transformative advancement towards enhanced efficiency, accuracy, and compliance in drug testing. By harnessing this cutting-edge technology, laboratories can optimize their verification processes, ensuring that both raw materials and finished products meet the highest quality standards. This commitment not only bolsters regulatory compliance but also significantly elevates the overall safety and efficacy of pharmaceutical products.

Key benefits of FT-NIR technology are evident, including:

- Its non-destructive testing capabilities

- Exceptional precision in material analysis

- Expedited raw material testing

- Notable cost-effectiveness

The capacity to acquire real-time data and seamlessly incorporate FT-NIR into existing workflows further emphasizes its crucial role in contemporary pharmaceutical practices. With a proven track record of enhancing operational efficiency and reliability, FT-NIR technology is rapidly becoming indispensable in the industry.

As the demand for faster and more reliable quality control methods escalates, adopting FT-NIR spectroscopy is essential for pharmaceutical labs striving to maintain a competitive edge. Investing in this innovative technology not only amplifies laboratory capabilities but also furthers the overarching goal of ensuring patient safety and product integrity. The future of pharmaceutical testing rests with those prepared to embrace advanced solutions like FT-NIR, paving the way for more efficient and effective drug development processes.